Patents

Literature

49results about How to "Reduce coke rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Suspended bed hydrocracking catalyst and preparation method

ActiveCN107754818AStrong focusing abilityHigh yieldPhysical/chemical process catalystsHydrocarbon oil crackingSulfurNitrogen

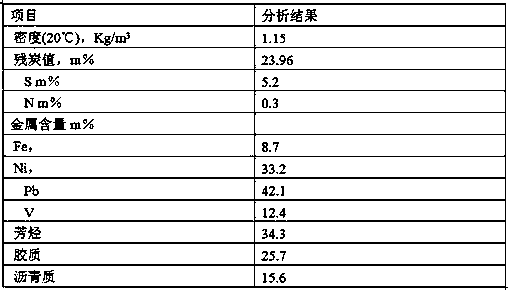

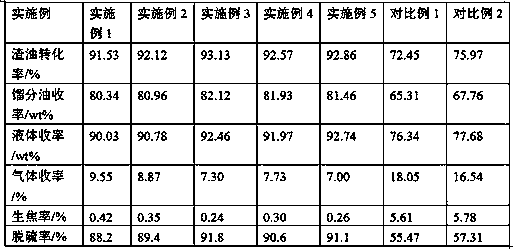

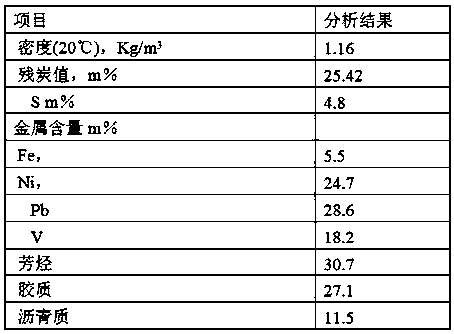

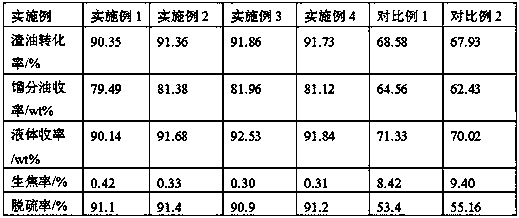

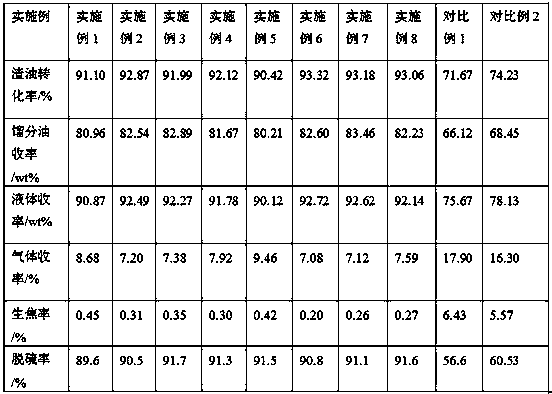

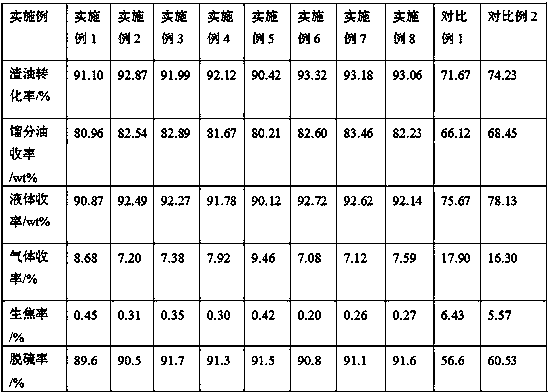

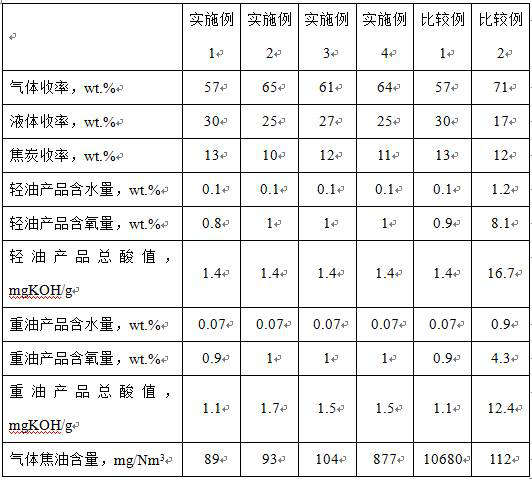

The invention discloses a suspended bed hydrocracking catalyst and a preparation method thereof. The suspended bed hydrocracking catalyst comprises a sulfurized bauxite and zinc oxide, wherein the content of the zinc oxide is 1.0-50.0wt%; the suspended bed hydrocracking catalyst can be prepared by dryly mixing the sulfurized bauxite and the zinc oxide. The suspended bed hydrocracking catalyst is high in conversion rate, low in coking rate, high in desulfurization rate and strong in capability of resisting sulfur, metal, nitrogen, residual charcoal and other impurities, and is applied to a suspension bed hydrocracking reaction of poor-quality heavy oil.

Owner:FUZHOU UNIV

Heavy oil suspended bed hydro-cracking catalyst and preparation method thereof

ActiveCN107754820AStrong focusing abilityHigh yieldPhysical/chemical process catalystsHydrocarbon oil crackingSulfurFuel oil

The invention discloses a heavy oil suspended bed hydro-cracking catalyst. The catalyst comprises 15.0-55.0 percent by weight of vulcanized kaolin powder, 10.0-65.0 percent by weight of zinc oxide powder and 1.0-25.0 percent by weight of vulcanized molybdenum-containing compound powder; and the catalyst can be prepared by dry-blending the vulcanized kaolin powder, the vulcanized molybdenum-containing compound powder and the zinc oxide powder. In addition, the catalyst disclosed by the invention can also comprise vulcanized lanthanum ferrite. The prepared catalyst is used for the suspended bedhydro-cracking reaction of inferior heavy oil, is low in coke yield, high in liquid yield and desulfurization rate and strong in resistance to sulfur, colloids and other impurities.

Owner:FUZHOU UNIV

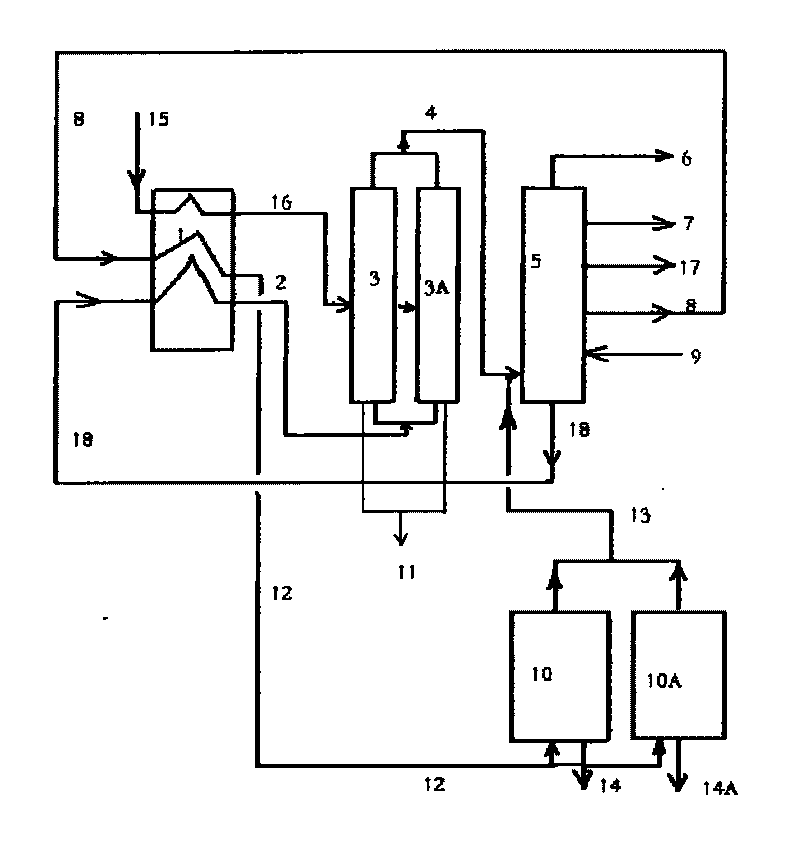

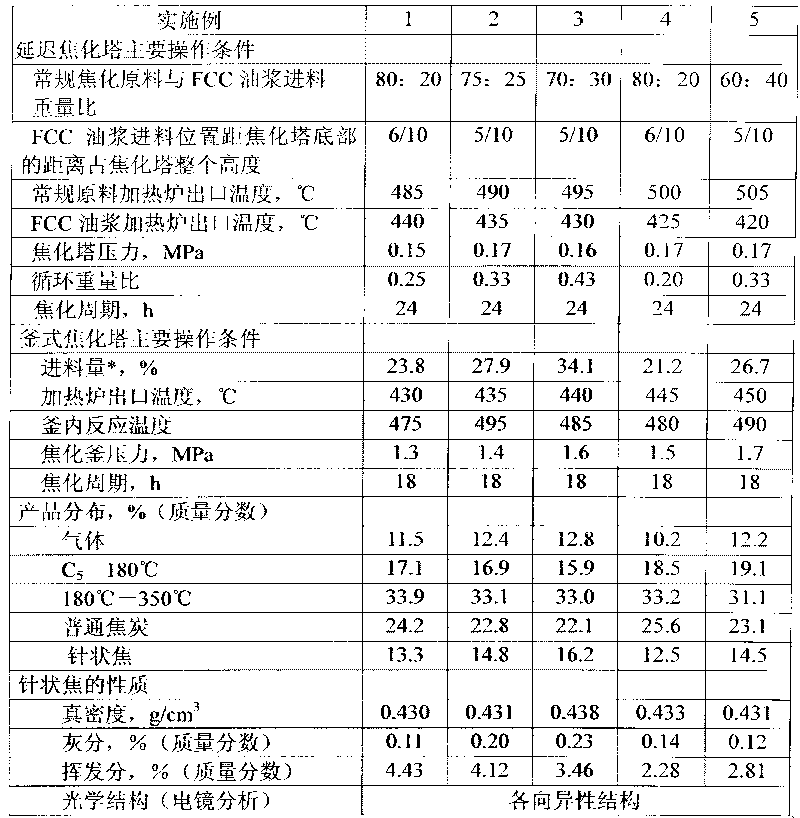

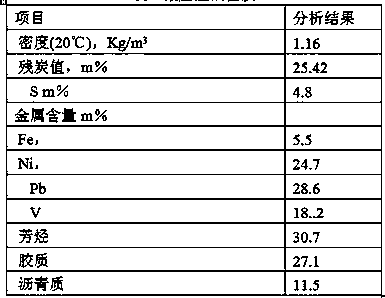

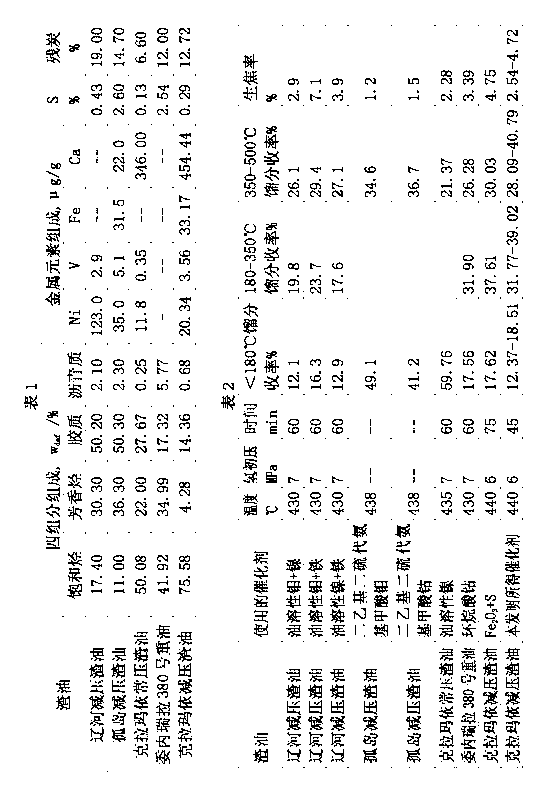

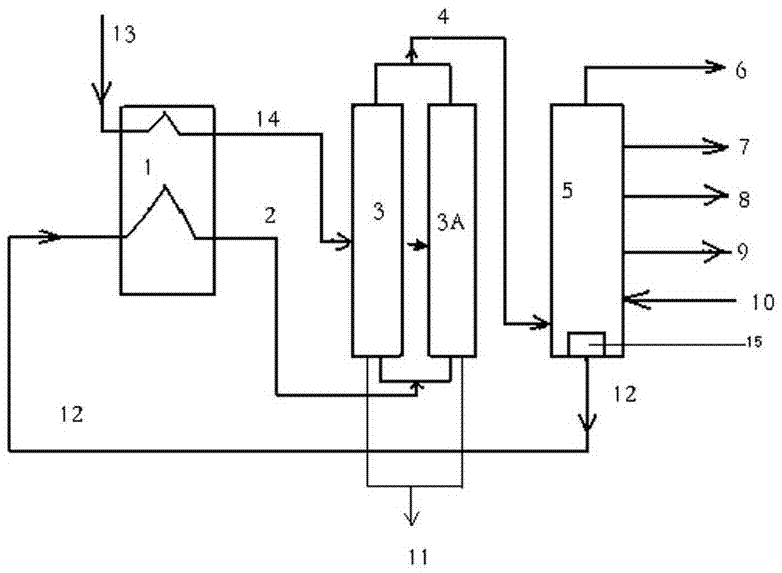

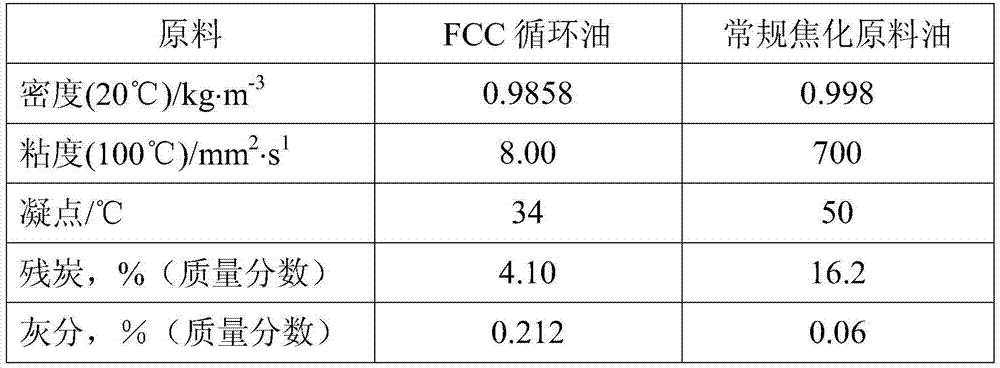

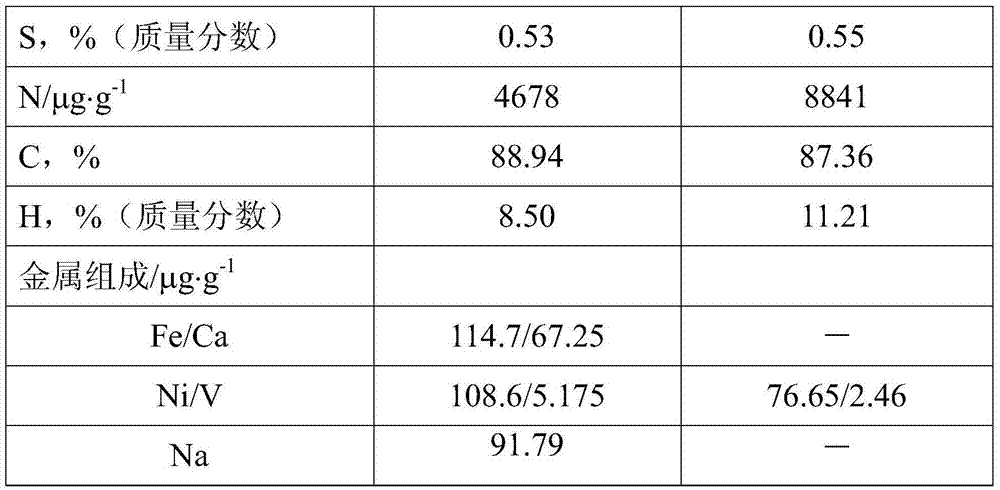

Production method of needle coke raw material

ActiveCN101724420AExpand sourceThe method flow is simpleCoking carbonaceous materialsDecompositionCoke rate

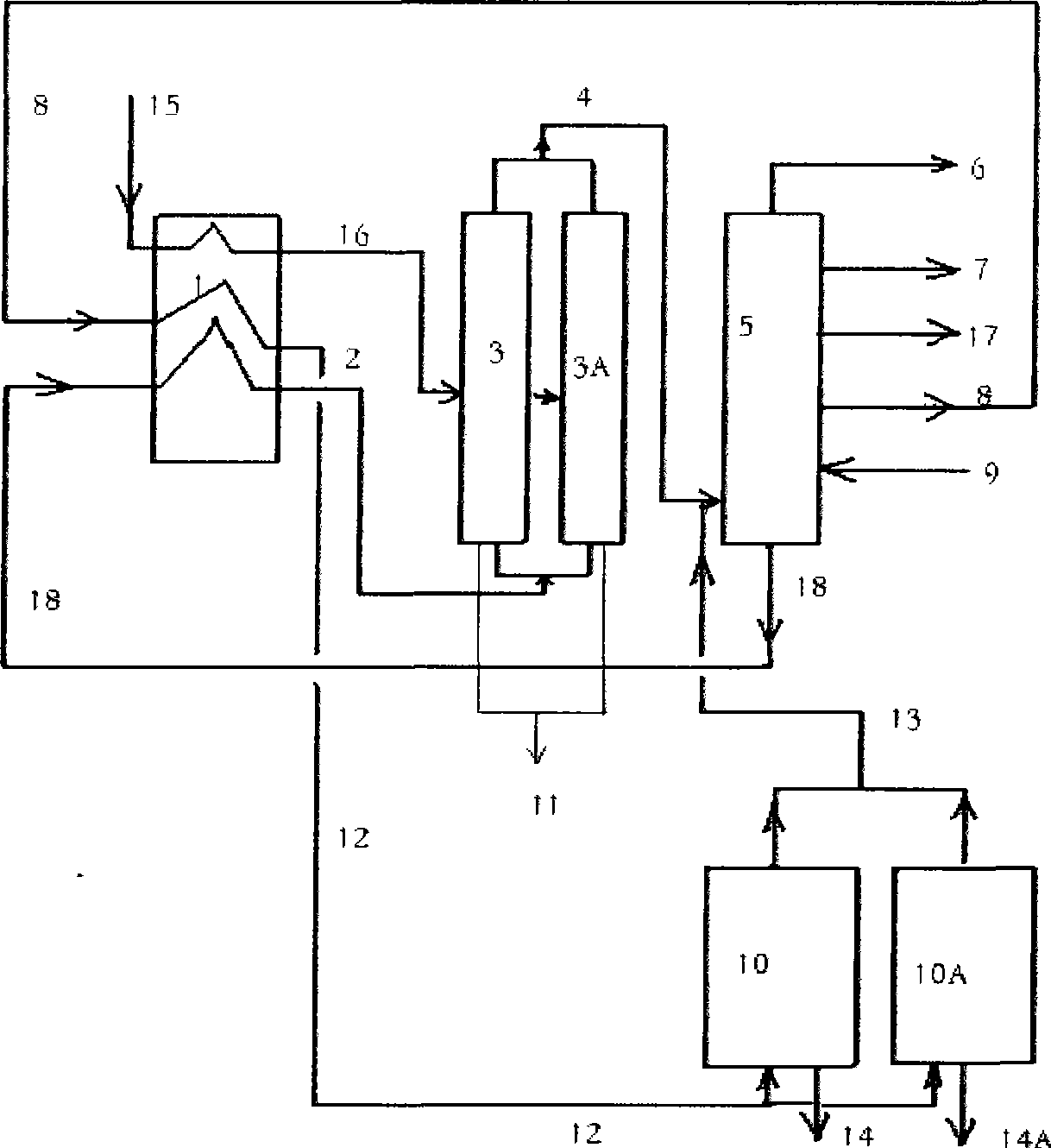

The invention discloses a method of needle coke raw material by using delay coking technique to treat FCC slurry oil and conventional coking raw material. The method comprises: introducing FCC slurry oil with low temperature into a delay coking tower from the upper part inside the tower, leading the introduced FCC slurry oil to be contacted with high temperature oil gas generated by the conventional coking raw material which is introduced into the tower from the bottom and treated by high temperature decomposition, and reacting under the condition of delay coking; and separating the generated oil gas in a coking fractionating tower, and obtaining the needle coke raw material. In the method, as the FCC slurry oil enters into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of needle coke raw material

