Dual-cycle mode catalytic cracking reaction regenerative system production technology and device

A catalytic cracking and reaction regeneration technology, applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problems of large deviation of light oil yield, coking effect, high coking rate, etc., to improve activity and service life, and improve gasoline quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments.

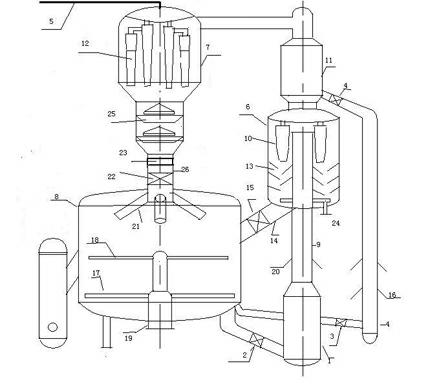

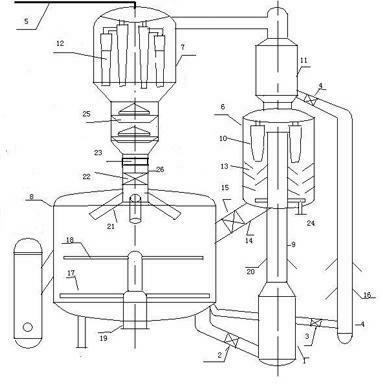

[0032] Such as figure 1Shown, a kind of dual-cycle mode catalytic cracking reaction regeneration system production device adopts the design structure of riser, two-stage settler, stripper and high and low parallel reaction regenerator 8 for carrying out two-stage catalytic cracking reaction; The heavy oil riser (1) is a riser structure for two-stage catalytic cracking reactions. The heavy oil riser 1 has a heavy oil riser first reactor 9 and a heavy oil riser second reactor 11; A first settler 6 is arranged between the first reactor 9 and the second reactor 11 of the heavy oil riser, and the first settler 6 divides the reaction of the heavy oil riser 1 into the first catalyst circulation system and the first catalytic cracking reaction section and catalyst second circulation system and cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com