Patents

Literature

38results about How to "High molybdenum content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

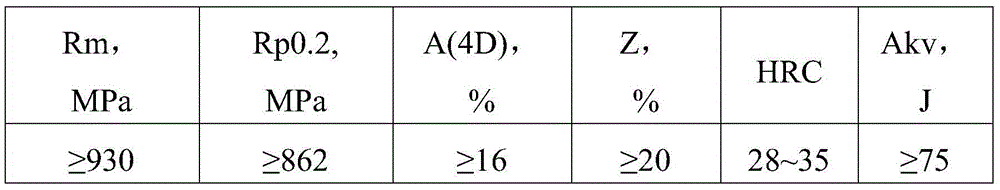

Low-nickel aging strengthening type iron-nickel based corrosion resistant alloy and preparation method thereof

The invention relates to a low-nickel aging strengthening type iron-nickel based corrosion resistant alloy. The alloy is prepared from the following components in percentage by weight: 36.0-42.0 percent of Ni, 19.0-25.0 percent of Cr, 3.0-6.0 percent of Mo, 1.0-3.50 percent of Cu, 1.5-3.0 percent of Ti, 0.2-0.6 percent of Al, less than or equal to 0.5 percent of Nb, less than or equal to 0.03 percent of C, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Mn, less than or equal to 0.0010 percent of S, less than or equal to 0.005 percent of P, 0.01-0.6 percent of trace elements and the balance of Fe. The alloy has high strength, high toughness and high corrosion resistance of existing iron-nickel based alloy. Compared with existing iron-nickel based alloy, the alloy has the advantages of better thermal processing performance and lower cost.

Owner:CHONGQING MATERIALS RES INST

Vacuum grade aluminum-molybdenum-silicon alloy

The invention relates to an interalloy for smelting. A vacuum aluminium-molybdenum-silicon alloy, is charactrized in that the alloy has close structure without slag inclusion and segregation, comprising, based on weight percentage, Mo of 40-63%, si of 4.0-5.0%, O of not more than 0.015%, H of not more than 0.002%, N of not more than 0.006%, C of not more than 0.06%, Fe of not more than 0.10%, and the residual is Al. The invention solves the technical problem that the non-vacuum aluminium -silicon alloy has segregation, slag inclusion, high content gas impurity without close structure, secondly solves the technical problem of low content of molybdenum in the alloy.

Owner:上海康臣特种金属材料有限公司

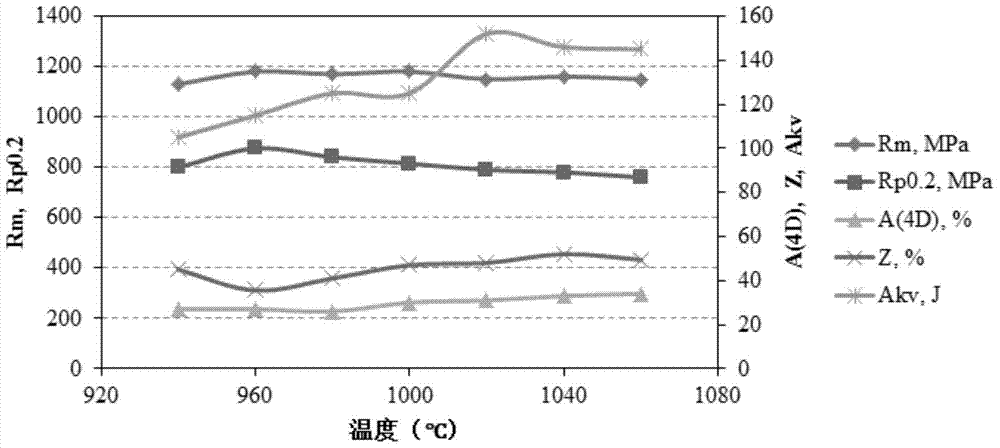

High-performance cold extrusion die steel and metallurgical manufacturing method thereof

ActiveCN101649419AReduced brittle tendencyImprove metallurgical qualitySteelmakingChemical composition

The invention provides high-performance cold extrusion die steel and metallurgical manufacturing method thereof. The high-performance cold extrusion die steel comprises the following chemical components in percentage by mass: 0.95 to 1.02 percent of C, 0.20 to 0.40 percent of Mn, 8.60 to 9.00 percent of Cr, 0.87 to 1.10 percent of Si, 1.80 to 2.00 percent of Mo, 0.40 to 0.60 percent of V, less than or equal to 0.30 percent of Cu, less than or equal to 0.25 percent of Ni, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. According to the component proportion, the toughness performance of the high-performance cold extrusion die steel can be greatly improved. The metallurgical manufacturing method comprises theprocesses of electric furnace steel making, electroslag remelting and steel forging by a radial forging press. In the process of electroslag remelting, the voltage is between 57 and 59V, and the current is between11,000 and 12,000A; and in the process of steel forging by the radial forging press, steel ingots are heated to between 1,150 DEG C and 1,170 DEG C, and the temperature keeps for 2 to 4hours. The method is simple and convenient, and can remarkably improve the performance index of the steel.

Owner:宝武特种冶金有限公司

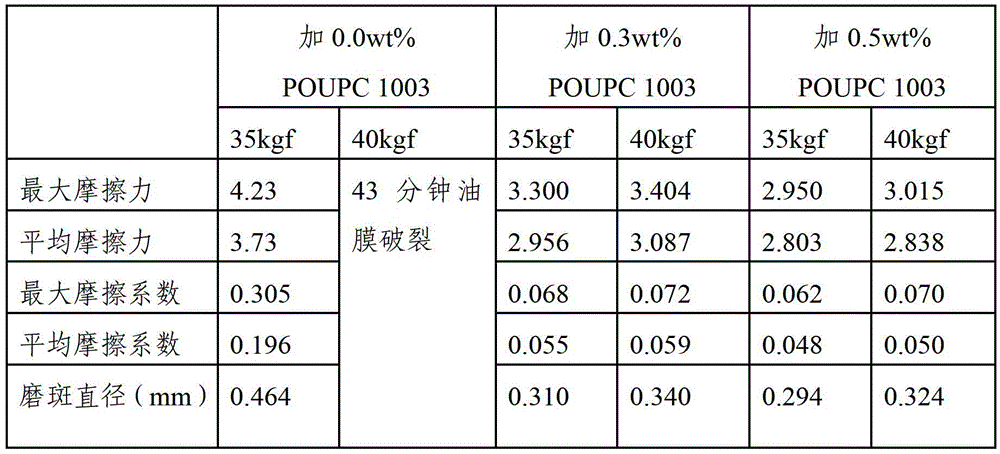

Molybdenum dialkyldithiocarbamate compositions and lubricating compositions containing the same

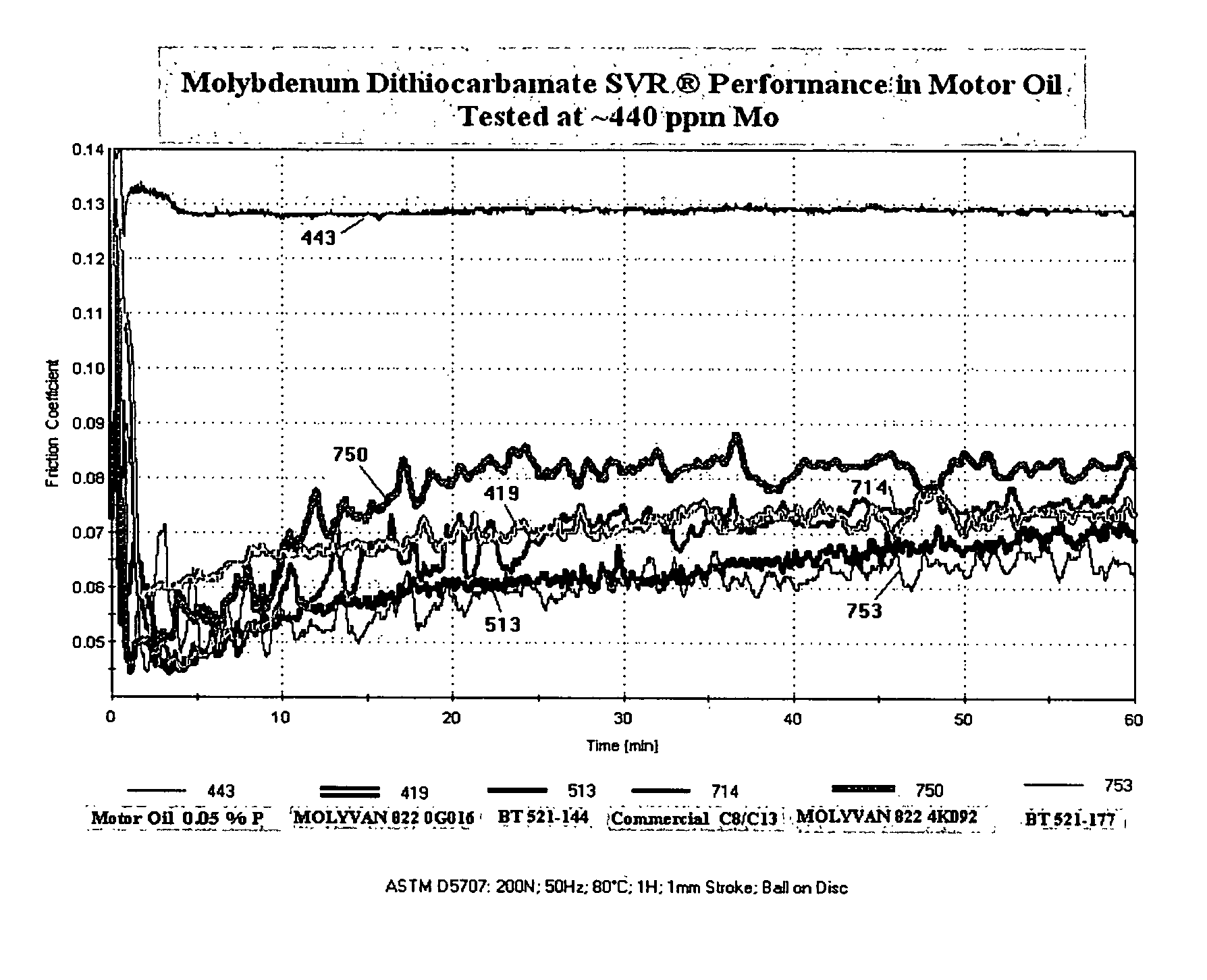

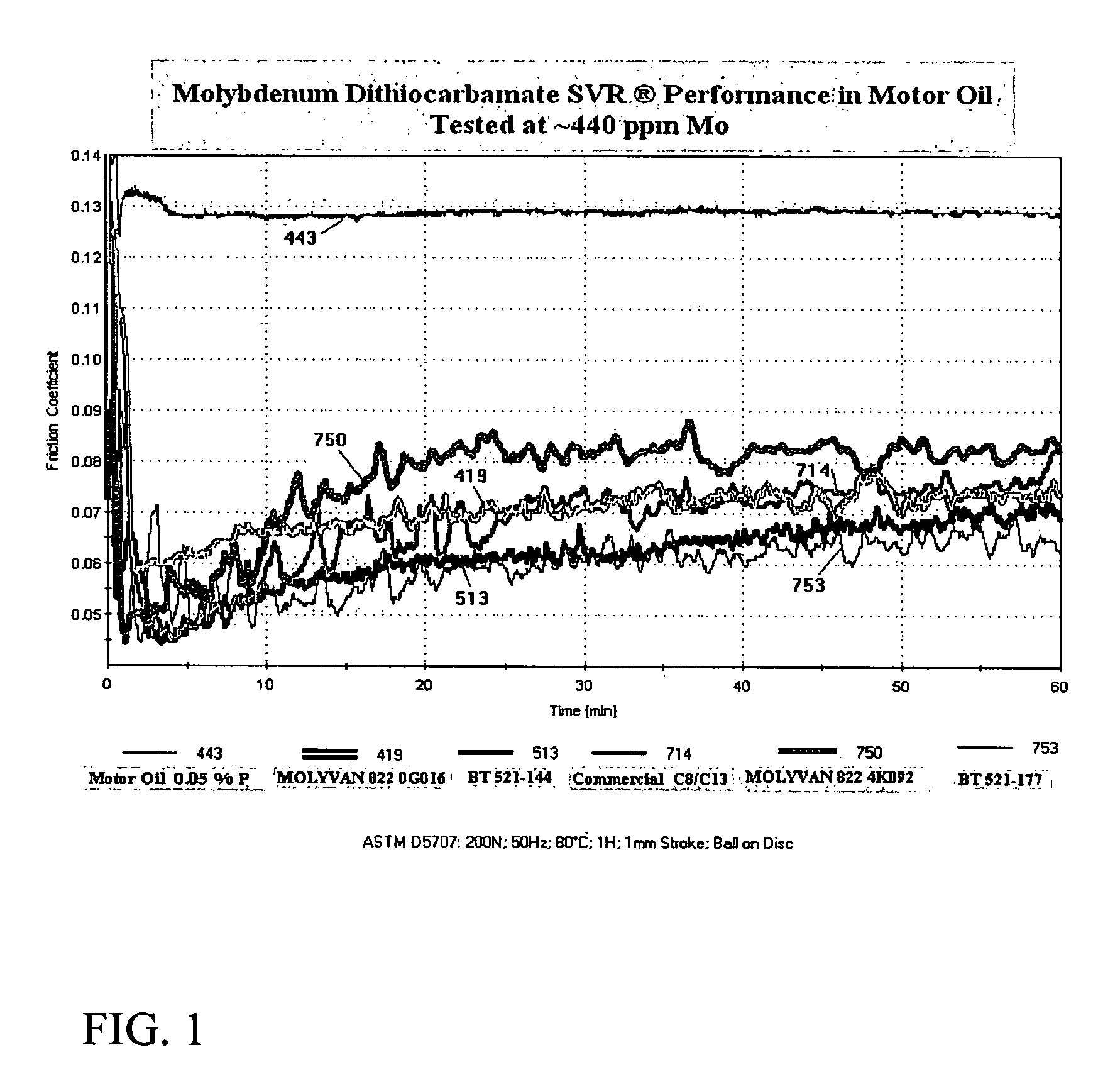

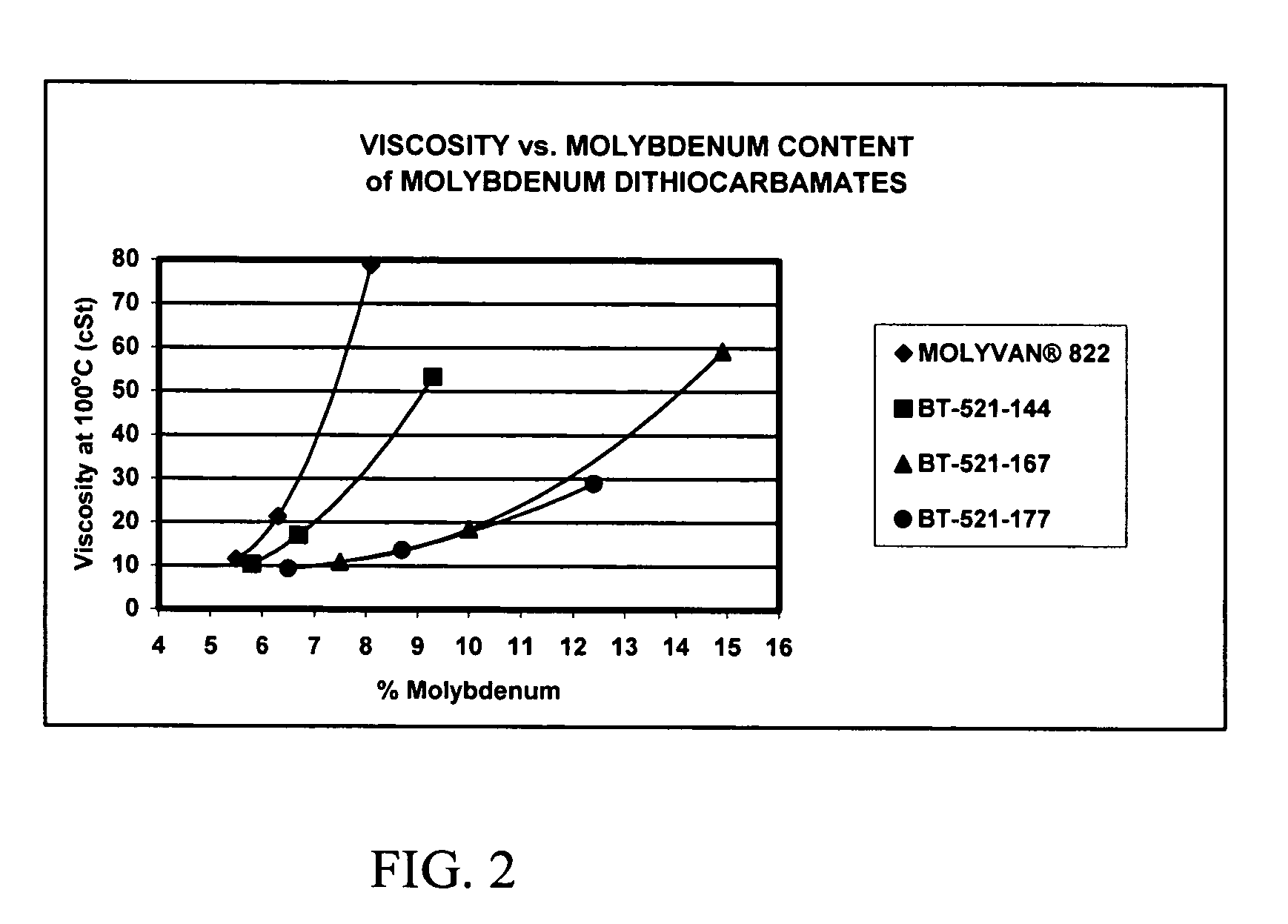

ActiveUS7763744B2Improve solubilityIncrease frictionGroup 6/16 element organic compoundsAdditivesThio-Physical chemistry