ActiveCN101724420BHigh reactivityExpand sourceThermal non-catalytic crackingCoking carbonaceous materialsCoke rateDecomposition

Owner:CHINA PETROLEUM & CHEM CORP +1

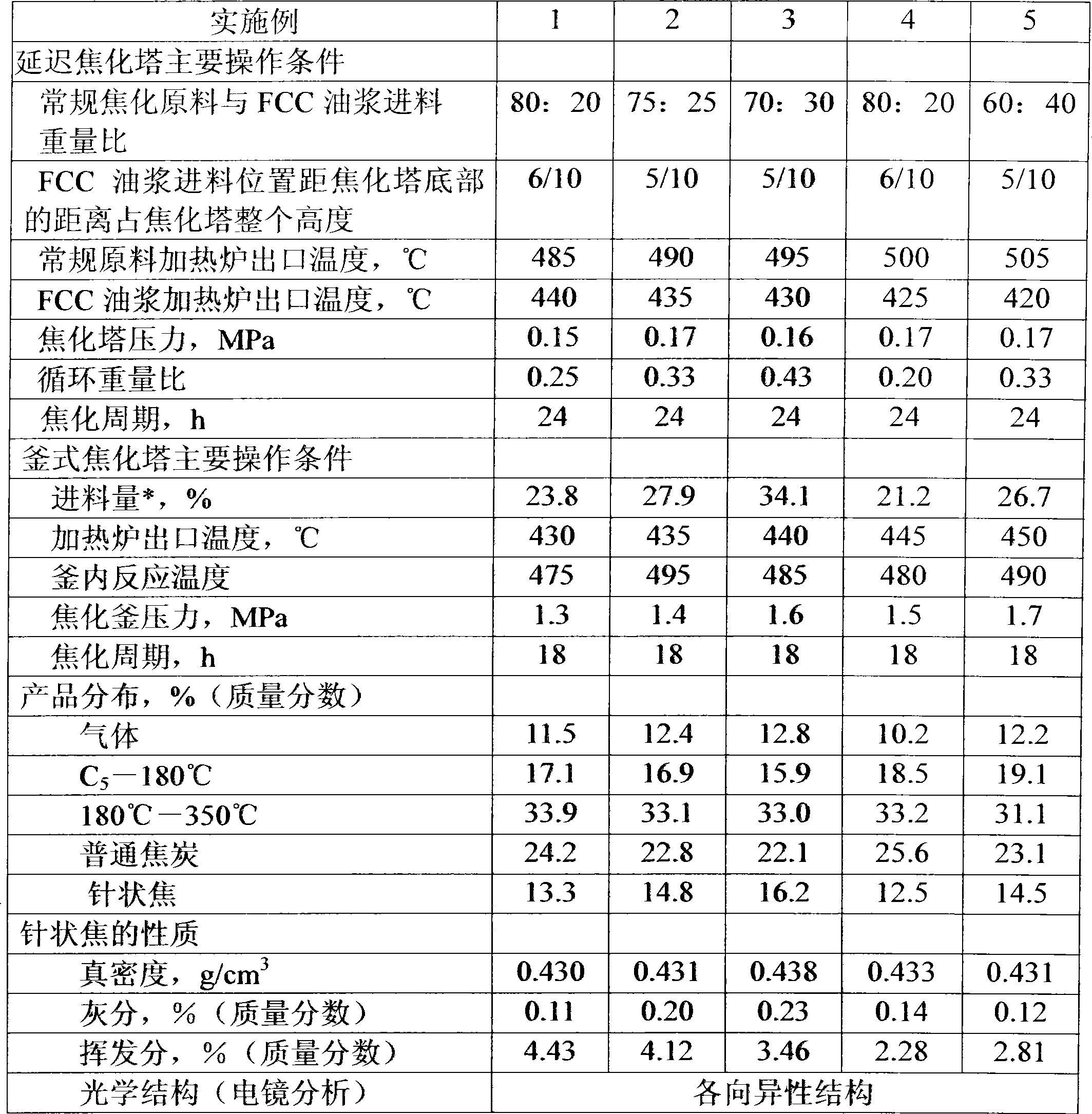

Production method of needle coke

The invention discloses a method for producing needle coke by adopting the technique combining delay coking and kettle-type coking. The method comprises: when treating the conventional coking raw material by using the delay coking technique, introducing FCC slurry oil into a delay coking tower from the upper part inside the tower at the low temperature, and obtaining needle coke raw material by fractionating high temperature oil gas obtained by the reaction; and then, treating the needle coke raw material by using the kettle-type coking technique, and obtaining high quality needle coke. In the method, as the FCC slurry oil is injected into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

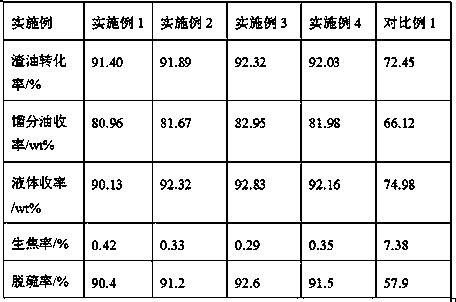

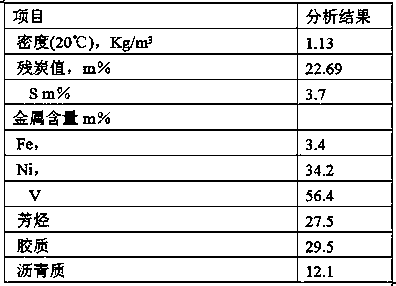

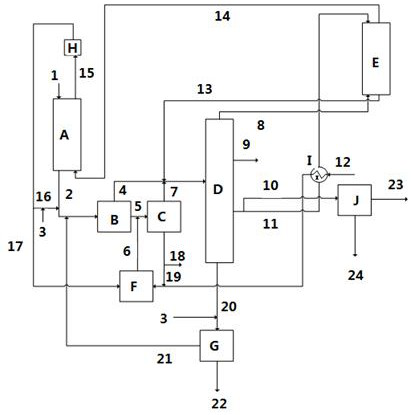

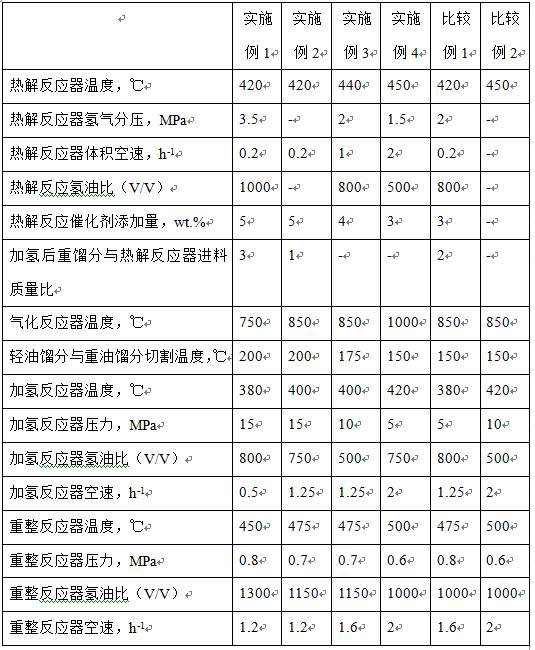

A kind of heavy oil suspended bed hydrocracking process

ActiveCN107892941BInhibition of transitional crackingImprove conversion rateHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionGas phase

Owner:FUZHOU UNIV

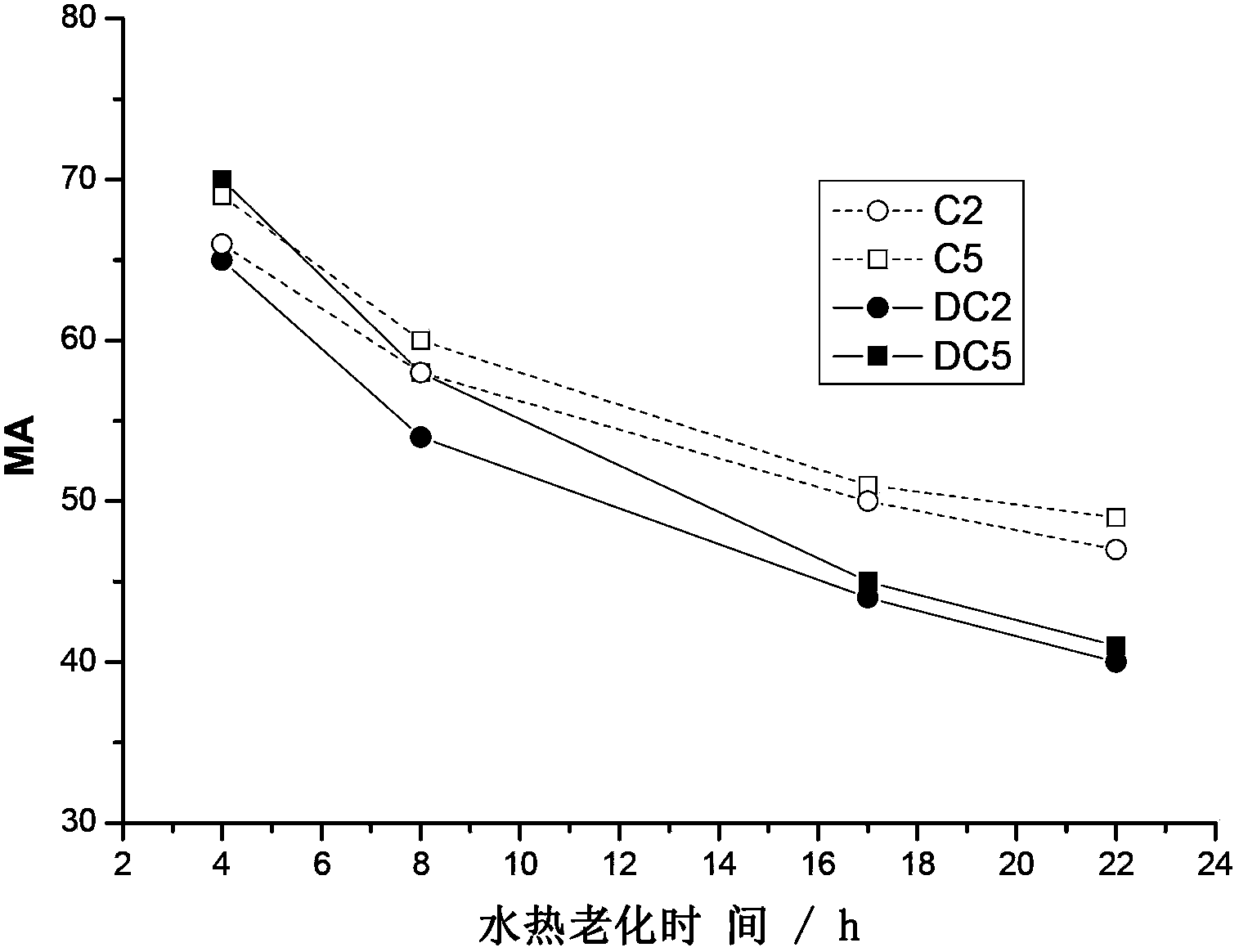

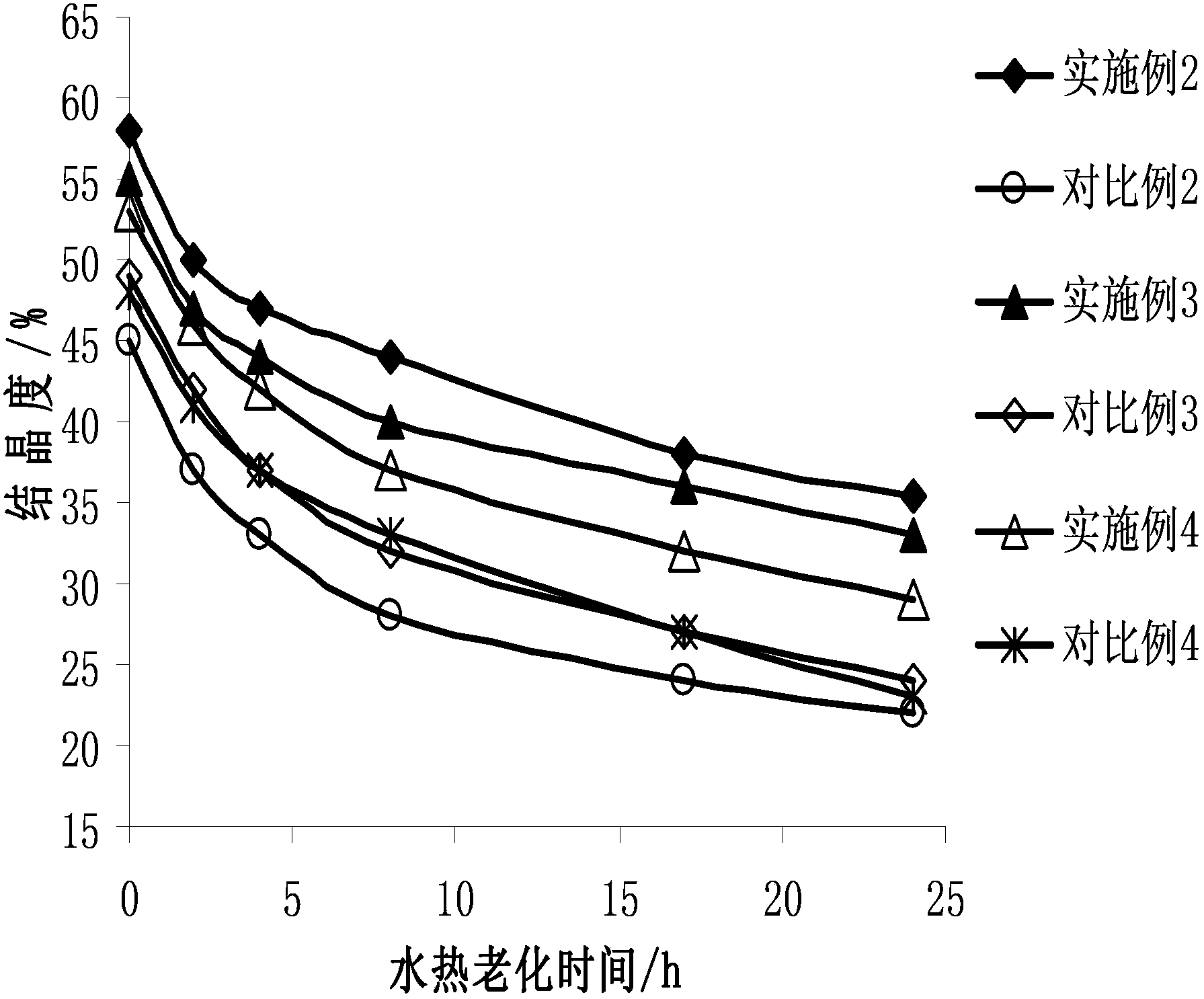

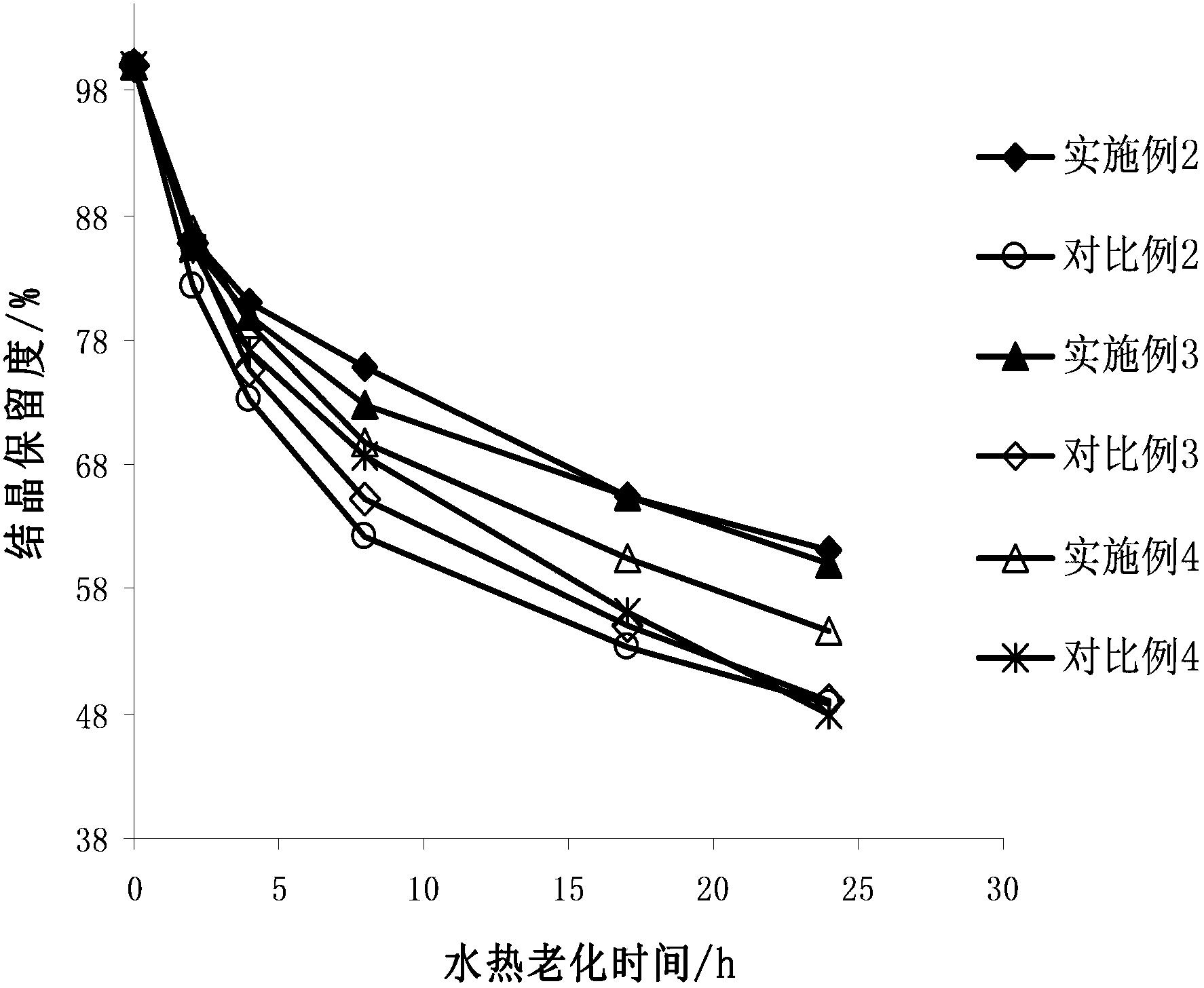

Catalytic cracking catalyst

ActiveCN103506154AImprove stabilityReduce coke rateCatalytic crackingMolecular sieve catalystsMolecular sieveDry basis

