Technological method for suspended bed hydrocracking of heavy oil

A hydrocracking and suspended bed technology, used in chemical instruments and methods, hydrocarbon oil cracking, petroleum industry, etc., can solve problems such as unsatisfactory desulfurization effect, and achieve strong coking inhibition, temperature surge inhibition, and impurity inhibition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for hydrocracking of heavy oil suspended bed, the specific steps are:

[0039] 1) Preparation of catalyst: After mixing 20.00g of nickel-containing ore, 30.00g of tungsten-containing ore, and 25.00g of iron-containing ore (both are 60-mesh powder), carry out vulcanization treatment with a vulcanizing agent, which is carbon disulfide, and then mix with 25.00 g of 60-mesh ordinary zinc oxide powder was dry-blended, fully stirred, and evenly mixed to obtain Catalyst 1.

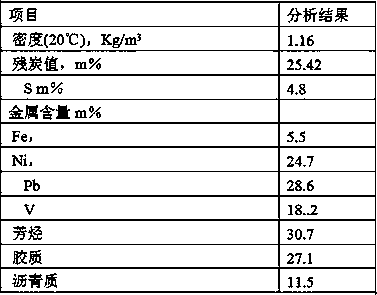

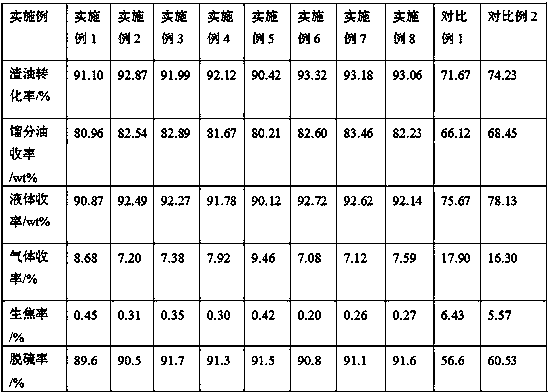

[0040] The vacuum residual oil is used as the reaction raw material, and the properties of the residual oil are shown in Table 1. From Table 1, it can be seen that the residual oil has a high content of aromatics, colloids, asphaltenes, and carbon residue, as well as a high content of metals and sulfur. Add 60.00g of vacuum residue and 700ppm catalyst to a 0.3L high-pressure reactor, and the reaction pressure is 11MPa; the reaction temperature is 400°C, the reaction time is 2h, the hydrogen-oil volu...

Embodiment 2

[0042] After roasting the three ores at 450°C, take 30.00g of nickel-containing ore, 22.00g of tungsten-containing ore, and 30.00g of iron-containing ore (both 80 meshes) and mix them evenly, and then use a vulcanizing agent for vulcanization treatment. The vulcanizing agent is carbon disulfide. Then 18.00 g was dry-blended with zinc oxide powder containing zinc-aluminum spinel structure, fully stirred, and mixed uniformly to obtain catalyst 2. The reaction raw material oil and process conditions are the same as in Example 1, and the reaction results are shown in Table 2.

Embodiment 3

[0044] After roasting the three kinds of ores and zinc oxide at 450°C, take 22.00g of nickel-containing ore, 18.00g of tungsten-containing ore, and 15.00g of iron-containing ore (all 100 mesh) and mix them evenly, and then use a vulcanizing agent for vulcanization treatment. It is carbon disulfide, and then dry-mixed with 45.00 g of zinc oxide powder containing zinc-aluminum spinel structure, fully stirred, and mixed uniformly to obtain catalyst 3. The reaction raw material oil and process conditions are the same as in Example 1, and the reaction results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com