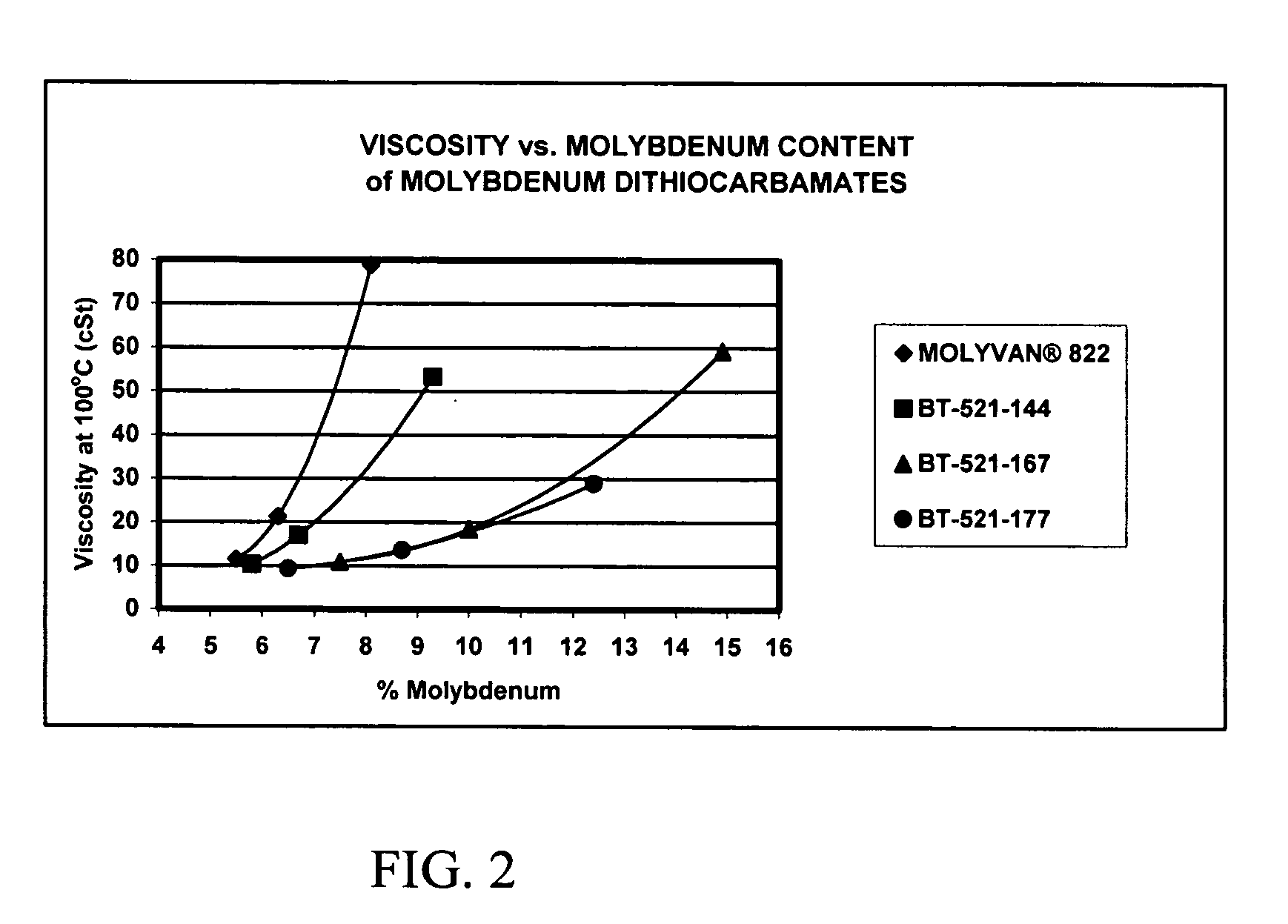

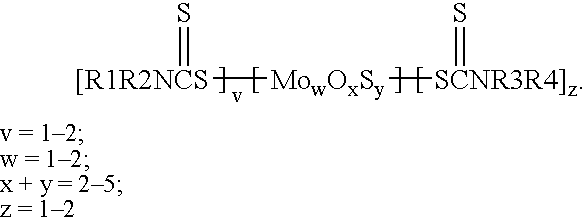

The invention relates to a novel asymmetrical, secondary dialkylamine-based molybdenum dithiocarbamate with improved friction reducing performance, viscosity and solubility, and lubricating compositions containing the same. The compounds are produced from asymmetrical dialkylamine of the formula R1-NH—R2 where R1 and R2 are different, and are independently selected from alkyl groups C3 to C19. In a preferred embodiment, R3 and R4 are different and are independently selected from alkyl groups C3 to C19. The molybdenum dithiocarbamates can be represented by the following formula:

Owner:VANDERBILT CHEM LLC

Molybdenum dialkyldithiocarbamate compositions and lubricating compositions containing the same

ActiveUS20060199745A1Improve solubilityHigh molybdenum contentAdditivesGroup 6/16 element organic compoundsSolubilityViscosity

Thie invention relates to a novel asymmetrical, secondary dialkylamine-based molybdenum dithiocarbamate with improved friction reducing performance, viscosity and solubility, and lubricating compositions containing the same. The compounds are produced from asymmetrical dialkylamine of the formula R1-NH-R2 where R1 and R2 are different, and are independently selected from alkyl groups C3 to C19. In a preferred embodiment, R3 and R4 are different and are independently selected from alkyl groups C3 to C19. The molybdenum dithiocarbamates can be represented by the following formula:

Owner:VANDERBILT CHEM LLC

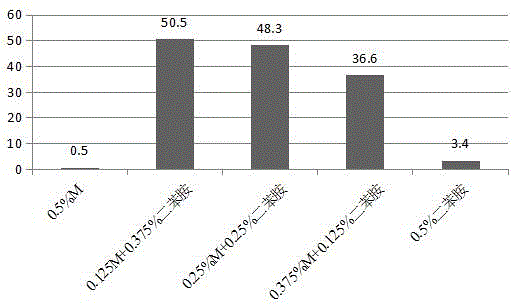

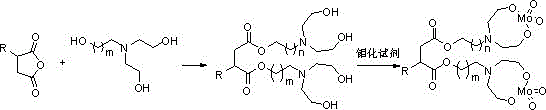

Molybdenum modification dispersant, and preparation method and applications thereof

ActiveCN106221862AHigh molybdenum contentLow costAdditivesGroup 6/16 organic compounds without C-metal linkagesAntioxidantWear resistant

The invention discloses a molybdenum modification dispersant, and a preparation method and applications thereof. The molybdenum modification dispersant comprises an imine diethanol molybdic acid diester group. The preparation method comprises the following steps: mixing succinic acid with alkyl chains and / or succinic anhydride with alkyl chains, alcohol amine compounds, and / or a diluent, carrying out first-phase reactions, removing residual unreacted substances that may exist, and adding a molybdenum reagent to carry out second phase reactions to obtain the target product. The molybdenum modification dispersant does not contain any sulfur or phosphor. Each molecule comprises an imine diethanol molybdic acid diester group, and thus the molybdenum content of the dispersant can be increased. Moreover, the raw material namely succinic acid with alkyl chains is commercial, the cost is largely reduced; the dispersant can generate a prominent high temperature synergetic antioxidant effect with alkylated diphenylamine antioxidant in lubricating oil; moreover, the dispersant can generate a good synergetic wear-resistant and friction reducing effect with zinc dialkyl dithiophosphate, the using amount of similar additive is reduced, the phosphor content is reduced, and the economy of fuel oil is improved.

Owner:江西福安路润滑材料有限公司

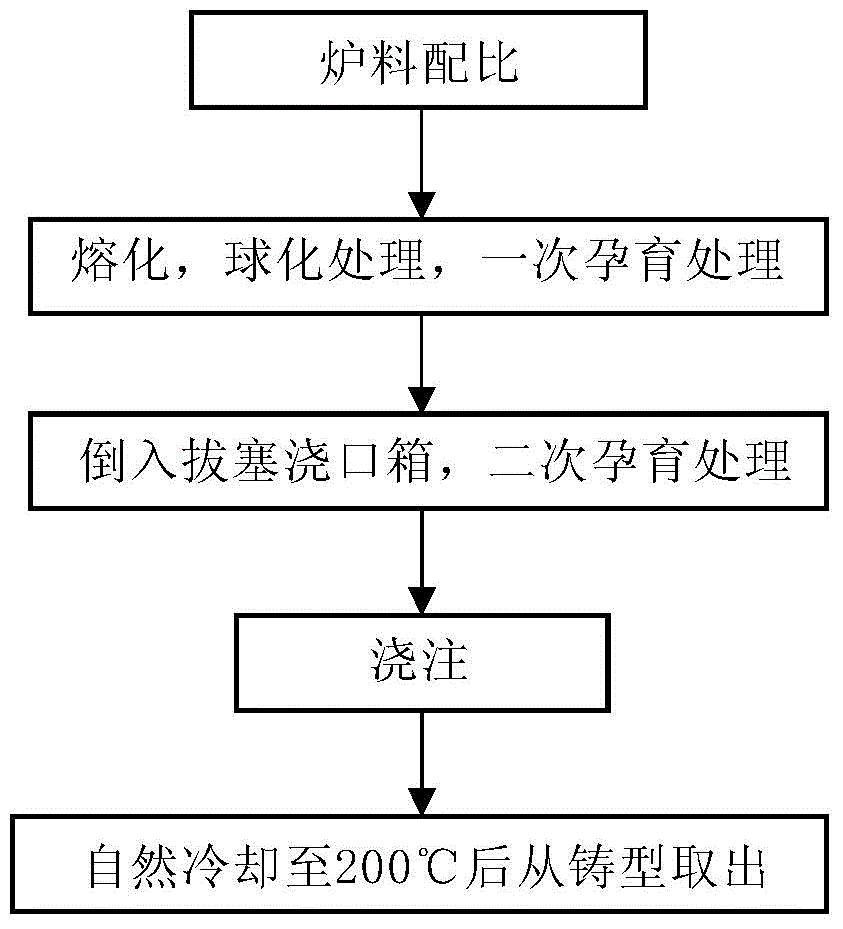

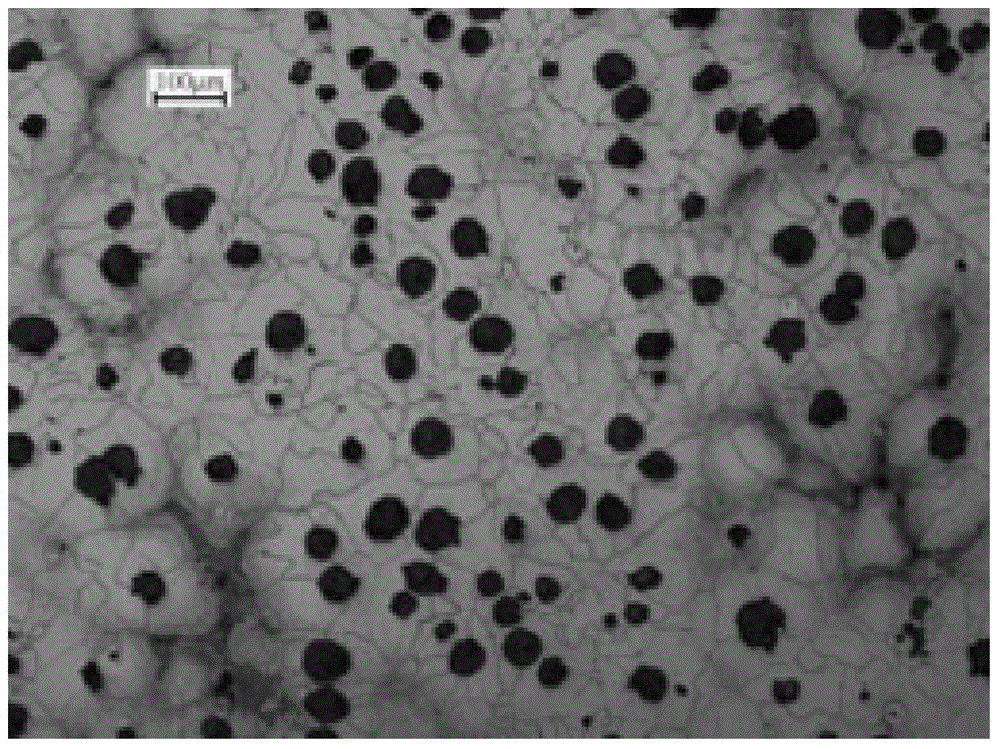

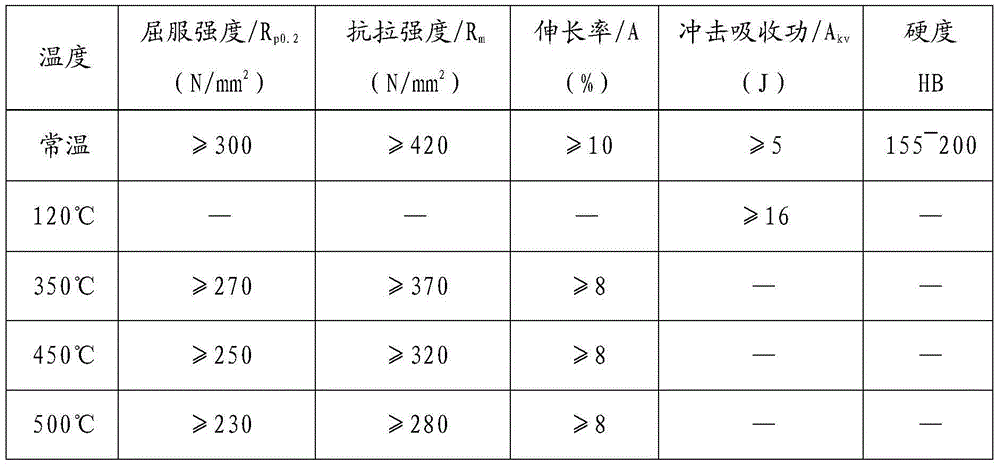

High-temperature-resistant silicon molybdenum ferrite nodular cast iron for steam turbine and preparation technology therefor

InactiveCN104911461AIncrease the brittle-ductile transition temperatureIncrease the number ofIntermediate frequencyFerrosilicon

The invention discloses high-temperature-resistant silicon molybdenum ferrite nodular cast iron for a steam turbine and a preparation technology therefor. The nodular cast iron comprises components: 3.0-3.5% of C, 2.8-3.2% of Si, less than 0.2% of Mn, less than 0.040% of P, less than 0.015% of S, 0.5-0.8% of Mo, less than 0.010% of Re, 0.040-0.055% of Mg, and 0.004-0.007% of Sb, the balance being iron and residual elements. The preparation technology comprises furnace charge matching; intermediate frequency induction furnace fusing; spheroidizing and addition of first inoculation ferrosilicon; control of contents of elements; pouring into a pulling runner box for secondary inoculation; casting moulding. The obtained nodular cast iron has good combination properties and a low cost, the nodularity reaches more than 80% of the nodularity prescribed by GB / T9441-2009 nodular cast iron metallographic examination, the ferrite amount is more than 90%, and normal temperature and high temperature mechanical properties meet production requirements.