The invention discloses a catalytic cracking catalyst containing 10-50wt% of modified Y-type molecular sieve, 0-30wt% of other molecular sieves, 10-70wt% of clay and 10-40wt% of inorganic oxide binder, wherein the contents of the modified Y-type molecular sieve, the other molecular sieves and the clay are measured according to dry basis, and the content of the inorganic oxide binder is measured according to oxides; the modified Y-type molecular sieve has the lattice constant of 2.420-2.440nm and the specific hydroxyl nest concentration of less than 0.35mmol / g and contains 0.05-6wt% of P, 0.03-10wt% of RE2O3 and less than 22wt% of aluminum oxide according to the weight percentage. The catalytic cracking catalyst disclosed by the invention has favorable stability in a catalytic cracking process and can be used for reducing green cokes and increasing the utilization ratio of heavy oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coking method for processing highly acid crude oil

ActiveCN101280213AReduce corrosionCorrosion is reduced or even avoidedThermal non-catalytic crackingTowerCorrosion

The invention discloses a method of processing highly-acidic crude oil through the delayed coking process; the method includes that the low temperature highly-acidic crude oil is fed from the middle-lower part and the high temperature low-acidic coking raw material is fed from the bottom; the high temperature oil gas generated by the high temperature cracking of the low-acidic coking raw material is mixed with the low temperature highly-acidic crude oil so that the highly-acidic crude oil is enabled to realize the purpose of the deacidification through the pyrolysis deacidification under high temperature; meanwhile, the cracking temperature of the low-acidic coking raw material is lowered; the high temperature cracking time of the conventional raw materials; thereby, the coking yield is reduced and the stable operation period of the single tower is prolonged; besides, the preheating temperature of the highly-acidic crude oil can avoid the strong corrosion stage of the acid; the corrosion on the heating device caused by the acid can be reduced or avoided when the temperature is even lower than the corrosion temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

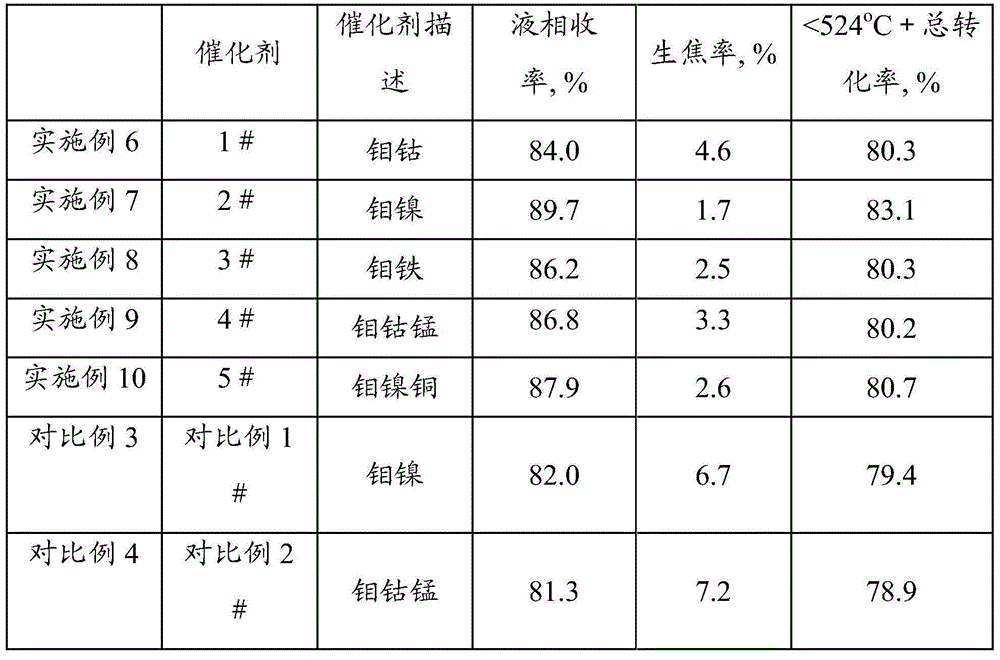

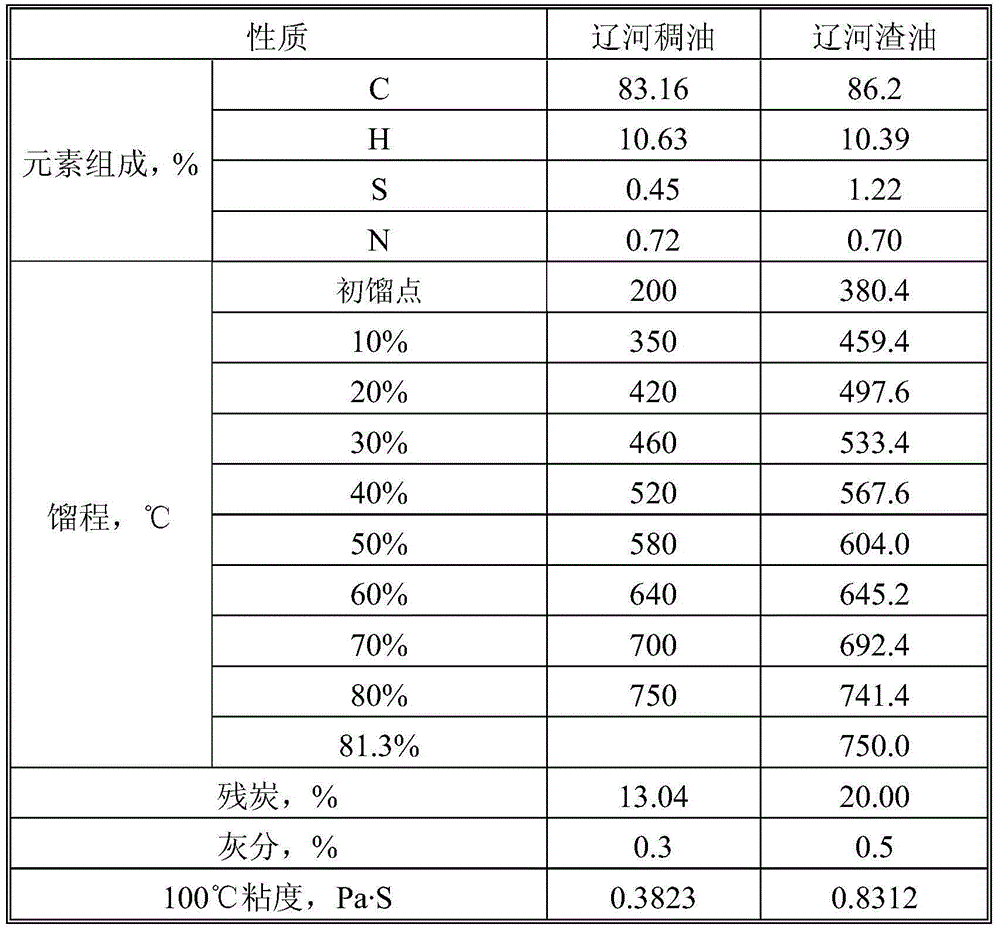

Preparation method of hydrogenation catalyst for slurry bed of heavy oil as well as catalyst and application thereof

InactiveCN106311341AThe initial particle size of precipitation is smallEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsTreatment with moving solid particlesManganeseFuel oil

The invention provides a preparation method of a hydrogenation catalyst for a slurry bed of heavy oil as well as the catalyst and an application thereof. The preparation method comprises the following steps: a molybdenum-containing compound and at least one soluble salt of a metal element which is selected from nickel, cobalt, iron, manganese and copper are dissolved in an aqueous solution; organic acid is added in order to generate sol; a sulfuration reaction is directly carried out in order to obtain ultrafine solid powder in sulfurized state; emulsification and dispersion of the obtained ultrafine solid powder in sulfurized state and distillate oil are carried out, in order to obtain the hydrogenation catalyst for a slurry bed of heavy oil. The hydrogenation catalyst for the slurry bed of heavy oil is applied to a hydrogenation process of a heavy oil raw material of the slurry bed or a suspended bed, the catalyst has good dispersion performance and hydrocracking performance in heavy oil, and coking formation rate can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

