Method for improving gasoline yield of catalytic cracking technology and device thereof

A technology of catalytic cracking gasoline and catalytic cracking unit, which is applied in the field of improving gasoline yield, can solve the problem of low gasoline yield, and achieve the effect of increasing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Conventional FCC process: Only quench water is used to control the FCC reaction in the riser.

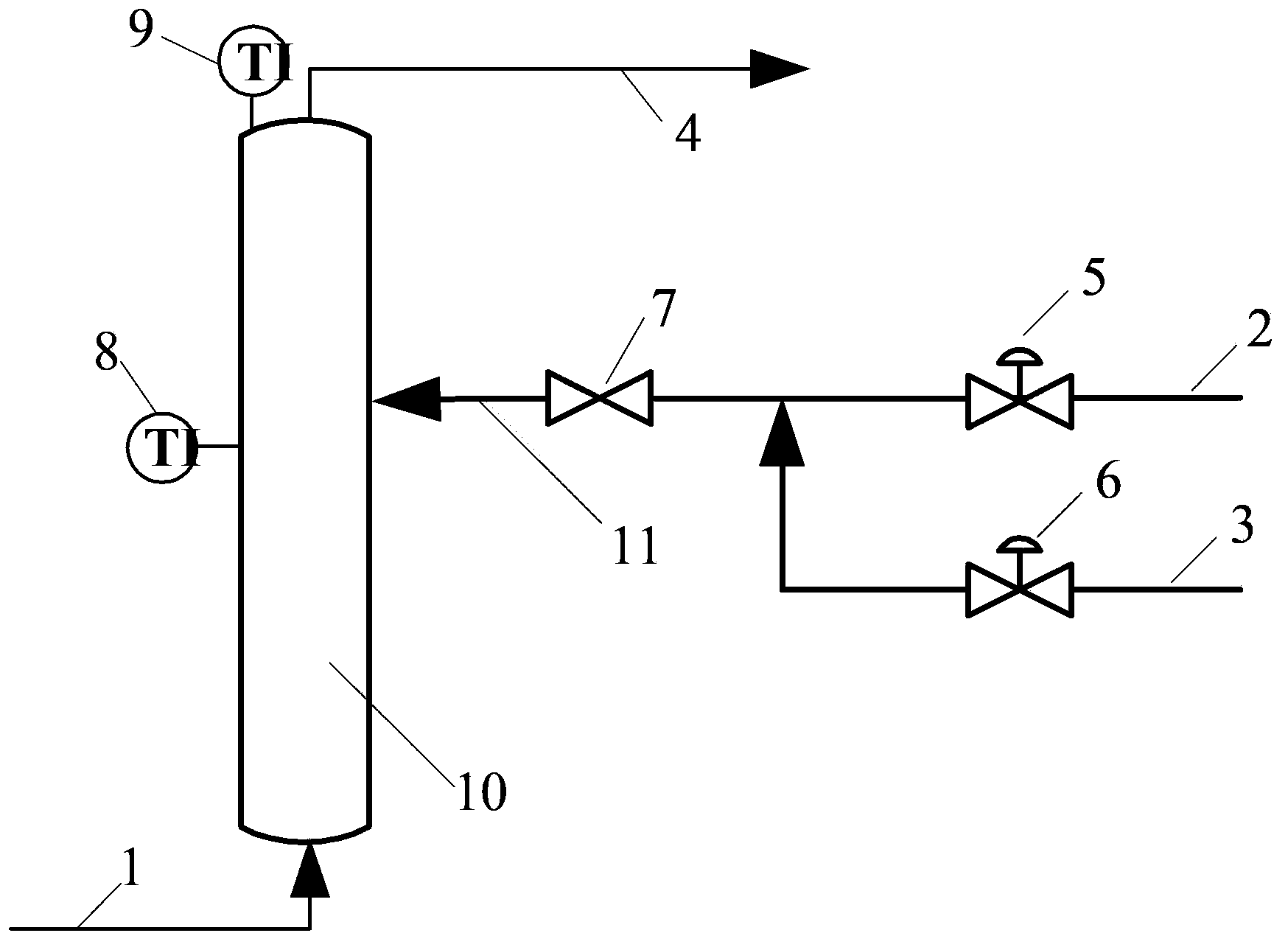

[0024] Device for use: including feed pipeline 1 and riser 10, the bottom of riser 10 is connected to feed pipeline 1, the outlet at the top of riser 10 is connected to oil and gas pipeline 4, the middle of riser 10 is connected to quenching water pipeline 2, and the outlet of riser 10 is set Thermometer A9.

[0025] In Example 1, the yield of gasoline under typical working conditions is 47.3%, the yield of catalytic cracking coke and oil slurry is 7.9%, the yield of catalytic cracking dry gas and liquefied gas is 23.4%, and the yield of diesel oil is 21.4%.

Embodiment 2

[0027] The catalytic cracking process is as follows: in the catalytic cracking process of the above-mentioned embodiment 1, the normal line oil from the atmospheric and vacuum distillation unit is injected into the middle part of the riser 10 of the catalytic cracking unit as quench oil. Quenching oil is injected continuously. Quench oil is a light oil component in the petroleum refining process, with a distillation range of 150°C to 280°C. The quenching oil injection temperature is 30°C-200°C, and the pressure is 0.3MPa-0.6MPa.

[0028] The device used in the process of the present invention is: on the basis of the catalytic cracking unit used in the above-mentioned embodiment 1, the quench oil pipeline 3 using the normal line oil of the atmospheric and vacuum distillation unit as the quench oil is introduced in the middle of the riser 10. Its structure is as follows: it includes an atmospheric and vacuum distillation unit and a catalytic cracking riser 10, the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com