Method for producing needle coke raw material by using delayed coking process

A technology for needle coke raw materials and coking raw materials, which is applied in the coking carbon-containing materials, coke ovens, petroleum industry, etc. Coke-like raw material yield and other issues, to achieve the effect of low cost, easy to master, and flexible operation

Active Publication Date: 2011-05-04

CHINA PETROLEUM & CHEM CORP +1

View PDF12 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, some full-fraction coal tar is mixed with vacuum residue for delayed coking, which is used to improve the yield and properties of needle coke raw materials, but the amount of full-fraction coal tar should not be too much, otherwise the delayed coking will be significantly shortened. The operation cycle of the single tower, and the whole fraction of coal tar reacts at a higher temperature, and the reaction time is long, so that the fraction suitable for needle coke raw material will be aggregated in large quantities, reducing the yield of needle coke raw material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

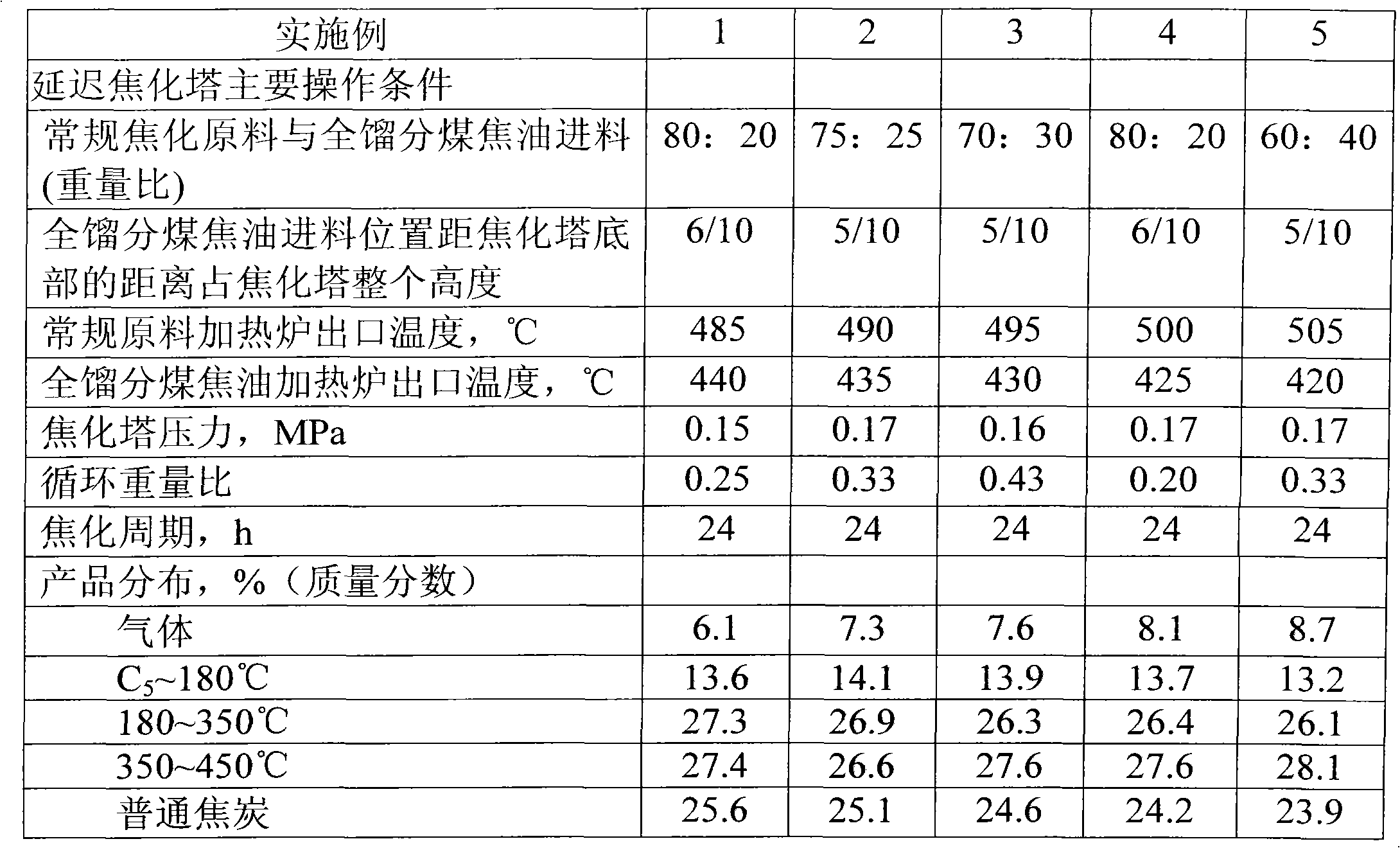

Embodiment 1-5

[0032] In the embodiment, all experiments use the same raw material oil, aiming to compare the effects under different operating conditions.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