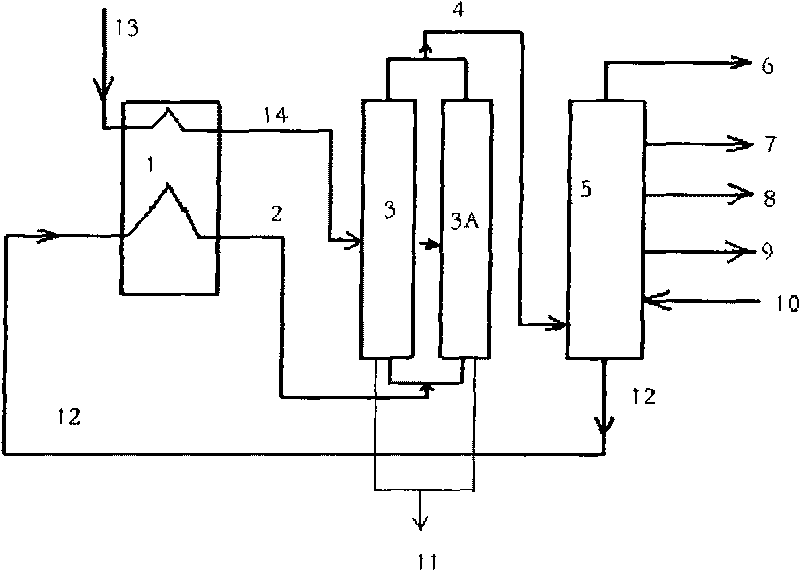

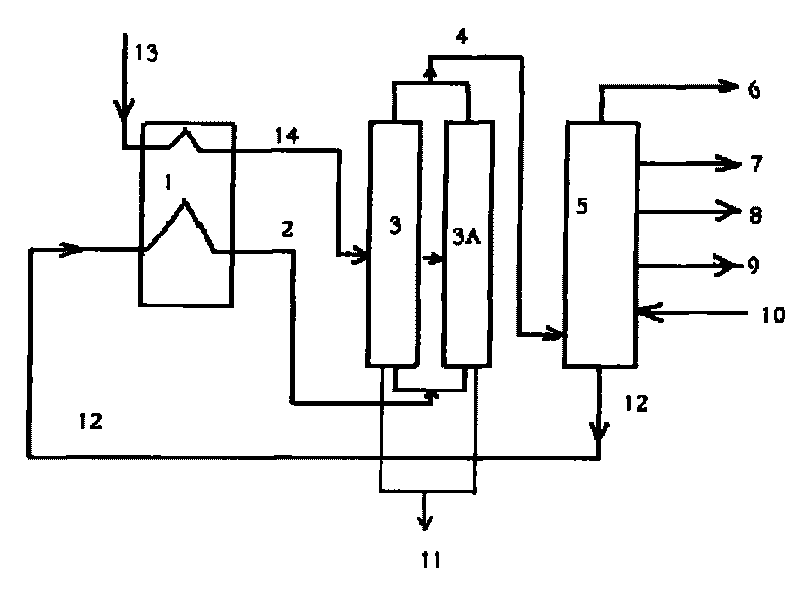

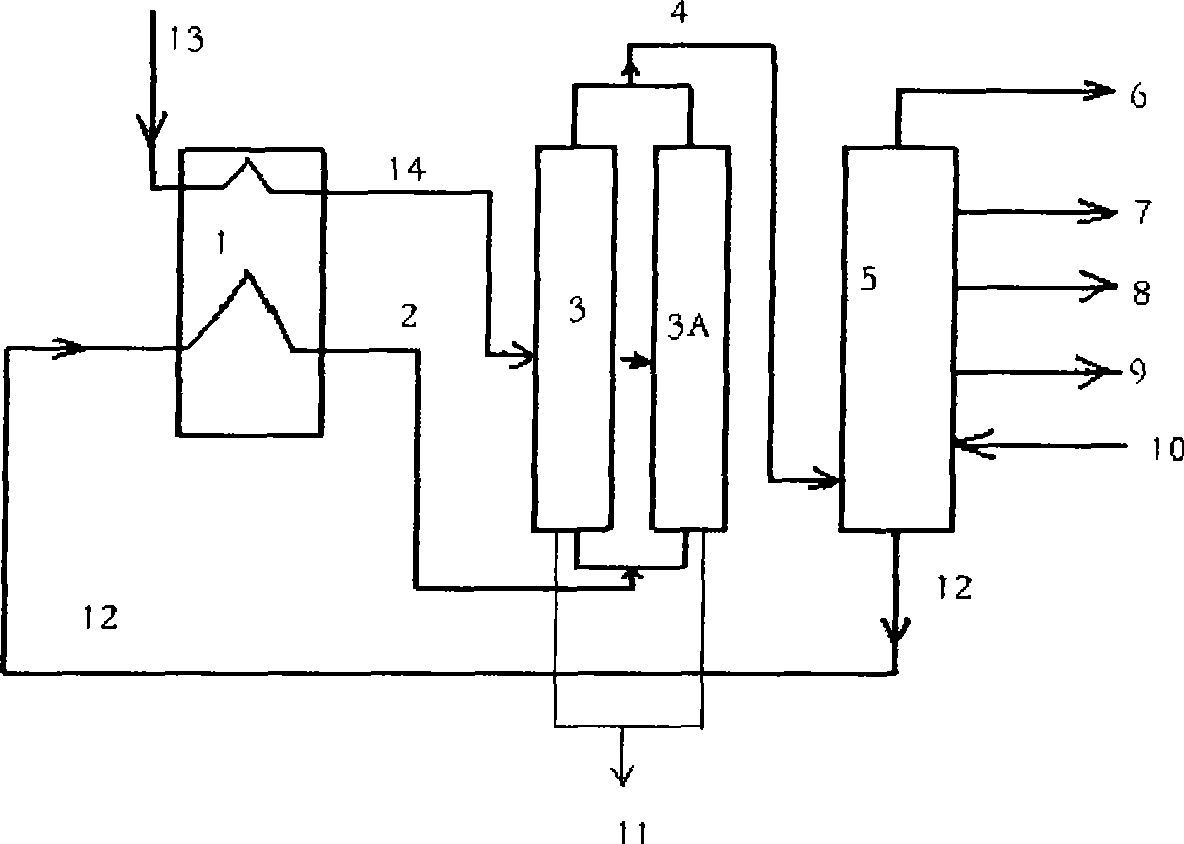

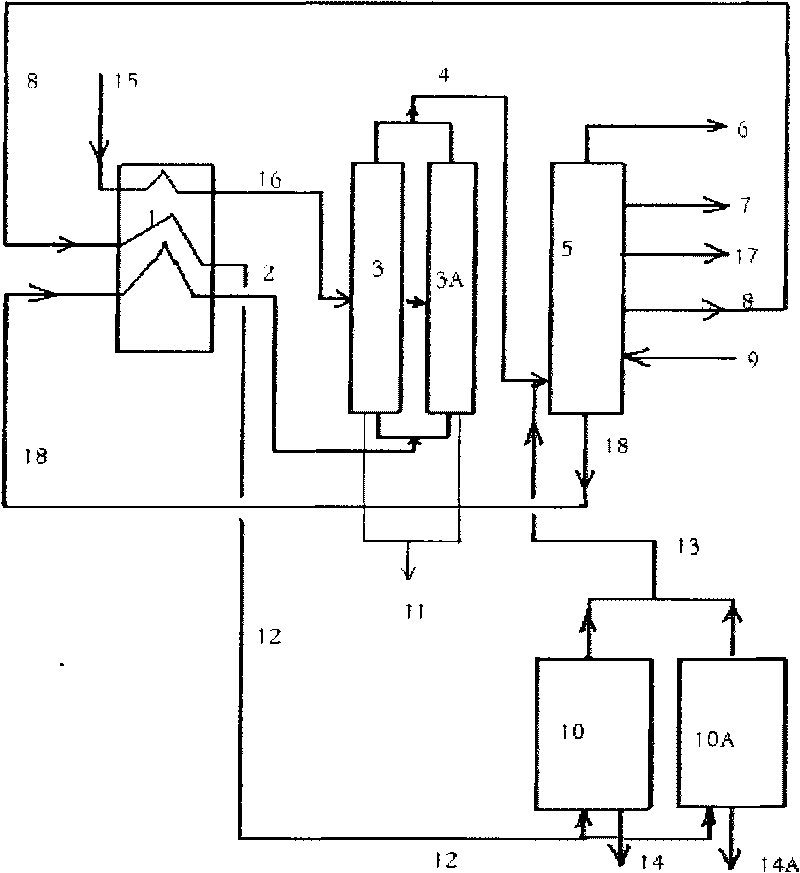

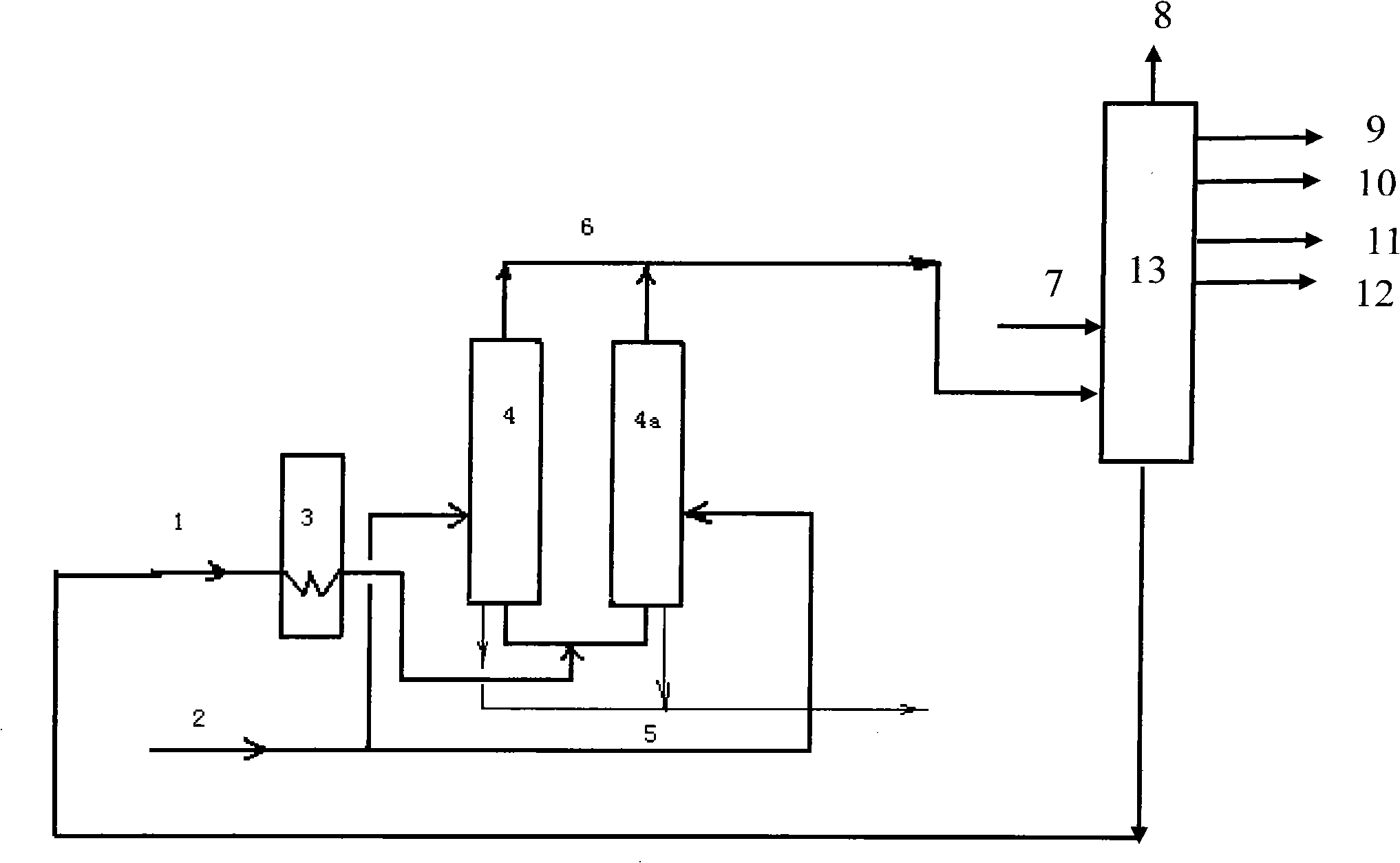

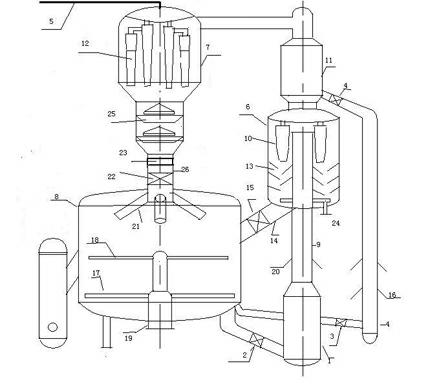

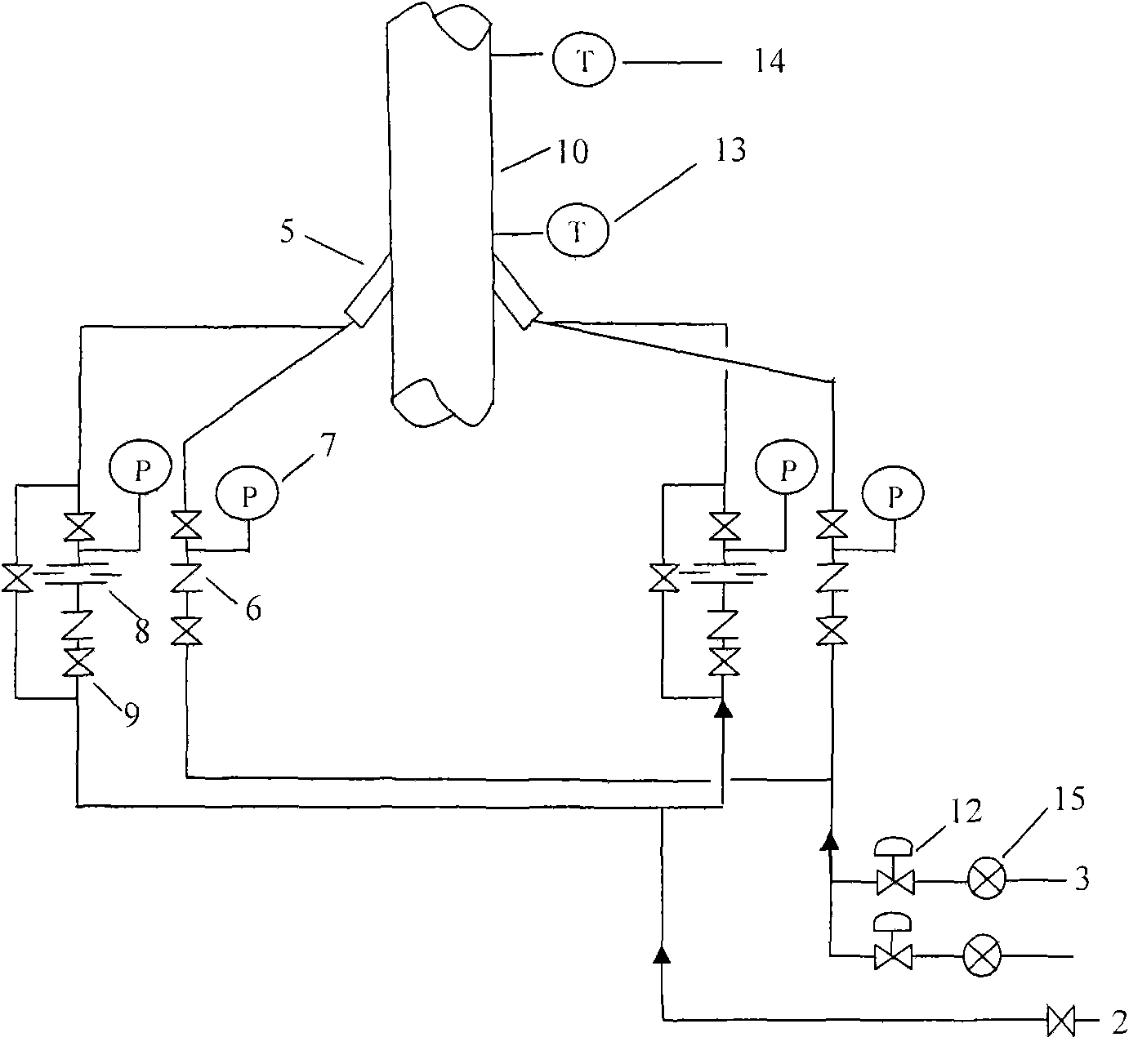

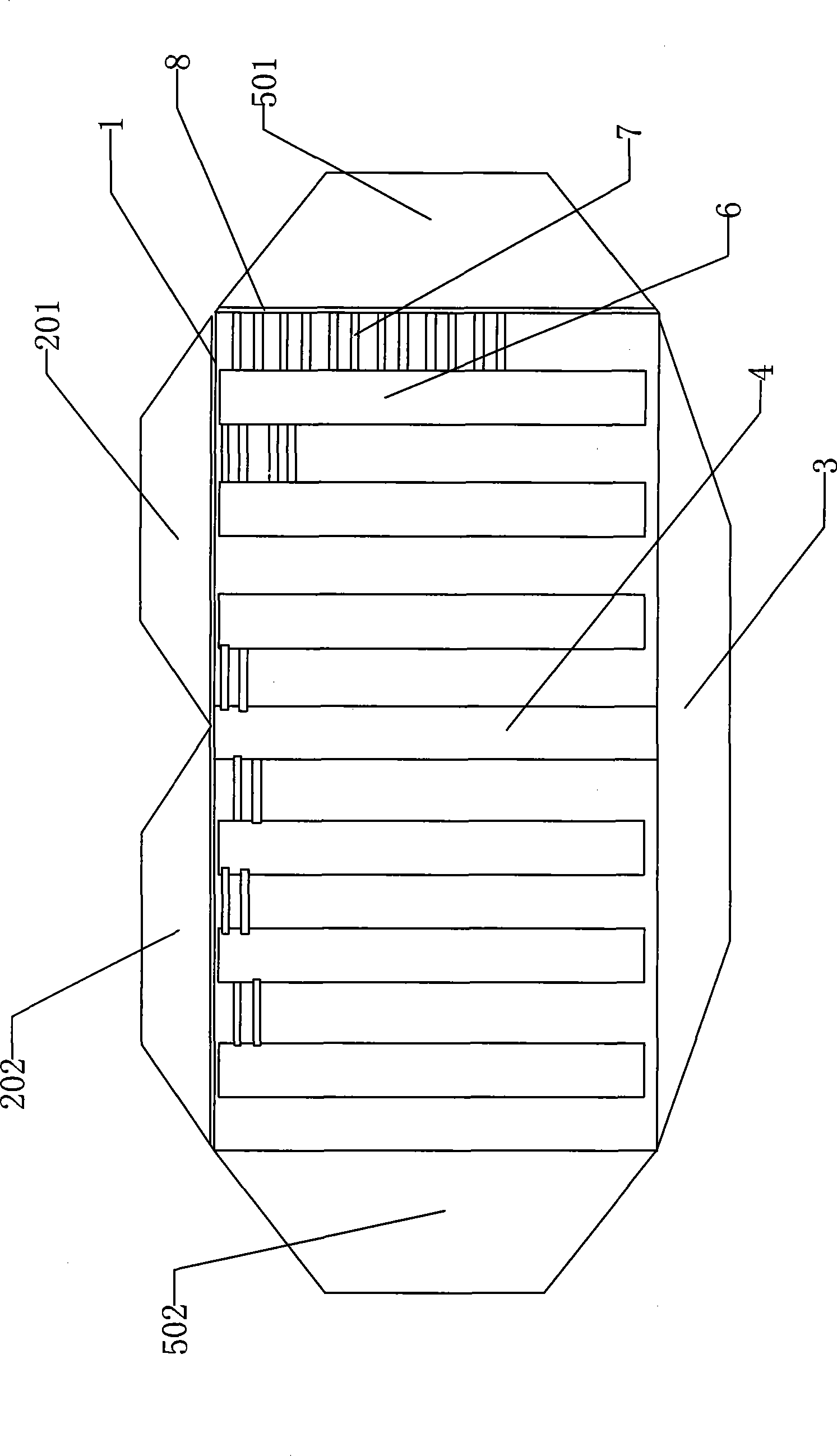

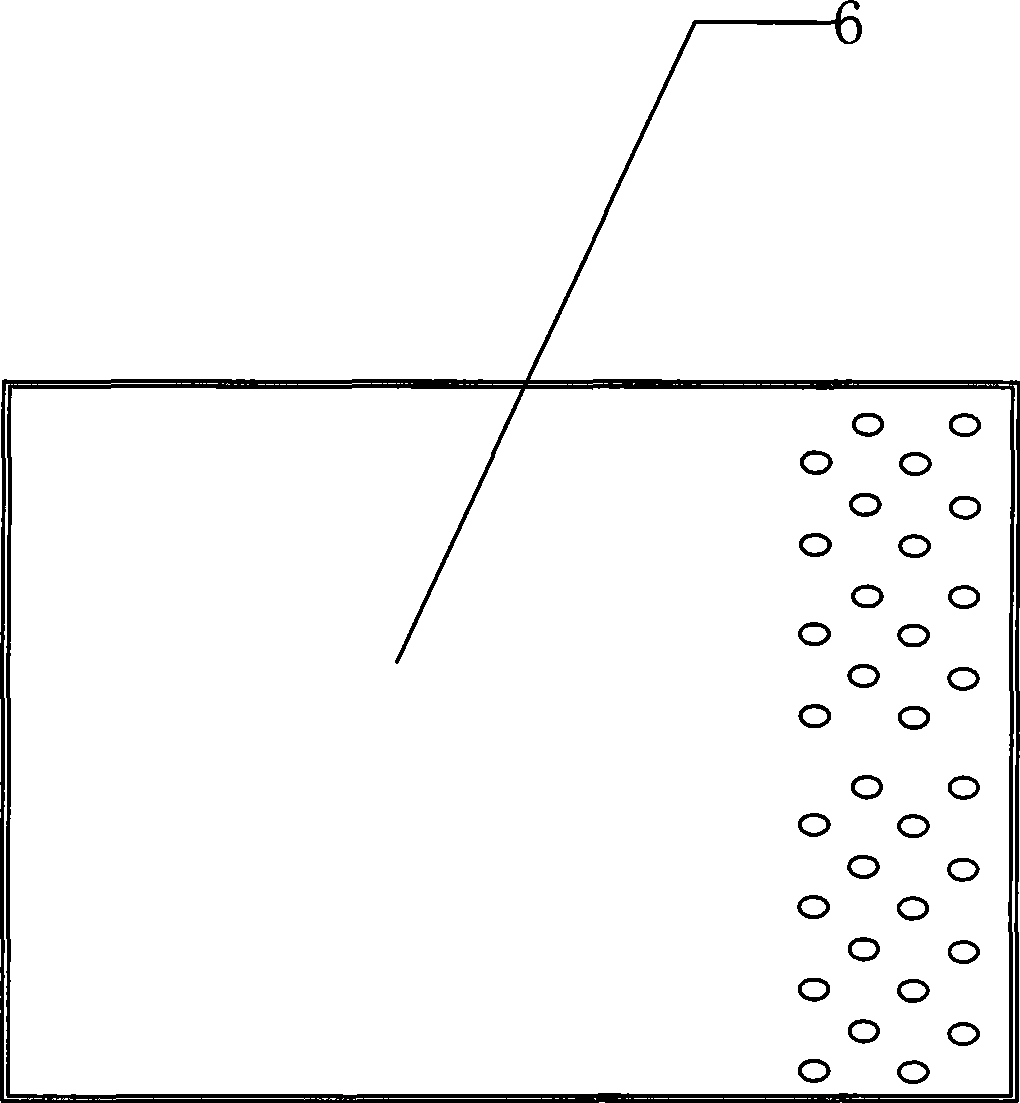

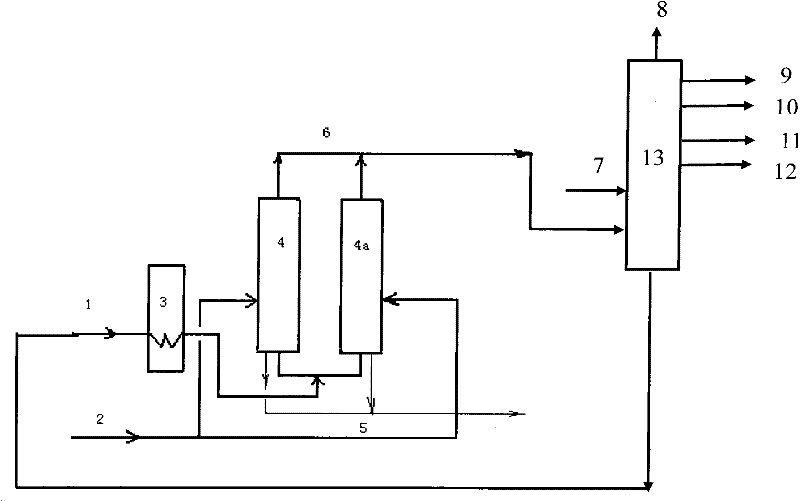

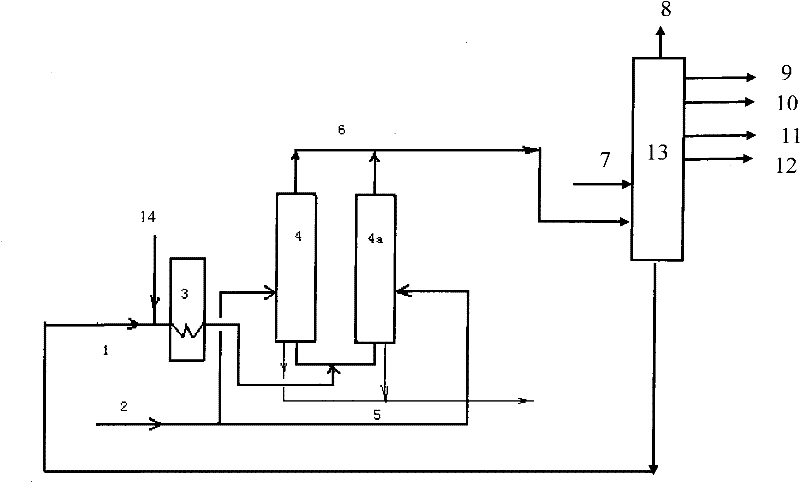

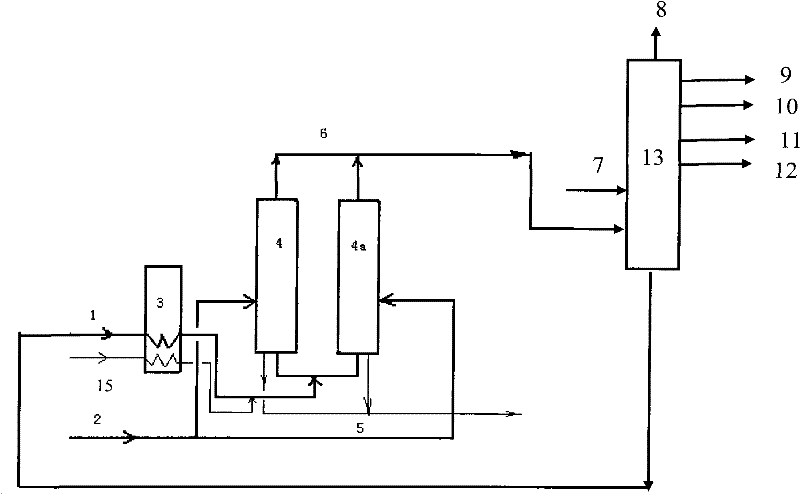

Dual-cycle mode catalytic cracking reaction regenerative system production technology and device

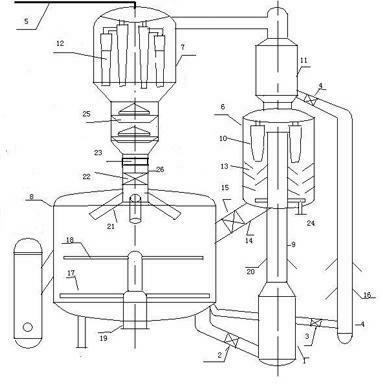

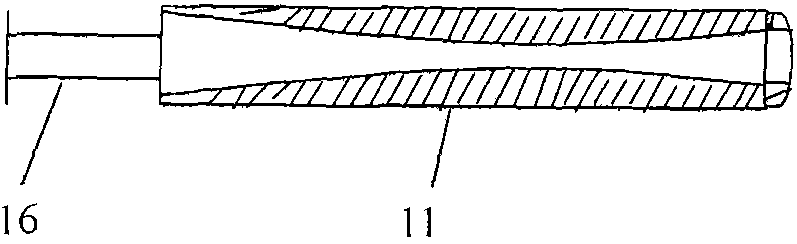

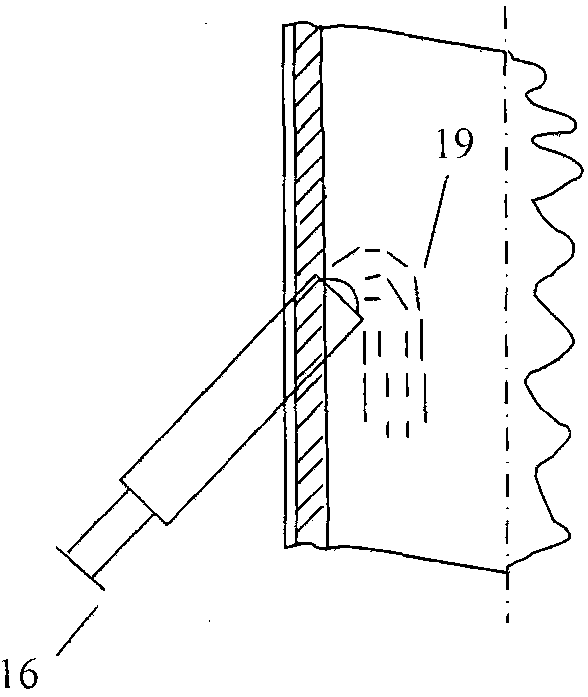

The invention belongs to the technical field of catalytic racking reaction and provides a dual-cycle mode catalytic cracking reaction regenerative system production device which is of a design structure consisting of a riser used for carrying out two-stage catalytic cracking reaction, a two-stage precipitator, a stripper and a high-and-low parallel reaction regenerator (8); a heavy oil riser (1) is of a riser structure used for carrying out the two-stage catalytic cracking reaction, and is provided with a heavy oil riser first reactor (9) and a heavy oil riser second reactor (11); a first precipitator (6) is arranged between the heavy oil riser first reactor (9) and the heavy oil riser second reactor (11), and with the adoption of the first precipitator (6), the reaction of the heavy oil riser is divided into a catalyst first cyclic system and catalytic cracking first reaction stage, and a catalyst second cyclic system and catalytic cracking second reaction stage; and according to the invention, the problems of large light oil yield deviation, high coking rate, coking influence, catalyst regeneration and the like found in the traditional riser production process are solved.

