Engine dual-cycle forced cooling system

A technology of forced cooling and external circulation cooling, which is used in the cooling of engines, engine components, machines/engines, etc., can solve the problems of aggravating friction pair wear, heavy friction pair wear, and high viscosity of lubricating oil, and achieves reduction of process resistance, The effect of reducing power consumption and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

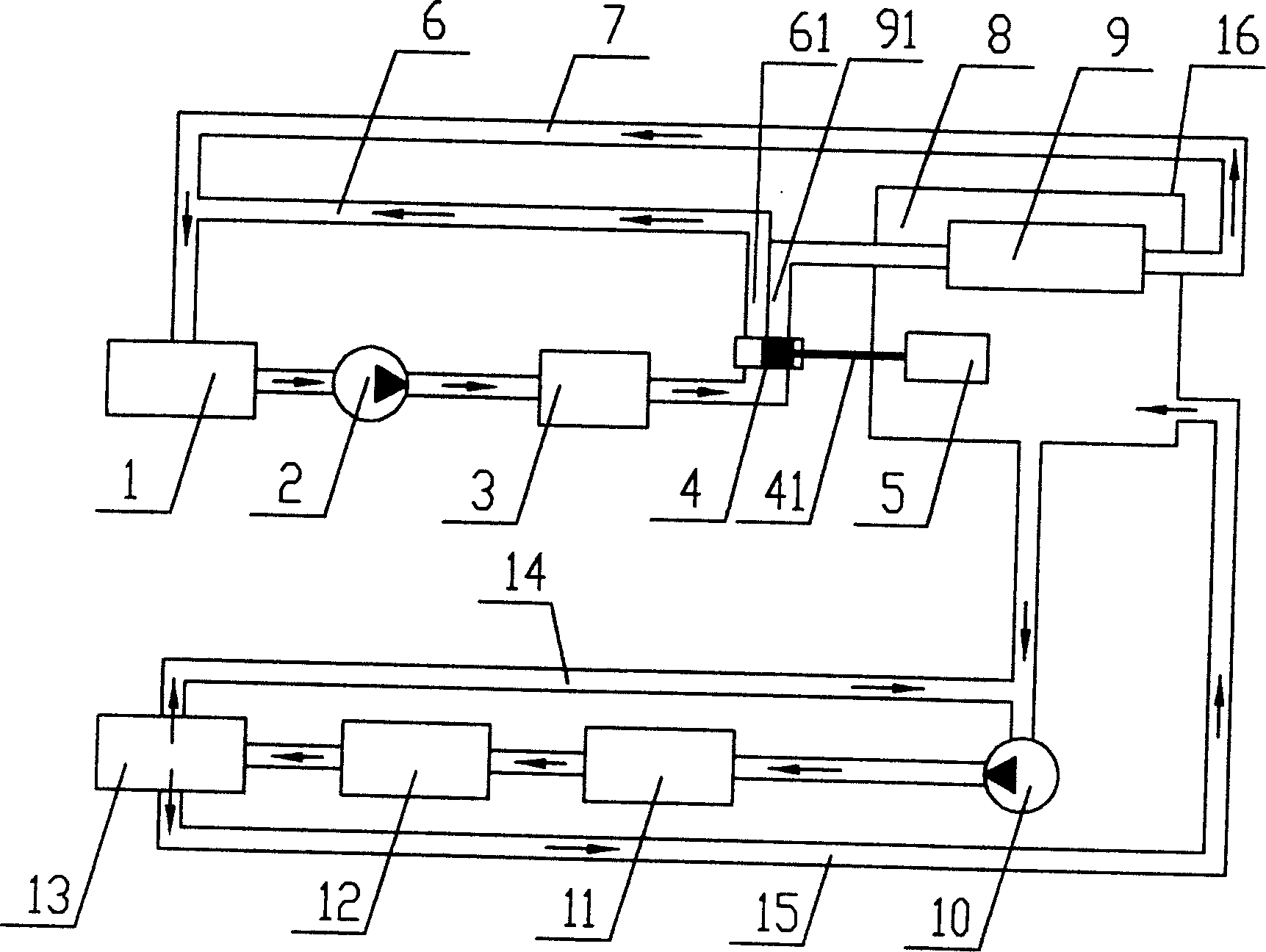

[0014] As shown in Figure 1, the dual-circulation forced cooling system of the engine includes an inner circulation cooling subsystem and an outer circulation cooling subsystem, and the outer circulation cooling subsystem is connected to the outer circulation water chamber 9 of the heat exchanger, and the inner circulation The cooling subsystem pipe is connected to the internal circulation water cavity 8 of the heat exchanger, and the pipeline of the external circulation cooling subsystem is also provided with a flow control valve 4 capable of controlling the flow of the external circulation cooling medium through the heat exchanger. A temperature sensing device of the water chamber, the temperature sensing device drives the flow control valve 4 .

[0015] The flow control valve is arranged at the water inlet 91 of the outer circulating water chamber 9 of the heat exchanger, and the temperature sensing device is arranged in the inner circulating water chamber 8 of the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com