A preparation method of matte color superhydrophobic stainless steel based on square wave etching

A stainless steel, super-hydrophobic technology, applied in anodizing and other directions, can solve the problems of reducing the corrosion resistance of the stainless steel substrate, the negative impact of the corrosion resistance of the coloring film, and involving chemical etching liquids, etc., to achieve uniform coloring effect, highlight energy saving and environmental protection value, Ease of handling recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method based on square wave etching of matte type super-hydrophobic colored stainless steel, comprising the following steps:

[0038] (1) Clean the stainless steel surface. The specific operation is: cut the 304 stainless steel plate sample into a shape of 1cm×5cm, put it in anhydrous ethanol and ultrasonically clean it for 5min; then put it in hot alkali (NaOH and NaOH and 3 PO 4 The compound alkaline solution, NaOH and Na in the alkaline solution 3 PO 4 The concentrations are 40g / L and 30g / L) solution, carry out alkaline washing and degreasing for 8min; finally rinse the surface of the stainless steel plate sample with deionized water.

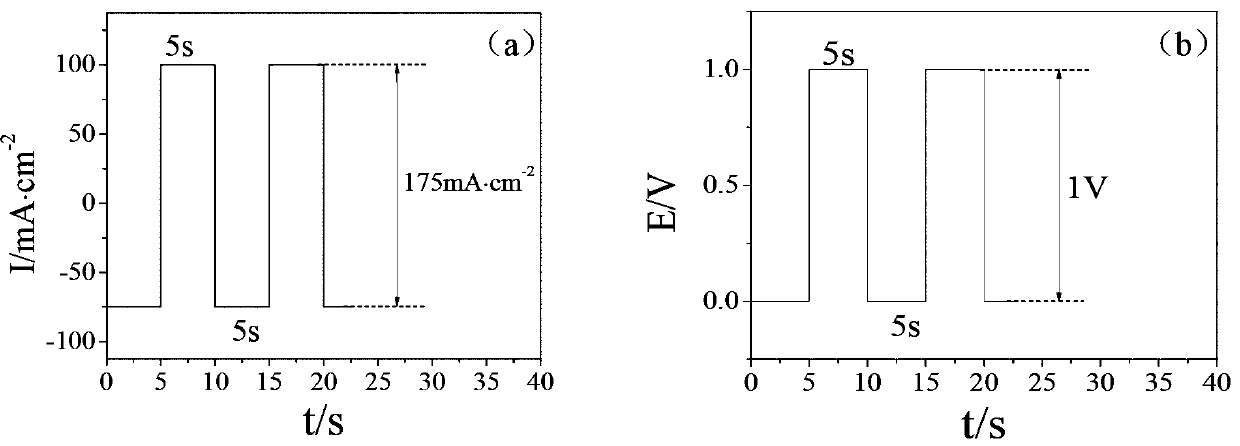

[0039] (2) Put the cleaned stainless steel in an acid solution, and use square wave current polarization to etch the surface of the stainless steel. The specific operation is: put the stainless steel plate sample in a sulfuric acid solution with a temperature of 60 °C and a concentration of 2.5 mol / L In this method, t...

Embodiment 2

[0043] A preparation method based on square wave etching of matte type super-hydrophobic colored stainless steel, comprising the following steps:

[0044] (1) Clean the stainless steel surface. The specific operation is: cut the 304 stainless steel plate sample into a shape of 1cm×5cm, put it in anhydrous ethanol and ultrasonically clean it for 5min; then put it in hot alkali (NaOH and NaOH and 3 PO 4 The compound alkaline solution, NaOH and Na in the alkaline solution 3 PO 4 concentrations of 40g / L and 30g / L) solution, carry out alkaline washing and degreasing for 5min; finally rinse the surface of the stainless steel plate sample with deionized water.

[0045] (2) Put the cleaned stainless steel in an acid solution, and use square wave current polarization to etch the surface of the stainless steel. The specific operation is: put the stainless steel plate sample in a sulfuric acid solution with a temperature of 70 °C and a concentration of 2.5 mol / L In this method, the st...

Embodiment 3

[0049] A preparation method based on square wave etching of matte type super-hydrophobic colored stainless steel, comprising the following steps:

[0050] (1) Clean the stainless steel surface. The specific operation is: cut the 304 stainless steel plate sample into a shape of 1cm×5cm, put it in anhydrous ethanol and ultrasonically clean it for 5min; then put it in hot alkali (NaOH and NaOH and 3 PO 4 The compound alkaline solution, NaOH and Na in the alkaline solution 3 PO 4 The concentrations are 40g / L and 30g / L) solution, carry out alkaline washing and degreasing for 8min; finally rinse the surface of the stainless steel plate sample with deionized water.

[0051] (2) Place the cleaned stainless steel in an acidic solution, and use square wave current polarization to etch the surface of the stainless steel. The specific operation is: place the stainless steel plate sample in a sulfuric acid solution with a temperature of 80 °C and a concentration of 2.0 mol / L In this met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com