Owner:马俊杰

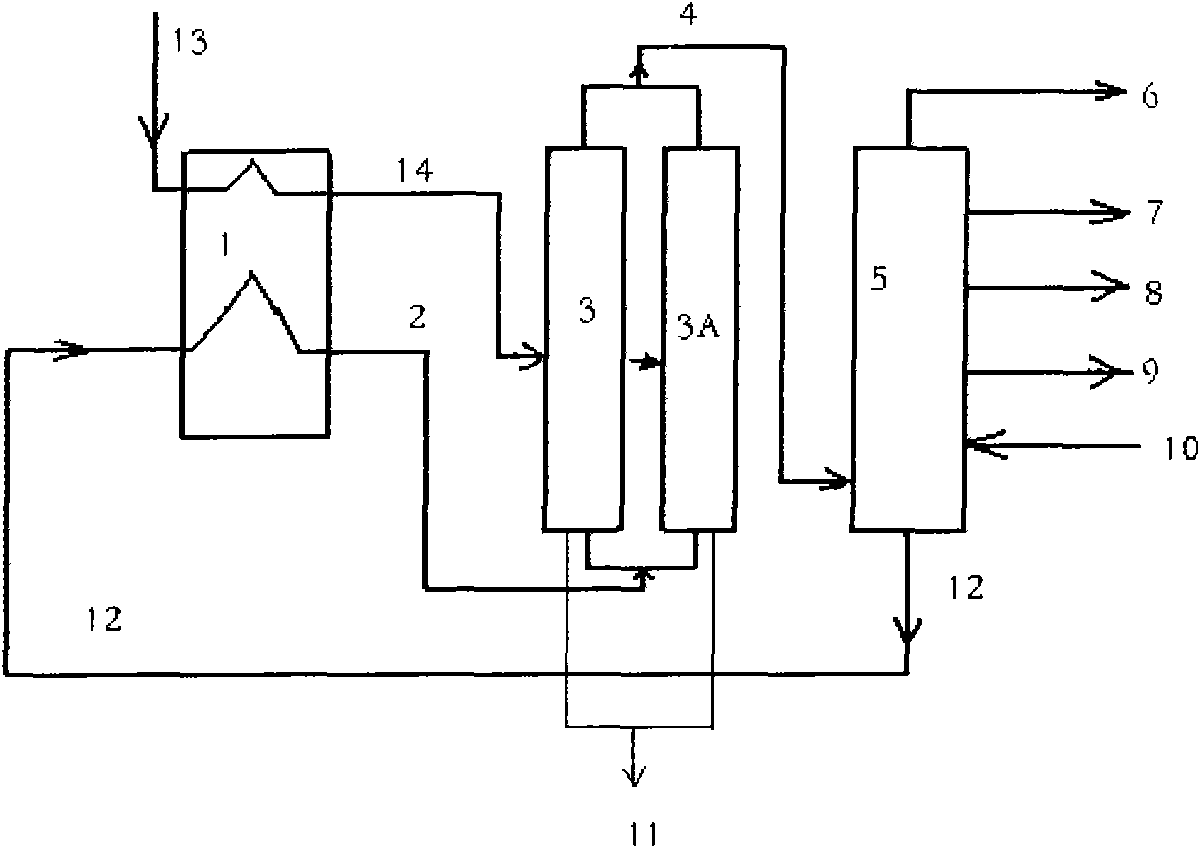

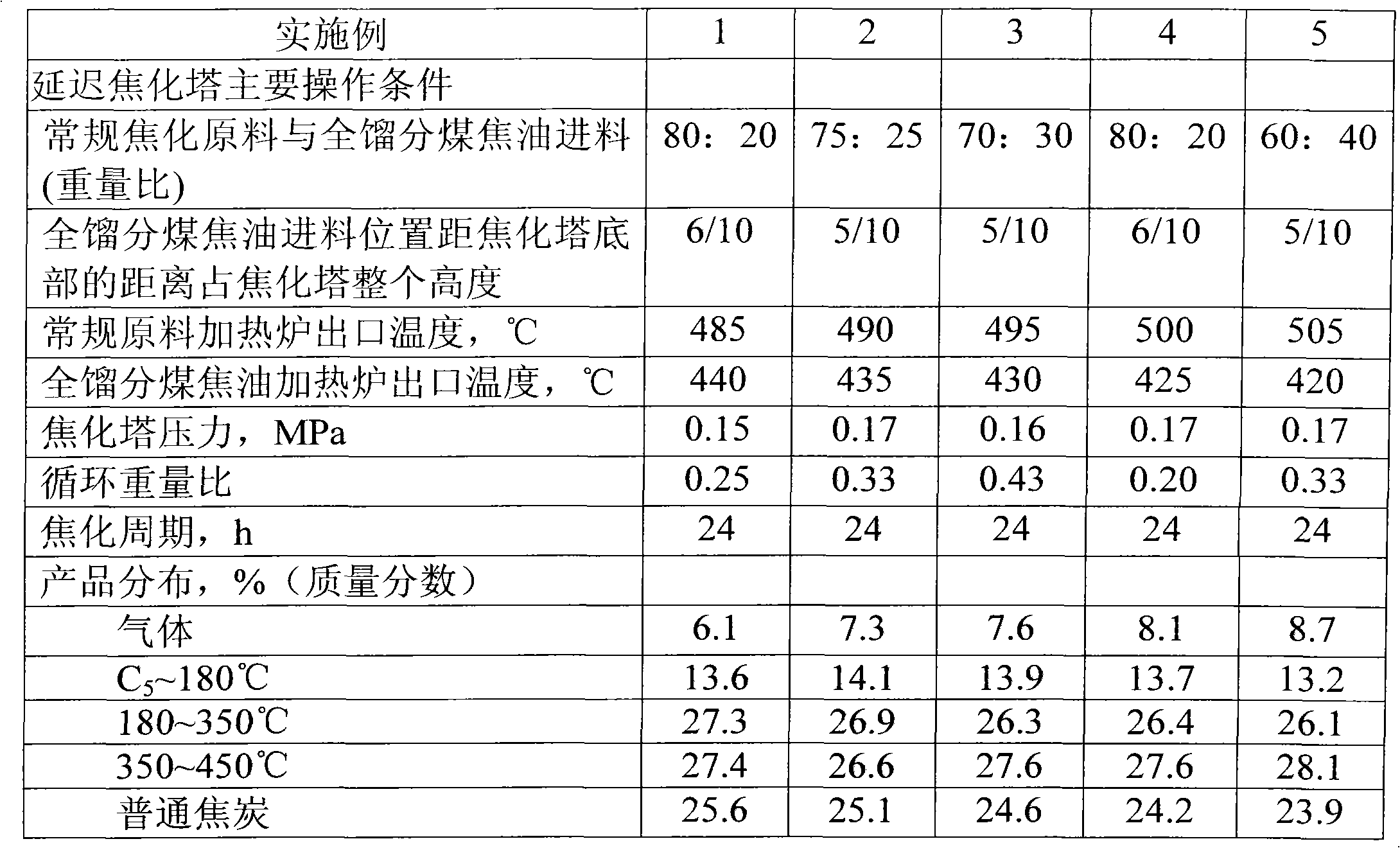

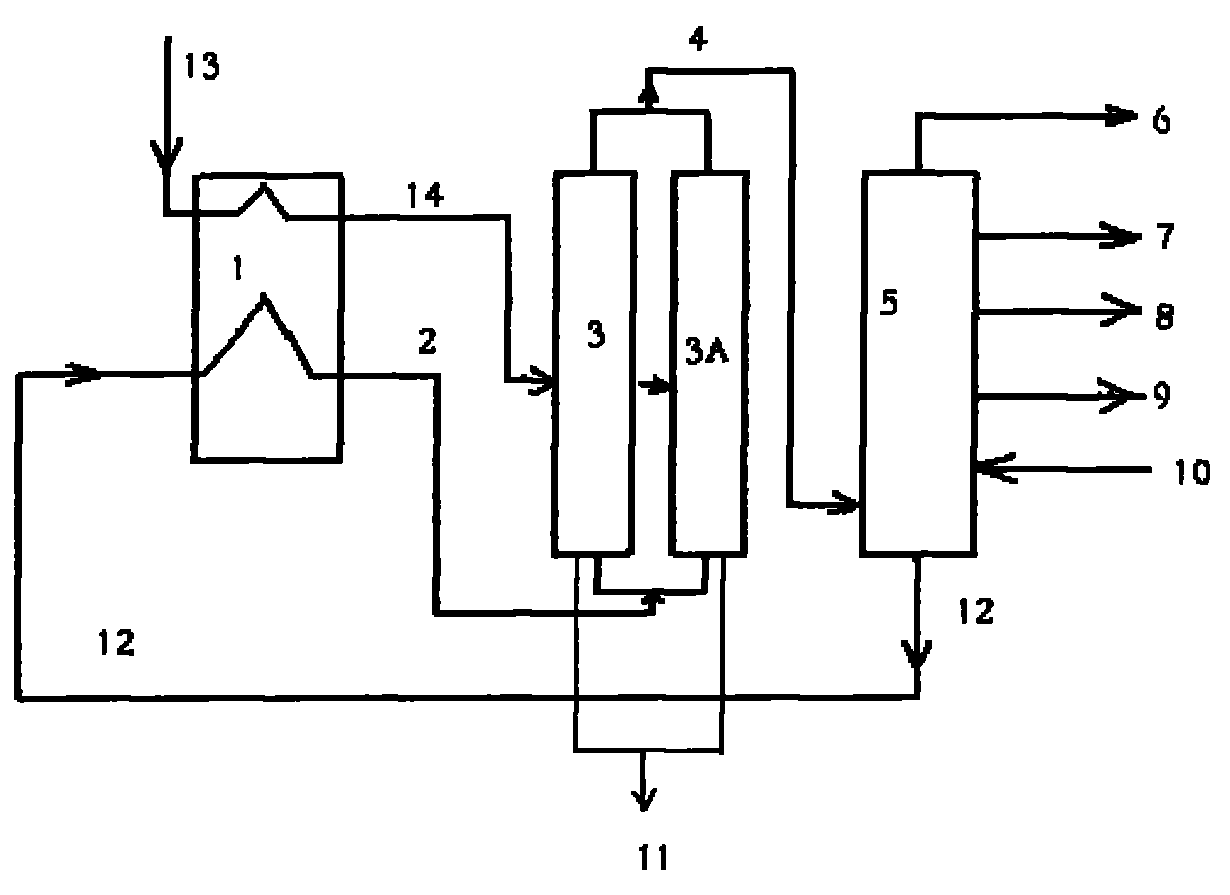

Method for producing needle coke raw material by using delayed coking process

ActiveCN102041013AExpand sourceThe method flow is simpleCoking carbonaceous materialsGeneration rateDesorption

The invention discloses a method for producing a needle coke raw material by using a delayed coking process. In the method, full-range coal tar is imported to the top and the middle and a high-temperature conventional coking raw material is imported to the bottom; the high-temperature oil gas generated by the conventional coking raw material via high-temperature cracking is mixed with the full-range coal tar with lower temperature at the top and the middle of a reactor so that the full-range coal tar can crack hydrocarbon molecules with high reaction activity at a proper high temperature to achieve the aim of desorption; for the full-range coal tar, under the condition of the delayed coking process, asphaltene and partial colloid are condensed to form coke which is deposited in a coking tower so as to remove the components going against the production of the needle coke; furthermore, by means of the injection of the low-temperature full-range coal tar, the cracking temperature of the conventional coking raw material is reduced, the high-temperature cracking time of the conventional raw material is shortened, the secondary reaction is decreased, the coke generation rate is reduced and the stable operation period of a single tower is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

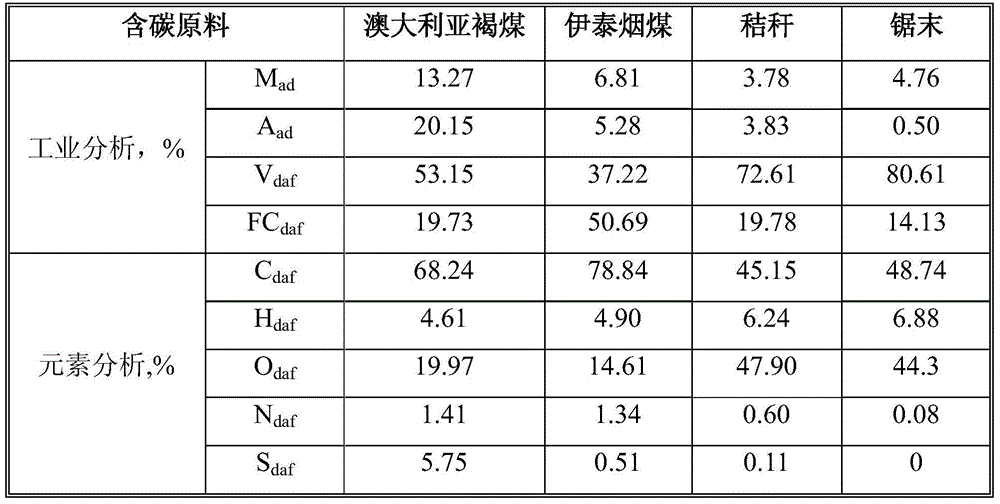

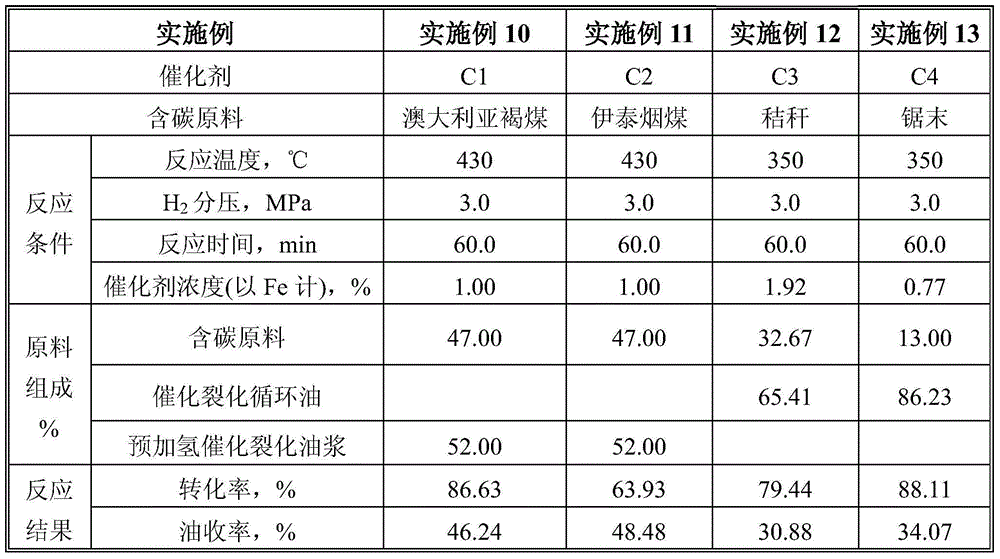

Hydro-liquefied iron-based catalyst containing carbon materials and preparation method and application of hydro-liquefied iron-based catalyst

ActiveCN105363450AReduce usageSufficient raw materialsLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsNaphthaSulfate

The invention discloses a hydro-liquefied iron-based catalyst containing carbon materials and a preparation method and application of the hydro-liquefied iron-based catalyst. The method comprises the following steps that 1, a ferrous sulfate solution is prepared; 2, when SiO2 and / or Al2O3 is contained in an additive, a silicon source and / or aluminum source are / is added to the ferrous sulfate solution, a precipitating agent is added for coprecipitation, and precipitated slurry is obtained; 3, the precipitated slurry is washed with water and filtered to obtain a filter cake; 4, the missible-oil-shaped iron-based catalyst is obtained according to the following step 1 or 2, according to the step 1, the filter cake is mixed with solvent naphtha or mixed liquid of solvent naphtha and a dispersing agent to obtain a mixture, the mixture is crushed through mechanical stirring, the crushed material is sheared to obtain the missible-oil-shaped iron-based catalyst, the dehydration process is carried out during the shearing process, and according to the step 2, when MgO and / or CaO is contained in the additive, the method is carried out according to the following step a or b. The missible oil catalyst is stable in system state, is not layered in the storage process, and can be continuously stored for more than three months without going bad, and therefore the catalyst is very suitable for large industrial use.

Owner:SYNFUELS CHINA TECH CO LTD

Method for controlling upper-middle temperature of catalytic cracking raising pipe

The invention provides a method for controlling the upper-middle temperature of a catalytic cracking raising pipe, comprising the following steps of: atomizing a medium which is easy to vaporize, such as an oil-water mixture, by using an incondensable dry gas, and injecting into a reactor by selecting a nozzle with an atomization function; and fast vaporizing on the downstream position of a spray nozzle positioned on the upper-middle appropriate position of the catalytic cracking raising pipe, wherein a temperature reducing amplitude can maximally reach 20 DEG C. The invention can also eliminate water attack vibration noises generated when vapors contact with the medium and reduce the yield of the incondensable dry gas about 0.3 percent and the coke yield about 0.2 percent.

Owner:CHINA PETROCHEMICAL CORP

A kind of iron-based catalyst for hydrogenation liquefaction of carbon-containing raw materials and its preparation method and application

ActiveCN105363450BReduce usageSufficient raw materialsLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSlurrySolvent

Owner:SYNFUELS CHINA TECH CO LTD

Hydrocracking catalyst for vacuum residue suspension bed and preparation method and use method thereof

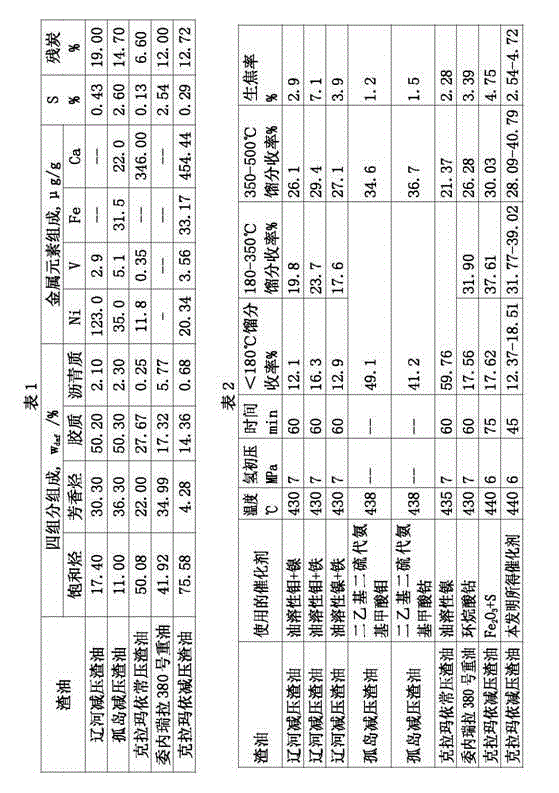

InactiveCN102719269APrevents temperature spikesWide variety of sourcesHydrocarbon oil crackingPyriteHigh pressure

The invention discloses a hydrocracking catalyst for a vacuum residue suspension bed and a preparation method and a use method thereof. The hydrocracking catalyst for the vacuum residue suspension bed is prepared by the following step of: selecting iron pyrite of which the mass percentage content of iron is 40-50 percent for serving as a raw material. The hydrocracking catalyst for the vacuum residue suspension bed is prepared from a cheap iron pyrite raw material, and has the advantages of wide raw material source and simple treatment and preparation processes; the coke yield is low and the fraction yield is high under a low pressure condition; generated coke can suspend in liquefaction oil without being attached to the inner wall of a high-pressure electromagnetic stirring reaction kettle, so that blockage of a reactor and a pipeline in an industrial device is prevented; hydrogenation lightening is performed on vacuum residues through a two-section reaction, the temperature is controlled stably, the phenomenon of violent temperature rise in a hydrogenation lightening process of vacuum residues is avoided, and the coke yield is further suppressed; and a foundation is laid for the industrialization of a vacuum residue suspension bed hydrocracking technology.

