Preparation method of organic three-nuclear molybdenum additive

A technology of trinuclear molybdenum and additives, applied in the field of lubricant additives, can solve the problems of the total synthesis technology without trinuclear molybdenum additives, difficulty in forming a trinuclear molybdenum structure with molybdenum content, unfavorable health and environmental protection, etc. R & D and marketing, excellent anti-wear performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

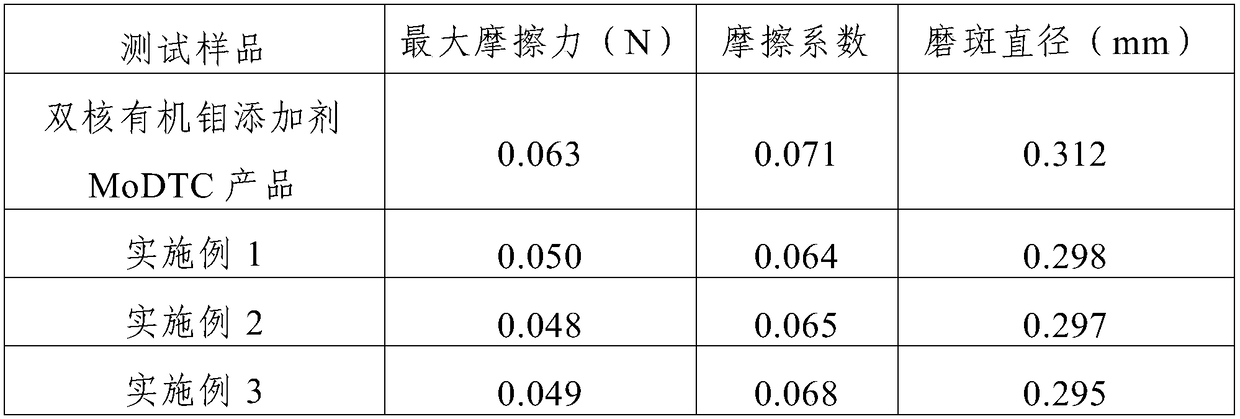

Examples

Embodiment 1

[0027] The preparation method of the present embodiment comprises the following steps:

[0028] Step 1, the preparation of tetrahydrocarbyl thiuram disulfide: mix ethanol and distilled water in a volume ratio of 2:1, then add sodium hydroxide to dissolve, and obtain an aqueous ethanol solution with a mass concentration of 5% sodium hydroxide after dissolving. Take 100mL of sodium hydroxide aqueous ethanol solution and add it to a 250mL three-necked flask, then add 5mol of dibutyl secondary amine, and then slowly add carbon disulfide dropwise at a rate of 0.05mL / s under ice-water bath, wherein dibutyl secondary amine and carbon disulfide The molar ratio is 1.35:1. After the dropwise addition, stir at a constant temperature for 2 hours at a temperature of 30°C, then add 5mL of hydrogen peroxide (analytical pure), and react at a constant temperature for 1 hour. After vacuum concentration and evaporation to dryness, the intermediate product disulfide Tetrahydrocarbylthiuram;

[0...

Embodiment 2

[0037] The preparation method of the present embodiment comprises the following steps:

[0038] Step 1, the preparation of tetrahydrocarbyl thiuram disulfide: mix ethanol and distilled water in a volume ratio of 3:1, then add sodium hydroxide to dissolve, and obtain an aqueous ethanol solution with a mass concentration of 5% sodium hydroxide after dissolving. Take 100mL of sodium hydroxide aqueous ethanol and add it to a three-necked flask, then add 5mol of dioctyl secondary amine, and then slowly add carbon disulfide dropwise at a rate of 0.05mL / s under ice-water bath, wherein the moles of dioctyl secondary amine and carbon disulfide The ratio is 1.2:1. After the dropwise addition, stir at a constant temperature for 2 hours at a temperature of 30°C, then add 4 mL of hydrogen peroxide, react at a constant temperature for 1 hour, and concentrate and evaporate to dryness in a vacuum to obtain the intermediate product tetrahydrocarbyl thiuram disulfide;

[0039] Step 2, the prepa...

Embodiment 3

[0046] The preparation method of the present embodiment comprises the following steps:

[0047] Step 1, the preparation of tetrahydrocarbyl thiuram disulfide: mix ethanol and distilled water in a volume ratio of 1:1, then add sodium hydroxide to dissolve, and obtain an ethanol aqueous solution with a mass concentration of 5% sodium hydroxide after dissolving. Take 100mL of sodium hydroxide aqueous ethanol and add it to a three-necked flask, then add 5mol of ditridecylamine, and then slowly add carbon disulfide dropwise at a rate of 0.05mL / s under an ice-water bath, wherein ditridecylamine and carbon disulfide The molar ratio is 1.5:1. After the dropwise addition, stir at a constant temperature for 2 hours at a temperature of 30°C, then add 6mL of hydrogen peroxide, and react at a constant temperature for 1 hour. Mu;

[0048] Step 2, the preparation of organic trinuclear molybdenum additive crude product: the mixed solvent of tetrahydrocarbyl thiuram disulfide and 20mL obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com