Dual-cycle fluidized bed device for coal-based chemical chain process

A chemical chain and double cycle technology, applied in the direction of fluidized bed combustion equipment, fuel burned in molten state, combustion type, etc., can solve the structural principle and cumbersome process, the low utilization rate of heat transfer in the reactor, and the operation of the flow sealing valve Complicated problems, to achieve the effect of simple process integration, improved particle fluidization characteristics, and simplified space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

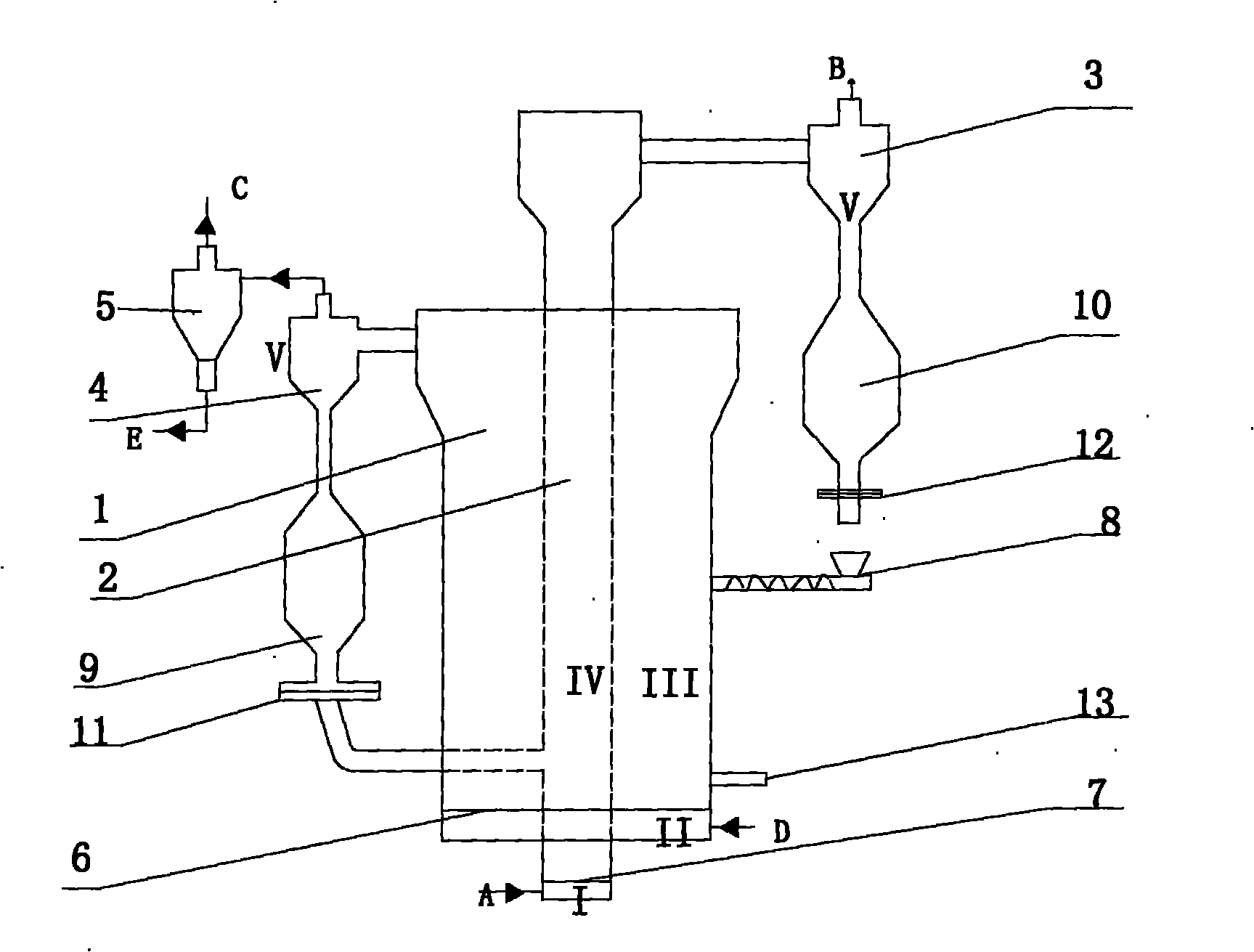

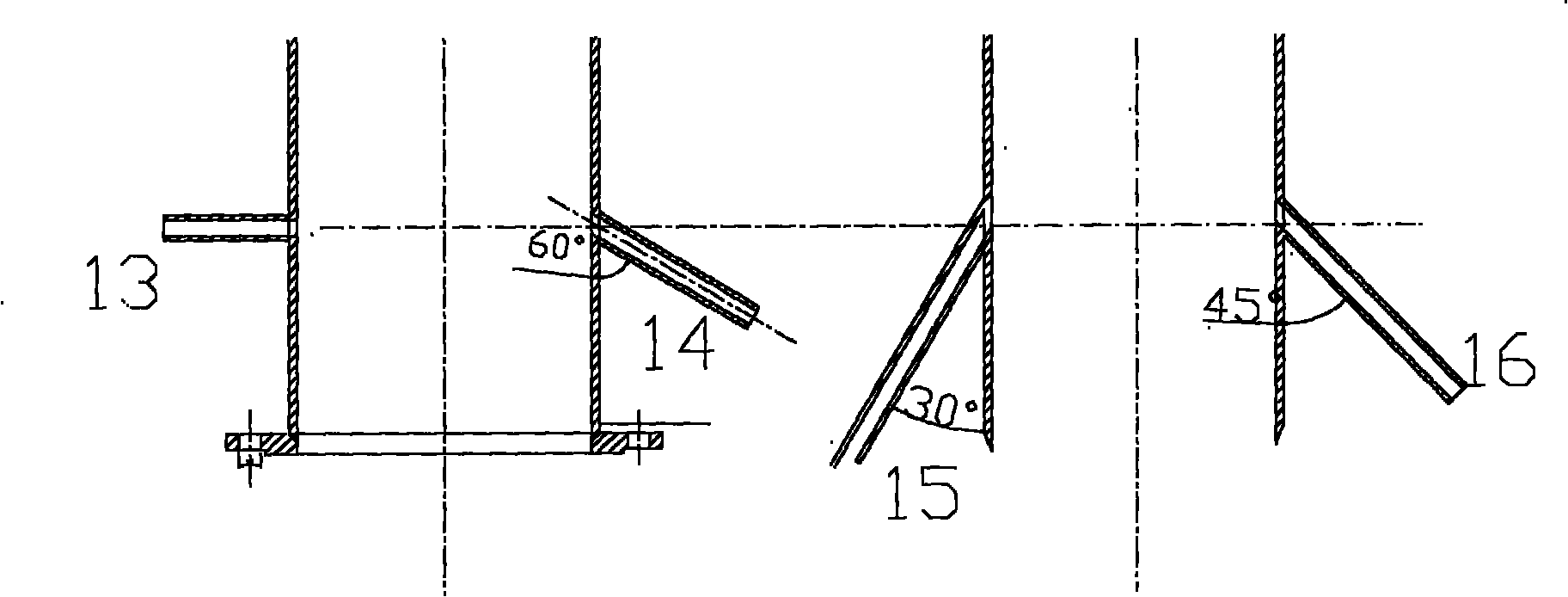

[0011] The main functional structure of this embodiment includes an oxidation reactor gas pre-distribution chamber I, a reduction reactor gas pre-distribution chamber II, an oxidation reaction zone III, a reduction reaction zone IV, and a gas-solid separation zone V; the main structure includes a reduction reactor 1, Oxidation reactor 2, cyclones 3, 4 and 5, screw feeder 8, gas predistribution plates 6 and 7, material storage 9 and 10, control valves 11 and 12, jet pipes 13, 14, 15 and 16 Gas pre-distribution plates 6 and 7 are respectively formed on the bottom of the reduction reactor 1 and the oxidation reactor 2 of the inverted column type, and the jet tube 13 with different inclinations is formed on the bottom side of the reduction reactor, and the reduction reaction on the top of the jet tube 13 A screw feeder 8 is formed on the side wall of the device 1; the center of the inner cavity of the reduction reactor 1 is vertically divided into a reduction reaction zone IV or an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com