Owner:XINJIANG UNIVERSITY

Method for producing needle-shaped coke raw material by delayed coking process

InactiveCN106867554AExpand sourceThe method flow is simpleCoking carbonaceous materialsWaxCavitation

The invention discloses a method for producing a needle-shaped coke raw material through treating FCC circulating oil and a conventional coked raw material by a delayed coking process. The method comprises the steps: low temperature FCC circulating oil is introduced to a medium-upper part of a delayed coking tower and makes contact with a high temperature oil gas phase produced from high temperature cracking of the conventional coked raw material introduced from the bottom of the delayed coking tower, a reaction is performed under delayed coking conditions, generated oil and gas enter a coking fractionating tower and are separated, and thus the needle-shaped coke raw material is obtained. An ultrasonic generator is mounted at the bottom of the coking fractionating tower, the ultrasonic wave cavitation principle is utilized, and the fractionation effect is improved, so the wax oil distilling-off rate is improved, and the high-quality high-yield needle-shaped coke raw material is obtained.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

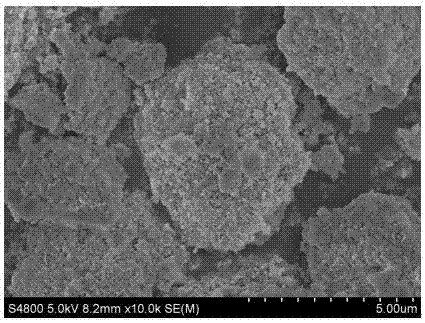

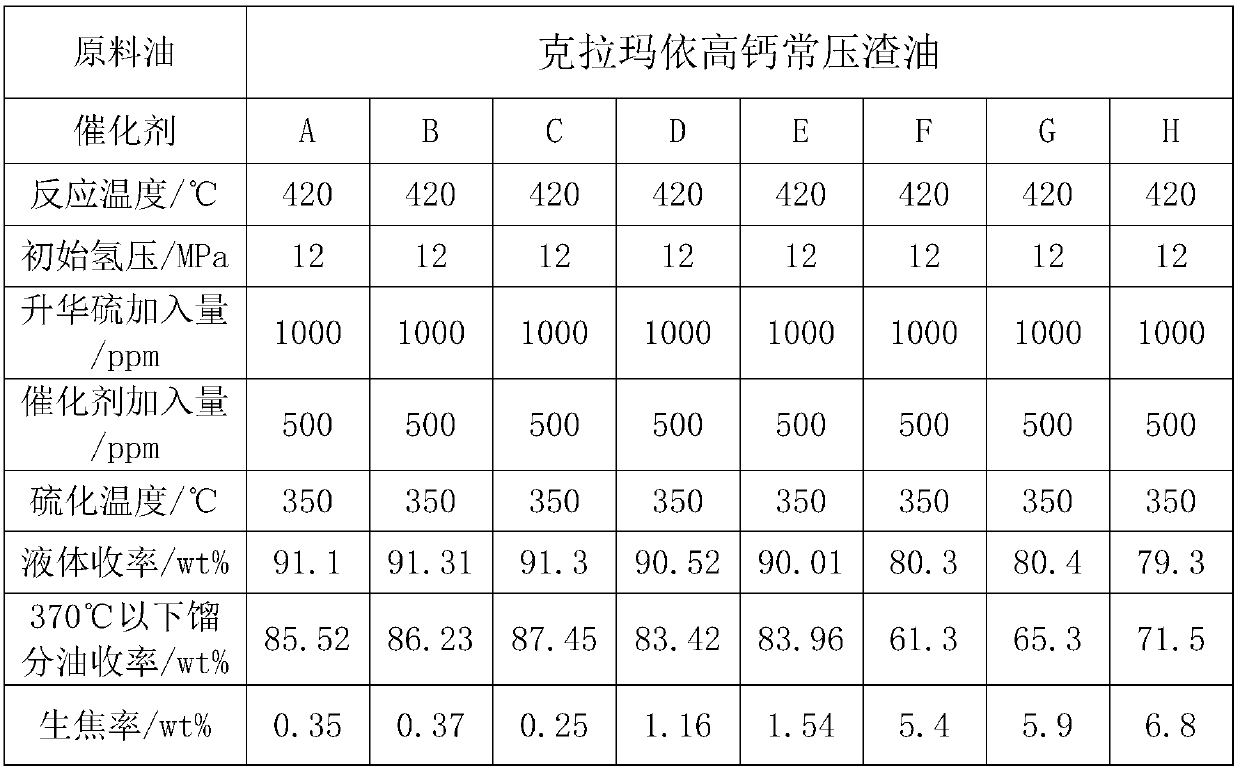

Suspended bed hydrocracking catalyst for coal tar and preparation method thereof

ActiveCN111420671ALow costImprove conversion rateHydrocarbon oil crackingChemical recyclingPtru catalystCoke rate

The invention discloses a suspended bed hydrocracking catalyst for coal tar and a preparation method thereof. The preparation method comprises the following specific steps: adding a ferrous sulfate solution into semi-coke powder suspension, conducting stirring, adjusting a pH value through ammonia water, and then introducing air for an oxidation reaction so as to obtain a semi-coke powder suspension b loaded with an iron compound; then adding regenerated powder of a waste cobalt-molybdenum-nickel series hydrocracking catalyst into the suspension b, successively carrying out stirring, filteringand drying to obtain solid powder containing semi-coke, the iron compound and the regenerated powder of the waste cobalt-molybdenum-nickel series hydrocracking catalyst; and finally, uniformly mixingthe solid powder with red mud powder to obtain the suspended bed hydrocracking catalyst for coal tar. The catalyst prepared by using the method provided by the invention can effectively improve the conversion rate of heavy oil in coal tar and increase the yield of light oil, and is low in coking rate and relatively low in catalyst cost, so the economic benefit of a device can be obviously improved.

Owner:YANAN UNIV

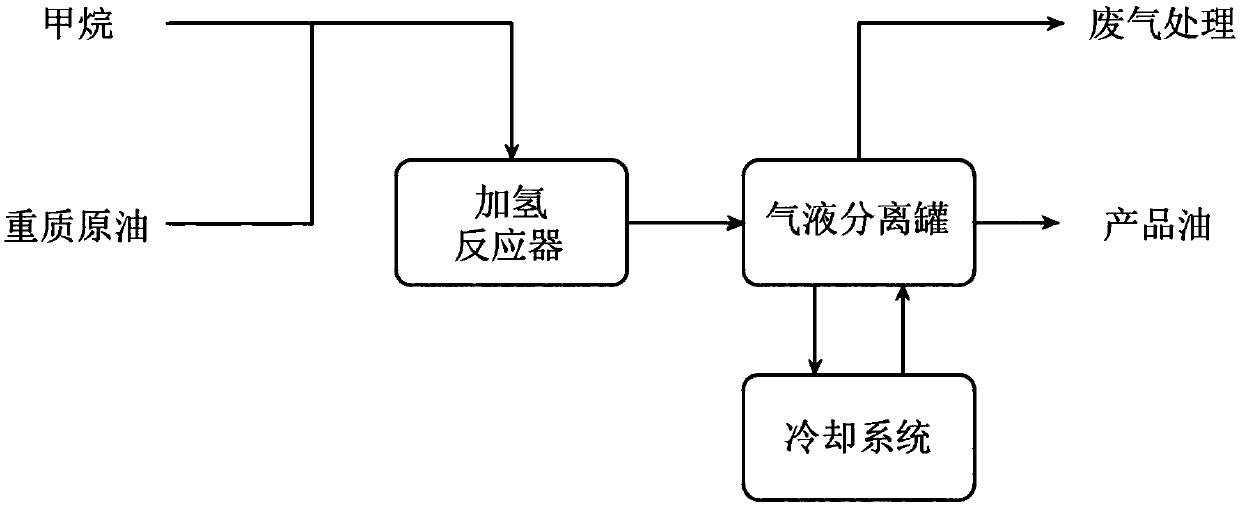

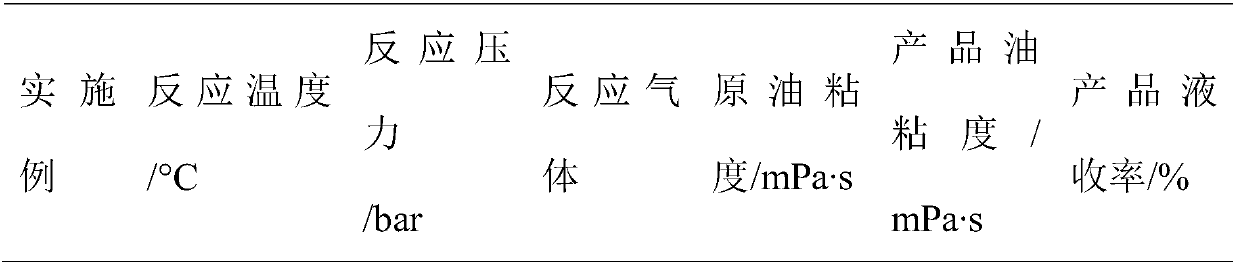

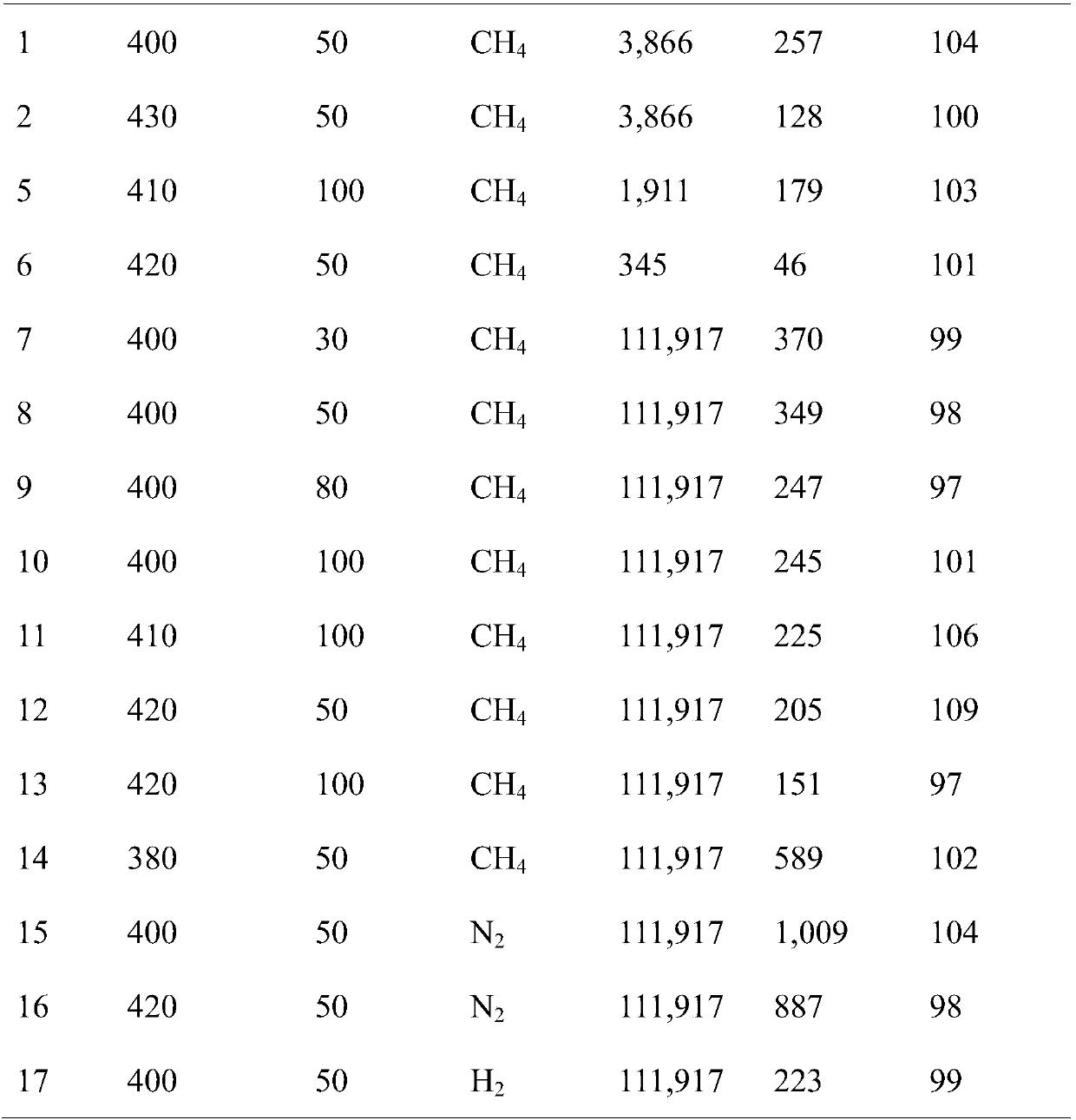

Method for catalytic hydrogenation of heavy crude oil by using methane

InactiveCN109517624ARealize green operationEliminate the step of reforming to produce hydrogenTreatment with hydrotreatment processesAlkaneHydrogenation reaction

The invention discloses a method for catalytic hydrogenation of heavy crude oil by using methane. Heavy crude oil is pumped into a hydrogenation reactor containing catalysts; methane is used as reaction gas for catalytic hydrogenation reaction; macromolecules in the heavy crude oil are decomposed into alkane and light-weight aromatic compounds; product oil flows out from a lower side of the hydrogenation reactor and is introduced into a gas-liquid separation tank for gas-liquid separation; tail gas flows out from the pipeline from the top of the gas-liquid separation tank and is used for subsequent treatment; product oil flows into a product tank from the bottom of the gas-liquid separation tank to be collected; the gas liquid separation tank is connected with a cooling system for reducingthe temperature of the product oil; the viscosity of the obtained product oil is 107 to 379 mPa.s; the density is 0.9511 to 0.9642 g / ml; the total acidity is 0.02 to 1.55 mg KOH / g; the average molecular weight is 172 to 210 g / mol; the water content is 0.21 to 0.30 weight percent; the product liquid yield is 96.9 to 104 percent. The operation cost of the technical flow process is reduced; the hydrogenation reaction effect is effectively improved; the operation pressure is reduced; a green and environmental-friendly process is achieved.

Owner:广西华大骄阳能源环保科技有限公司

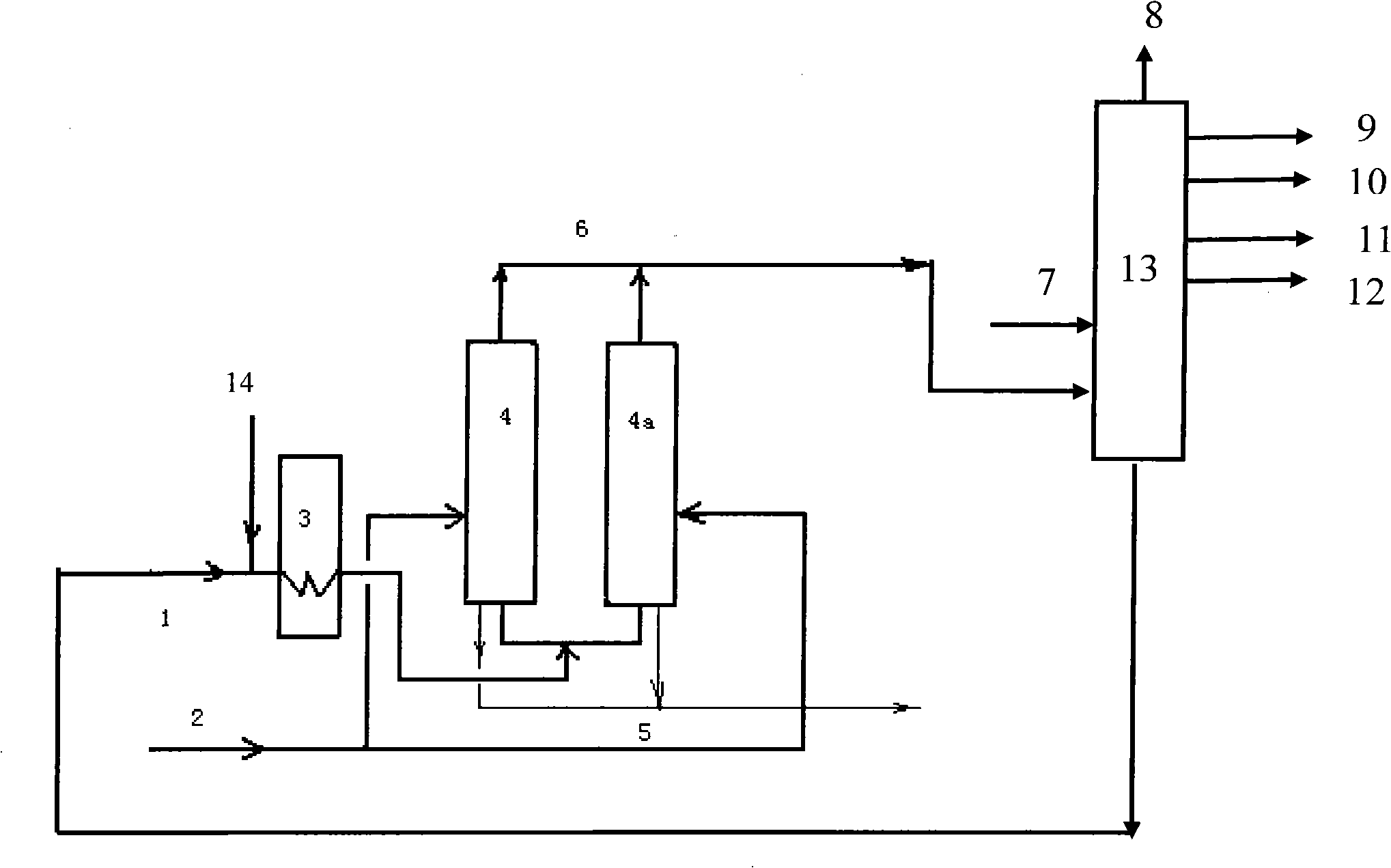

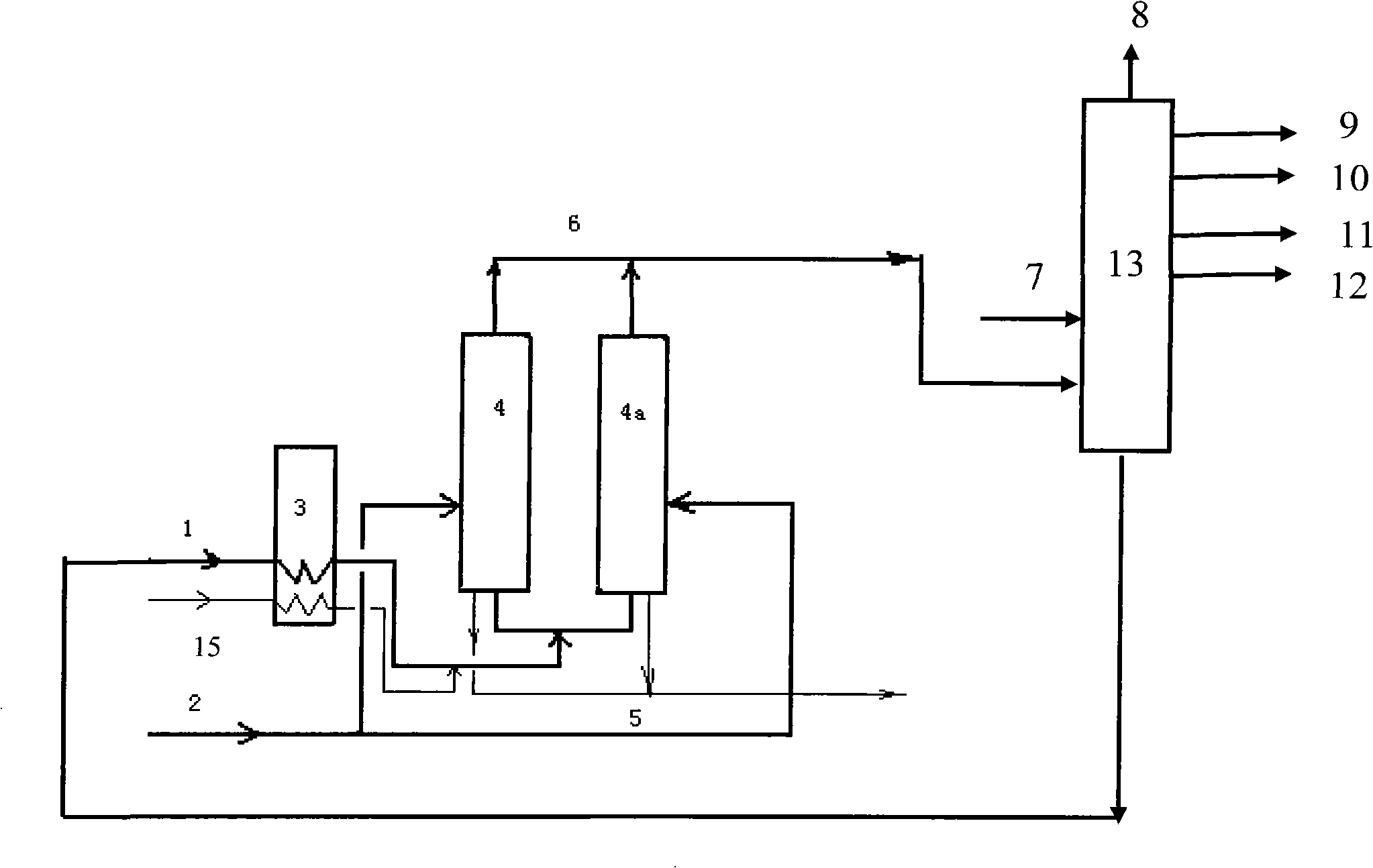

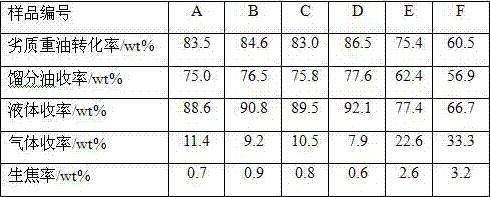

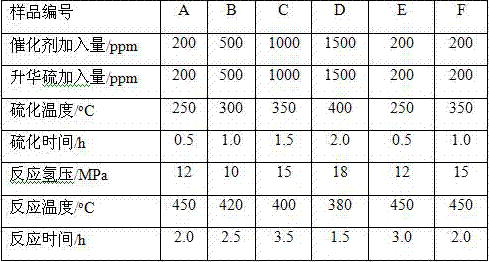

Technological method for suspended bed hydrocracking of heavy oil

ActiveCN107892941AInhibition of transitional crackingImprove conversion rateHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionGas phase

The invention discloses a method for suspended bed hydrocracking of heavy oil, wherein the method comprises the steps: mixing a low-quality heavy oil suspended bed hydrogenation catalyst and low-quality heavy oil evenly, then allowing the mixture to enter a suspended bed hydrogenation reactor, wherein the catalyst includes a zinc oxide powder and an ore component powder; and heating up to a reaction temperature, and carrying out a hydrogenation reaction, wherein the temperature of the hydrogenation reaction is 320-500 DEG C, the reaction pressure is 5-20 MPa, the reaction time is 0.5-4 h, thehydrogen and oil volume ratio is 100-2000 and the space velocity is 0.2-4.0 h<-1>. The technological method has strong adaptability to raw materials, can effectively reduce gas phase yield, and has the advantages of high conversion rate of the low-quality heavy oil, low coking yield, high desulfurization rate and good activity.