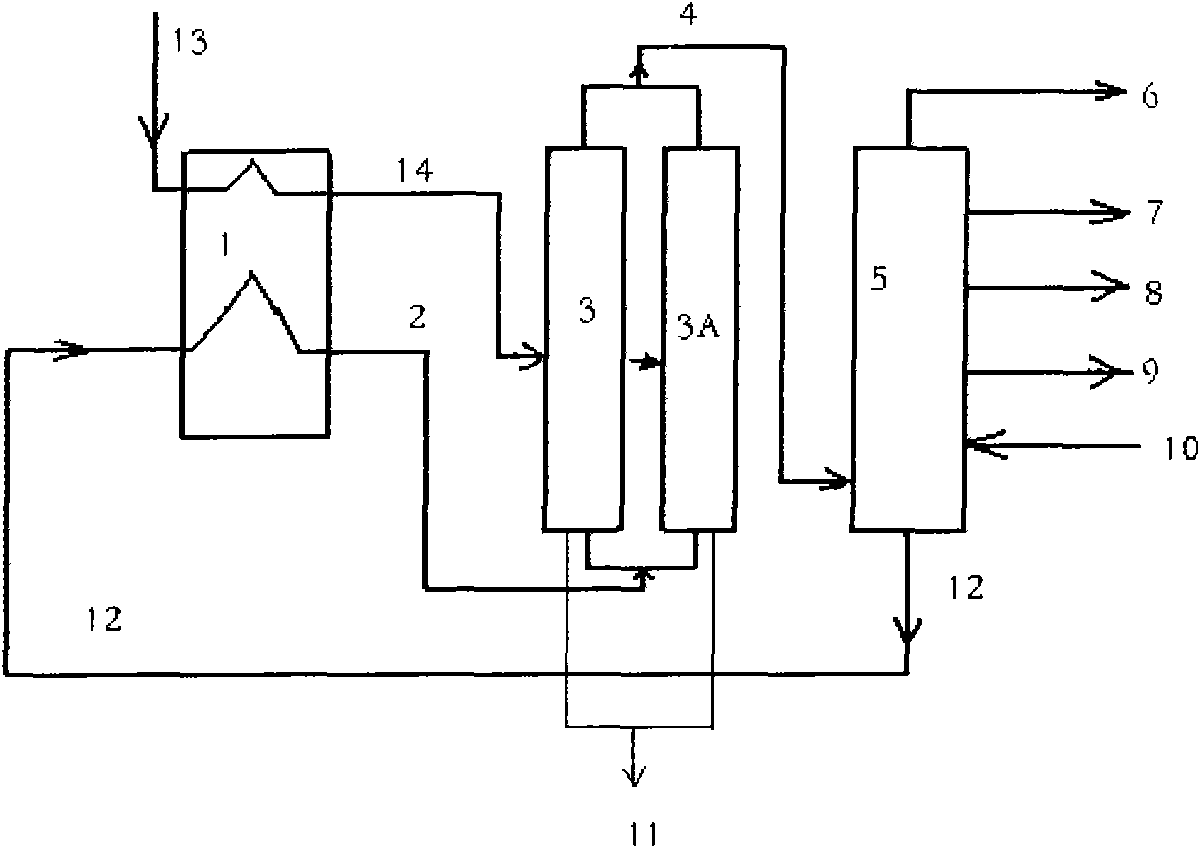

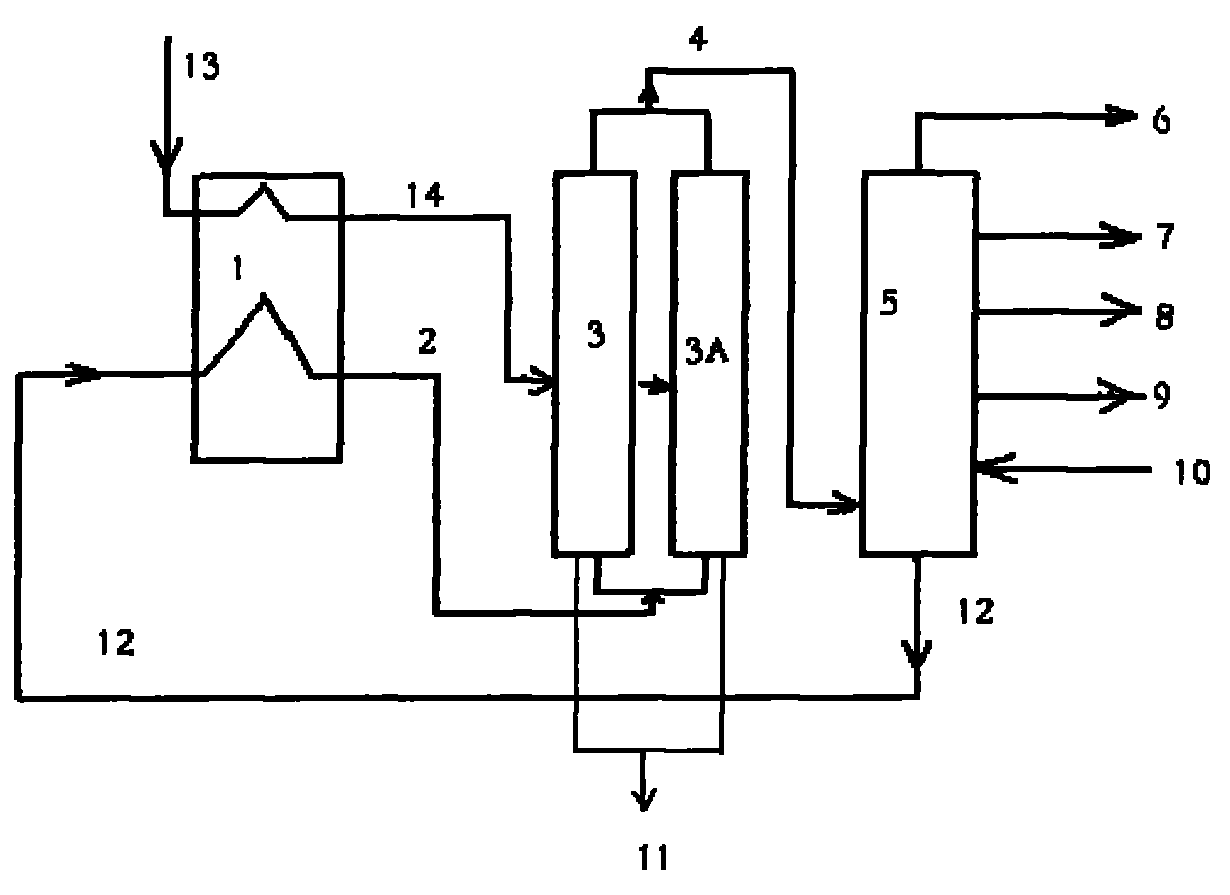

The invention discloses a method for producing a needle coke raw material by using a delayed coking process. In the method, full-range coal tar is imported to the top and the middle and a high-temperature conventional coking raw material is imported to the bottom; the high-temperature oil gas generated by the conventional coking raw material via high-temperature cracking is mixed with the full-range coal tar with lower temperature at the top and the middle of a reactor so that the full-range coal tar can crack hydrocarbon molecules with high reaction activity at a proper high temperature to achieve the aim of desorption; for the full-range coal tar, under the condition of the delayed coking process, asphaltene and partial colloid are condensed to form coke which is deposited in a coking tower so as to remove the components going against the production of the needle coke; furthermore, by means of the injection of the low-temperature full-range coal tar, the cracking temperature of the conventional coking raw material is reduced, the high-temperature cracking time of the conventional raw material is shortened, the secondary reaction is decreased, the coke generation rate is reduced and the stable operation period of a single tower is prolonged.

Description

technical field [0001] The invention belongs to a process method for producing needle coke raw materials. Specifically, it is a method of producing needle coke raw materials and simultaneously producing light distillate oil and coke by using a delayed coking process. Background technique [0002] Needle coke is the main raw material for producing high-power and ultra-high-power graphite electrodes. The most critical issues in the production of needle coke are the selection and pretreatment of raw materials. According to the coke formation mechanism of needle coke, the raw materials for producing needle coke must meet the requirements of high aromatic content, among which the content of linearly connected three-ring and four-ring short side chain aromatics is mostly, generally requiring the content of aromatics to reach 30%-50%; colloid Colloids and asphaltenes are low in content of asphaltenes. Colloids and asphaltenes are hydrocarbon compounds with macromolecular condense...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10B57/08C10B55/00

Inventor 张学萍蒋立敬胡长禄韩照明初人庆郑庆华勾连忠

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com