Owner:上海宏钢电站设备铸锻有限公司

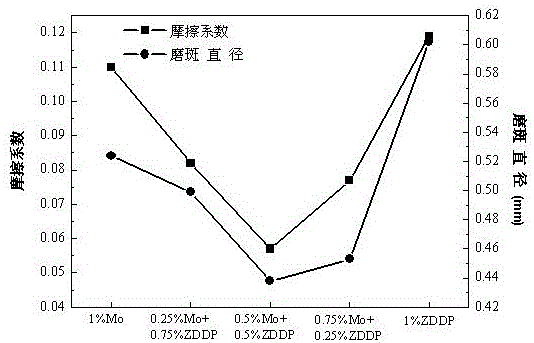

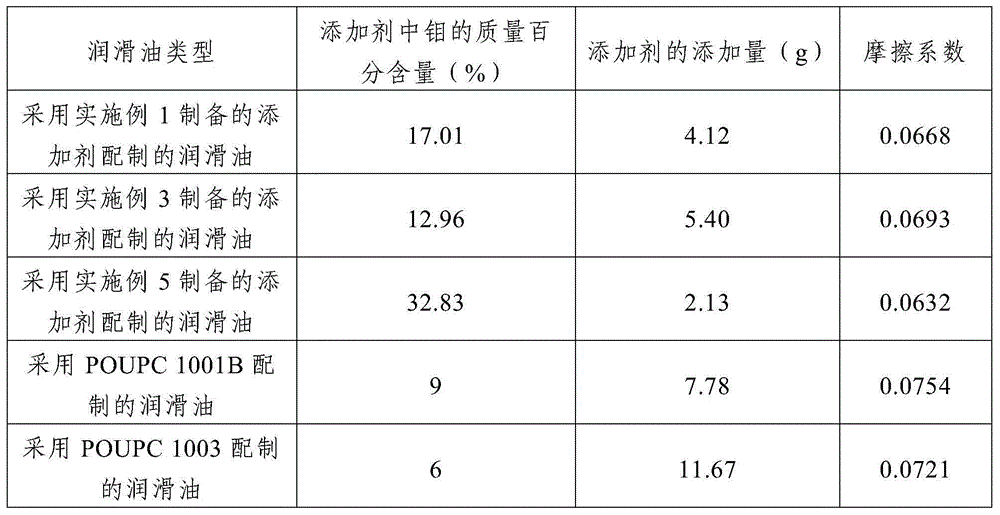

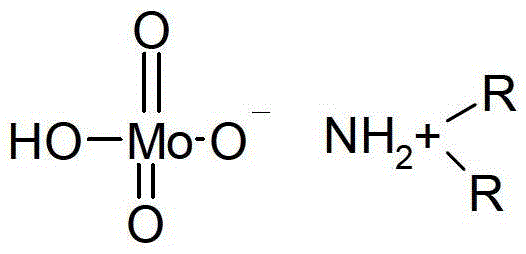

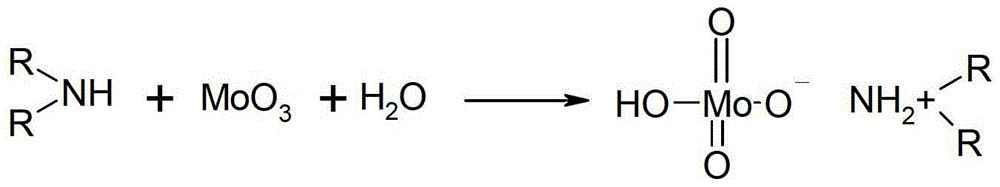

Preparation method of molybdenum-sulfur complex lubricating oil additive with high molybdenum content

The invention discloses a preparation method of a molybdenum-sulfur complex lubricating oil additive with high molybdenum content. The preparation method comprises the following steps: I, preparing a mixed liquid A from a hexavalent molybdenum compound, a sulfur-containing compound and distilled water, and then adjusting a pH value; II, adding dialkyl amine into the mixed liquid A which is subjected to pH value adjustment, then stirring, and then adding a phase transfer catalyst to obtain a mixed liquid B; III, under the protection of a nitrogen atmosphere, dropwise adding carbon disulfide into the mixed liquid B to obtain a mixed liquid C; and IV, standing the mixed liquid C till the mixed liquid C is layered, removing a water phase, washing an organic phase by virtue of an alkaline solution and an organic solvent, then distilling, and drying to obtain the high-molybdenum-content molybdenum-sulfur complex lubricating oil additive of which the mass percentage content of molybdenum is not less than 10%. The preparation method disclosed by the invention is simple in preparation process, and is favorable for industrial production; and the prepared molybdenum-sulfur complex lubricating oil additive has relatively high molybdenum content and good oil solubility, and after the additive is added into lubricating oil, the anti-wear and friction reduction properties of the lubricating oil can be greatly improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

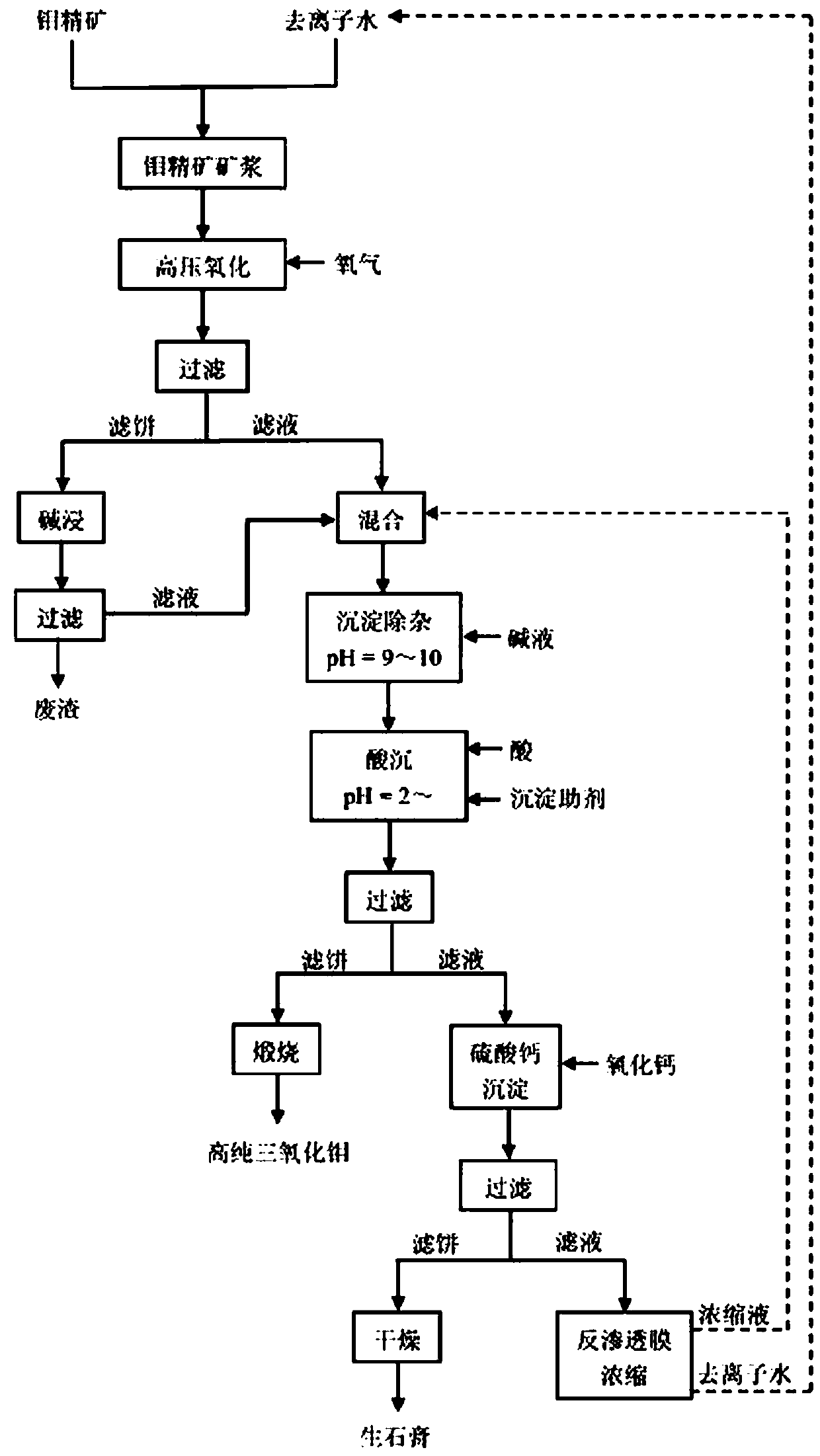

Method for preparing high-purity molybdenum trioxide from molybdenum concentrate through hydrometallurgy

ActiveCN107585789AHigh molybdenum contentAvoid pollutionMolybdenum oxides/hydroxidesMolybdateHydrometallurgy

The invention provides a method for preparing high-purity molybdenum trioxide from molybdenum concentrate through hydrometallurgy. The method comprises steps as follows: the molybdenum concentrate anddeionized water are mixed uniformly, and molybdenum concentrate pulp is prepared; the molybdenum concentrate pulp is subjected to a high-pressure oxygenolysis reaction, the reacted pulp is filtered;an obtained filter cake is subjected to alkaline leaching, filtered and washed, and a molybdate solution and waste residues are obtained; obtained filtrate and the molybdate solution are mixed, alkaliis added to adjust the pH, and the mixture is precipitated for impurity removal; the pH of a solution obtained after filtration of precipitates is adjusted to be neutral, a precipitation aid is addedand mixed sufficiently, and sulfuric acid is continuously added for pH adjustment, and acid settlement is performed; a material subjected to acid settlement is filtered again, a filter cake is calcined, and the high-purity molybdenum trioxide is obtained. The molybdenum content of the high-purity molybdenum trioxide obtained with the method can reach 66% or above, the total recovery rate of molybdenum can reach 98% or above, and meanwhile, raw gypsum products can be produced. The method is a production process which cannot cause environmental pollution, adopts a simple technological process and is used for preparing the high-purity molybdenum trioxide.

Owner:HENAN UNIV OF SCI & TECH

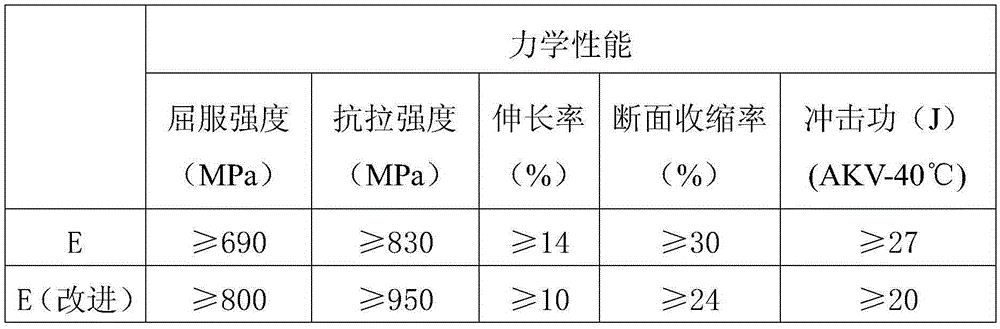

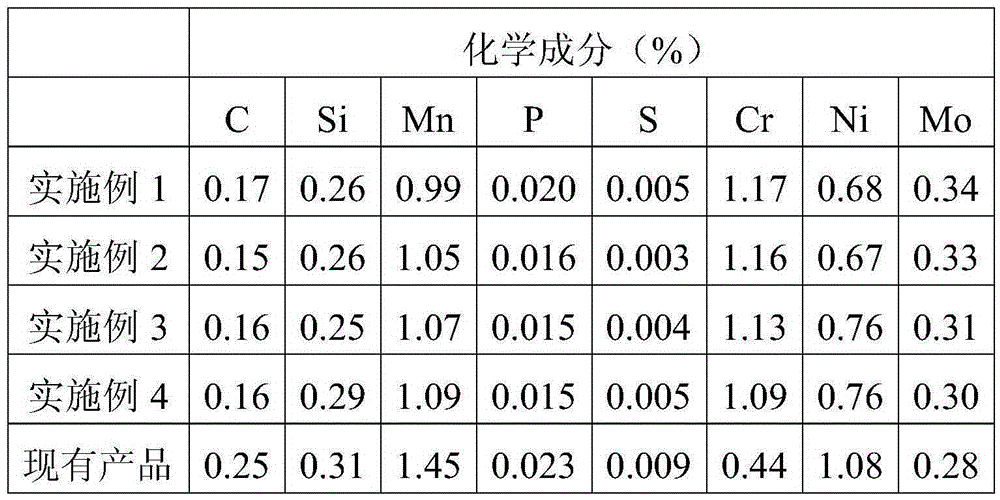

High-strength high-tenacity alloy cast steel material used for draw gears of railway vehicles

The invention discloses a high-strength high-tenacity alloy cast steel material used for draw gears of railway vehicles. The alloy caste steel material is composed of, by weight, 0.14-0.20 part of C, 0.20-0.40 part of Si, 0.90-1.20 parts of Mn, 1.00-1.20 parts of Cr, 0.60-0.90 part of Ni, 0.20-0.40 parts of Mo, 0-0.030 part of S, 0-0.030 part of P and the balance Fe and inevitable impurities. According to the alloy caste steel material, the yield strength is equal to or larger than 800 MPa, the tensile strength is equal to or larger than 920 MPa, the elongation is equal to or larger than 14%, the percentage reduction of area is equal to or larger than 40%, and the ballistic work at the temperature of-40 DEG C is equal to or larger than 35 J.