Owner:FUZHOU UNIV

Production method of needle coke

ActiveCN101724421BExpand sourceSimple processThermal non-catalytic crackingCoking carbonaceous materialsDecompositionSlurry

The invention discloses a method for producing needle coke by adopting the technique combining delay coking and kettle-type coking. The method comprises: when treating the conventional coking raw material by using the delay coking technique, introducing FCC slurry oil into a delay coking tower from the upper part inside the tower at the low temperature, and obtaining needle coke raw material by fractionating high temperature oil gas obtained by the reaction; and then, treating the needle coke raw material by using the kettle-type coking technique, and obtaining high quality needle coke. In the method, as the FCC slurry oil is injected into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of low-quality heavy oil suspended bed hydrogenation catalyst and its preparation and use method

ActiveCN105126815BReduce manufacturing costSimple processMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystHydrogenation process

A low-quality heavy oil suspension bed hydrogenation catalyst and its preparation and use method, in particular to a low-quality heavy oil suspension bed hydrogenation solid powder catalyst with sub-molten salt activated bauxite ore powder as a carrier and its preparation and use method . It is characterized in that the catalyst uses activated bauxite ore powder as a carrier, and one or several transition metals in VIB and VIII groups are loaded on it. The low-quality heavy oil hydrogenation catalyst prepared by the present invention has high catalytic activity and low coke formation rate for the hydrogenation and upgrading of low-quality heavy oil, and the source of raw materials is wide and the price is low, which can greatly reduce the preparation cost of the catalyst and hydrogenation The operating cost of the process has broad application prospects.

Owner:FUZHOU UNIV

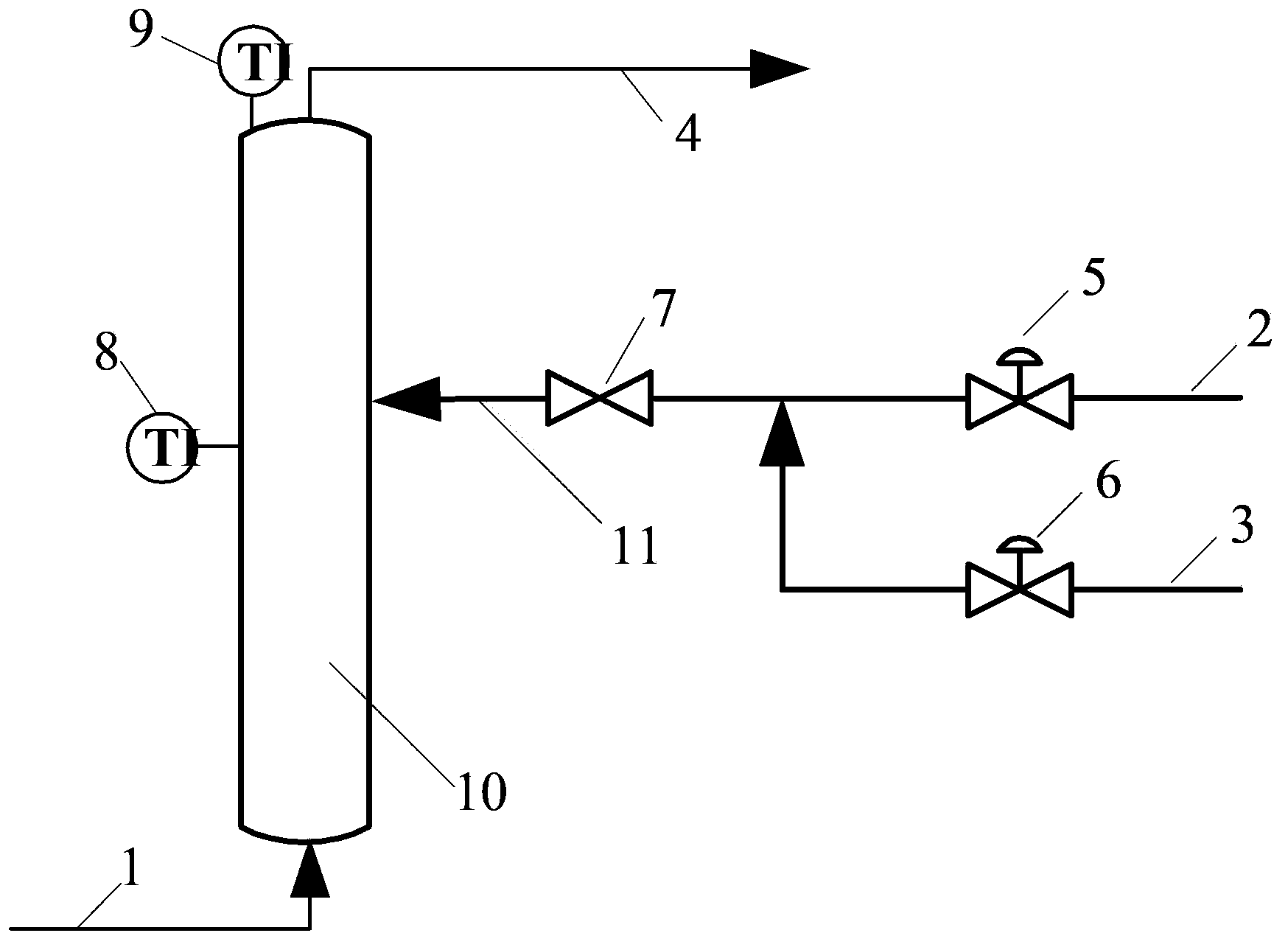

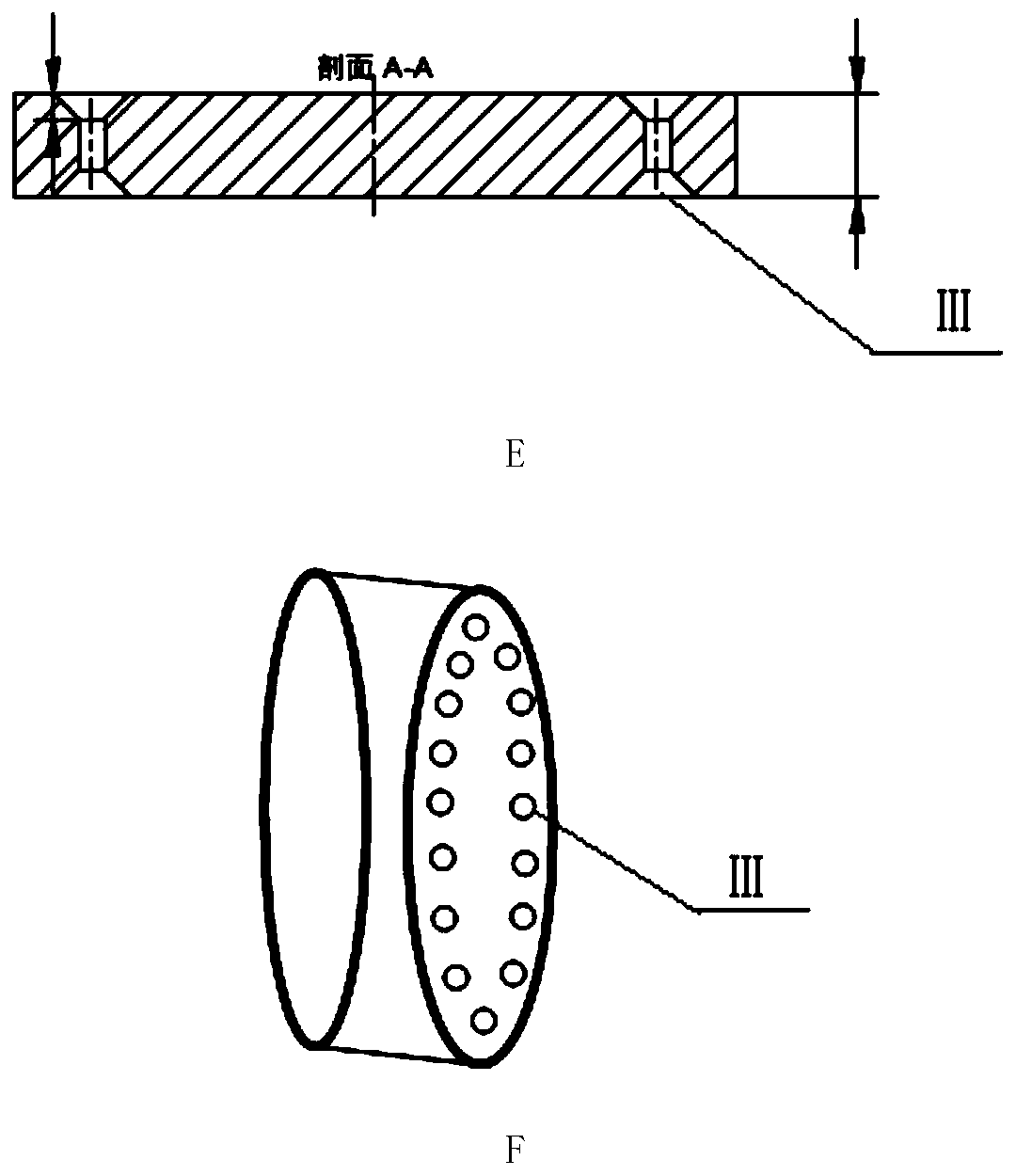

Waste heat recovery heat exchange device of belt type updraft sintering machine

InactiveCN101532789AEasy to operateReduce usageHeat exchanger casingsStationary tubular conduit assembliesCoke rateFresh air

The invention relates to a waste heat recovery heat exchange device of belt type updraft sintering machine which includes a heat exchange case, an right upper part of the heat exchange case is equipped with a waste heat inlet, a left upper part of the heat exchanger case is equipped with a waste heat outlet, a down part of the heat exchanger case is equipped with a collect dust bucket, a middle part of the heat exchanger case is equipped with a middle gas chamber, a right side of the heat exchanger case is equipped with a fresh air inlet, a left side of the heat exchanger is equipped with a fresh air outlet; two sides of the middle gas chamber are equipped with some exchanging gas chambers symmetrically; an air inlet clapboard is welded on the fresh air inlet, the air inlet clapboard connects with an exchange gas chamber on right side of the heat exchanger case inner through certain connecting pipes. The waste heat recovery heat exchange device has advantages of increasing maneuverability of each post in manufacturing system, reducing coal consumption amount 20-22%, reducing coking rate 1.5-2%, saving fuel consumption amount, reducing manufacturing cost and increasing manufacturing ability.

