Coking method for processing highly acid crude oil

A high-acid crude oil and high-temperature coking technology is applied in the field of thermal cracking and deacidification to achieve the effects of increasing heating temperature, increasing reaction temperature and processing capacity, and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

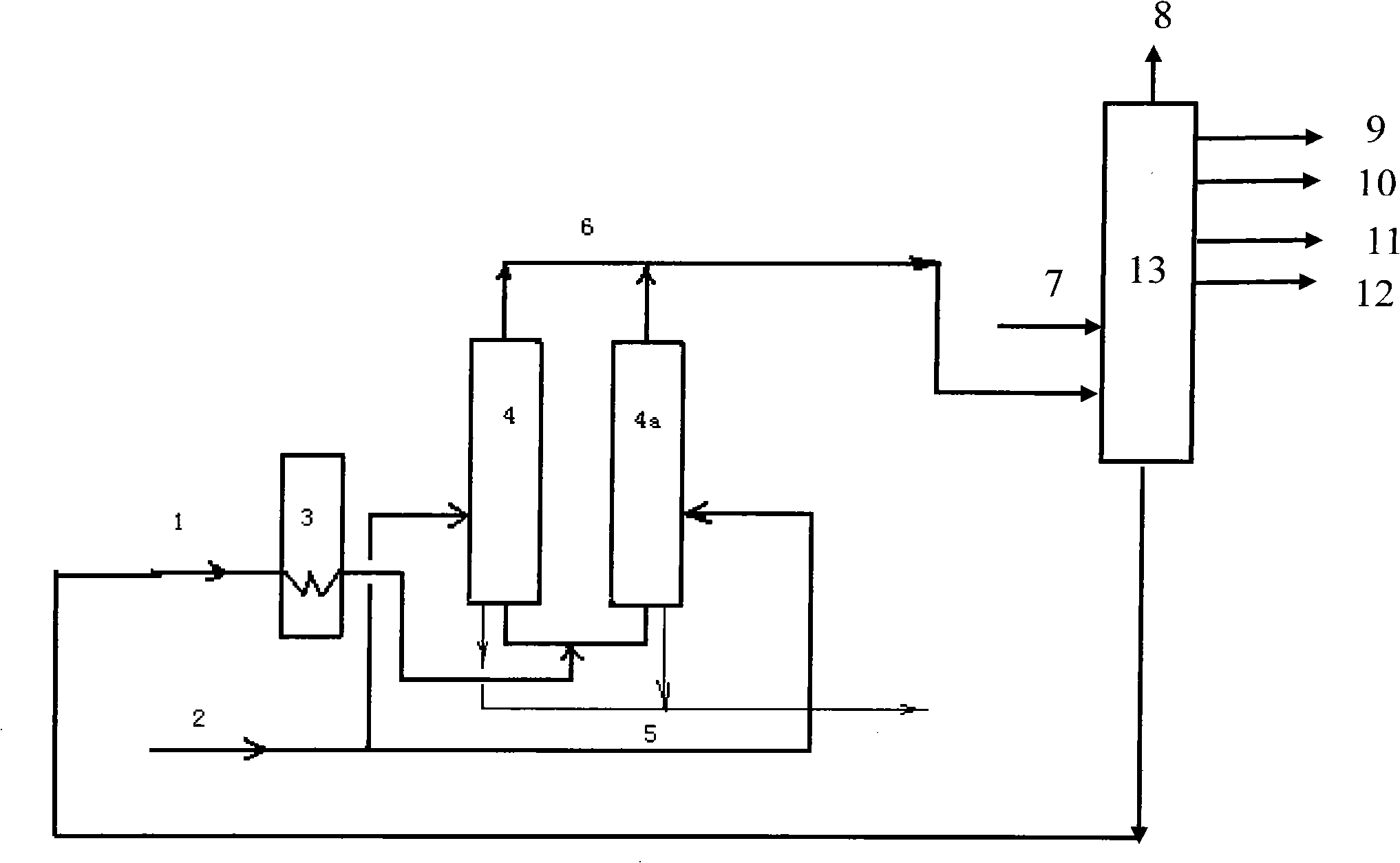

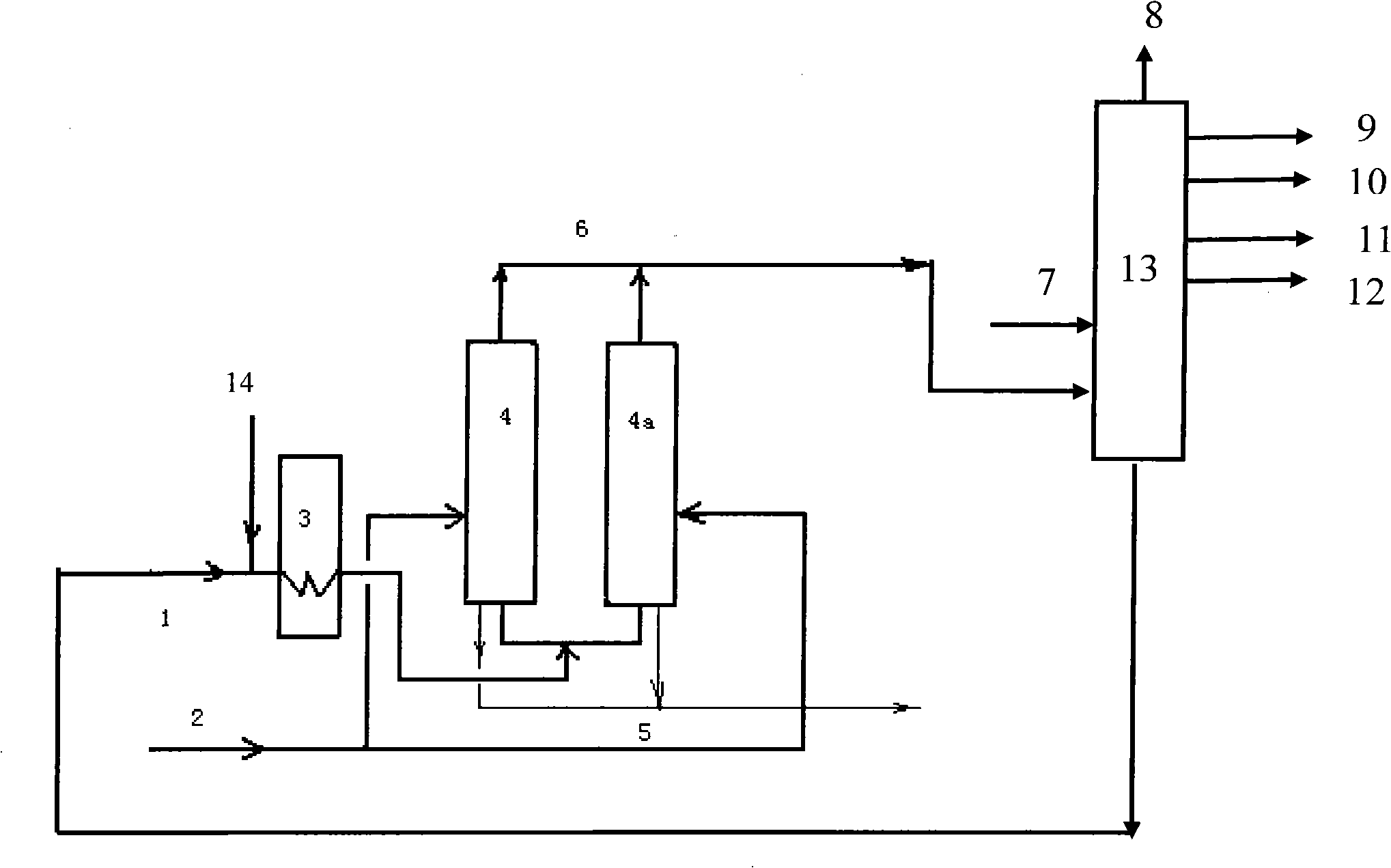

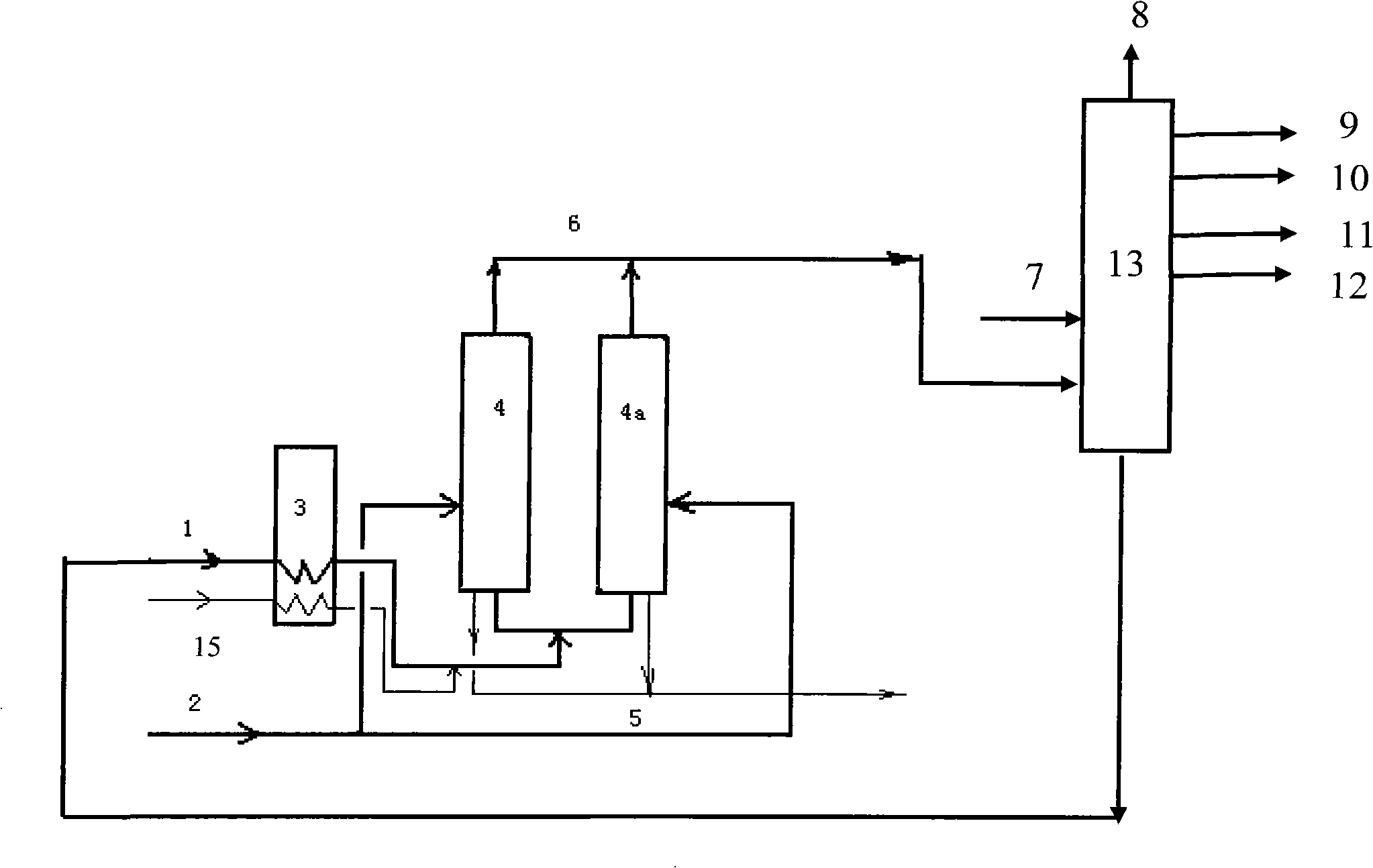

Method used

Image

Examples

Embodiment 1-15

[0051] Example description: the deacidification effect of the method provided by the present invention.

[0052] The calculation method of deacidification rate is as follows: deacidification rate=(total acid value of high-acid crude raw material-total acid value of obtained liquid phase product) / total acid value of high-acid crude raw material×100%.

[0053] All experiments in the examples use the same raw material oil, aiming to compare the deacidification effects under different operating conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com