Preparation method of mesoporous carbon-based electrocatalyst

An electrocatalyst and mesoporous carbon technology, which is applied in the fields of carbon preparation/purification, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of long pre-carbonization time, low synthesis efficiency, and cumbersome synthesis process, etc. Achieve the effect of short preparation time, short time consumption and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

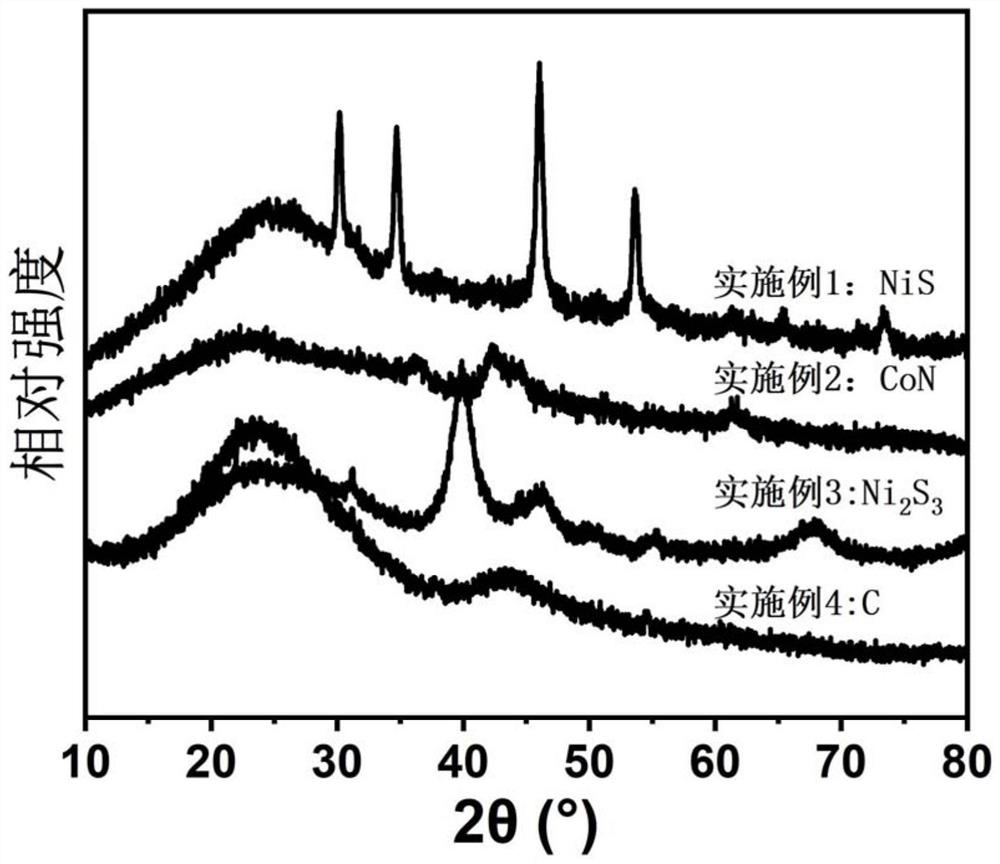

Embodiment 1

[0040] A method for preparing a mesoporous carbon-based electrocatalyst, comprising the following steps:

[0041] 1) Add the cysteine solution (composed of cysteine and water at a mass ratio of 1:8) dropwise to an equal mass of benzaldehyde solution (composed of benzaldehyde and ethanol at a mass ratio of 1:5), and heat Reflux at 120°C for 0.5h to obtain a reaction solution containing Schiff's base;

[0042] 2) Add nickel chloride solution (composed of nickel chloride and ethanol at a mass ratio of 1:8) dropwise to an equal mass of reaction solution containing Schiff base, stir evenly, and then heat to 120°C for distillation to obtain transition Metal Schiff base complexes;

[0043] 3) Place the transition metal Schiff base complex in an infrared drying oven for 20 minutes of infrared pre-carbonization, then place it in a tube furnace filled with nitrogen atmosphere, heat up to 700°C at a rate of 5°C / min, and carbonize for 2h, that is mesoporous carbon-based electrocatal...

Embodiment 2

[0045] A method for preparing a mesoporous carbon-based electrocatalyst, comprising the following steps:

[0046] 1) Arginine solution (composed of arginine and water at a mass ratio of 1:8) was added dropwise to 3 times the mass of salicylaldehyde solution (composed of salicylaldehyde and ethanol at a mass ratio of 1:7), Heating to 130°C for reflux reaction for 1 hour to obtain a reaction solution containing Schiff's base;

[0047] 2) Add cobalt nitrate solution (composed of cobalt nitrate and ethanol at a mass ratio of 1:12) dropwise to 0.5 times the mass of the reaction solution containing Schiff base, stir evenly, and then heat to 130°C for distillation to obtain transition metal Schiff base complexes;

[0048] 3) Place the transition metal Schiff base complex in an infrared drying oven for infrared pre-carbonization for 15 minutes, then place it in a tube furnace filled with nitrogen atmosphere, heat up to 800°C at a rate of 8°C / min, and carbonize for 0.5h. That is, the...

Embodiment 3

[0050] A method for preparing a mesoporous carbon-based electrocatalyst, comprising the following steps:

[0051] 1) Add thiourea solution (composed of thiourea and water at a mass ratio of 1:10) dropwise to twice the mass of vanillin solution (composed of vanillin and ethanol at a mass ratio of 1:10), and heat to 135°C Reflux reaction 1h, obtains the reaction solution containing Schiff's base;

[0052] 2) Add nickel nitrate solution (composed of nickel nitrate and ethanol at a mass ratio of 1:15) dropwise to an equal mass of reaction solution containing Schiff base, stir evenly, and then heat to 135°C for distillation to obtain a transition metal mat Phosphate base complexes;

[0053] 3) Place the transition metal Schiff base complex in an infrared drying oven for 30 minutes of infrared pre-carbonization, then place it in a tube furnace filled with nitrogen atmosphere, heat up to 750°C at a rate of 5°C / min, and carbonize for 1h, that is mesoporous carbon-based electrocataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com