Molybdenum modification dispersant, and preparation method and applications thereof

A dispersant and modification technology, applied in chemical instruments and methods, additives, organic chemistry, etc., can solve the problems of high raw material cost, failure to meet environmental protection requirements, poor compatibility of other additives, etc., achieve shortened reaction time, good synergistic resistance Reduce friction and improve fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

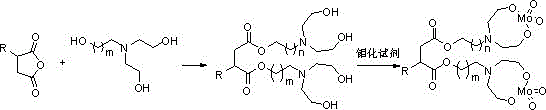

[0036] Another aspect of the present invention provides a method for preparing a molybdenum-modified dispersant, which includes: mixing an alkyl chain succinic acid and / or an alkyl chain succinic anhydride, a diluent that may or may not be added, and an alcohol amine compound Carry out the first-stage reaction, then remove possible residual unreacted substances, then add molybdenum reagent to carry out the second-stage reaction, and finally obtain the target product through post-treatment.

[0037] Specifically, the preparation method includes: after fully mixing the alkyl chain succinic acid and / or alkyl chain succinic anhydride with the diluent, adding the alkanolamine compound at one time or in batches and optionally adding or not adding The accelerator is used for the first-stage reaction, and then the possible remaining unreacted substances are removed, and then the molybdenum reagent is added at one time or in batches for the second-stage reaction, and finally the target ...

Embodiment 1

[0072] Weigh 10.0 g of polyisobutylene succinic anhydride (PIBSA, 0.01 mol) and add it directly into a 250 ml three-neck flask, then add 3.8 g (0.025 mol) of triethanolamine (TEA) and 50 ml of xylene solvent into the flask. Heating in an oil bath, the temperature rises to 110°C~130°C, use N 2 The generated by-product water was extracted and reacted for 6h. Weigh 4.0g (0.02mol) of ammonium molybdate, dissolve it in 10ml of water to obtain a milky white or colorless solution, put it into a three-necked bottle, and react at 130°C for 6h, the color of the solution is dark green, heat it in an oil bath, and raise the temperature to 160°C , magnetic stirring, xylene or toluene reflux, separate the water in the system with a water separator, and react for 6 hours. The reaction is completed when no water is evaporated. The reaction product is a dark green solution. After the reaction is completed, carry out suction filtration while it is hot. After separation, the solution was dark g...

Embodiment 2

[0074] Weigh 10.0g of polyisobutylene succinic anhydride (PIBSA, 0.01mol) and add it directly into a 250ml three-neck flask, then add 2.7g (0.025mol) of diethanolamine (DEA) and 50ml of toluene solvent into the flask. Heating in an oil bath, the temperature rises to 110°C~130°C, use N 2 The generated by-product water was extracted and reacted for 6h. Weigh 2.9g (0.02mol) of molybdenum trioxide, dissolve it in 10ml of water to obtain a milky white or colorless solution, put it into a three-necked bottle, and react at 130°C for 6h, the color of the solution is dark green, heat it in an oil bath, and raise the temperature to 160°C , magnetic stirring, xylene or toluene reflux, separate the water in the system with a water separator, and react for 6 hours. The reaction is completed when no water is evaporated. The reaction product is a dark green solution. After the reaction is completed, carry out suction filtration while it is hot. After separation, the solution was dark green,...

PUM

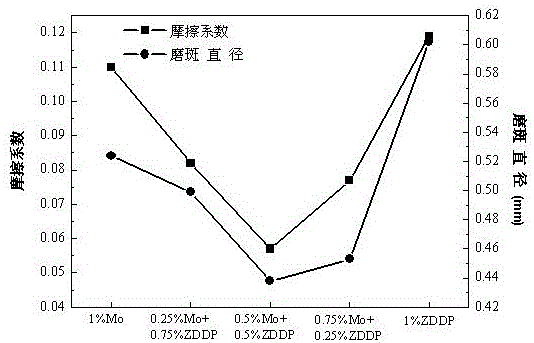

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com