Polymonoether for polycarboxylate superplasticizer and polycarboxylate superplasticizer, and preparation methods thereof

A technology of polycarboxylic acid series and monomer polyether, which is applied in the field of polycarboxylate water reducing agent monomer polyether, can solve the problem of high impurity content, unsaturation not meeting the requirements, number average molecular weight not increasing, etc. problems, to achieve the effect of low impurity content, reduced impurity content, and improved application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

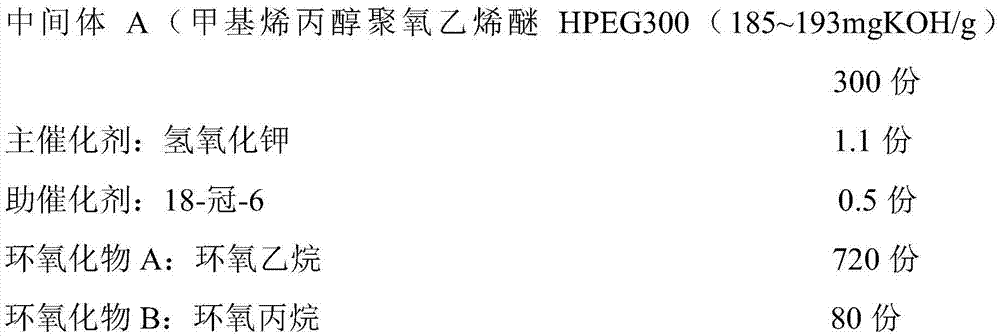

[0083] The raw material formula that present embodiment adopts is as follows:

[0084] Preparation:

[0085] Intermediate A→Intermediate B steps:

[0086]

[0087] Mix the intermediate A, the main catalyst and the co-catalyst, vacuum the ethoxylation device, turn on the canned pump, then raise the temperature to 95-105°C, vacuum dehydrate for 1 hour, and add ethylene oxide under the pressure of -0.095MPa One-third of the total amount of alkanes, mature, then add one-half of the total amount of propylene oxide, mature; then add one-third of the total amount of ethylene oxide, mature, then add the total amount of propylene oxide One-half of the ethylene oxide is added for curing; then the remaining ethylene oxide is added for curing. During the whole reaction process, the pressure of the reaction system is controlled at 0.2-0.4 MPa;

[0088] Intermediate B→monomer polyether:

[0089] Intermediate B

[0090]

[0091]Mix the intermediate B, the main catalyst and the co-c...

Embodiment 2

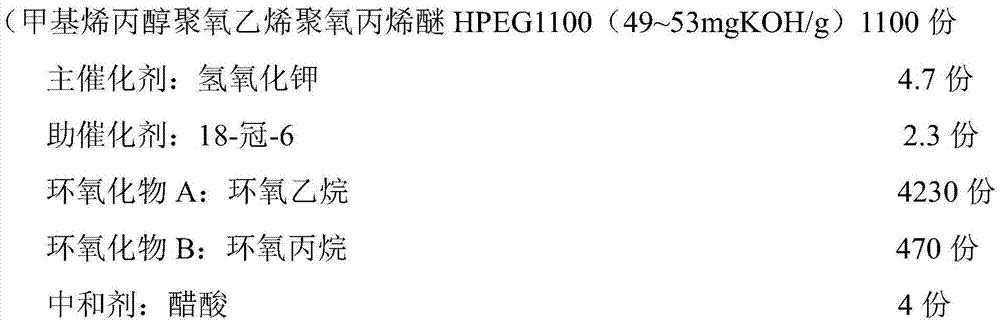

[0094] The raw material formula that present embodiment adopts is as follows:

[0095] Preparation:

[0096] Intermediate A→Intermediate B steps:

[0097]

[0098] Mix the intermediate A, the main catalyst and the co-catalyst, vacuum the ethoxylation device, turn on the canned pump, then raise the temperature to 95-105°C, vacuum dehydrate for 1 hour, and add ethylene oxide under the pressure of -0.095MPa One-third of the total amount of alkanes, mature, then add one-half of the total amount of propylene oxide, mature; then add one-third of the total amount of ethylene oxide, mature, then add the total amount of propylene oxide One-half of the ethylene oxide is added for curing; then the remaining ethylene oxide is added for curing. During the whole reaction process, the pressure of the reaction system is controlled at 0.2-0.4 MPa;

[0099] Intermediate B→monomer polyether:

[0100] Intermediate B

[0101]

[0102] Mix the intermediate B, the main catalyst and the co-...

Embodiment 3

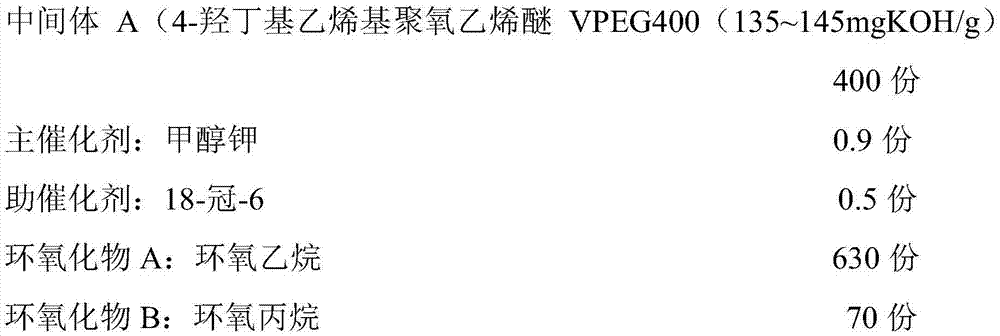

[0105] The raw material formula that present embodiment adopts is as follows:

[0106] Preparation:

[0107] Intermediate A→Intermediate B steps:

[0108]

[0109] Mix the intermediate A, the main catalyst and the co-catalyst, vacuum the ethoxylation device, turn on the canned pump, then raise the temperature to 95-105°C, vacuum dehydrate for 1 hour, and add ethylene oxide under the pressure of -0.095MPa One-third of the total amount of alkanes, mature, then add one-half of the total amount of propylene oxide, mature; then add one-third of the total amount of ethylene oxide, mature, then add the total amount of propylene oxide One-half of the ethylene oxide is added for curing; then the remaining ethylene oxide is added for curing. During the whole reaction process, the pressure of the reaction system is controlled at 0.2-0.4 MPa;

[0110] Intermediate B→monomer polyether:

[0111] Intermediate B

[0112]

[0113] Mix the intermediate B, the main catalyst and the co-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com