A suspension bed hydrocracking method

A technology of suspended bed and hydrogenation catalyst, which is applied in the fields of hydrocarbon oil cracking, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of unsatisfactory desulfurization effect and high catalyst production cost, and achieve the ability to suppress coking, suppress temperature soaring, and reduce production The effect of focal ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 60.00 g of 60-mesh bauxite powder was vulcanized with a vulcanizing agent, the vulcanizing agent being carbon disulfide, and then dry-mixed with 15.00 g of 80-mesh zinc oxide powder, fully stirred, and evenly mixed to obtain Catalyst 1.

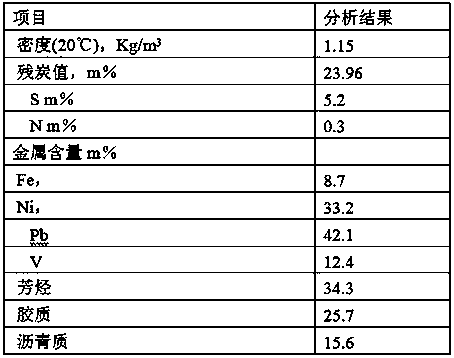

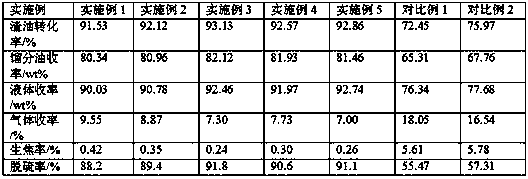

[0030]The vacuum residual oil is used as the reaction raw material, and the properties of the residual oil are shown in Table 1. From Table 1, it can be seen that the residual oil has a high content of aromatics, colloids, asphaltenes, and carbon residue, as well as a high content of metals and sulfur. Add 60.00g of vacuum residue and 700ppm of the catalyst of Example 1 above into a 0.3L autoclave with a reaction pressure of 11MPa; the reaction temperature is 400°C, and the reaction time is 2h. After the reaction is completed, wait for the temperature to drop to room temperature , the liquid oil taken out was weighed, and the reaction results are shown in Table 2.

Embodiment 2

[0032] After mixing 40.00g of 80-mesh bauxite powder and 8.00g of 80-mesh cobalt-molybdenum-containing spent catalyst powder, carry out vulcanization treatment with a vulcanizing agent, the vulcanizing agent is carbon disulfide, and then dry-mix with 20.57g of nano-zinc oxide powder, fully stir, and mix Catalyst 2 was obtained after uniformity.

[0033] The reaction raw material oil and process conditions are the same as in Example 1, and the reaction results are shown in Table 2.

Embodiment 3

[0035] After mixing 40.00g of bauxite powder and 8.00g of spent catalyst powder containing cobalt and molybdenum (both 120 meshes), carry out vulcanization treatment with a vulcanizing agent, the vulcanizing agent is carbon disulfide, and then oxidized with 20.57g of zinc-aluminum spinel structure The zinc powder is dry mixed, fully stirred, and the catalyst 3 is obtained after mixing evenly.

[0036] The reaction raw material oil and process conditions are the same as in Example 1, and the reaction results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com