Owner:CRRC YANGTZE CO LTD

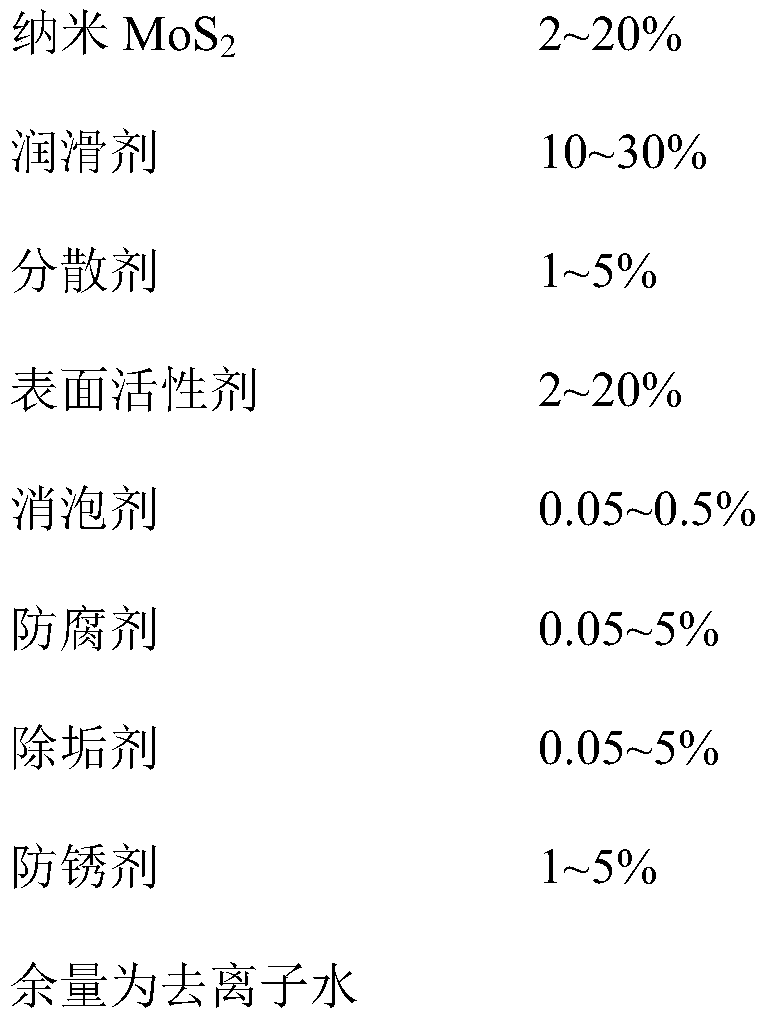

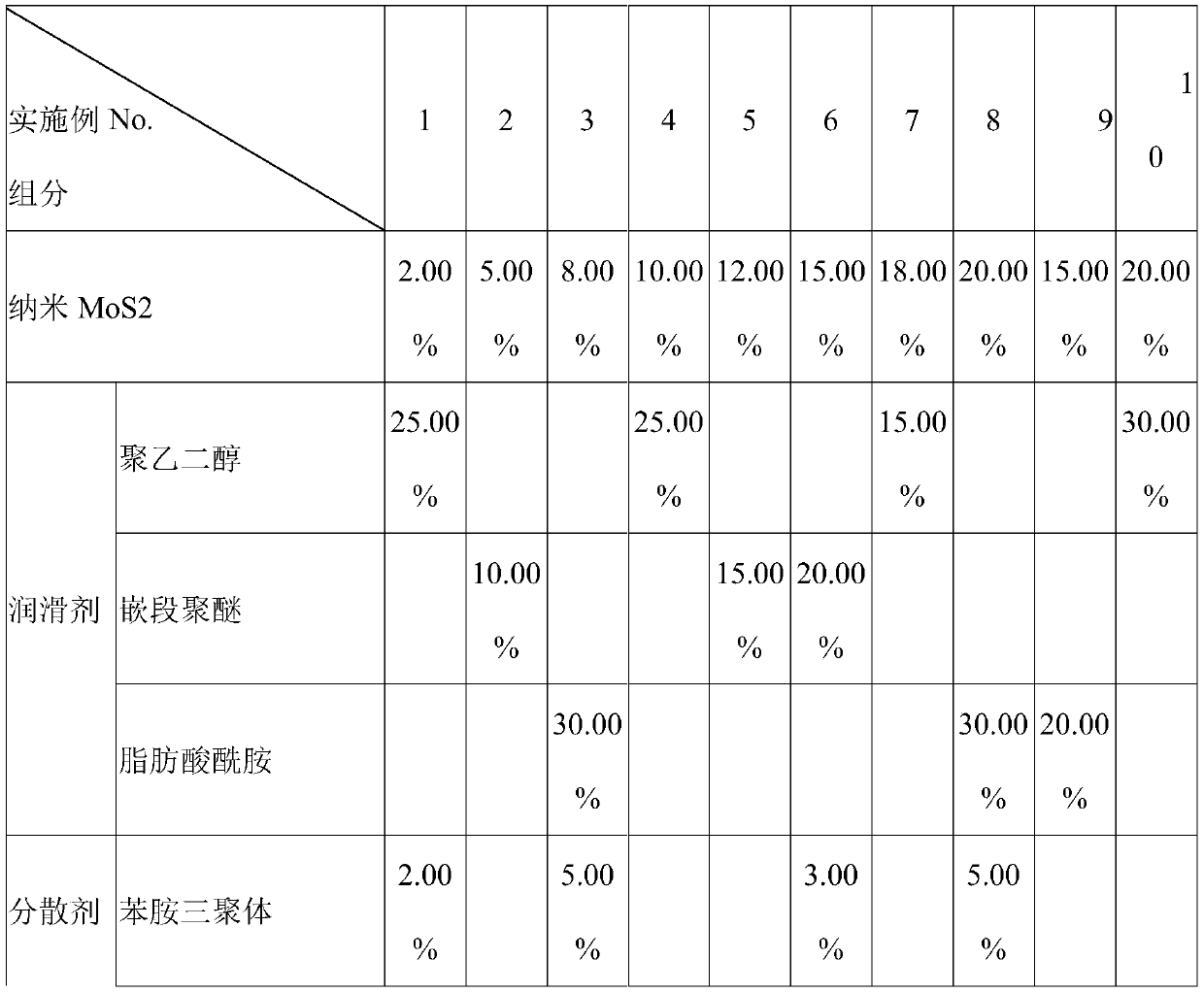

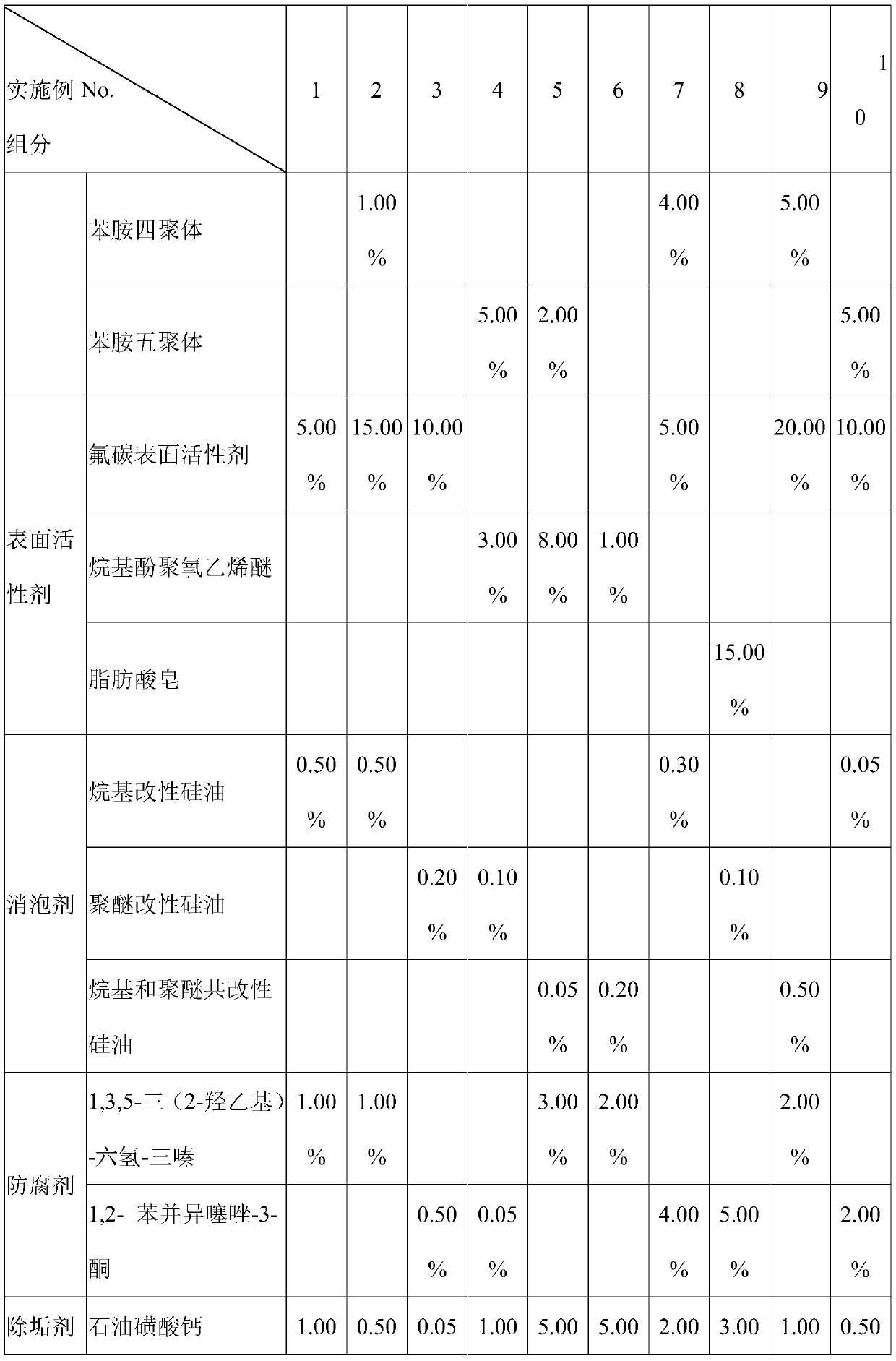

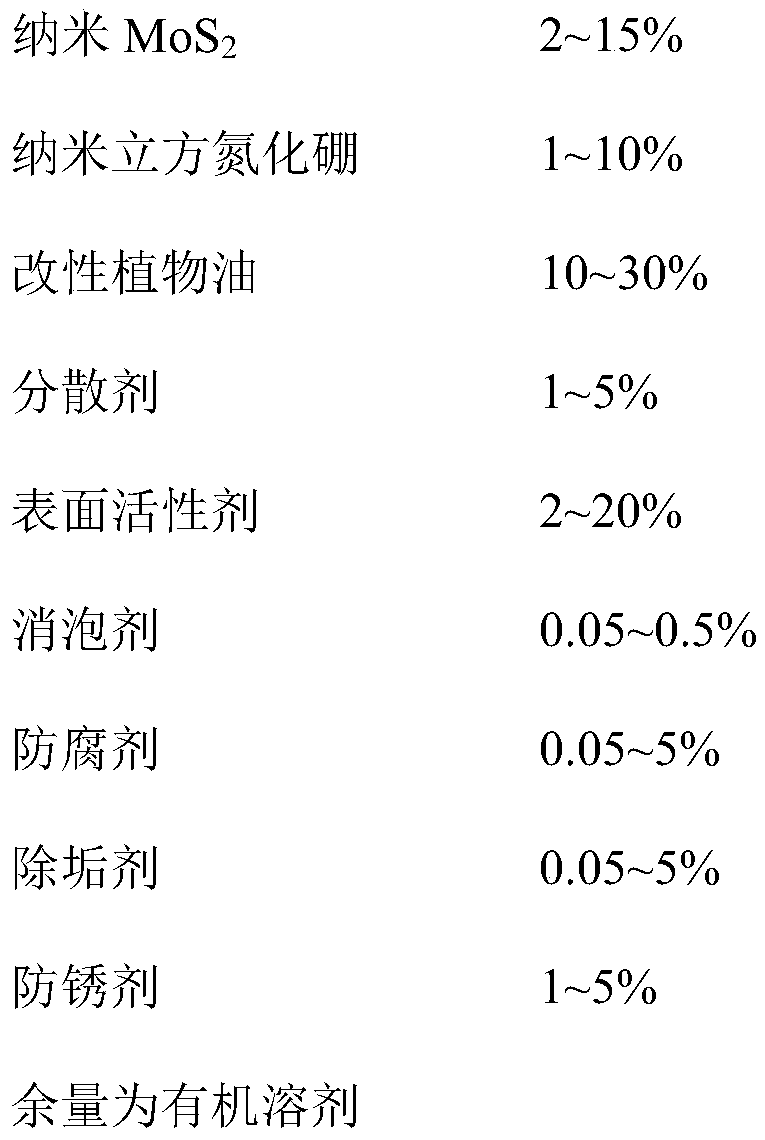

Water-soluble minimum quantity lubricating liquid containing MoS2

The invention discloses a water-soluble minimum quantity lubricating liquid containing MoS2. The lubricating liquid comprises the following components in percentage by weight: 2-20% of nano MoS2, 10-30% of a lubricant, 1-5% of a dispersing agent, 2-20% of a surfactant, 0.05-0.5% of a defoaming agent, 0.05-5% of a preservative, 0.05-5% of a descaling agent, 1-5% of an antirust agent and the balanceof deionized water, wherein the sum of the weight percentages of the nano MoS2 and the nano cubic boron nitride is 3-30%; the particle size distribution of the nano MoS2 is 20-150nm, the average particle size is 50-80nm, and the specific surface area is 50-150 m<2> / g; the particle size distribution of the nano cubic boron nitride is 50-200 nm, and the average particle size is 70-80 nm. The lubricating liquid has the characteristics that molybdenum disulfide is small in particle size and uniform in distribution, precipitation, blockage and other faults are not likely to be formed, fog drops can be efficiently formed, the molybdenum content in the lubricating liquid is high, and the lubricating effect is good.

Owner:苏州福瑞斯德新材料科技有限公司

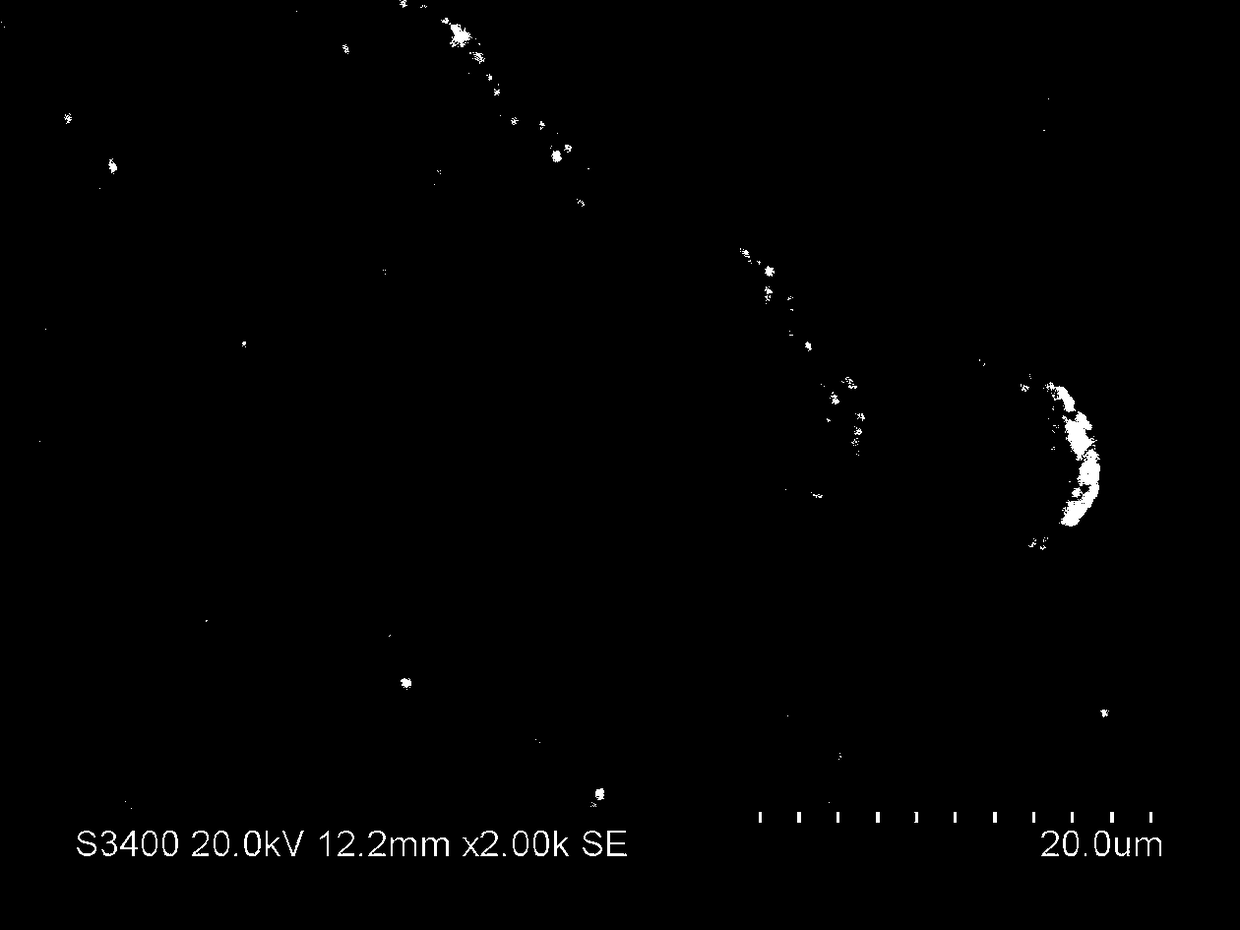

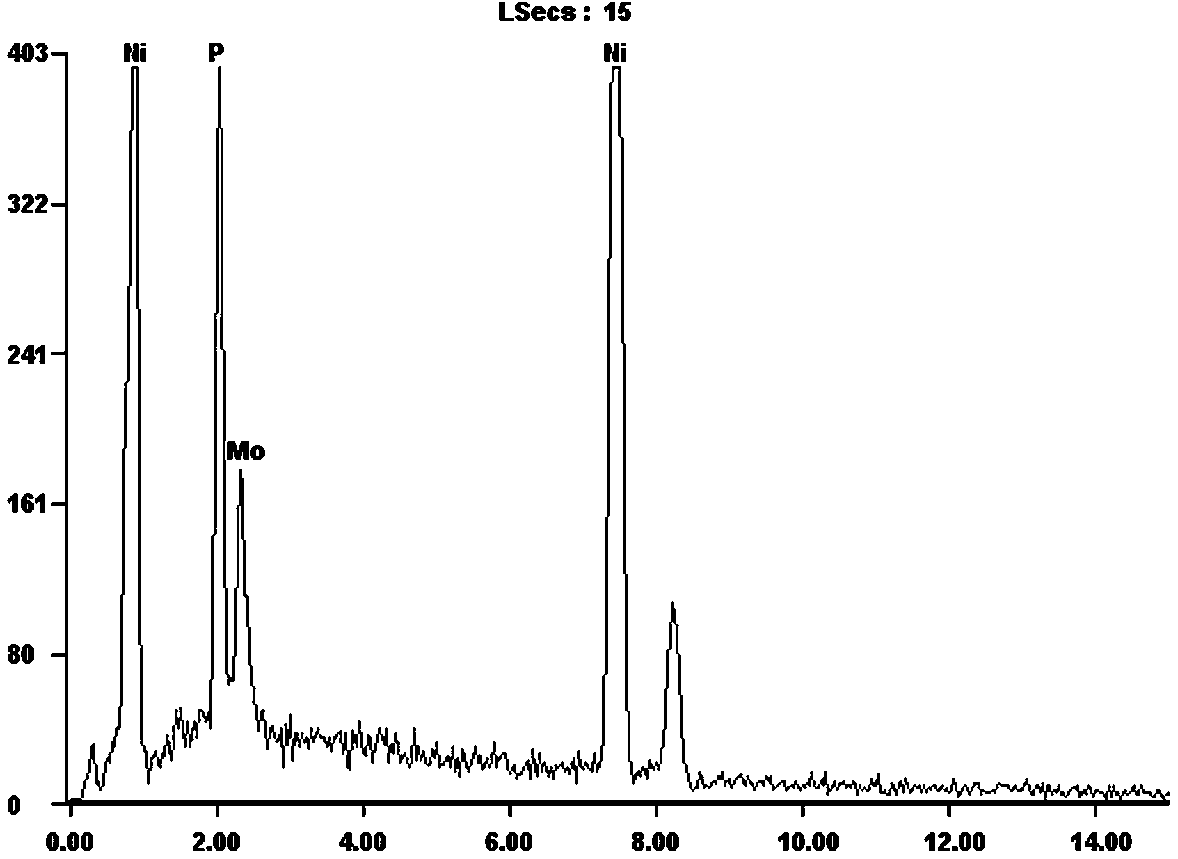

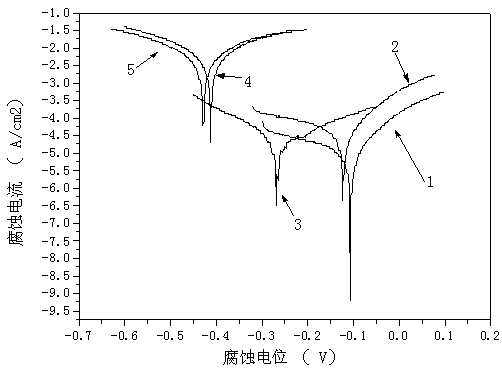

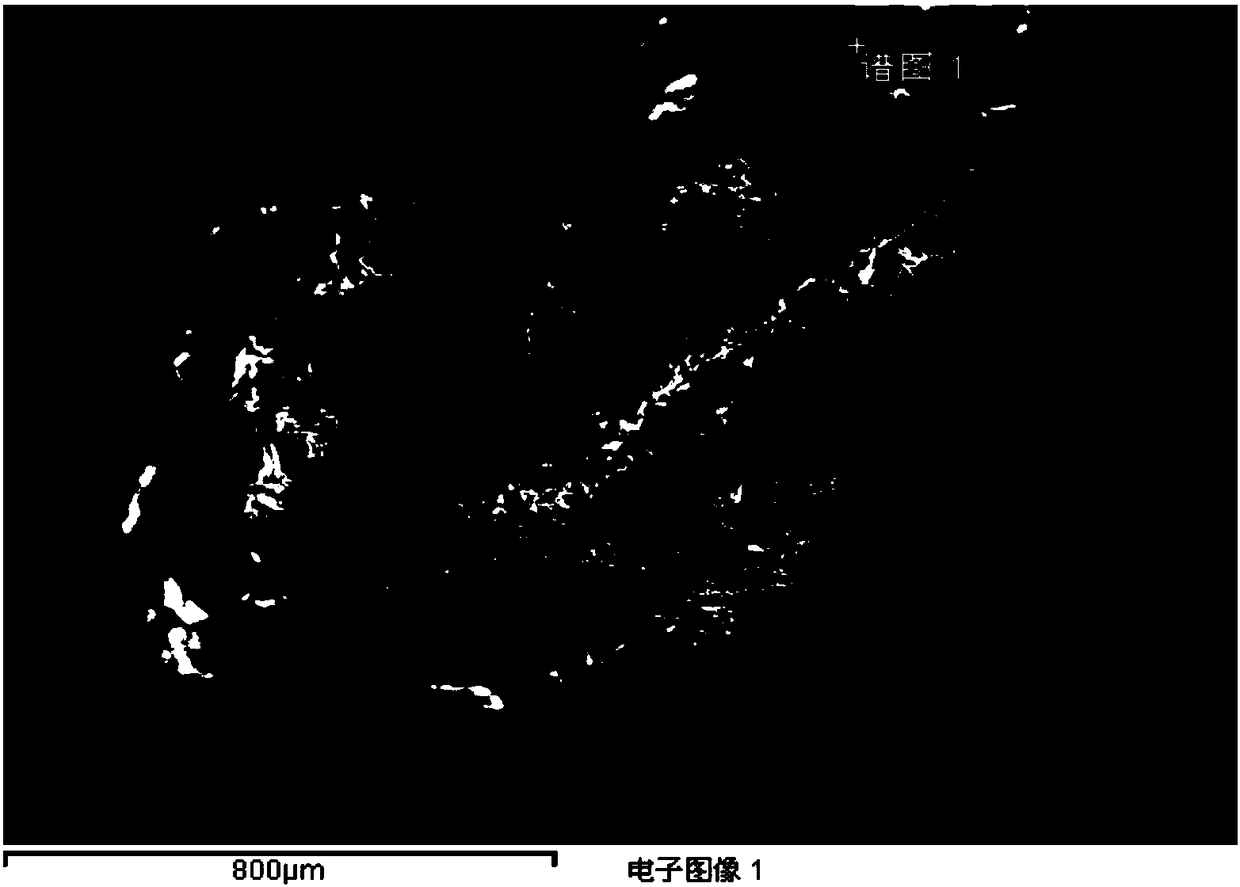

Chemical nickel-plating-molybdenum-phosphorus alloy solution for preparing high molybdenum and high phosphorus coating

InactiveCN108277486AImprove thermal stabilityStop the spreadLiquid/solution decomposition chemical coatingSodium acetatePropanoic acid

The invention discloses a chemical nickel-plating-molybdenum-phosphorus alloy solution for preparing a high molybdenum and high phosphorus coating. The problem that an existing chemical nickel-plating-molybdenum-phosphorus alloy solution cannot simultaneously prepare a coating with high Mo and P contents is solved. The chemical nickel-plating-molybdenum-phosphorus alloy solution comprises nickel sulfate, sodium hypophosphite, sodium molybdate, sodium citrate, propionic acid, sodium tetraborate, sodium acetate and saccharin; and the PH is 8.0-8.5, and the plating solution temperature is 75-80 DEG C. The deposition rate of the coating is required to be controlled at 5-8 microns per hour. The results of scanning electron microscopy showed that the contents of molybdenum and phosphorus are higher in the coating prepared by the chemical nickel-plating-molybdenum-phosphorus alloy solution. The chemical nickel-plating-molybdenum-phosphorus alloy solution can be widely used in the field whichboth the thermal stability and amorphous structures are required and a chemical nickel-plating-molybdenum-phosphorus coating is used as a diffusion impervious layer in electron industries.

