Ammonia-ammonium sulfate method dual circulation three segments desulfurizing tower

A dual-circulation, desulfurization tower technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of large flue gas flow resistance, ammonia carry-over and escape, ammonia secondary pollution, etc., to reduce the overall cost, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

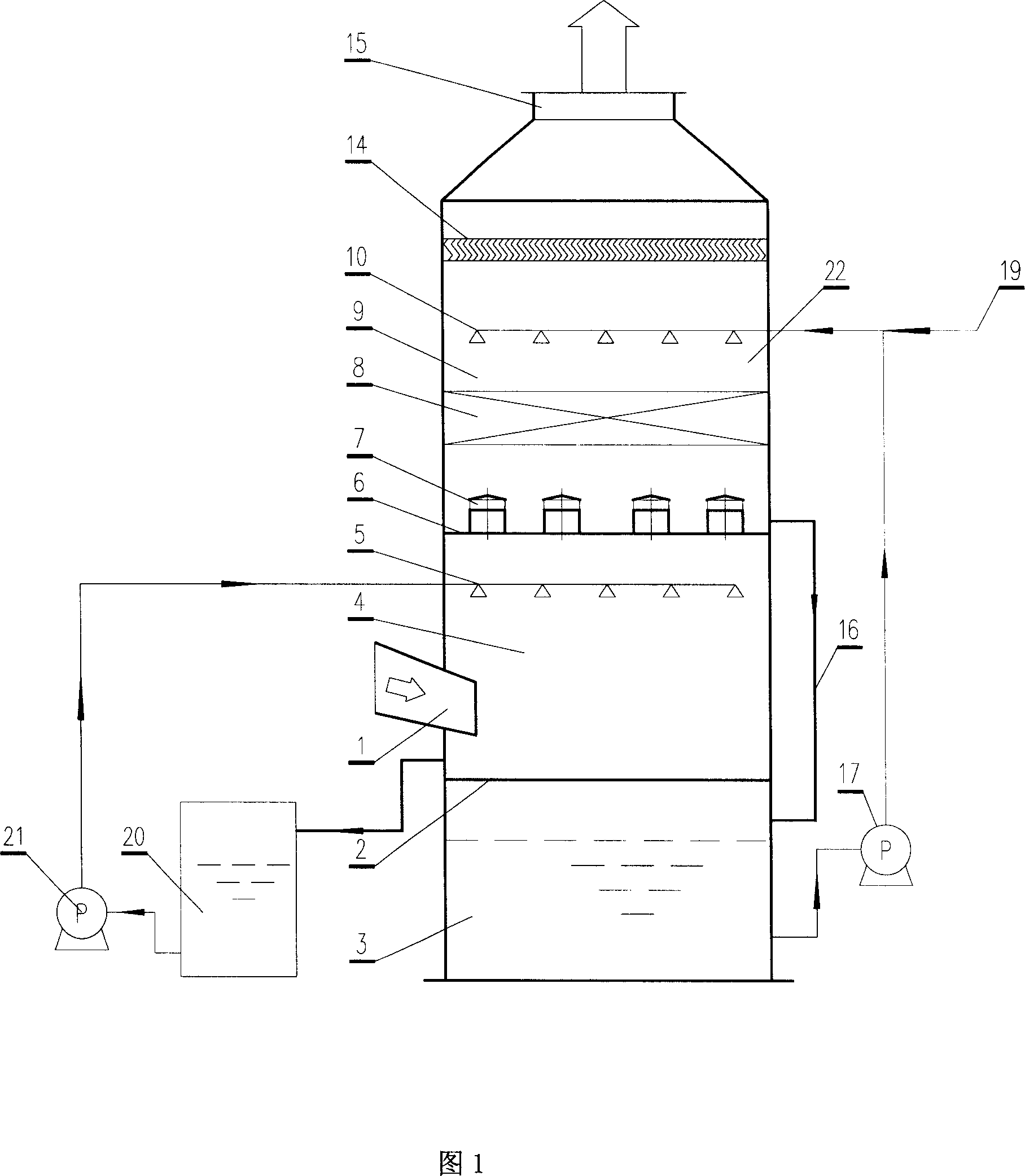

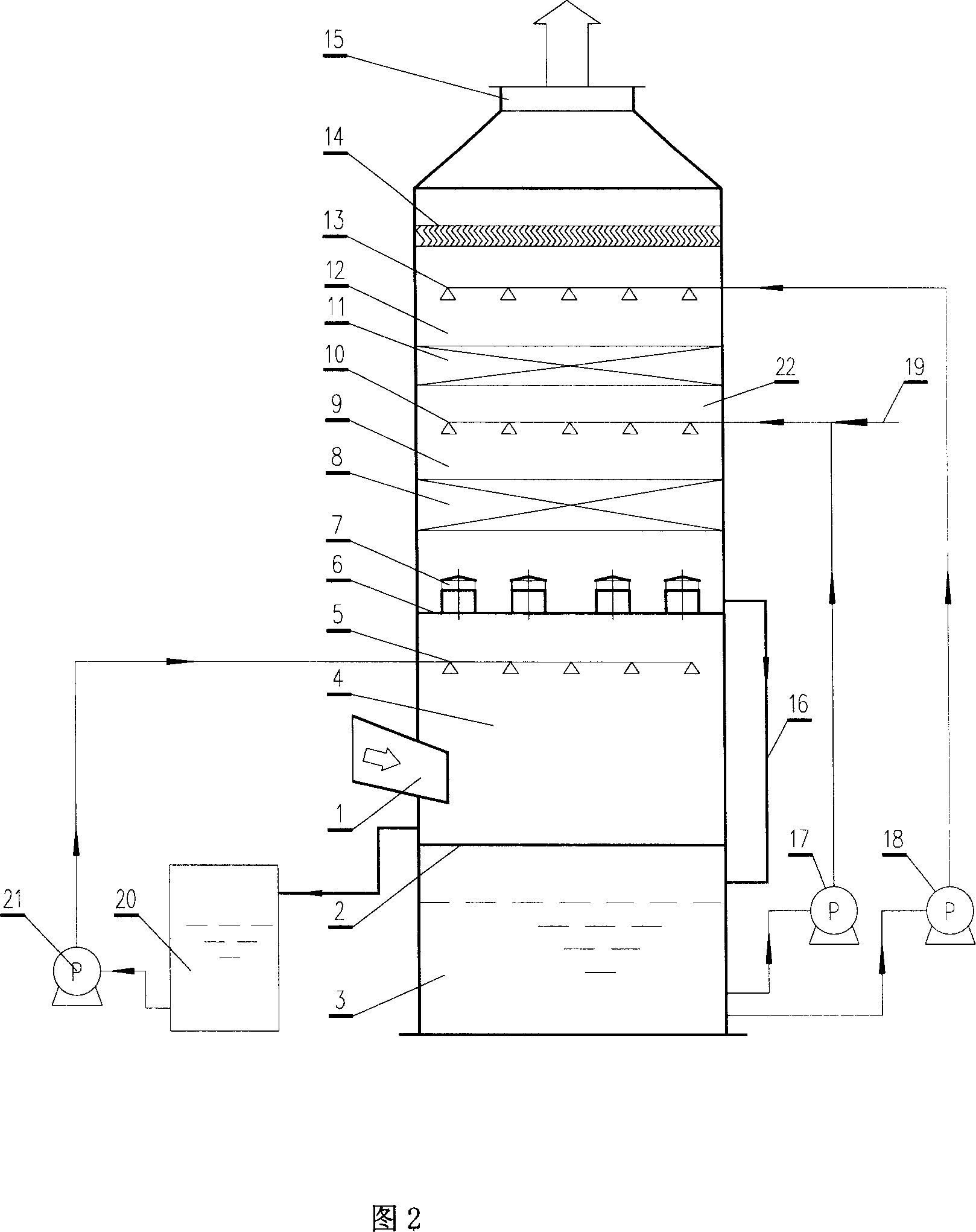

[0019] See Figure 2

[0020] The two-stage absorption cycle structure tower is to add a one-stage absorption cycle liquid pump (18) on the basis of a single-stage absorption cycle structure, and add an absorption spray layer (13) and a packing layer (11) to the absorption section (22). ), so that the absorption cycle has two stages. The absorption section is equipped with two-stage absorption liquid spray layers, and besides the empty tower absorption section with effective height, there is also a packing layer under each spray layer. The flue gas rises evenly through the packing layer (8), the empty tower absorption section (9), the absorption spray layer (10), the packing layer (11), the empty tower absorption section (12) and the absorption spray layer (13), Flue gas and spray absorption liquid carry out graded effective mass transfer, SO 2 Is graded for effective absorption. Absorbent ammonia or ammonium bicarbonate (19) supplements in spray layer (10), improves the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com