Hydrocracking catalyst for vacuum residue suspension bed and preparation method and use method thereof

A vacuum residue and hydrocracking technology, applied in hydrocarbon oil cracking, petroleum industry and other directions, can solve problems such as cost reduction, damage to equipment and safety hazards, soaring production temperature and other problems, achieve a wide range of raw material sources, prevent clogging, The effect of preventing temperature spikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

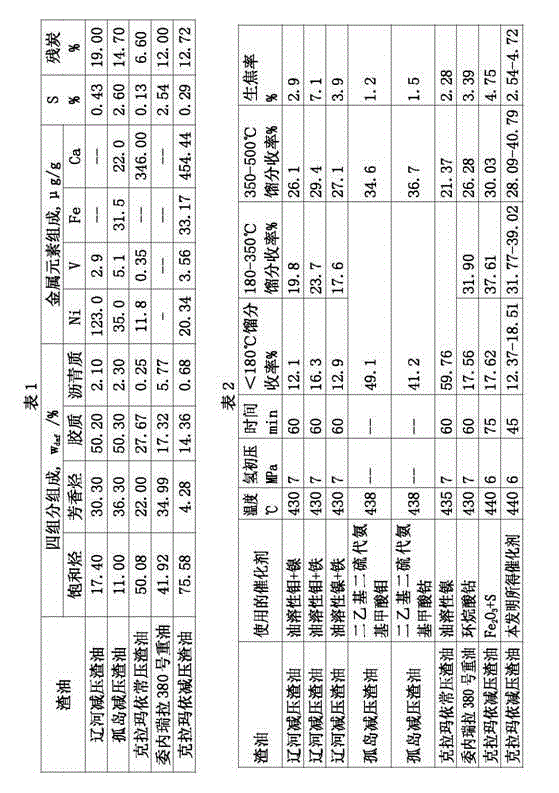

Image

Examples

Embodiment 1

[0016] Embodiment 1, the vacuum residue suspended bed hydrocracking catalyst is obtained according to the following steps: the first step, select pyrite, and the mass percentage of iron is 40% to 50% of pyrite as raw material; In the second step, the pyrite raw material selected in the first step is primary ground to a particle size of less than or equal to 200 mesh to obtain a vacuum residue suspended bed hydrocracking catalyst.

Embodiment 2

[0017] Embodiment 2, this vacuum residue suspended bed hydrocracking catalyst is obtained according to the following steps: the first step, select pyrite, the mass percent composition of iron is 40% to 50% and S: the mol ratio of Fe The pyrite of 1.6 to 2.0 is used as a raw material; in the second step, the pyrite raw material selected in the first step is primary ground to a particle size of less than or equal to 200 mesh to obtain a vacuum residue suspended bed hydrocracking catalyst.

Embodiment 3

[0018] Embodiment 3, the vacuum residue suspended bed hydrocracking catalyst is obtained according to the following steps: the first step, select pyrite, and use the pyrite whose mass percentage of iron is 40% to 50% as raw material; In the second step, the pyrite raw material selected in the first step is primary ground to a particle size less than or equal to 200 mesh to obtain a vacuum residue suspended bed hydrocracking catalyst; in the third step, the vacuum residue suspended bed The hydrocracking catalyst is deeply ground to a particle size of 100nm to 1μm to obtain a high-quality vacuum residue suspended bed hydrocracking catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com