Owner:SHENYANG POLYTECHNIC UNIV

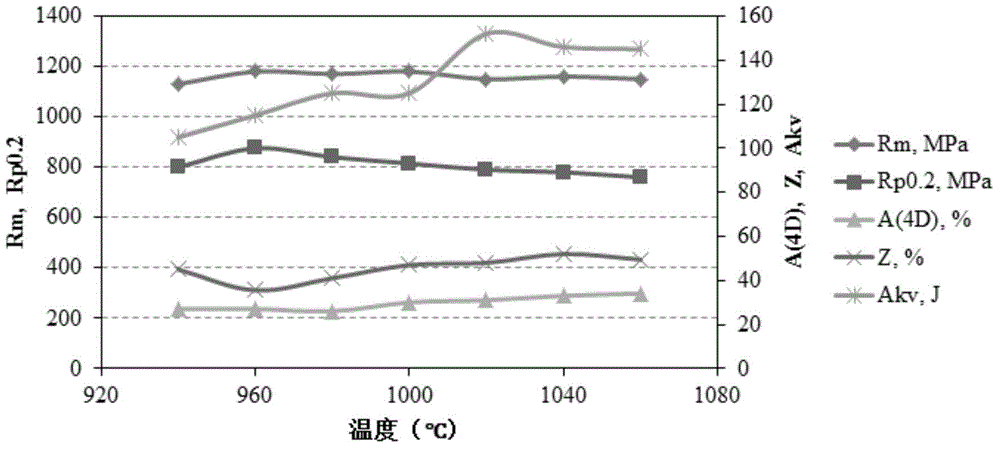

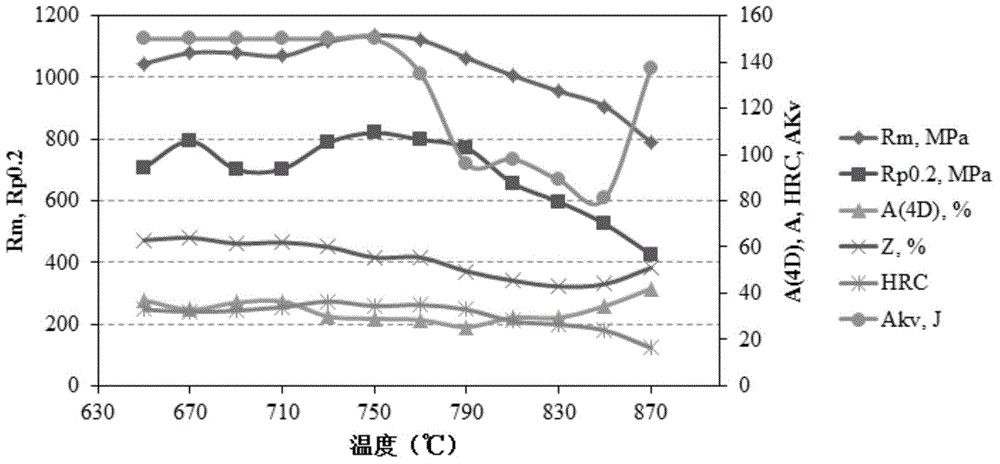

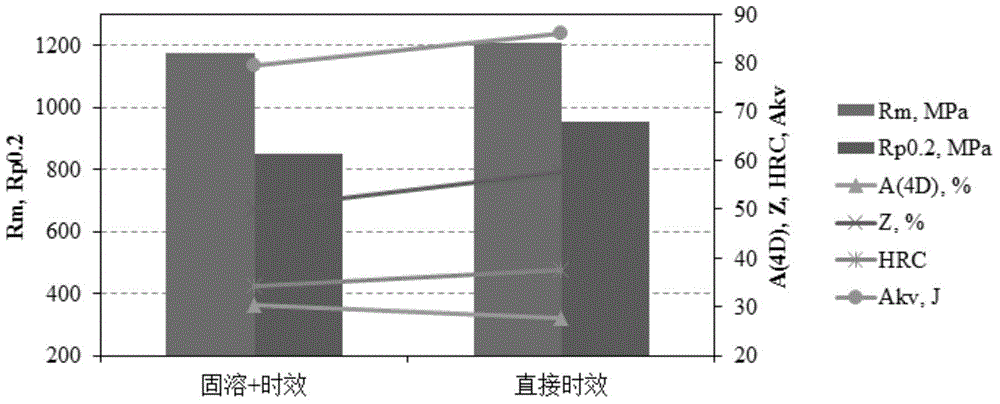

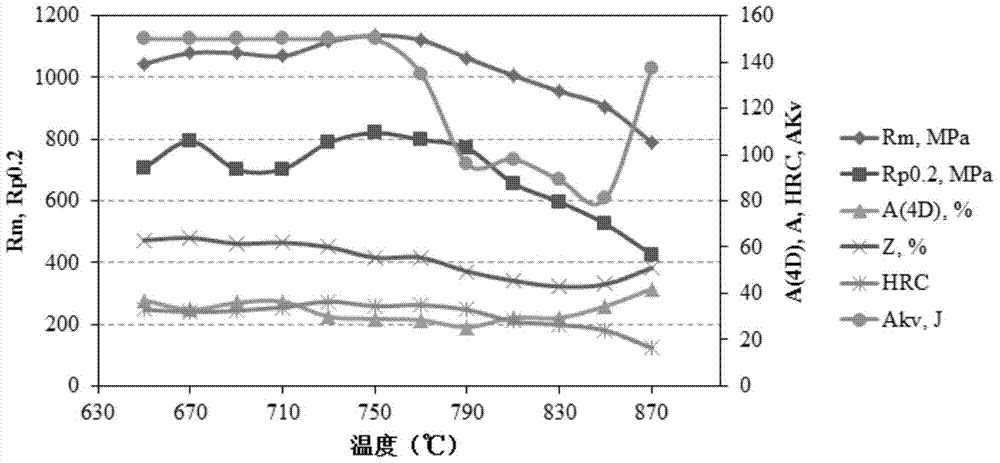

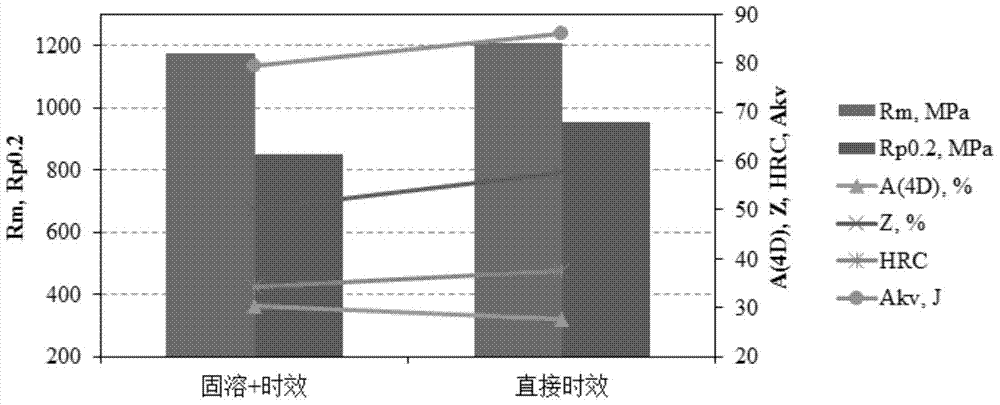

Ageing strengthening type iron nickel base corrosion resistant alloy easily processed into thick-walled seamless tube

ActiveCN105483494AHigh molybdenum contentHigh chromium and molybdenum contentCorrosion resistant alloyHot working

The invention relates to an ageing strengthening type iron nickel base corrosion resistant alloy easily processed into a thick-walled seamless tube. The alloy comprises the following components by weight percent: 40-45% of Ni, 20-25% of Cr, 2-5% of Mo, 1-3% of Cu, 1.5-3% of Ti, 0.1-0.5% of Al, 0.01-0.5% of V, 0.001-0.05% of Zr, 0.001-0.005% of B, 0.005-0.05% of Mg, 1.0% or less of Nb, 0.05% or less of C, 0.5% or less of Si and 0.5% or less of Mn, with the balance being Fe. According to the alloy, the hot working plasticity of the alloy can be improved, the heat checking tendency during the hot working process is reduced, the strength is high, the toughness and plasticity are good, the corrosion resistance is good, and the comprehensive performance is good.

Owner:CHONGQING MATERIALS RES INST

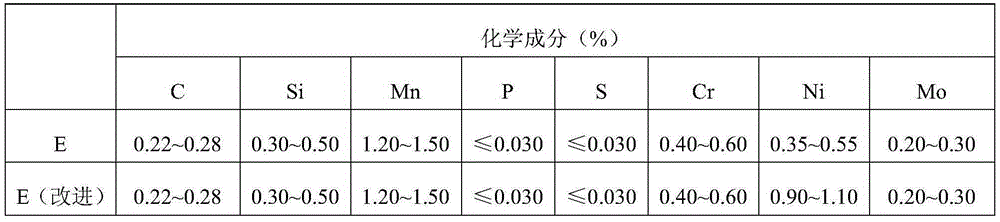

High-strength steel submerged-arc stranded wire and welding method thereof

InactiveCN110614458AImprove toughnessBest Match Chemical CompositionArc welding apparatusWelding/cutting media/materialsManganeseWeld seam

The invention discloses a high-strength steel submerged-arc stranded wire. The high-strength steel submerged-arc stranded wire comprises the following components of, by mass percentage, 0.08-1.2% of carbon, 0.4-0.8% of manganese, 0.05-0.1% of copper, 0.1-0.2% of nickel, 0.1-0.2% of zirconium, 0.11-0.18% of silicon, 0.02-0.08% of molybdenum, 0.01-0.02% of titanium, 0.2-0.4% of boron, less than 0.01% of phosphorus, not larger than 0.005% of sulfur and the balance iron and inevitable impurities. The invention discloses a welding method of the high-strength steel submerged-arc stranded wire. The welding method comprises the steps that a steel plate to be welded is pretreated, then the inner side welding and the outer side welding are carried out, and then heating, heat preservation and air cooling are carried out. A welding seam formed by welding has the beneficial effects of being good in low-temperature impact toughness, low in yield ratio, high in strength, attractive in forming and thelike; and moreover, the welding spatter is small, and the welding process performance is excellent.

Owner:河北联之捷焊业科技有限公司

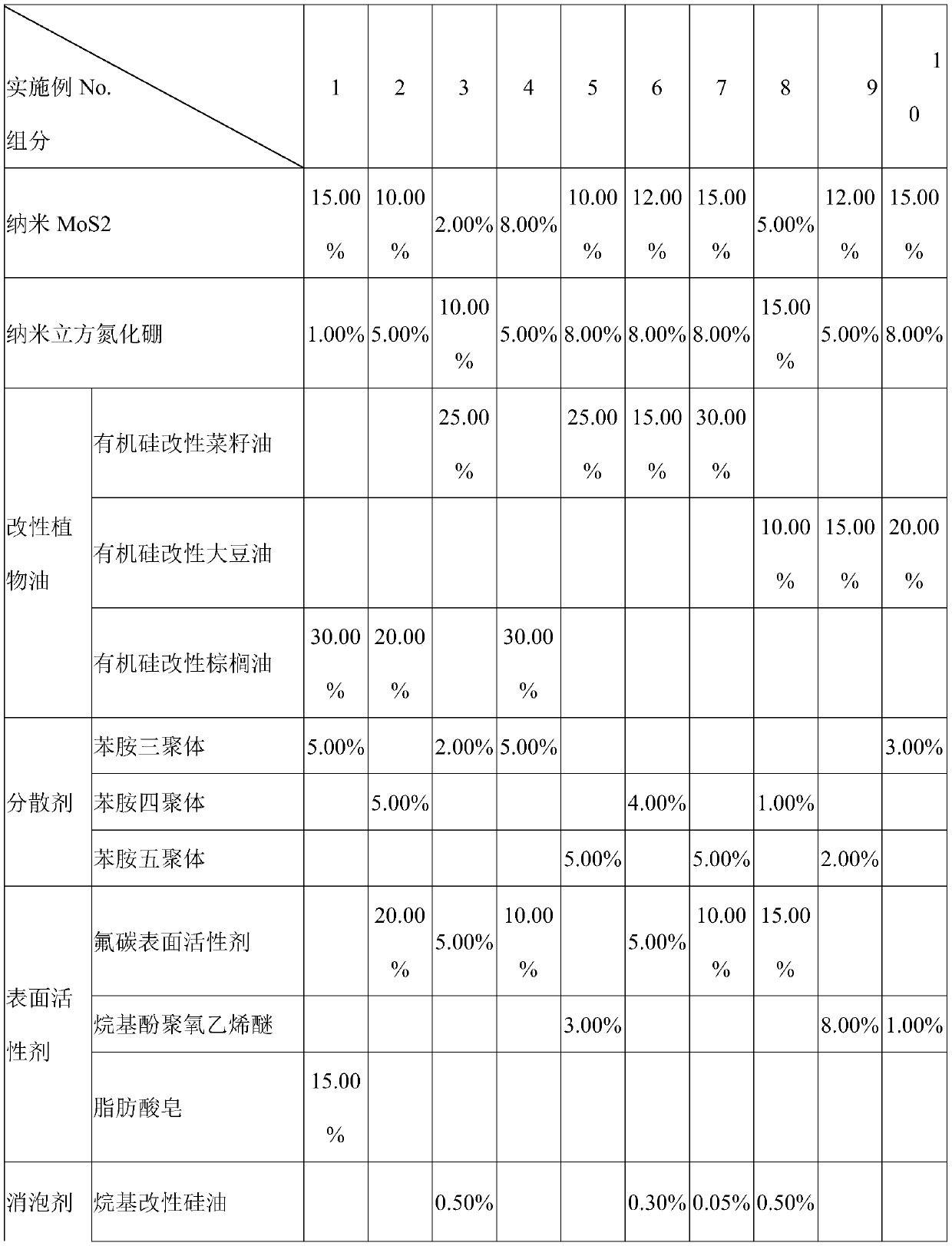

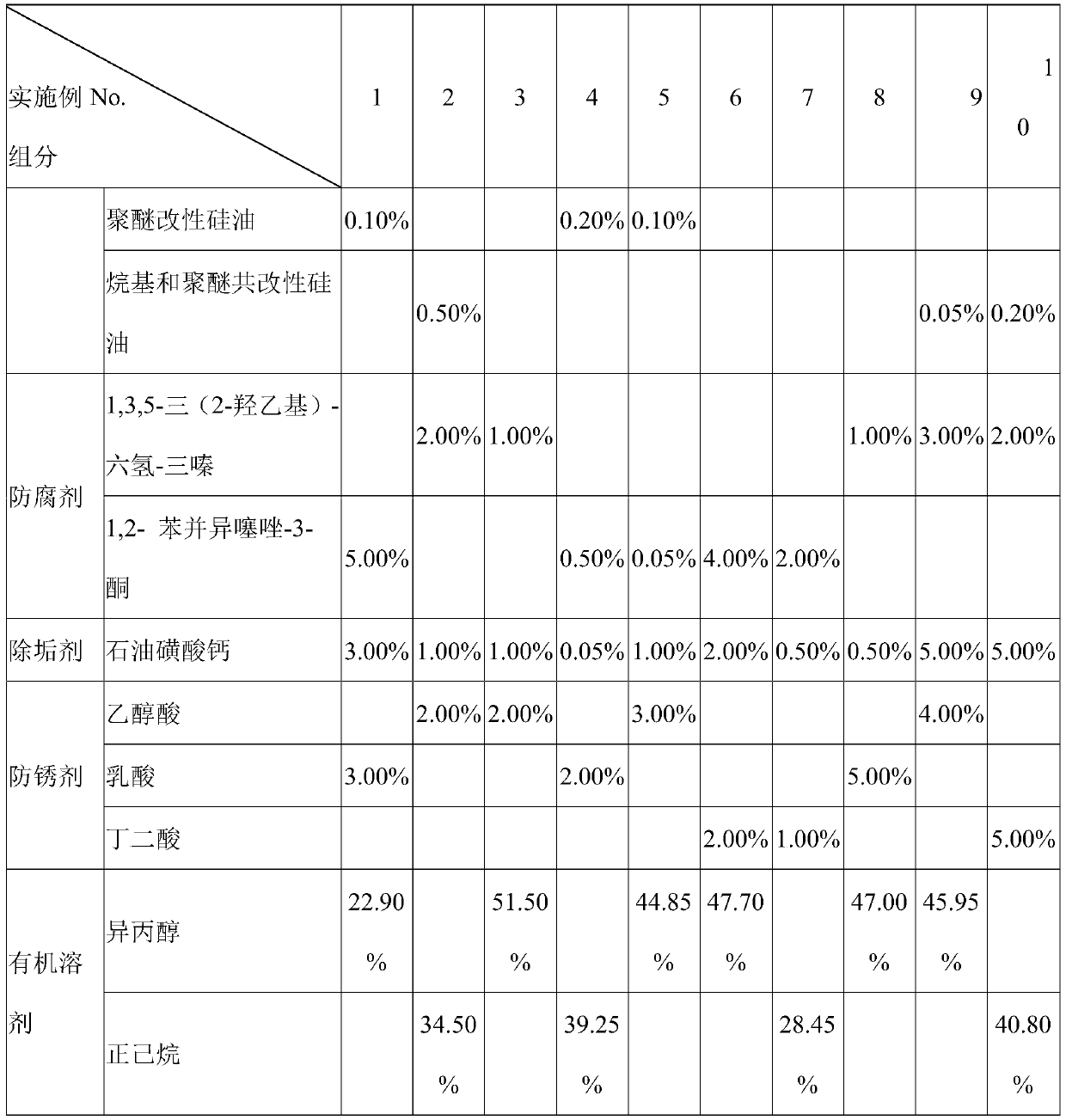

Non-water-soluble minimal quantity lubricating liquid containing MoS2

ActiveCN111019745ASmall particle sizeEvenly distributedLubricant compositionVegetable oilHexagonal boron nitride

