Hydro-liquefied iron-based catalyst containing carbon materials and preparation method and application of hydro-liquefied iron-based catalyst

A technology of iron-based catalysts and additives, applied in the preparation of liquid hydrocarbon mixtures, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of increasing particle size, increasing catalyst cost, Complex process and other problems, to achieve the effect of sufficient raw materials, easy operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

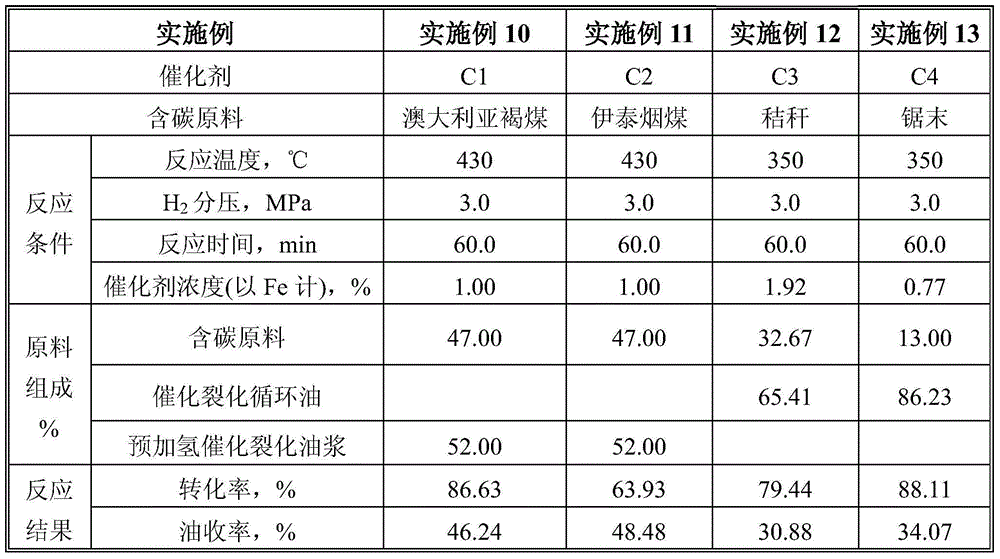

[0048] Example 1, preparation of creamy iron-based catalyst C-1

[0049] According to the component mass ratio Fe: auxiliary agent (in terms of oxide): mineral spirits=100:17:370, take by weighing industrial FeSO 4 ·7H 2 O400 kilograms, 38.67 kilograms of aluminum sols of 20wt%, 20.6 kilograms of silica sols of 30wt%, 300 kilograms of catalytic cracking cycle oils. 20wt% ammonia water was used as precipitating agent.

[0050] Add 1500 kilograms of deionized water in the salt solution preparation tank, the above-mentioned industrial FeSO 4 ·7H 2 O is added in the salt solution preparation tank and stirred and dissolved, aluminum sol and silica sol are added in the fully dissolved ferrous sulfate solution, and stirred evenly; the concentration of 20wt% ammoniacal liquor 1M is added in the precipitant tank 3 ; Add 1000 kilograms of deionized water in the synthetic kettle, start the synthetic kettle to stir, the FeSO containing aluminum sol and silica sol 4 The mixed solution...

Embodiment 2

[0054] Example 2, preparation of creamy iron-based catalyst C-2

[0055] By component mass ratio Fe: auxiliary agent (in terms of oxide): dispersant: mineral spirits=100:17:3.5:200, take by weighing industrial FeSO 4 ·7H 2 O400 kg, 38.67 kg of 20 wt% aluminum sol, 20.6 kg of 30 wt% silica sol, 200 kg of coal tar and 2.8 kg of Span-80. With 34wt% NaOH solution as precipitant, weigh 336.6 kg for later use.

[0056] Add 1500 kilograms of deionized water in the salt solution preparation tank, the above-mentioned industrial FeSO 4 ·7H 2 O is added to the salt solution preparation tank and stirred to dissolve, aluminum sol and silica sol are added to the fully dissolved ferrous sulfate solution, and stirred evenly; the weighed sodium hydroxide solution is added to the precipitant tank; 1000 Kilograms of deionized water, start the synthesis kettle to stir, the FeSO containing aluminum sol and silica sol 4 The mixed solution and the sodium hydroxide solution were continuously fed...

Embodiment 3

[0060] Example 3, preparation of creamy iron-based catalyst C-3

[0061] According to the component mass ratio Fe: auxiliary agent (in terms of oxide): dispersant: mineral spirits=100:20:3.5:500, take by weighing industrial FeSO 4 ·7H 2 O400 kg, 2.8 kg of CaO powder, 38.67 kg of 20wt% aluminum sol, 20.6 kg of 30wt% silica sol, 2.8 kg of Span-80 and 255 kg of catalytic cracking oil slurry. With 18wt% Na 2 CO 3 Solution is precipitating agent, takes by weighing 850 kilograms for subsequent use.

[0062] Add 1500 kilograms of deionized water in the salt solution preparation tank, the above-mentioned industrial FeSO 4 ·7H 2 O is added to the salt solution preparation tank and stirred to dissolve, aluminum sol and silica sol are added to the ferrous sulfate solution that is completely dissolved, and stirred evenly; the weighed sodium carbonate solution is put into the precipitant tank; Kilograms of deionized water, start the synthesis kettle to stir, the FeSO containing alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com