Chemical nickel-plating-molybdenum-phosphorus alloy solution for preparing high molybdenum and high phosphorus coating

A technology of electroless nickel plating and alloy solution, applied in liquid electroless plating, coating, metal material coating process, etc., can solve the problem of not being able to prepare Mo and P content at the same time, achieve good diffusion barrier performance and improve reliability , the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

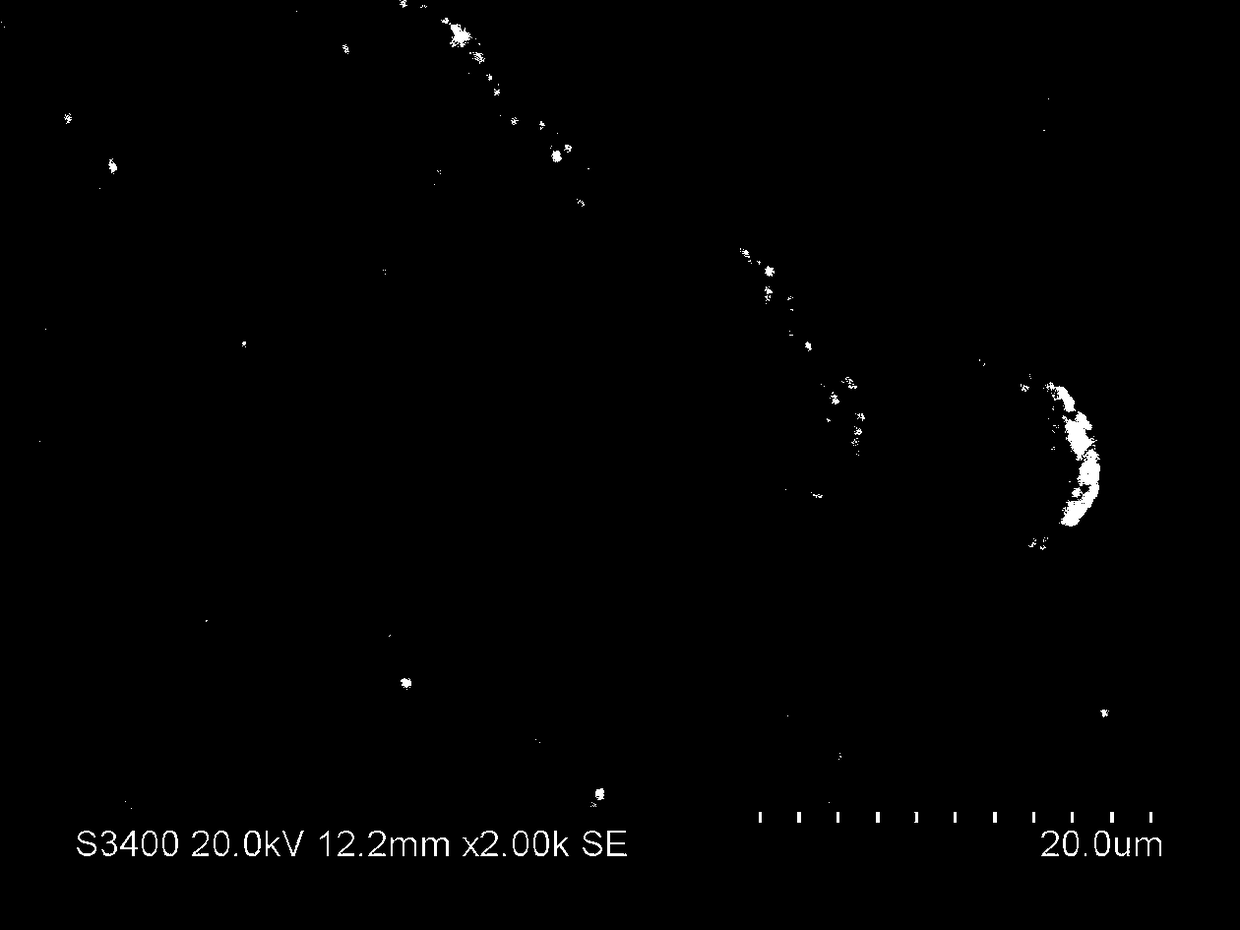

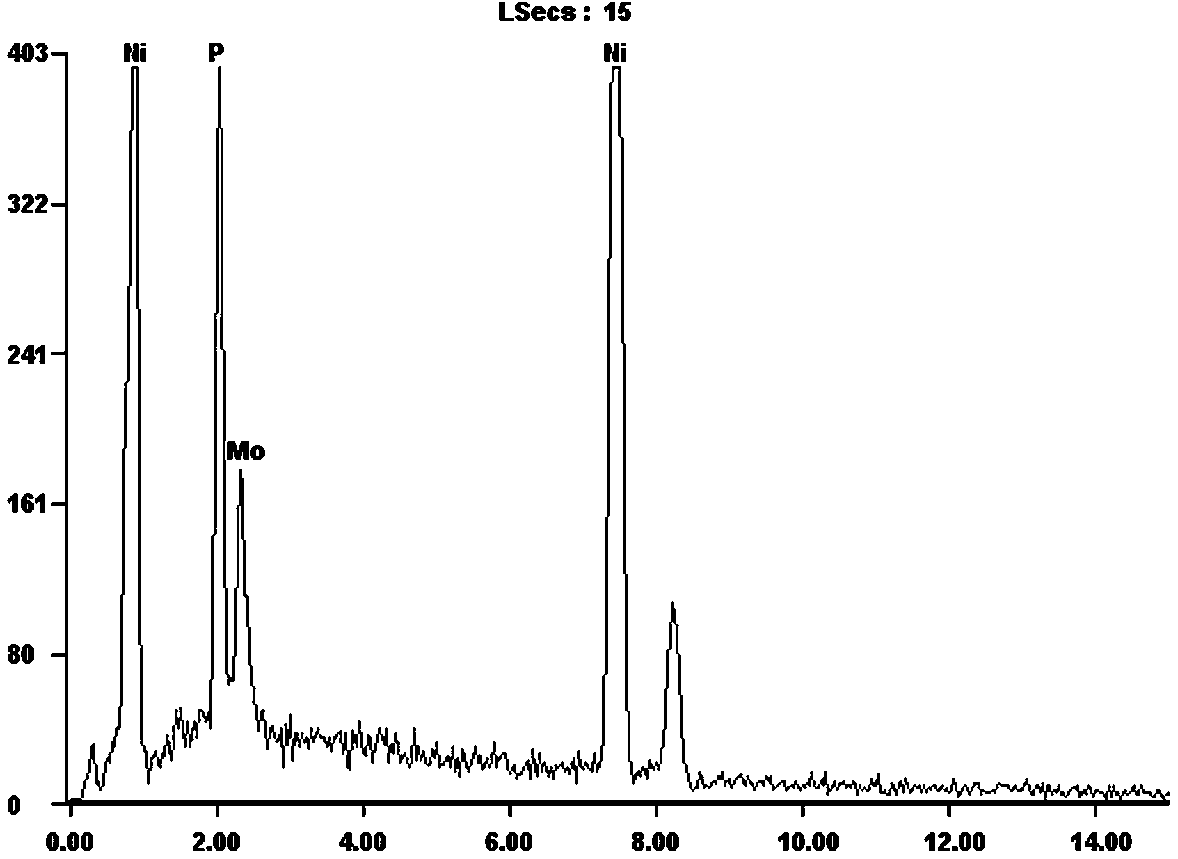

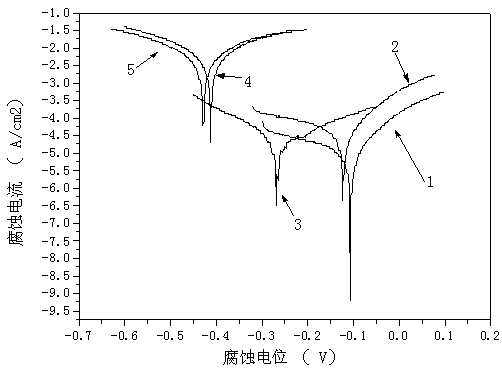

Image

Examples

Embodiment 1

[0061] Nickel sulfate: 26 g / L

[0062] Sodium hypophosphite: 27 g / l

[0063] Sodium molybdate: 0.6 g / L

[0064] Sodium citrate: 40 g / l

[0065] Propionic acid: 1ml / L

[0066] Sodium tetraborate: 10 g / L

[0067] Sodium acetate: 10 g / L

[0068] Saccharin: 0.8 g / L

[0069] pH: 8.5 (adjust pH with ammonia water)

[0070] Temperature: 80°C

[0071] Add water to volume

Embodiment 2

[0073] Nickel sulfate: 36 g / L

[0074] Sodium hypophosphite: 37 g / l

[0075] Sodium molybdate: 0.7 g / L

[0076] Sodium citrate: 50 g / l

[0077] Propionic acid: 2.5 ml / l

[0078] Sodium tetraborate: 15 g / L

[0079] Sodium acetate: 20 g / l

[0080] Saccharin: 0.9 g / l

[0081] pH: 8.5 (adjust pH with ammonia water)

[0082] Temperature: 80°C

[0083] Add water to volume

Embodiment 3

[0085] Nickel sulfate: 30 g / L

[0086] Sodium hypophosphite: 32 g / L

[0087] Sodium molybdate: 0.66 g / L

[0088] Sodium citrate: 45 g / l

[0089] Propionic acid: 2ml / L

[0090] Sodium tetraborate: 12 g / l

[0091] Sodium acetate: 15 g / l

[0092] Saccharin: 0.84 g / L

[0093] pH: 8.3 (adjust pH with ammonia water)

[0094] Temperature: 76°C

[0095] Add water to volume

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com