The invention discloses a non-water-soluble minimal quantity lubricating liquid containing MoS2. The lubricating liquid comprises 2-15 wt% of nanometer molybdenum disulfide, 1-10 wt% of nanometer cubic boron nitride, 10-30 wt% of modified vegetable oil, 1-5 wt% of a dispersing agent, 2-20 wt% of a surfactant, 0.05-0.5 wt% of a defoaming agent, 0.05-5 wt% of a preservative, 0.05-5 wt% of a descaling agent, 1-5 wt% of an antirust agent, and the balance of an organic solvent. The molybdenum content in the lubricating liquid is high, and the hexagonal boron nitride and the nano-MoS2 particles canform a synergistic effect to achieve the good lubricating effect; and the degradable modified vegetable oil is used for replacing mineral oil, so the service life is long, and environmental protectionis achieved.

Owner:苏州福瑞斯德新材料科技有限公司

Foamed nickel-molybdenum alloy doped with carbon quantum dots and preparation method

InactiveCN112853394AImprove coating qualityImprove hydrogen evolution performanceElectrolytic coatingsElectrodesAlloyHydrogen evolution

The invention discloses a carbon quantum dot-doped foamed nickel-molybdenum alloy and a preparation method thereof. The method comprises the following steps: (1) preparing a part of electroplate liquid for electrodeposition of the foamed nickel-molybdenum alloy according to a known formula; (2) preparing a glucose carbon quantum dot solution by adopting a glucose hydrothermal method; (3) freezing and drying glucose carbon quantum dots into a carbon quantum dot solid, grinding the carbon quantum dot solid into carbon quantum dot powder, and adding the carbon quantum dot powder into the solution obtained in the step (1) to obtain an electro-deposition solution; (4) using nickel and molybdenum as anodes, foamed nickel as a cathode, placing the anodes and the cathodes in the electro-deposition solution, and performing electro-deposition in a single-cathode and double-anode mode; and (5) heating the solution to 35-55 DEG C, and carrying out electro-deposition under the condition that the apparent cathode current density is 110-130 mA / cm<2>. The foamed nickel-molybdenum alloy doped with the carbon quantum dots prepared by the method has the beneficial effects of good plating quality, good hydrogen evolution effect, high stability and high molybdenum content.

Owner:HUNAN UNIV

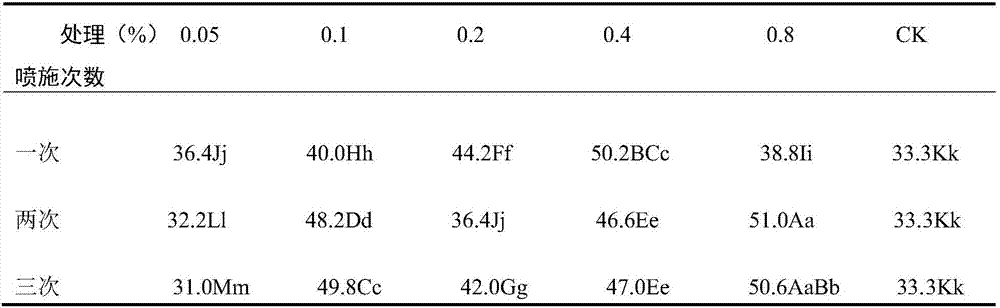

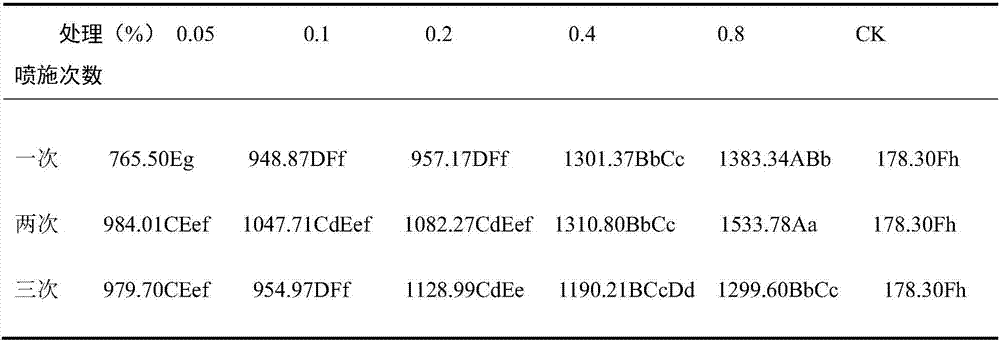

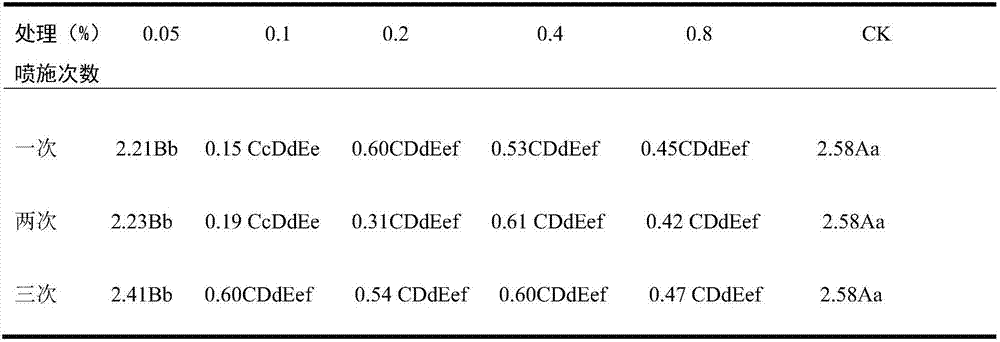

Oilseed rape planting method

InactiveCN106034698AImprove germination rateHuge market potentialPlant cultivationCultivating equipmentsPathogenic microorganismMonopotassium phosphate

The invention discloses a method for planting rapeseed, adding an aqueous solution containing sodium selenite and the concentration of the solution during germination, not only can selenium-enriched rapeseeds be selected by drying, but also the accumulation of selenium in rapeseeds can be increased. And can kill some pathogenic microorganisms wherein, described thinning and topdressing are beneficial to the growth that improves rapeseed seedling, and can improve the output of field, described rapeseed flowering period molybdenum fertilizer, potassium dihydrogen phosphate, boron fertilizer, water are mixed evenly Spraying the rape leaves can not only prevent the rape leaves from turning yellow and the flower buds fall off, but also increase the molybdenum content of the rapeseed grains. The rapeseed in the early flowering stage can prevent and control sclerotinia and aphids with trimethazine and aphids. The rapeseed planted by this planting method has the advantages of high germination rate and high yield, and has huge market potential and broad prospects.

Owner:HEFEI HUIGU AGRI TECH CO LTD

Vacuum grade aluminum-molybdenum-silicon alloy

The invention relates to an interalloy for smelting. A vacuum aluminium-molybdenum-silicon alloy, is charactrized in that the alloy has close structure without slag inclusion and segregation, comprising, based on weight percentage, Mo of 40-63%, si of 4.0-5.0%, O of not more than 0.015%, H of not more than 0.002%, N of not more than 0.006%, C of not more than 0.06%, Fe of not more than 0.10%, and the residual is Al. The invention solves the technical problem that the non-vacuum aluminium -silicon alloy has segregation, slag inclusion, high content gas impurity without close structure, secondly solves the technical problem of low content of molybdenum in the alloy.

Owner:上海康臣特种金属材料有限公司

Special rich-molybdenum fertilizer for lilies and preparation method thereof

InactiveCN107056380AReduce dosageIncrease profitAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCuticlePotassium

The invention provides a special rich-molybdenum fertilizer for lilies. A foliage top-dressing leaf spray application mode is used. Nitrogen, phosphorus, potassium and molybdenum elements are prepared into a water solution according to a specific proportion; then, the water solution is sprayed onto the lily leafs in the growth process; the fertilizer passes through leaf cuticle membranes, reaches the skin cell plasma membranes through ectodesmata and enters the plant bodies. After the application of the fertilizer, the content of lead and cadmium in the lily bulbs can be obviously reduced; the lead content is reduced by 0.17 to 2.43 ug / g; the reduction rate is 6.59 to 94.19 percent; the cadmium content is reduced by 0.49 to 1.17 ug / g; the reduction rate is 26.63 to 63.59 percent; the positive effect on effectively controlling the heavy metal element content in the product is achieved. The preparation process is simple; the equipment investment is low; the application and the use are convenient; the fertilizer is suitable for large-scale popularization.

Owner:SOUTHWEST UNIV

Cultivation method for molybdenum-enriched corn

InactiveCN106069168APromote absorptionPromote growthBio-organic fraction processingWaste based fuelNutrient solutionNutrient content

The invention discloses a cultivation method for molybdenum-enriched corn, and belongs to the technical field of crop planting. The cultivation method for the molybdenum-enriched corn includes conventional steps of land selection and preparation, seed selecting, soaking and sowing, fertilization, field management and harvesting. In the seed soaking step, plump corn seeds free from disease and pest injuries are soaked in a molybdenum-enriched solution for 3-8 hours; fertilizer applied in the fertilization step refers to molybdenum fertilizer and compound fertilizer; according to the field management step, in the corn earing stage, a molybdenum-enriched nutrient solution is sprayed onto corn plants, and the molybdenum fertilizer is applied additionally. The molybdenum-enriched nutrient solution and the molybdenum fertilizer contain rich molybdenum, and accordingly, absorption of the corn plants is benefited; through seed soaking by the molybdenum-enriched nutrient solution and application of the molybdenum fertilizer, the content of molybdenum in the corn plants is increased effectively; through spraying of the molybdenum-enriched nutrient solution and additional application of the molybdenum fertilizer to the corn plants in the corn earing stage, the corn plants can absorb the microelement molybdenum better, growth of the corn plants is promoted, and yield and nutrition ingredients of the corn are increased.

Owner:陈国仁

Method for planting oilseed rape

InactiveCN106034707AImprove germination rateHuge market potentialPlant cultivationCultivating equipmentsPhosphatePotassium

The invention discloses a method for planting oilseed rape. According to the method, an aqueous solution containing sodium selenite is added during germination accleration, and the concentration of the solution is controlled, so that selenium-enriched oilseed rape seeds can be screened, the accumulation of selenium in seeds of rapeseeds can be increased, and a number of pathogenic micro-organisms in the seeds can be killed; thinning and topdressing are beneficial to improving growth of oilseed rape seedlings and increasing the field yield; molybdenum fertilizer, potassium dihydrogen phosphate, boron fertilizer and water are mixed and uniformly sprayed to the leaf surfaces of oilseed rape during the flowering phase of oilseed rape, so that yellow oilseed rape leaves and flower abscission can be prevented, and the content of molybdenum in the seeds of rapeseeds can be increased; chemicals for preventing powdery mildew and killing aphids are used during the initial flowering phase of the rape, so that sclerotinia sclerotiorum and the aphids can be prevented and controlled. Oilseed rape planted by adopting the method has the advantages of high germination rate and high yield, and has huge market potential and wide prospect.

Owner:ANHUI JINPEIYIN TECH

An oil-soluble non-sulfur phosphorus organic molybdenum compound, its preparation method and application

ActiveCN103319539BImprove antioxidant capacityImprove high temperature oxidation resistanceGroup 6/16 element organic compoundsAdditivesPhysical chemistryMolybdenum compounds

