A hydrogenation catalyst and its preparation method and use method

A technology of hydrogenation catalyst and molybdenum source, which is applied in the field of hydrogenation catalyst preparation, can solve the problems of low hydrogenation yield, easy coking of hydrogenation catalyst, etc., and achieves the advantages of improving hydrogenation yield, improving catalytic effect and stabilizing surface state. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

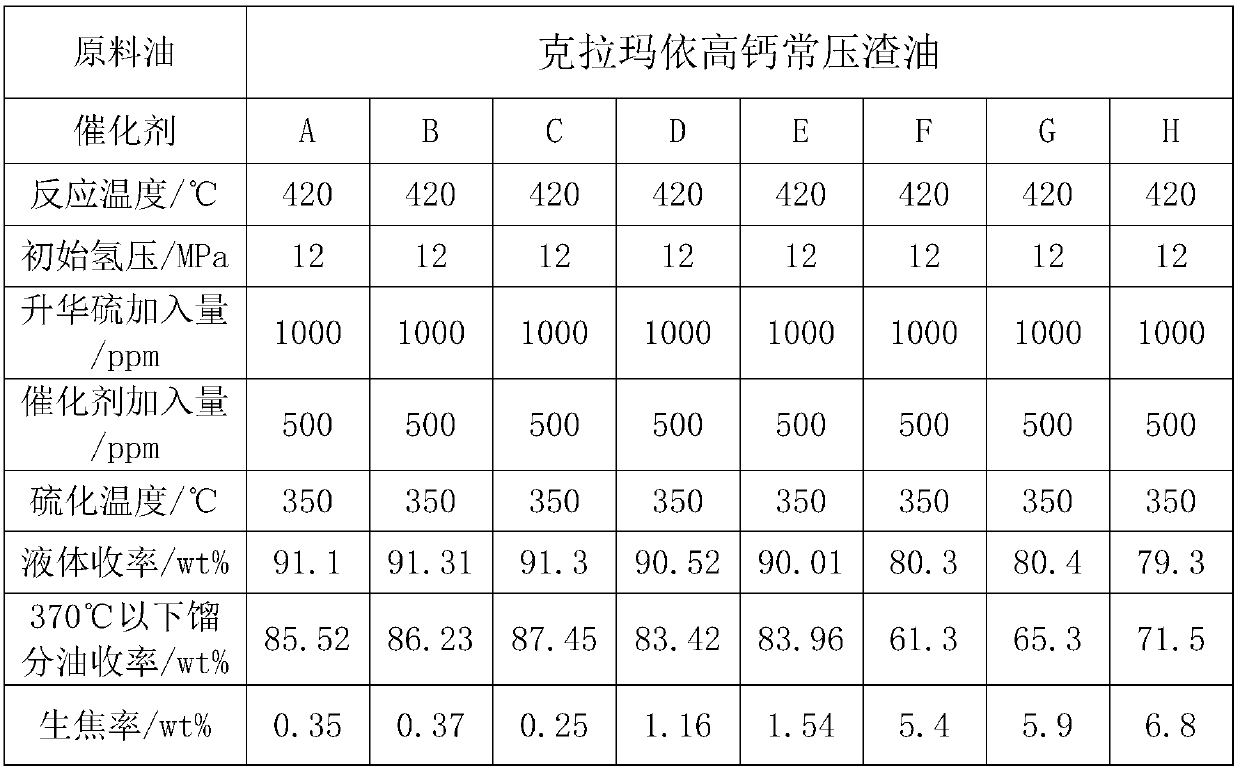

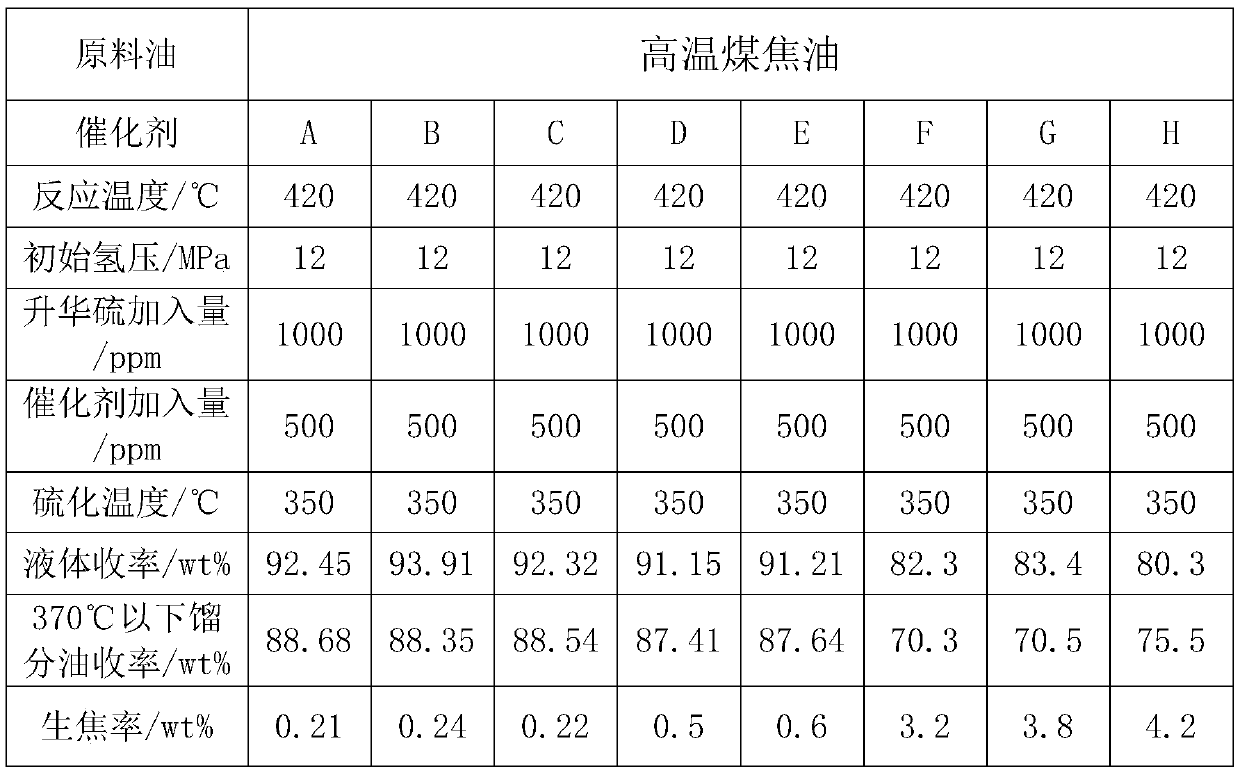

Examples

Embodiment 1

[0035] This embodiment provides a hydrogenation catalyst and its preparation method. The hydrogenation catalyst is obtained by bonding organic phosphonic acid and molybdenum source after reaction, wherein the organic phosphonic acid is dihexylaminomethylphosphonic acid, the molybdenum source is ammonium heptamolybdate, and the mole of molybdenum in the organic phosphonic acid and molybdenum source The ratio is 1:0.5;

[0036] The preparation method of above-mentioned hydrogenation catalyst comprises the steps:

[0037] 1) Weigh 0.005mol of dihexylaminomethylphosphonic acid, place it in a single-necked flask, add 30mL of ethanol to dissolve it completely;

[0038] Take by weighing the ammonium heptamolybdate of 0.44g, and add it in the above-mentioned one-necked flask;

[0039] 2) Place a spherical condenser on the above-mentioned single-necked flask, stir the mixture obtained in step 1), and heat the mixture to 80° C. to reflux, and stop the reaction after keeping for 4 hour...

Embodiment 2

[0043] This embodiment provides a hydrogenation catalyst and its preparation method. The hydrogenation catalyst is obtained by bonding an organic phosphonic acid and a molybdenum source after reaction, wherein the organic phosphonic acid is diisooctylamine methylphosphonic acid, the molybdenum source is sodium molybdate, and the mole of molybdenum in the organic phosphonic acid and the molybdenum source The ratio is 1:1;

