Biomass hydropyrolysis-gasification co-production process and system

A technology of biomass and biomass raw materials, which is applied in the petroleum industry and the manufacture of combustible gas, etc., can solve the problems of low conversion rate of biomass raw materials, poor quality of combustible gas and bio-oil, high tar content and high oxygen content, and reduce biomass Effects of coke rate, increase in light fraction yield, and increase in liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

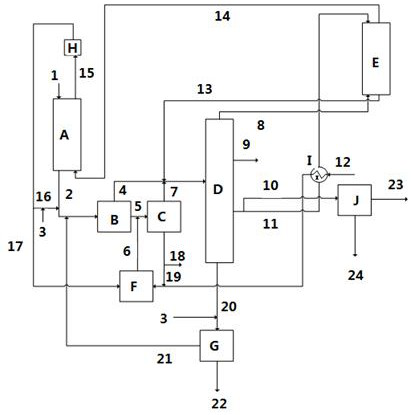

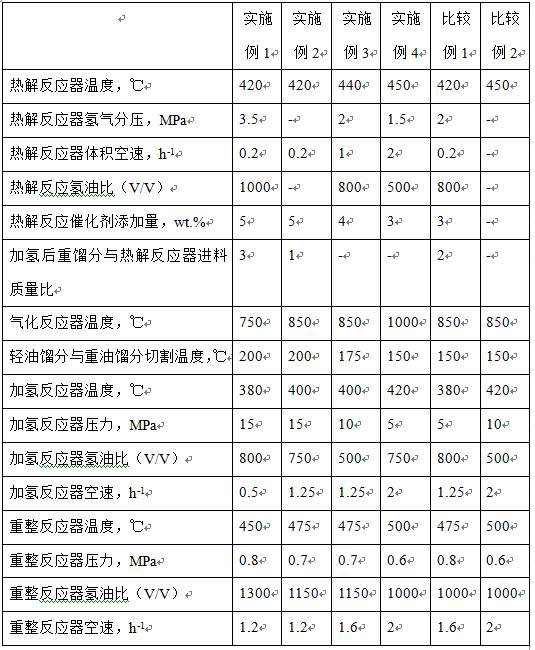

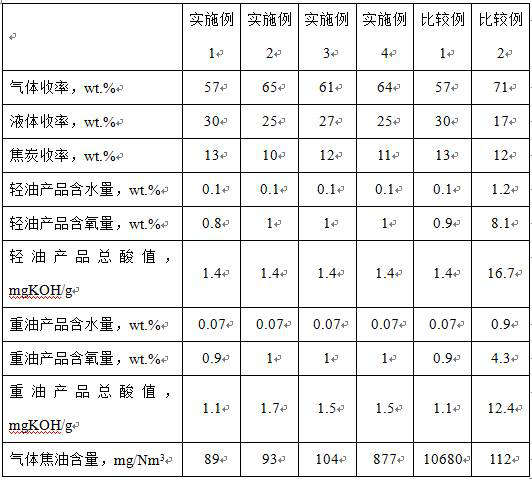

[0051] using the present invention figure 1 The flow shown in which the heavy ends and hydrogen after hydrogenation both enter the pyrolysis reactor. The raw material is Larch from Northeast China. Before the experiment, the raw material is fully pulverized, sieved to 40-60 mesh, and fully dried until the moisture content in the raw material is less than 5wt.%; It enters the pyrolysis reactor together with the hydrogenated heavy fractions and hydrogen, and the pyrolysis reaction occurs under the catalysis of the oil-soluble molybdenum-based catalyst; the pyrolyzed volatiles enter the rectification tower, and the semi-coke enters the gasification reactor and The water vapor undergoes a gasification reaction under the action of a gasification catalyst, and the gasification catalyst refers to a modified calcium oxide adsorbent, that is, the aluminum chloride solution and the calcium chloride solution are in accordance with Al / Ca=3:10 (mol / mol ), and then spray pyrolysis at 1000 ...

Embodiment 2

[0053] using the present invention figure 1 As shown in the process, wherein the heavy fractions enter the pyrolysis reactor after hydrogenation, and the hydrogen does not enter the pyrolysis reactor. The raw material is Larch from Northeast China. Before the experiment, the raw material is fully pulverized, sieved to 40-60 mesh, and fully dried until the moisture content in the raw material is less than 5wt.%; It enters the pyrolysis reactor together with the hydrogenated heavy fraction, and undergoes a pyrolysis reaction under the catalysis of the oil-soluble molybdenum-based catalyst; the pyrolyzed volatiles enter the rectification tower, and the semi-coke enters the gasification reactor and water vapor. A gasification reaction occurs under the action of a gasification catalyst. The gasification catalyst refers to a modified calcium oxide adsorbent, that is, the aluminum chloride solution and the calcium chloride solution are mixed according to Al / Ca=3:10 (mol / mol) , and t...

Embodiment 3

[0055] using the present invention figure 1 Shown in the process, wherein the heavy fraction does not enter the pyrolysis reactor after hydrogenation, and hydrogen enters the pyrolysis reactor. The raw material is Larch from Northeast China. Before the experiment, the raw material is fully pulverized, sieved to 40-60 mesh, and fully dried until the moisture content in the raw material is less than 5wt.%; It enters the pyrolysis reactor together with hydrogen, and the pyrolysis reaction occurs under the catalysis of the oil-soluble molybdenum-based catalyst; the volatile matter after pyrolysis enters the rectification tower, and the semi-coke enters the gasification reactor and the water vapor in the gasification catalyst. A gasification reaction occurs under the action of the gasification catalyst, and the gasification catalyst refers to a modified calcium oxide adsorbent, that is, the aluminum chloride solution and the calcium chloride solution are mixed according to Al / Ca=3:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com