Owner:JIAOZUO DONGFANG GOLD & LEAD

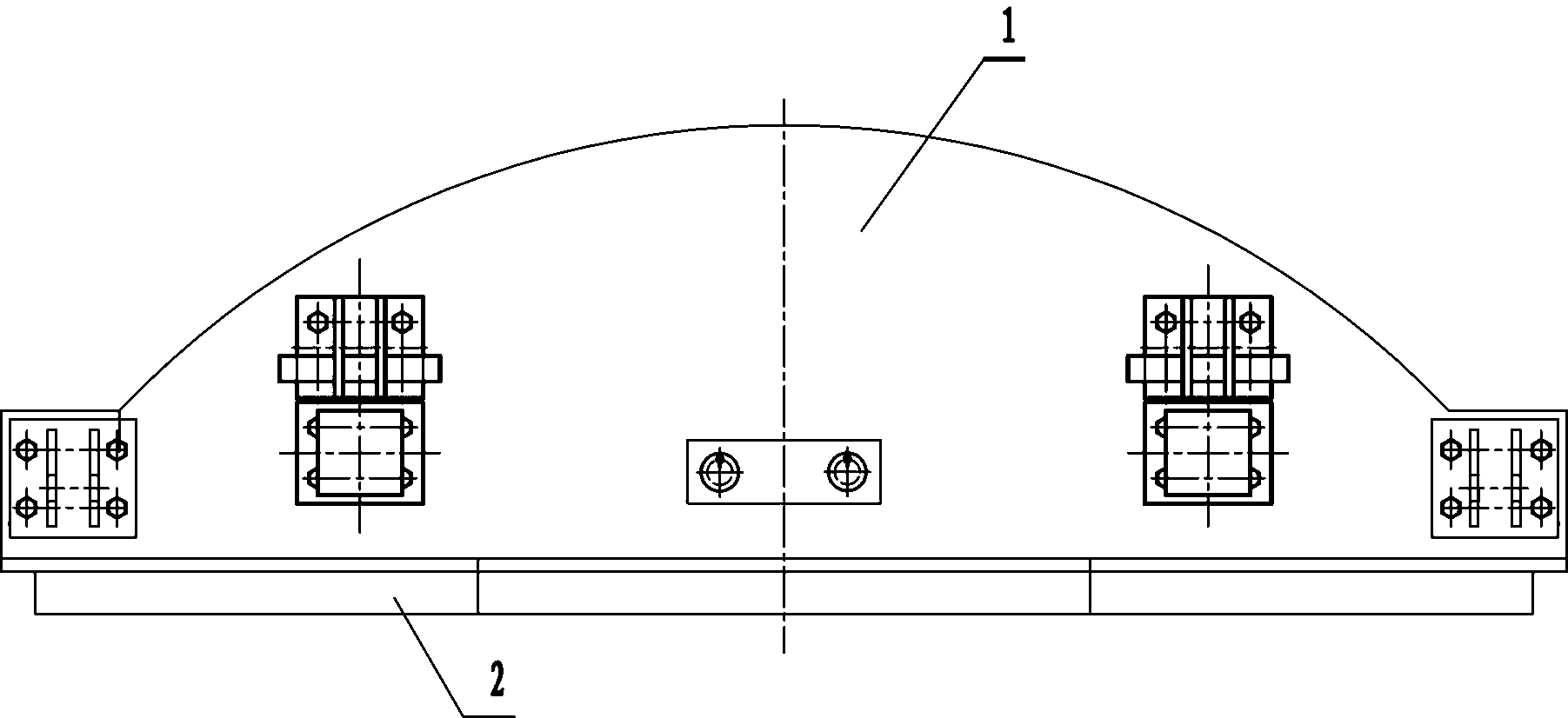

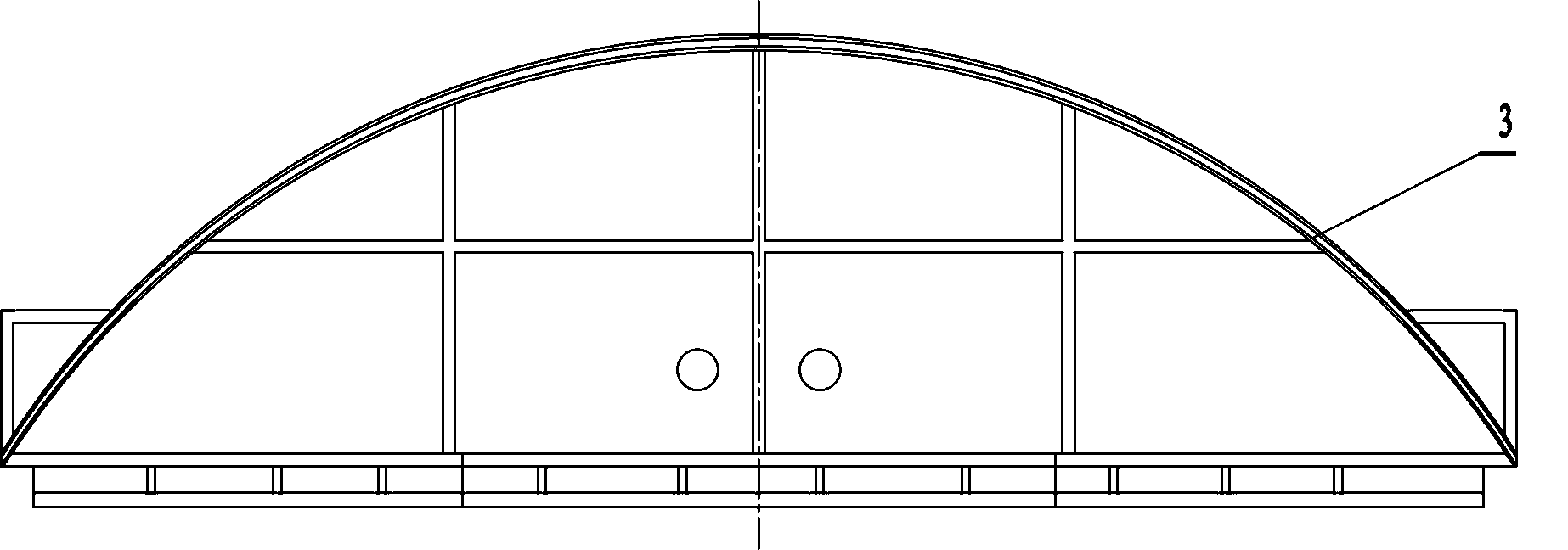

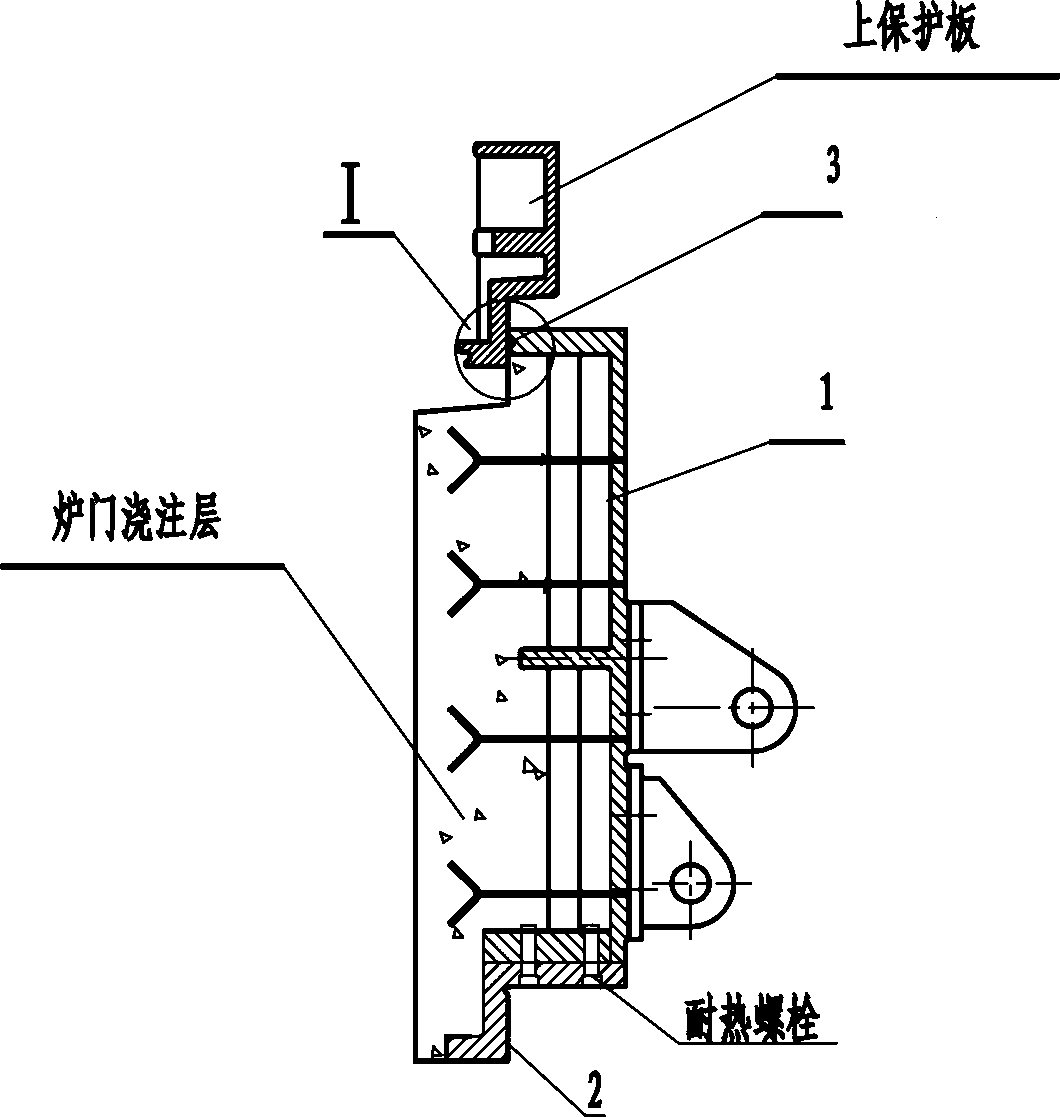

Upper furnace door of clean heat recovery coke oven

InactiveCN103074089AChange the tightnessChange Leakage SeriouslyEnergy inputCoke oven doors/closuresSocial benefitsEconomic benefits

The invention provides an upper furnace door of a clean heat recovery coke oven. The upper furnace door comprises a furnace door body (1) and three detachable zigzag-form cast iron lower edges (2), wherein an arc segment is arranged on the body (1) and is provided with a semicircular groove (3), an asbestine circular rope is arranged in the semicircular groove (3), and the detachable zigzag-form cast iron lower edges (2) are connected with the furnace door body (1) through heatproof bolts. According to the invention, through improvement of the structure of the furnace door and the material of a fireproof casting layer, the sealing mode of the furnace door is changed into flexible sealing, so the problems of poor sealing, severe leakage, unorganized air supply for the coke oven and great amount of heat dissipation of current rigid surface contact are overcome, the rate of non-fully coked char is reduced, waste heat utilization and total char yield are improved, and less resources are wasted; meanwhile, frequency of replacing of the whole upper furnace door due to burnt lower edges of the upper furnace door is reduced, and it only needs to replace a burnt lower edge with the detachable zigzag-form cast iron lower edge, so economic benefits and social benefits of an enterprise can be improved.

Owner:山西沁新能源集团股份有限公司

Method for improving gasoline yield of catalytic cracking technology and device thereof

InactiveCN103627426AHigh yieldLow yieldTreatment with plural serial stages onlyGeneration rateGasoline

The invention relates to a method for improving gasoline yield of catalytic cracking technology and a device thereof. The method comprises the following steps: in a catalytic cracking process, taking atmospheric first line oil as the quenching oil, and injecting the atmospheric first line oil into the middle part of a lifting pipe of a catalytic cracking device. The device comprises a lifting pipe and a quenching oil pipeline, the bottom of the lifting pipe communicates with a material feeding pipeline, the outlet in the top part of the lifting pipe communicates with an oil and gas pipeline, the middle part of the lifting pipe communicates with a quenching water pipeline, the middle part of the lifting pipe is provided with an introducing pipeline, the introducing pipeline communicates the quenching water pipeline and the quenching oil pipeline, and the quenching oil pipeline communicates with an atmospheric and vacuum distillation device. The method and the device thereof have the advantages that the gasoline yield is increased, the coke generation rate in the catalytic cracking proves is decreased, the dry gas yield and the liquefied gas yield during the catalytic cracking process are slightly reduced, the diesel oil yield is slightly improved, and thus the processing efficiency of the catalytic cracking device is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of low-quality heavy oil suspended bed hydrocracking catalyst and preparation method

ActiveCN107970952BImprove conversion rateHigh desulfurization rateMolecular sieve catalystsHydrocarbon oil crackingIronstoneCoke rate

Owner:FUZHOU UNIV

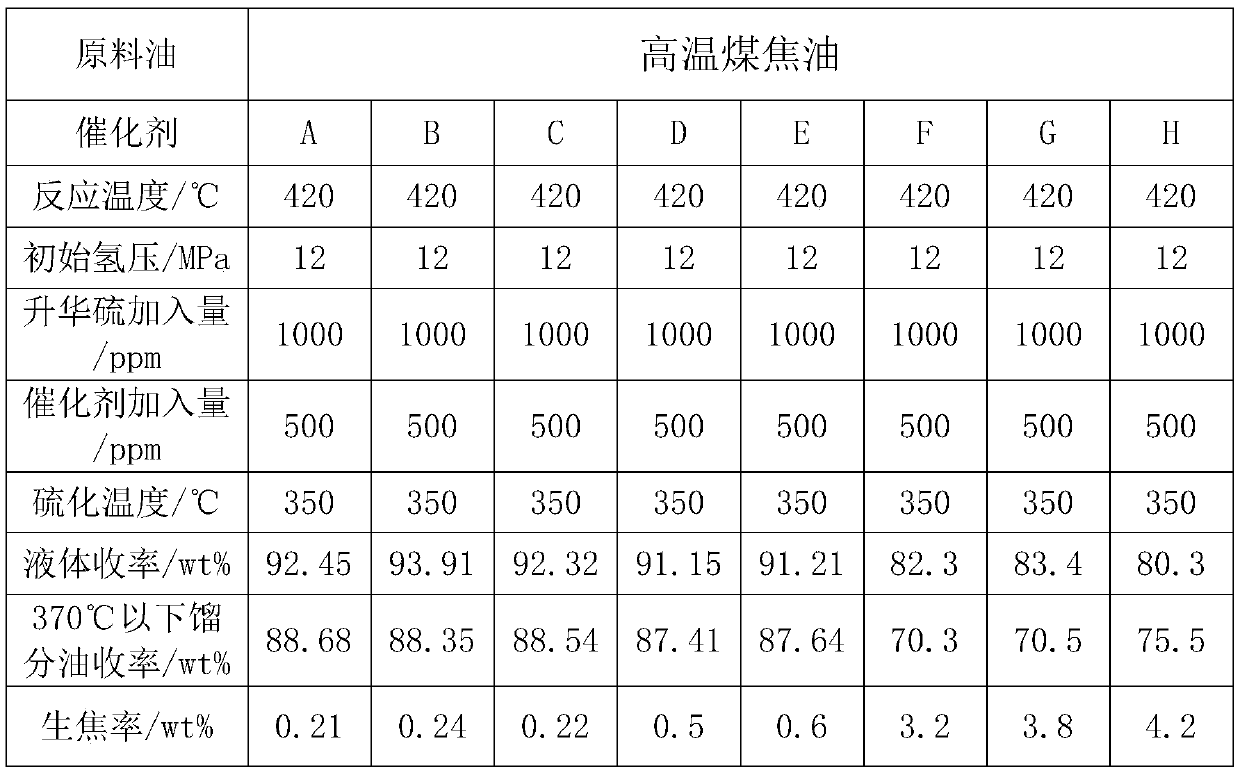

Biomass hydropyrolysis-gasification co-production process and system

ActiveCN114763497ASimple process routeImprove economyGasification processes detailsCombustible gas productionLiquid productProcess engineering

The invention discloses a biomass hydrogen pyrolysis-gasification co-production process and system. The process comprises the following steps: treating a biomass raw material and gas to obtain purified gas and a solid-phase material; pyrolyzing the solid-phase material to obtain pyrolyzed high-temperature oil gas and biological semicoke; carrying out gasification reaction on the biological semicoke to obtain charcoal and gasified high-temperature oil gas; treating the pyrolyzed high-temperature oil gas and the gasified high-temperature oil gas to obtain a gas phase, a light fraction and a heavy fraction; and carrying out contact treatment on the gas phase and the light fraction to obtain gas and a tar-rich light fraction. According to the present invention, the hydrogen-containing pyrolysis-gasification coupling process is adopted, such that the carbon conversion rate of the biomass and the liquid product yield are substantially improved, and the oxygen content of the product is reduced; the process flow is simple, the utilization rate of carbon atoms is high, products are diversified, flexible and adjustable, the added value is high, energy recycling is sufficient, and economical efficiency is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst for vacuum residue suspension bed and preparation method and use method thereof

InactiveCN102719269BPrevents temperature spikesWide variety of sourcesHydrocarbon oil crackingPyriteHigh pressure

The invention discloses a hydrocracking catalyst for a vacuum residue suspension bed and a preparation method and a use method thereof. The hydrocracking catalyst for the vacuum residue suspension bed is prepared by the following step of: selecting iron pyrite of which the mass percentage content of iron is 40-50 percent for serving as a raw material. The hydrocracking catalyst for the vacuum residue suspension bed is prepared from a cheap iron pyrite raw material, and has the advantages of wide raw material source and simple treatment and preparation processes; the coke yield is low and the fraction yield is high under a low pressure condition; generated coke can suspend in liquefaction oil without being attached to the inner wall of a high-pressure electromagnetic stirring reaction kettle, so that blockage of a reactor and a pipeline in an industrial device is prevented; hydrogenation lightening is performed on vacuum residues through a two-section reaction, the temperature is controlled stably, the phenomenon of violent temperature rise in a hydrogenation lightening process of vacuum residues is avoided, and the coke yield is further suppressed; and a foundation is laid for the industrialization of a vacuum residue suspension bed hydrocracking technology.

Owner:XINJIANG UNIVERSITY

A hydrogenation catalyst and its preparation method and use method

ActiveCN107824226BImprove catalytic performanceOptimal molar ratioOrganic-compounds/hydrides/coordination-complexes catalystsRefining to eliminate hetero atomsActive phaseCarbon deposit

The invention discloses a hydrogenation catalyst, a preparation method and an application method thereof. It uses organic phosphonic acid and molybdenum source as reaction raw materials, utilizes the reaction of the two, and bonds the two together to prepare a hydrogenation catalyst. Among them, the inventors found for the first time that P in the organic phosphonic acid can change the surface acidity of the active phase, increase the surface acidity of the hydrogenation catalyst after sulfidation, and the increase in acidity helps to enhance the hydrogenation activity of the hydrogenation catalyst; in addition, the presence of P has It helps stabilize asphaltenes, thereby inhibiting asphaltene condensation and coking, thereby reducing the amount of coke, slowing down catalyst deactivation, and finally reducing the coking rate and increasing the hydrogenation yield. At the same time, it is also found that the presence of P helps to change the structure of the active phase in the hydrogenation catalyst, which can reduce the amount of molybdenum with a tetrahedral structure that is difficult to vulcanize, and increase the amount of molybdenum with an octahedral structure that is easy to sulfide, which in turn facilitates the sulfuration of molybdenum. In the process, it is converted into molybdenum disulfide with suitable stacking layers, thereby increasing the activity of the hydrogenation catalyst and increasing the hydrogenation yield.

Owner:FUZHOU UNIV

Coking method for processing highly acid crude oil

ActiveCN101280213BReduce corrosionCorrosion is reduced or even avoidedThermal non-catalytic crackingTowerHot Temperature

Owner:CHINA PETROLEUM & CHEM CORP +1

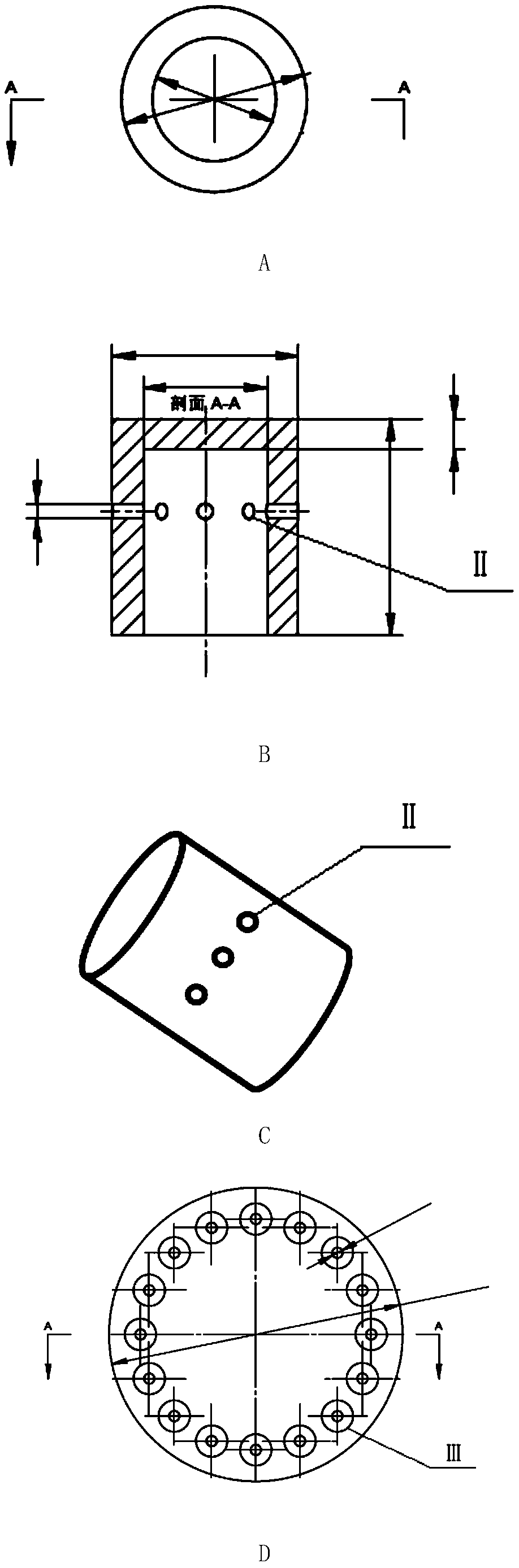

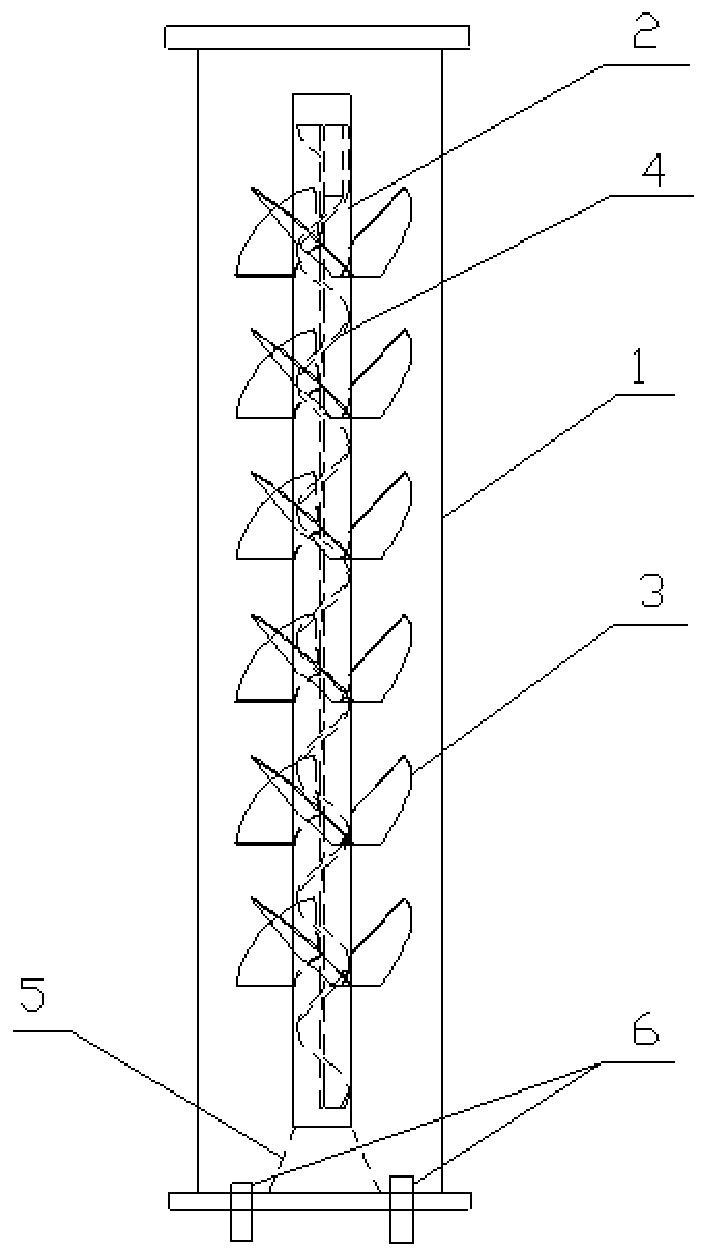

A suspension bed hydroconversion method for low-quality residual oil

ActiveCN107674704BPromote conversionReduce coke rateTreatment with hydrotreatment processesHydrocarbon oils refiningHydrogenChemical reaction

The invention discloses an inferior residual oil suspension bed hydrogenation conversion method, which comprises the following steps of (1) mixing hydrogen gas and a residual oil raw material containing a catalyst, then preheating, passing through a radial-axial secondary distributor to enter an air-lift loop reactor, and axially rotary lifting a reaction material in the air-lift loop reactor forcarrying out chemical reaction; (2) feeding the reaction material subjected to chemical reaction into a high-pressure separator and a low-pressure separator, and accomplishing residual oil conversionafter separation. According to the method provided by the invention, after the raw material is secondarily distributed efficiently, the raw material and the hydrogen gas are fully and efficiently mixed to enter the air-lift loop reactor, and a gas-liquid mixture rotatably lifts along an axial direction, so that the material and the temperature are uniformly distributed radially; the material rotatably lifts along an axial direction, so that the standing time of the material in the reactor is increased by 4 times, and the conversion rate is improved; with a rotary type special design of the reactor, the coking of the material in the reactor is greatly reduced, high-efficient conversion of inferior residual oil in a suspension bed reactor is realized, and coking is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com