[0044] The preparation method of above-mentioned hydrogenation catalyst comprises the steps:

[0045] 1) Weigh 0.005mol of diisooctylamine methylphosphonic acid, place it in a single-necked flask, add 30mL of ethanol to dissolve it completely;

[0046] Take by weighing the sodium molybdate of 1.2g, and it is added in the above-mentioned one-necked flask;

[0047] 2) Place a spherical condenser on the above-mentioned single-necked flask, stir the mixture obtained in step 1), and heat the mixture to 100° C. to reflux, and stop the reaction after keeping for ...

Embodiment 3

[0051] This embodiment provides a hydrogenation catalyst and its preparation method. The hydrogenation catalyst is obtained by bonding organic phosphonic acid and molybdenum source after reaction, wherein the organic phosphonic acid is octadecylaminomethylphosphonic acid, the molybdenum source is ammonium heptamolybdate, and the mole of molybdenum in the organic phosphonic acid and molybdenum source The ratio is 1:1.5;

[0052] The preparation method of above-mentioned hydrogenation catalyst comprises the steps:

[0053] 1) Weigh 0.005mol of octadecylaminomethylphosphonic acid, place it in a single-necked flask, add 30mL of ethanol to dissolve it completely;

[0054] Take by weighing the ammonium heptamolybdate of 1.32g, and it is added in the above-mentioned one-necked flask;

[0055] 2) Place a spherical condenser above the above-mentioned one-necked flask, stir the mixture obtained in step 1), and raise the temperature of the mixture to 120° C. to reflux, and stop the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com