Owner:江苏现代节能科技发展有限公司

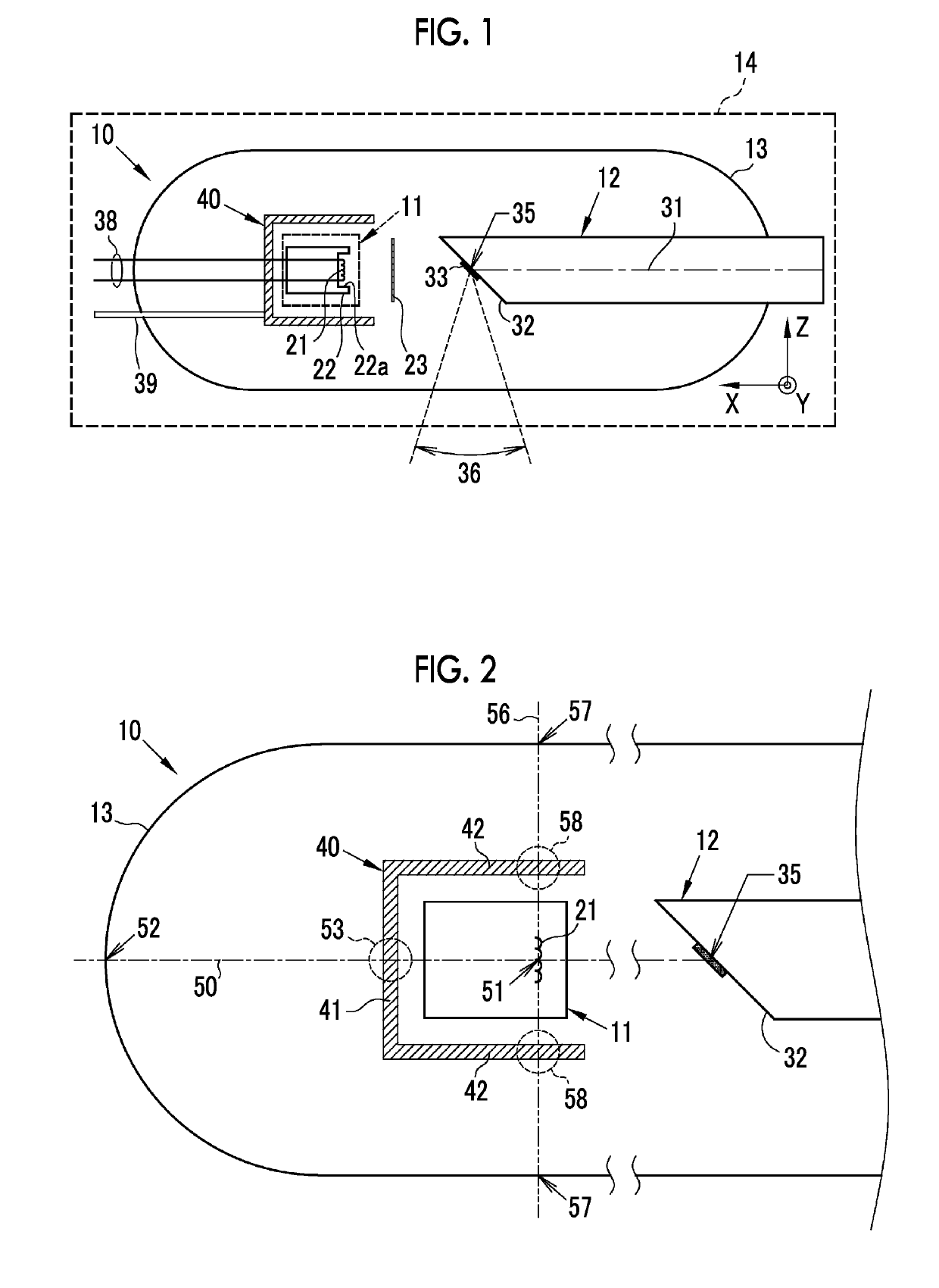

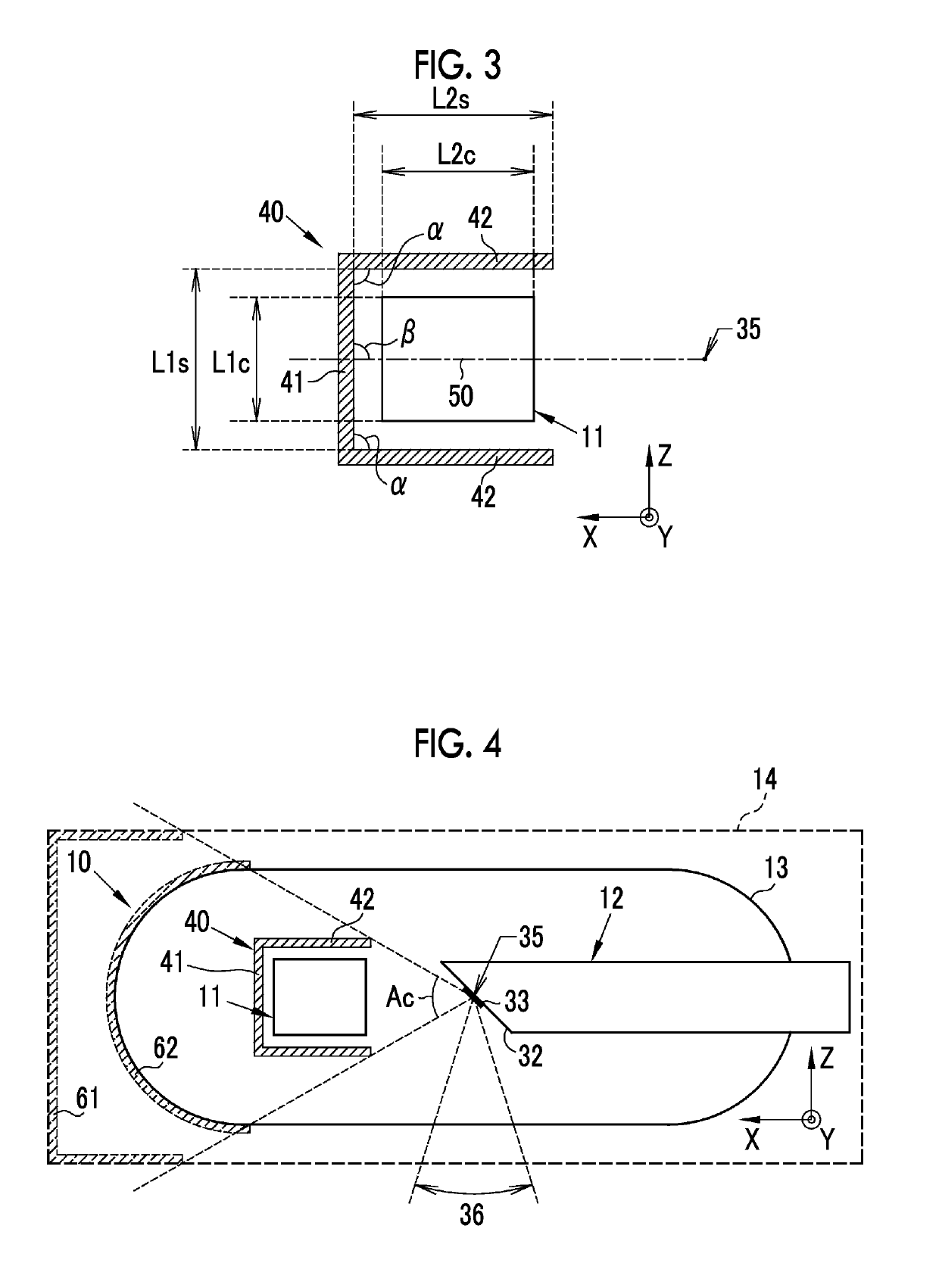

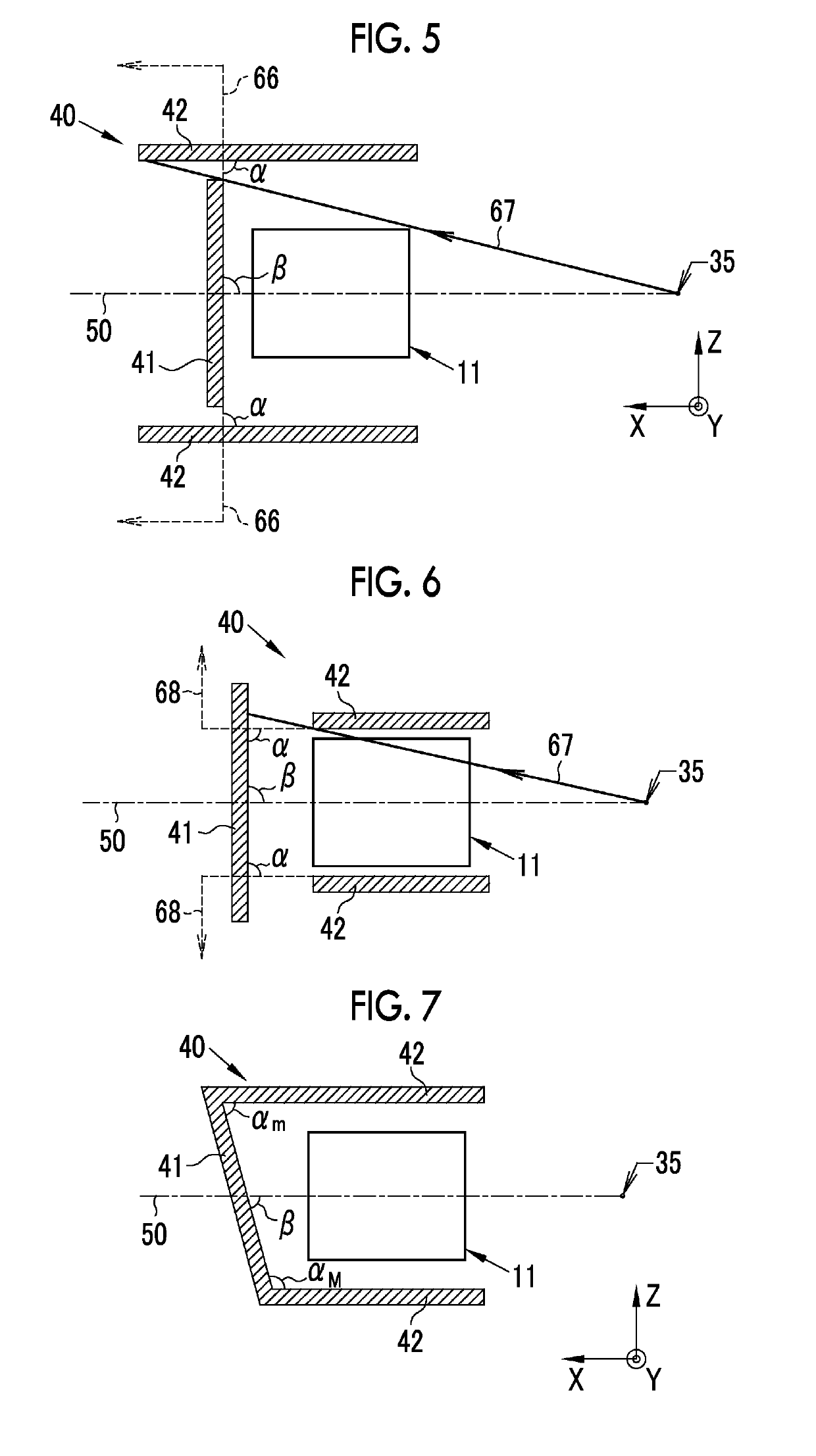

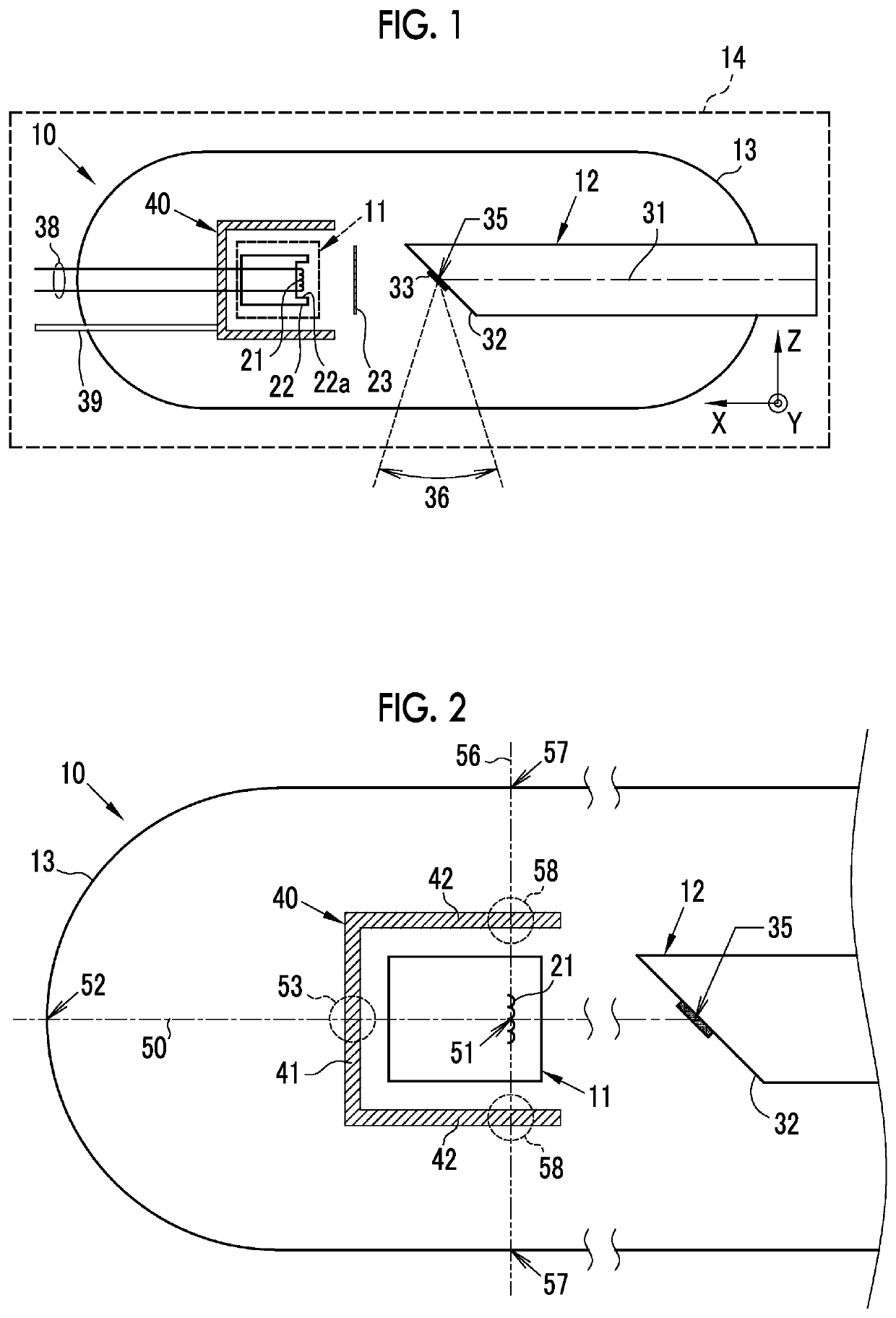

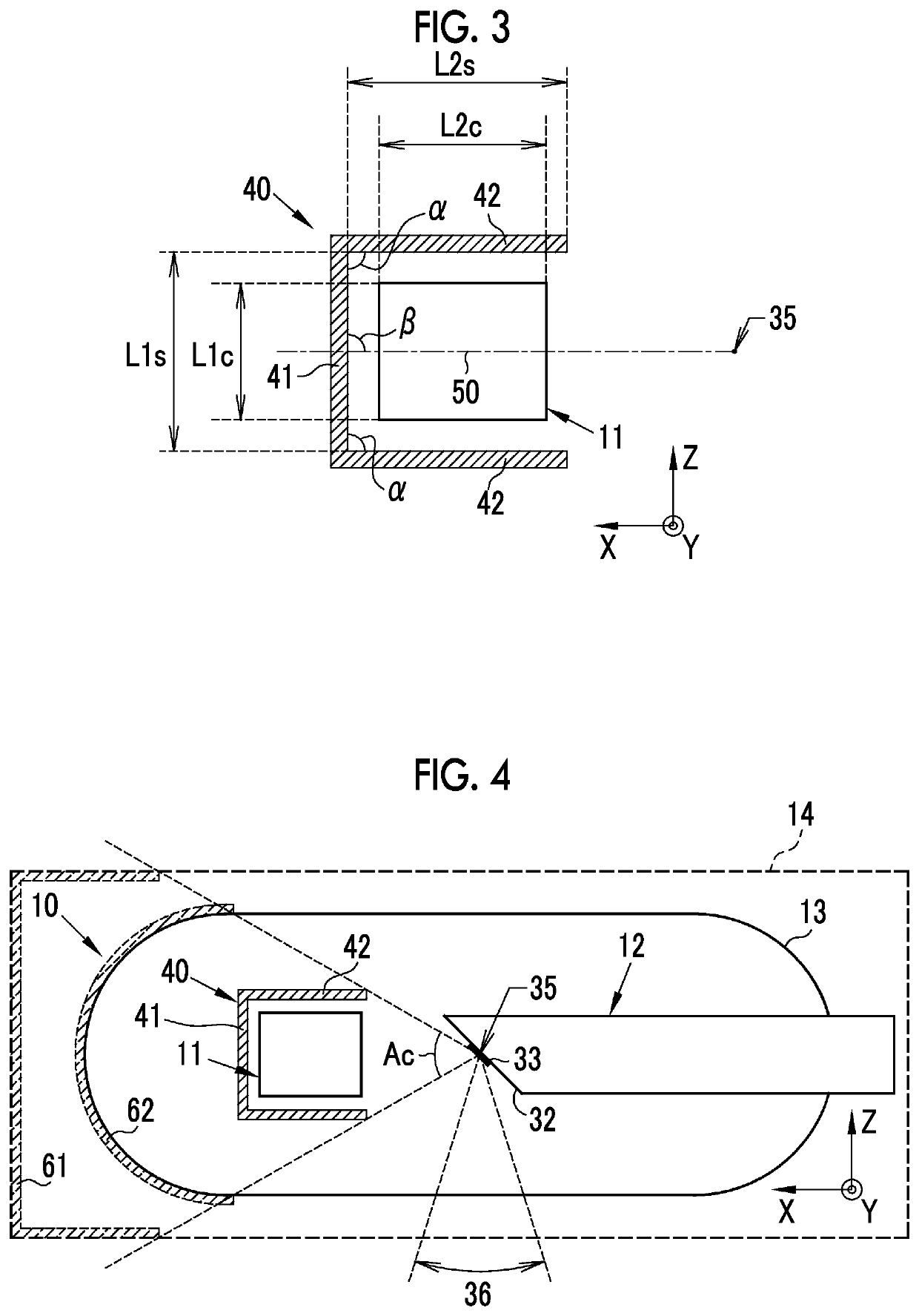

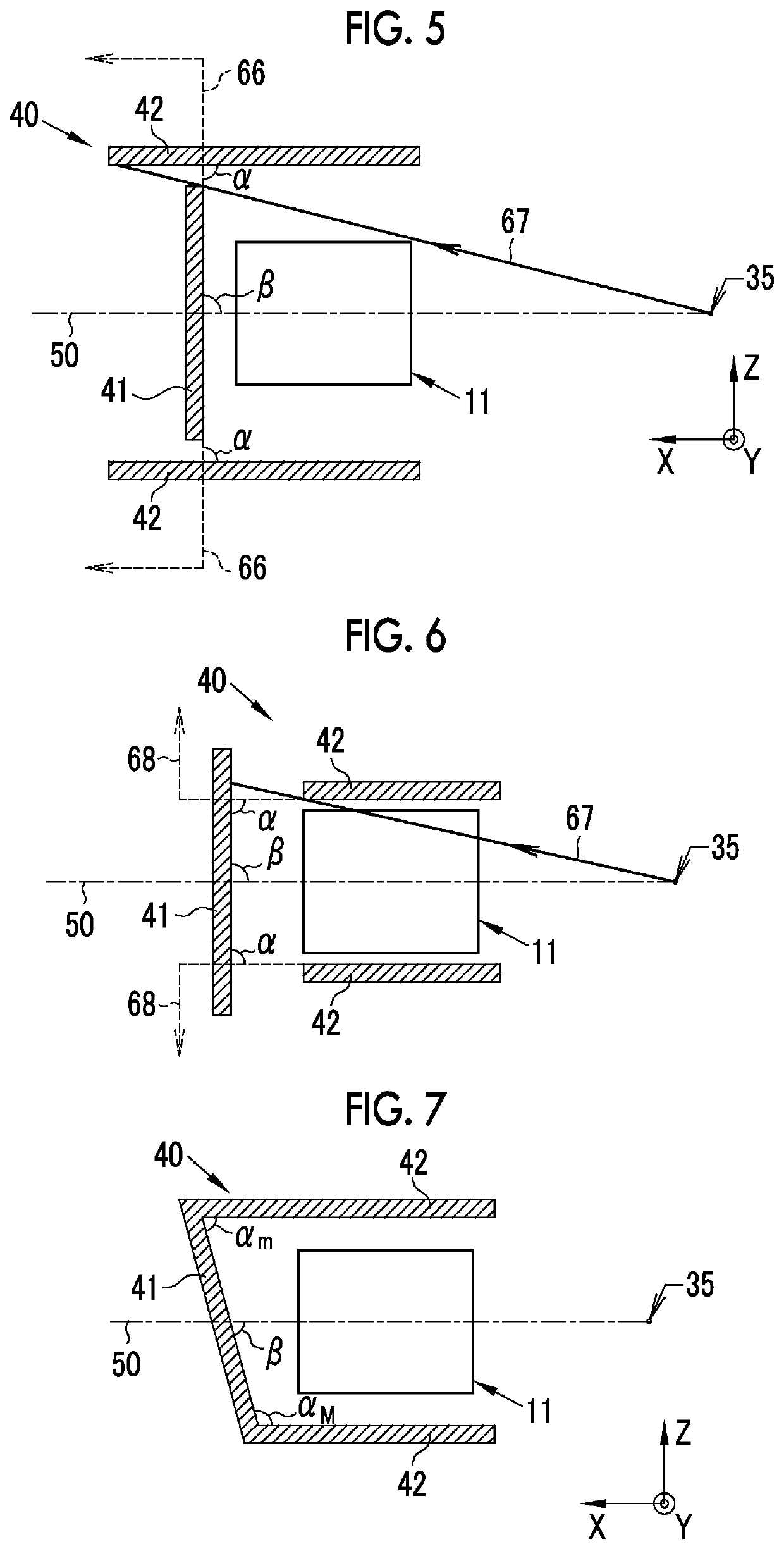

X-ray tube

ActiveUS20190304734A1Light weightHigh molybdenum contentX-ray tube electrodesX-ray tube vessels/containerX-ray shieldAtomic physics

An X-ray tube includes: an envelope that is a case; a cathode assembly that emits electrons in the envelope; and an anode including a first member of which at least a portion extends to the outside of the envelope, a second member that is provided in a direction perpendicular to a central axis of the first member, comes into contact with the first member, and has a higher X-ray shielding performance than the first member, and a target that receives the electrons emitted from the cathode assembly and generates X-rays.

