Double-cycle production line and production process of prefabricated building prefabricated parts

A technology of prefabricated components and production lines, which is applied in the direction of manufacturing tools, supply devices, ceramic molding workshops, etc., can solve the problems of large footprint and low production efficiency, and achieve the effects of saving space, high work efficiency, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

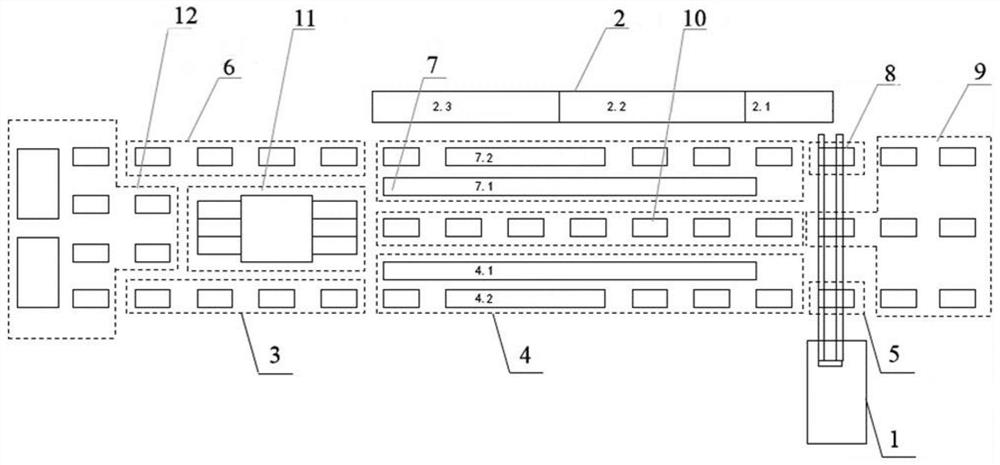

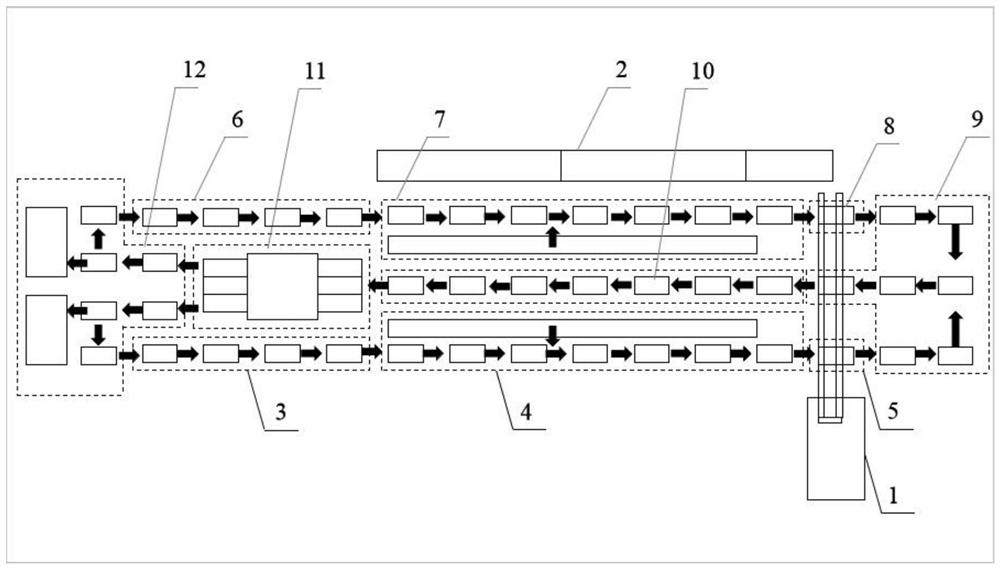

[0034] Such as figure 1 and figure 2 A double-cycle production line of prefabricated building components and its production process are shown, which include a formwork removal and hoisting area 12, a steam curing area 11, a component pre-curing area 10 and Ferry Rest Area 9;

[0035] The double-cycle production line also includes a first processing preparation area 3 and a second processing preparation area 6 symmetrically arranged on both sides of the steam curing area 11, and a first pouring preparation area 4 symmetrically arranged on both sides of the component pre-curing area 10. And the second pouring preparation area 7, the first pouring vibration area 5 and the second pouring vibration area 8 symmetrically arranged on both sides of the left end of the ferry resting area 9;

[0036] The outside of the second pouring preparation area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com