Low-viscosity epoxy acrylate paint for inner wall of food can and preparation method thereof

An epoxy acrylate, low-viscosity technology, used in epoxy resin coatings, coatings, etc., can solve the problems of inability to meet electron beam, low cross-linking density, low coating film hardness, etc., achieve excellent gloss, cross-linking The effect of high density and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

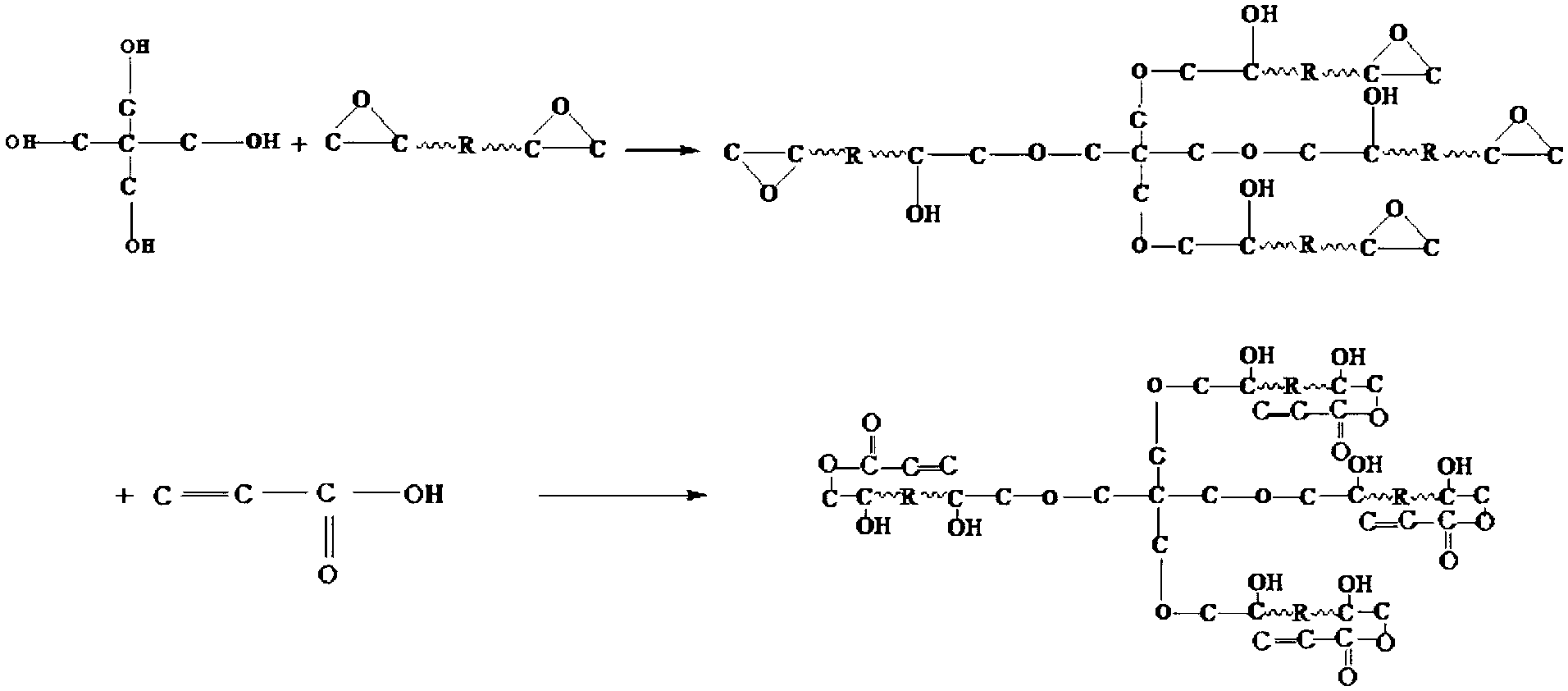

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of low-viscosity epoxy acrylate resin with high degree of branching

[0024] a. Add 156.8g (0.4mol) of bisphenol A epoxy resin E-51 and 0.47g of tetrabutylammonium bromide into the reaction vessel, stir and heat up to 100°C, add pentaerythritol: 5.45g (0.04mol), keep temperature and reflux for 2 hours to obtain pentaerythritol epoxy ester;

[0025] b. Take 100g (0.077mol) of the pentaerythritol epoxy ester prepared in step a and cool it down to 85°C, add dropwise 0.5g of tetrabutylammonium bromide, 0.03g of p-hydroxyanisole and 5.69g (0.079mol) of acrylic acid Mixture, control the mixture to be added dropwise within 30 minutes, and react at constant temperature for 4 hours; when the acid value of the system is measured to be ≤5mgKOH / g, cool and discharge to obtain low-viscosity epoxy acrylate;

[0026] (2) Preparation of low-viscosity epoxy acrylate coatings for inner walls of food cans

[0027] Get the low-viscosity epoxy acrylate 100g that makes in t...

Embodiment 2

[0029] a. Add bisphenol A type epoxy resin in the reaction vessel: E-44 156.8g (0.4mol) and catalyst: tetraethylammonium bromide 0.784g, stir and heat up to 100°C, add pentaerythritol: 10.892g (0.08mol ), keep the temperature and condense and reflux for 4 hours; make pentaerythritol epoxy ester;

[0030] b. Take out 100g (0.051mol) of the pentaerythritol epoxy ester prepared in a and cool it down to 85°C, add dropwise a catalyst: 0.8g of tetrabutylammonium bromide, a polymerization inhibitor: 0.05g of p-hydroxyanisole and 3.89g of acrylic acid (0.054mol) of the mixture, the control mixture was added dropwise within 60 minutes, and the constant temperature was reacted for 6 hours; when the system acid value was less than or equal to 5mgKOH / g, cooling and discharging produced low-viscosity epoxy acrylate;

[0031] (2) Preparation of low-viscosity epoxy acrylate coatings for inner walls of food cans

[0032] Get the highly branched low-viscosity epoxy acrylate 100g that makes in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com