A kind of acrylic polyurethane emulsion and its preparation method and application

A technology of acrylic polyurethane and acrylic resin, which is applied in the preparation of carboxylate, polyurea/polyurethane coatings, chemical instruments and methods, etc. It can solve the problems of increasing production costs, wasting resources, and not conforming to environmental protection trends, and achieves good water resistance. , the effect of high degree of branching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Compound A1 synthesis:

[0033] Add 90 g of glycidyl tert-carbonate and 30 g of acrylic acid into a four-necked flask, stir and raise the temperature to 100°C, and keep the temperature for 3 hours to obtain compound A1 containing double bonds;

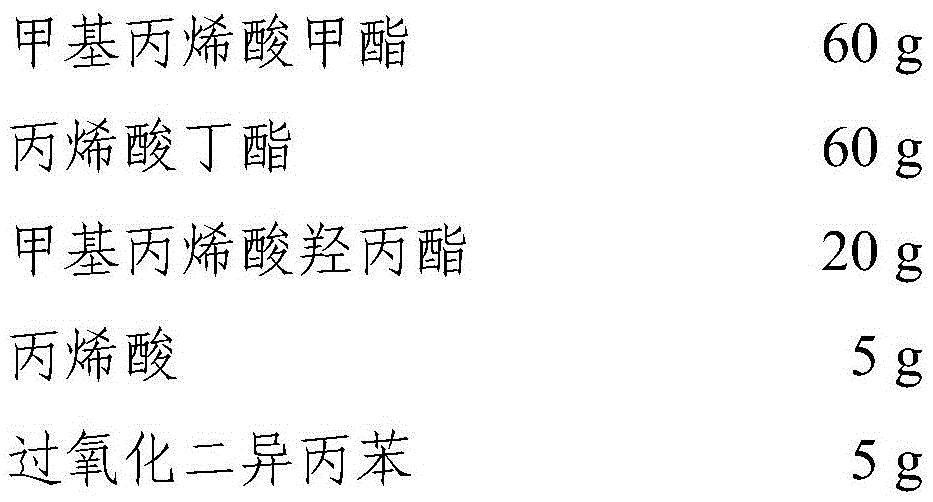

[0034] 2) Acrylic resin synthesis:

[0035]

[0036] Mix methyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, acrylic acid, and dicumyl peroxide evenly in advance, add dropwise to compound A1 at 150°C at a uniform speed, drop it for 3 hours, and then keep it warm for 1 hour. Acrylic resin is obtained;

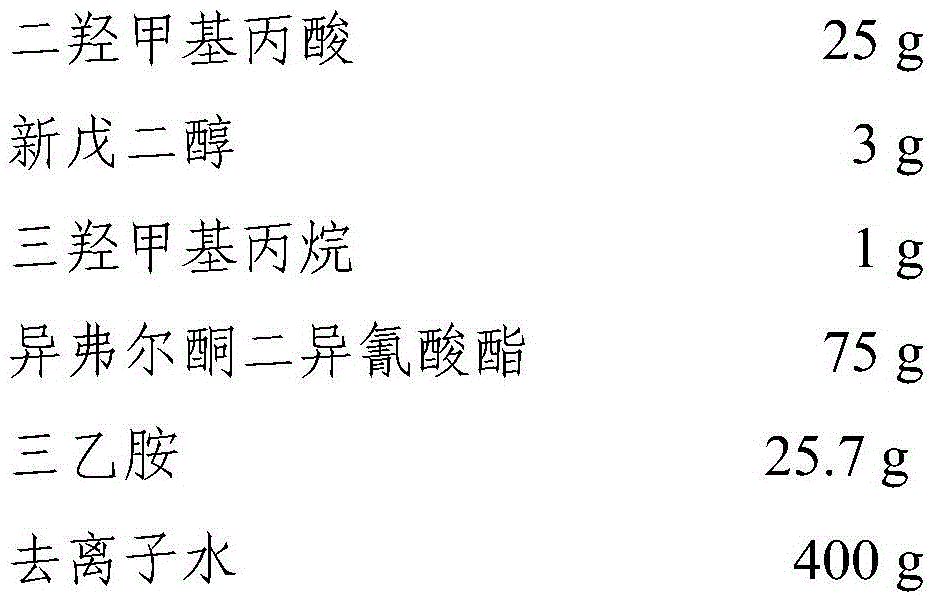

[0037] 3) Synthesis of PUA emulsion:

[0038]

[0039] Cool the acrylic resin to 80°C, add dimethylolpropionic acid, neopentyl glycol, and trimethylolpropane, mix well, drop isophorone diisocyanate within 2 hours, and keep warm for 2-3 hours until NCO The group reacted to the theoretical content and began to cool down. Cool down to 50°C, add triethylamine dropwise, drop it within 15 minutes, add deionized ...

