Suspended bed hydrocracking catalyst and preparation method

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrocarbon oil cracking, etc., can solve the problems of unsatisfactory desulfurization effect and high production cost, and achieve strong coking inhibition and coke carrying capacity. Strong, highly active hydrogenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

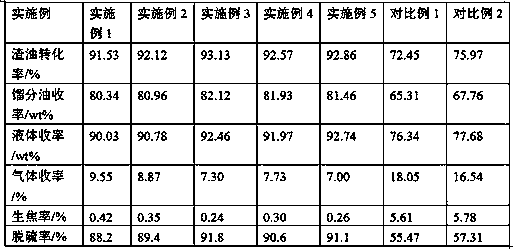

Embodiment 1

[0023] 60.00g of 60-mesh bauxite powder was vulcanized with a vulcanizing agent, and the vulcanizing agent was carbon disulfide, and then dry-mixed with 80-mesh 15.00g zinc oxide powder, fully stirred, and uniformly mixed to obtain catalyst 1.

Embodiment 2

[0025] After mixing 40.00g 80-mesh bauxite powder and 8.00g 80-mesh cobalt-containing molybdenum waste catalyst powder, use a vulcanizing agent to vulcanize, and the vulcanizing agent is carbon disulfide, and then dry-mix with 20.57g nano-zinc oxide powder, stir well, and mix Catalyst 2 was obtained after homogenization.

Embodiment 3

[0027] 40.00g of bauxite powder and 8.00g of cobalt-containing molybdenum waste catalyst powder (both 120 mesh) were vulcanized with a vulcanizing agent. The vulcanizing agent was carbon disulfide, and then mixed with 20.57g of zinc oxide containing zinc-aluminum spinel structure. The powders are dry mixed, fully stirred, and the catalyst 3 is obtained after mixing uniformly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com