A kind of low-quality heavy oil suspended bed hydrogenation catalyst and its preparation and use method

A hydrogenation catalyst and low-quality heavy oil technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of inability to convert hydrogenation, low hydrogenation activity, Problems such as high coke formation rate, to achieve the effect of improving dispersion, high hydrogenation activity, and low coke formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

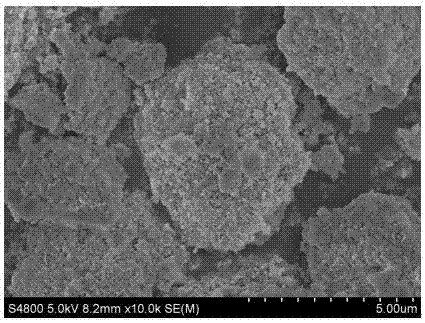

[0055] Weigh 50.00 g of natural bauxite ore raw powder and 60.00 g of 80% NaOH-H 2 O sub-molten salt solution mixed, kneaded evenly on the kneader, placed in 350 o C drying oven, then washed with deionized water to neutral to obtain a catalyst carrier, the specific surface area is 250 m 2 / g, the average pore diameter is 7.5 nm;

[0056] Weighed 20.00 g of the catalyst carrier prepared above and impregnated it in a layer containing 1.00 g of active metal Mo (as Mo 2 o 3 meter) of (NH 4 ) 6 Mo 7 o 24 4H 2 O aqueous solution, the active metal Mo is impregnated on the carrier by an equal volume impregnation method, the impregnation temperature is room temperature, and the impregnation time is 10 h, and then after 110 o C drying 8 h, 650 o C was roasted for 6 h to obtain the inferior heavy oil hydrogenation catalyst A.

Embodiment 2

[0058] Weigh 50.00 g of natural bauxite ore raw powder and 100.00 g of 75% NaOH-H 2 O sub-molten salt solution mixed, kneaded evenly on the kneader, placed in 250 o C drying oven, then washed with deionized water to neutral to obtain a catalyst carrier, the specific surface area is 280 m 2 / g, the average pore diameter is 5.6 nm;

[0059] Weighed 20.00 g of the catalyst carrier prepared above and impregnated it in a layer containing 0.20 g of active metal Mo (as Mo 2 o 3 meter) of (NH 4 ) 6 Mo 7 o 24 4H 2 Ni(NO 3 ) 2 ·6H 2 In the mixed aqueous solution of O, the active metals Mo and Ni were impregnated on the carrier by an equal volume impregnation method, the impregnation temperature was room temperature, and the impregnation time was 10 h, and after 130 o C drying 6 h, 500 o C was roasted for 4 h to obtain the inferior heavy oil hydrogenation catalyst B.

Embodiment 3

[0061] Weigh 50.00 g of natural bauxite ore raw powder and 25.00 g of 85% KOH-H 2 O sub-molten salt solution mixed, kneaded evenly on the kneader, placed in 150 o C drying oven, and then washed with deionized water to neutral to obtain a catalyst carrier, the specific surface area is 218 m 2 / g, the average pore diameter is 8.2 nm;

[0062] Weighed 20.00 g of the catalyst carrier prepared above and impregnated it in a layer containing 2.00 g of active metal Mo (as Mo 2 o 3 meter) of (NH 4 ) 6 Mo 7 o 24 4H 2 O aqueous solution, the active metal Mo is impregnated on the carrier by an equal volume impregnation method, the impregnation temperature is room temperature, and the impregnation time is 10 h, and then after 100 o C drying 12 h, 700 o C was roasted for 2 h to obtain the inferior heavy oil hydrogenation catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com