Treating method and treating apparatus for waste liquid produced in flue gas desulfurization

A desulfurization waste liquid and treatment device technology, which is applied in gaseous effluent wastewater treatment, gas treatment, filtration treatment, etc., can solve the problems of increasing the desulfurization waste liquid treatment scale, unable to effectively solve the problems of white smoke and high investment, and achieves a floor space of Small, reduced equipment investment and operating energy consumption, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The composition of sulfur-containing flue gas after denitration treatment of a boiler flue gas is shown in Table 1.

[0048] Table 1 The composition of sulfur-containing flue gas after denitrification of a boiler flue gas

[0049]

[0050] Calculate the dew point temperature of flue gas acid (sulfuric acid) before desulfurization treatment according to the following formula:

[0051]

[0052] in,[ H 2 O ]——Water vapor content in flue gas, vol%.

[0053] [ SO 3 ]--cigarette

[0054] Different water vapor content and different SO 3 The dew point temperature of sulfuric acid at the concentration is shown in Table 2.

[0055] Table 2 Different water vapor content and SO 3 Flue gas dew point temperature at content

[0056]

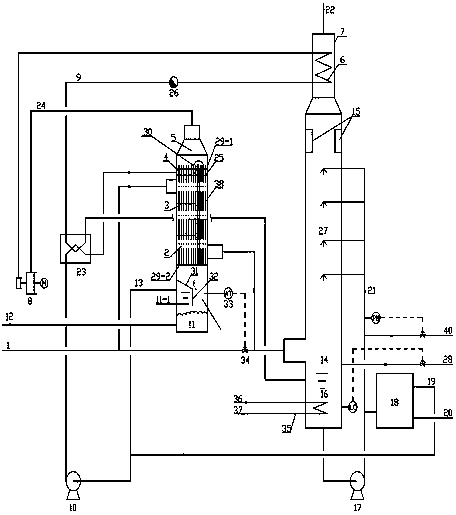

[0057] Using the present invention figure 1 The treatment device: the flue gas / desulfurization waste liquid heat exchanger adopts a vertical shell-and-tube heat exchanger, the flue gas goes on the shell side, the desulfurization wast...

Embodiment 2

[0061] SO in flue gas to be treated 2 Concentration 2000mg / Nm 3 , SO 3 Concentration 160mg / Nm 3 , and other parameters are the same as in Example 1.

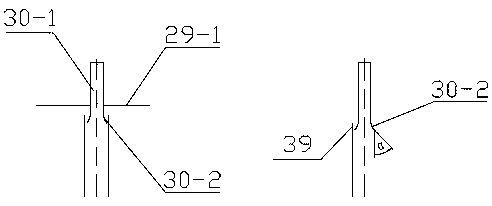

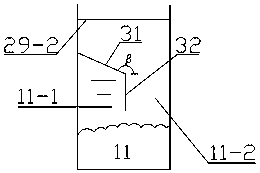

[0062] Using the present invention figure 1 The processing device: the specification of the heat exchange tube is DN25, and the flow rate of the desulfurization waste liquid in the heat exchange tube is 3m / s. The dust removal and desulfurization area adopts the form of absorbent spraying. The vertical distance between the upper tube sheet and the top of the heat exchange tube is 20mm; the bottom guide groove is inserted into the heat exchange tube, and the insertion length is 20mm; the axial angle α of the bottom end of the guide groove is 40°. The angle β between the guide plate and the horizontal direction is 120°, and the sealing plate is inserted below the liquid surface of the crystallization tank. The solid-liquid separator is precision filtration.

[0063] Operating conditions: (1) The absorbent adopts 30% NaOH sol...

Embodiment 3

[0066] To-be-treated flue gas SO 2 Concentration 3000mg / Nm 3 , SO 3 Concentration 260mg / Nm 3 , and other parameters are the same as in Example 1.

[0067] Using the present invention figure 1 The treatment device: the specification of the heat exchange tube is DN40, and the flow rate of the desulfurization waste liquid in the heat exchange tube is 3m / s. The dust removal and desulfurization area adopts the form of absorbent spraying. The vertical distance between the upper tube sheet and the top of the heat exchange tube is 40mm; the bottom guide groove is inserted into the heat exchange tube, and the insertion length is 40mm; the axial angle α of the bottom end of the guide groove is 50°. The angle β between the guide plate and the horizontal plane is 140°, and the sealing plate is inserted below the liquid surface of the crystallizing tank. The solid-liquid separator is "flocculation + drum filtration".

[0068] Operating conditions: (1) The absorbent adopts 40% NaOH s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com