Owner:FUJIFILM CORP

Low-nickel aging-strengthened iron-nickel-based corrosion-resistant alloy and preparation method thereof

ActiveCN104451339BImprove hot working plasticityOptimize body contentCorrosion resistant alloyTrace element

Owner:CHONGQING MATERIALS RES INST

X-ray tube

ActiveUS10916401B2High molybdenum contentLight weightX-ray tube electrodesX-ray tube vessels/containerEngineeringMechanical engineering

An X-ray tube includes: an envelope that is a case; a cathode assembly that emits electrons in the envelope; and an anode including a first member of which at least a portion extends to the outside of the envelope, a second member that is provided in a direction perpendicular to a central axis of the first member, comes into contact with the first member, and has a higher X-ray shielding performance than the first member, and a target that receives the electrons emitted from the cathode assembly and generates X-rays.

Owner:FUJIFILM CORP

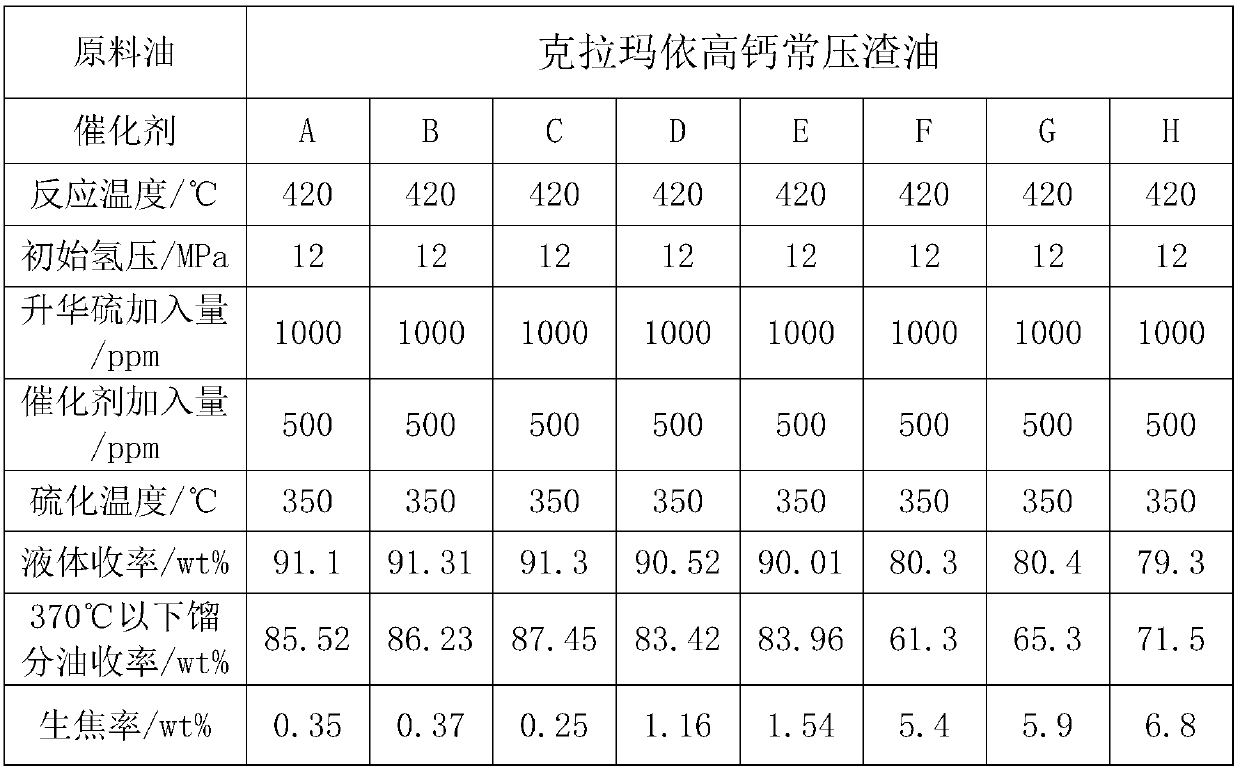

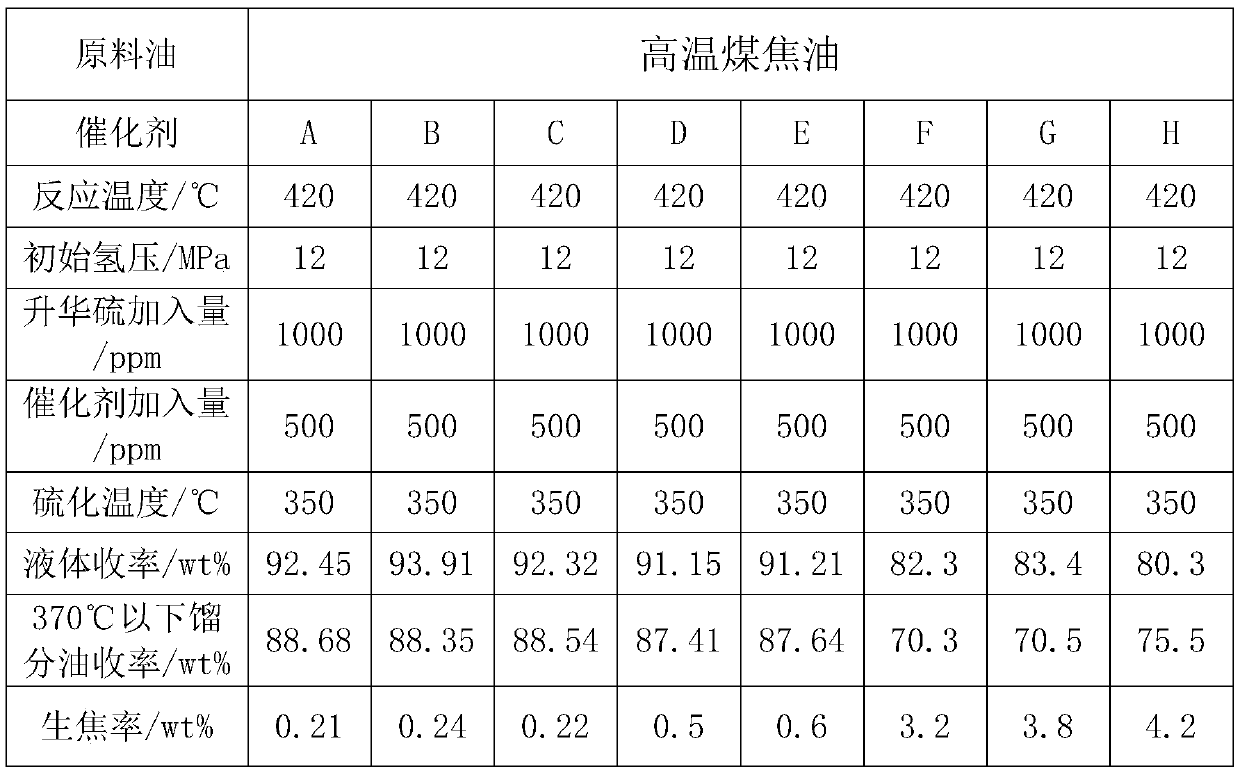

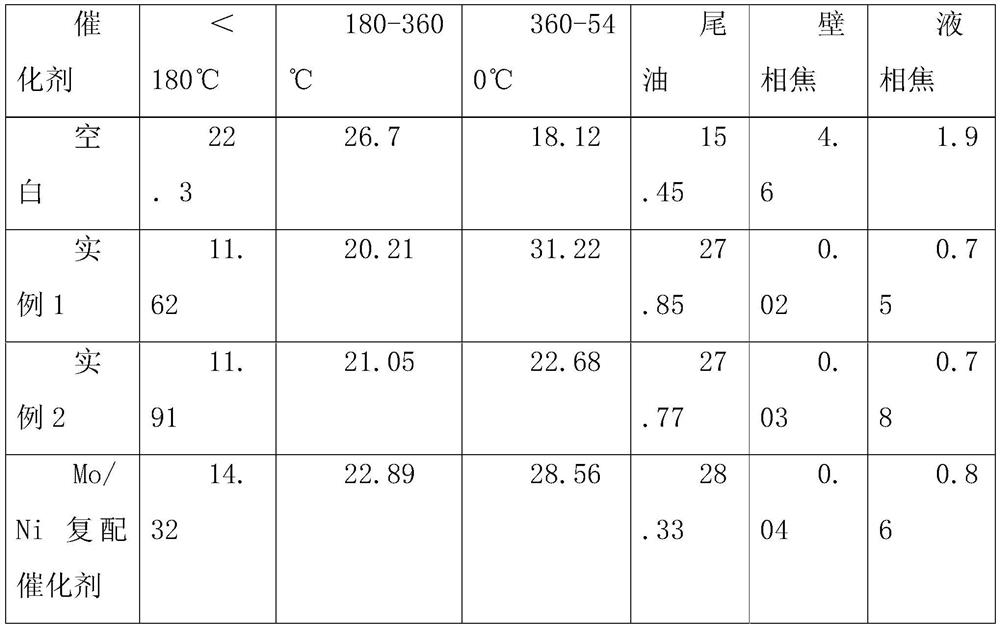

A hydrogenation catalyst and its preparation method and use method

ActiveCN107824226BImprove catalytic performanceOptimal molar ratioOrganic-compounds/hydrides/coordination-complexes catalystsRefining to eliminate hetero atomsActive phaseCarbon deposit

The invention discloses a hydrogenation catalyst, a preparation method and an application method thereof. It uses organic phosphonic acid and molybdenum source as reaction raw materials, utilizes the reaction of the two, and bonds the two together to prepare a hydrogenation catalyst. Among them, the inventors found for the first time that P in the organic phosphonic acid can change the surface acidity of the active phase, increase the surface acidity of the hydrogenation catalyst after sulfidation, and the increase in acidity helps to enhance the hydrogenation activity of the hydrogenation catalyst; in addition, the presence of P has It helps stabilize asphaltenes, thereby inhibiting asphaltene condensation and coking, thereby reducing the amount of coke, slowing down catalyst deactivation, and finally reducing the coking rate and increasing the hydrogenation yield. At the same time, it is also found that the presence of P helps to change the structure of the active phase in the hydrogenation catalyst, which can reduce the amount of molybdenum with a tetrahedral structure that is difficult to vulcanize, and increase the amount of molybdenum with an octahedral structure that is easy to sulfide, which in turn facilitates the sulfuration of molybdenum. In the process, it is converted into molybdenum disulfide with suitable stacking layers, thereby increasing the activity of the hydrogenation catalyst and increasing the hydrogenation yield.

Owner:FUZHOU UNIV

Method for preparing extender of nutriment with high molybdenum

A process for preparing high-Mo nutrient includes proportionally mixing mung bean, water and ammonium molybdate, culturing, solid-liquid separation, laying the solid material aside under 60-80% of relative humidify, adding it to the separated liquid, adding ammonium molybdate and water, mixing, culturing, solid-liquid separation, and laying the solid material aside under 60-80% of relative humidity.

Owner:郑冬

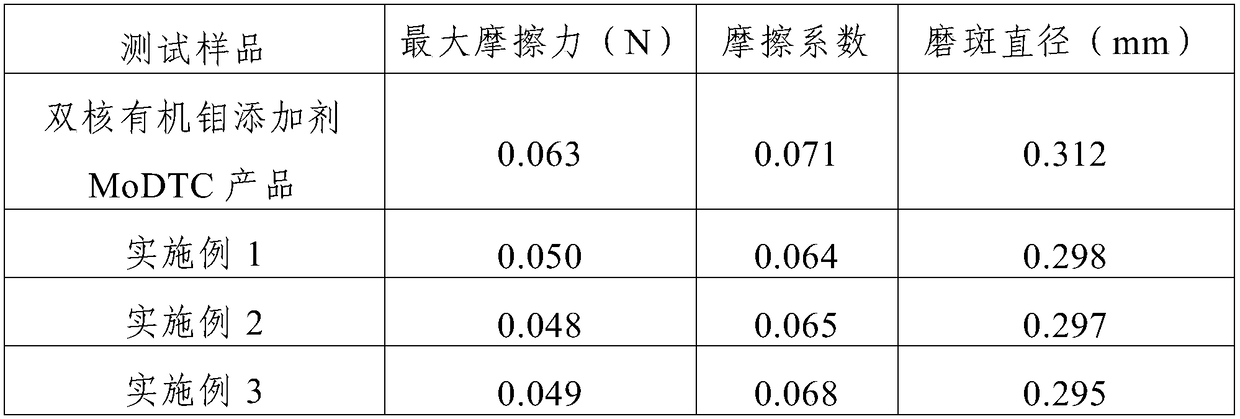

Preparation method of organic three-nuclear molybdenum additive

InactiveCN108129517AAvoid generatingLow costAdditivesGroup 6/16 organic compounds without C-metal linkagesMolybdateSolvent

The invention discloses a preparation method of an organic three-nuclear molybdenum additive. The preparation method comprises the following steps: firstly, preparing tetralkyl disulfide thiuram by adopting dialkyl secondary amine, carbon disulphide, ethanol aqueous solution of sodium hydroxide and hydrogen peroxide; secondly, preparing a crude organic three-nuclear molybdenum additive by adoptingammonium trithio molybdate crystals, the tetralkyl disulfide thiuram and a mixed solvent; thirdly, performing post-treatment on the crude organic three-nuclear molybdenum additive to obtain an oily organic three-nuclear molybdenum additive. The invention creatively designs the preparation method of the organic three-nuclear molybdenum additive; the organic three-nuclear molybdenum additive is synthesized by adopting the ammonium trithio molybdate crystals and the tetralkyl disulfide thiuram; compared with the existing two-nuclear molybdenum additive, the molybdenum content is higher; under the same friction performance, the adding amount of the additive added into lubricating oil is smaller, and the friction resistance is more excellent; toxic and harmful raw materials are not used in a preparation process, the emission of the toxic and harmful gas is also avoided, and the method is green and environment-friendly.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Fertilizer specially used for perilla frutescens in flowering stage and preparation method for fertilizer

InactiveCN103772030BPromote divisionIncrease enzyme activityFertilizer mixturesManufacturing technologyAnthesis

The invention discloses a fertilizer specially used for perilla frutescens in a flowering stage. The fertilizer consists of a macroelement fertilizer, a trace element fertilizer and a plant growth adjustment agent. Water is used as a medium; each liter of the fertilizer contains 5 grams of potassium nitrate, 3 grams of monopotassium phosphate, 1 grams of boric acid, 2 grams of ammonium molybdate and 25 milligrams of forchlorfenuron or 15 milligrams of kinetin or 25 milligrams of the forchlorfenuron and 15 milligrams of the kinetin; requirements on growth of the perilla frutescens and high yield and high quality of seeds are met. A field experiment result shows that the yield is increased by 15-27 percent; the content of molybdenum in 100 grams of seeds contain is increased by 0.5-1.0 micrograms; the seed oil content is increased by 3-8 percent; the content of alpha-linolenic acid in the oil is increased by 4-9 percent. The manufacturing technology is simple; the equipment investment is small; the fertilizer is convenient to apply.

Owner:SOUTHWEST UNIV

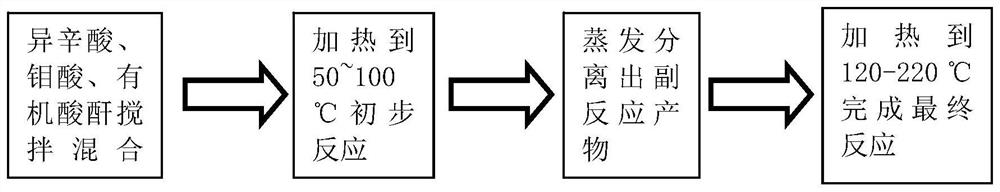

Oil-soluble molybdenum caprylate catalyst as well as preparation method and application thereof

PendingCN114073984AHigh molybdenum contentGood hydrogenation activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingProcess engineeringCoke

The invention discloses an oil-soluble molybdenum caprylate catalyst as well as a preparation method and application thereof. The prepared molybdenum caprylate catalyst is good in dispersity and high in active metal content, can be used for hydro-conversion of inferior heavy oil, residual oil, oil sand and asphalt, can also be used for coal / oil co-refining, and can effectively inhibit coke formation in the reaction process and guarantee long-period operation of a device.

Owner:刘虎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com