Embodiment 2

[0041] 1) Compound A1 synthesis:

[0042] Add 90 g of glycidyl tert-carbonate and 40 g of methacrylic acid into a four-neck flask, stir and raise the temperature to 90°C, and keep the temperature for 4 hours to obtain compound A1 containing double bonds;

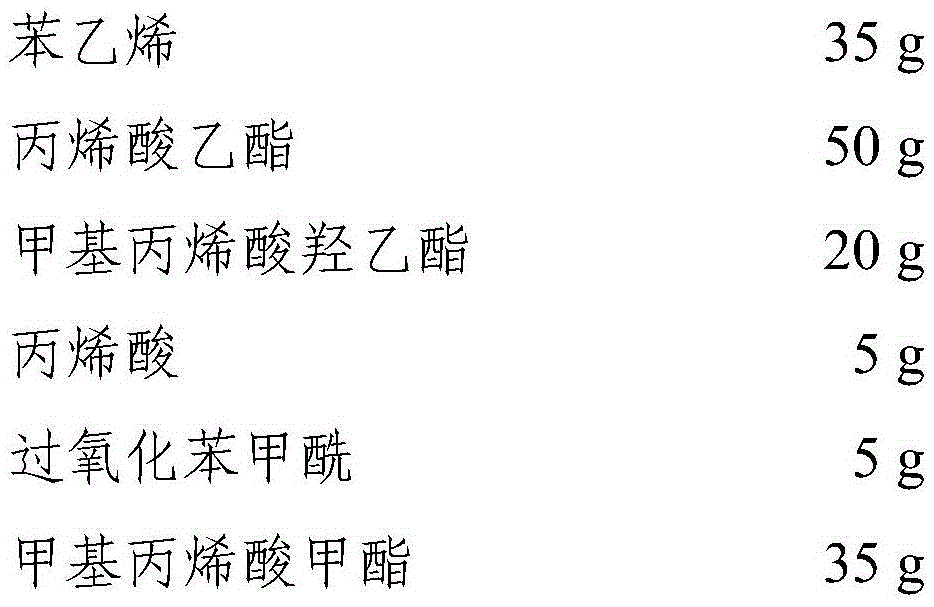

[0043] 2) Acrylic resin synthesis:

[0044]

[0045] The above components were pre-mixed uniformly, and added dropwise to compound A1 at 140°C at a constant speed for 5 hours, and then incubated for 1 hour to obtain an acrylic resin;

[0046]

[0047] Cool the acrylic resin to 60°C, add dimethylolpropionic acid, neopentyl glycol, and trimethylolpropane, mix well, drop toluene diisocyanate within 2 hours, and then keep it warm for 2-3 hours until the NCO group reacts When the theoretical content is reached, the temperature is lowered to 50°C, triethylamine is added dropwise, and the drop is completed within 15 minutes. Then, deionized water is added, and the mixture is quickly stirred and dispersed to obtain a solvent-...

Embodiment 3

[0049] 1) Compound A1 synthesis:

[0050] Add 90 g of glycidyl tert-carbonate and 35 g of methacrylic acid into a four-necked flask, stir and raise the temperature to 120°C, and keep the temperature for 2 hours to obtain compound A1 containing double bonds;

[0051] 2) Acrylic resin synthesis:

[0052]

[0053] Mix the above components uniformly in advance, add dropwise to compound A1 at 160°C at a constant speed, finish dropping after 2 hours, and keep warm for 1 hour to obtain acrylic resin;

[0054] 3) Synthesis of PUA emulsion:

[0055]

[0056] Cool the acrylic resin to 70°C, add dimethylolpropionic acid, neopentyl glycol, and trimethylolpropane, mix well, drop toluene diisocyanate within 2 hours, and then keep it warm for 2-3 hours until the NCO group reacts When the theoretical content is reached, the temperature is lowered, and the temperature is lowered to 50°C. Triethylamine is added dropwise, and the drop is completed within 15 minutes. Then, deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com