Method for controlling upper-middle temperature of catalytic cracking raising pipe

A catalytic cracking and riser technology, applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problems of oil and gas reaction not being effectively controlled, noise, equipment damage, etc., to achieve fast vaporization, safe operation, and decentralization Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below by way of examples, but the present invention is not limited to examples.

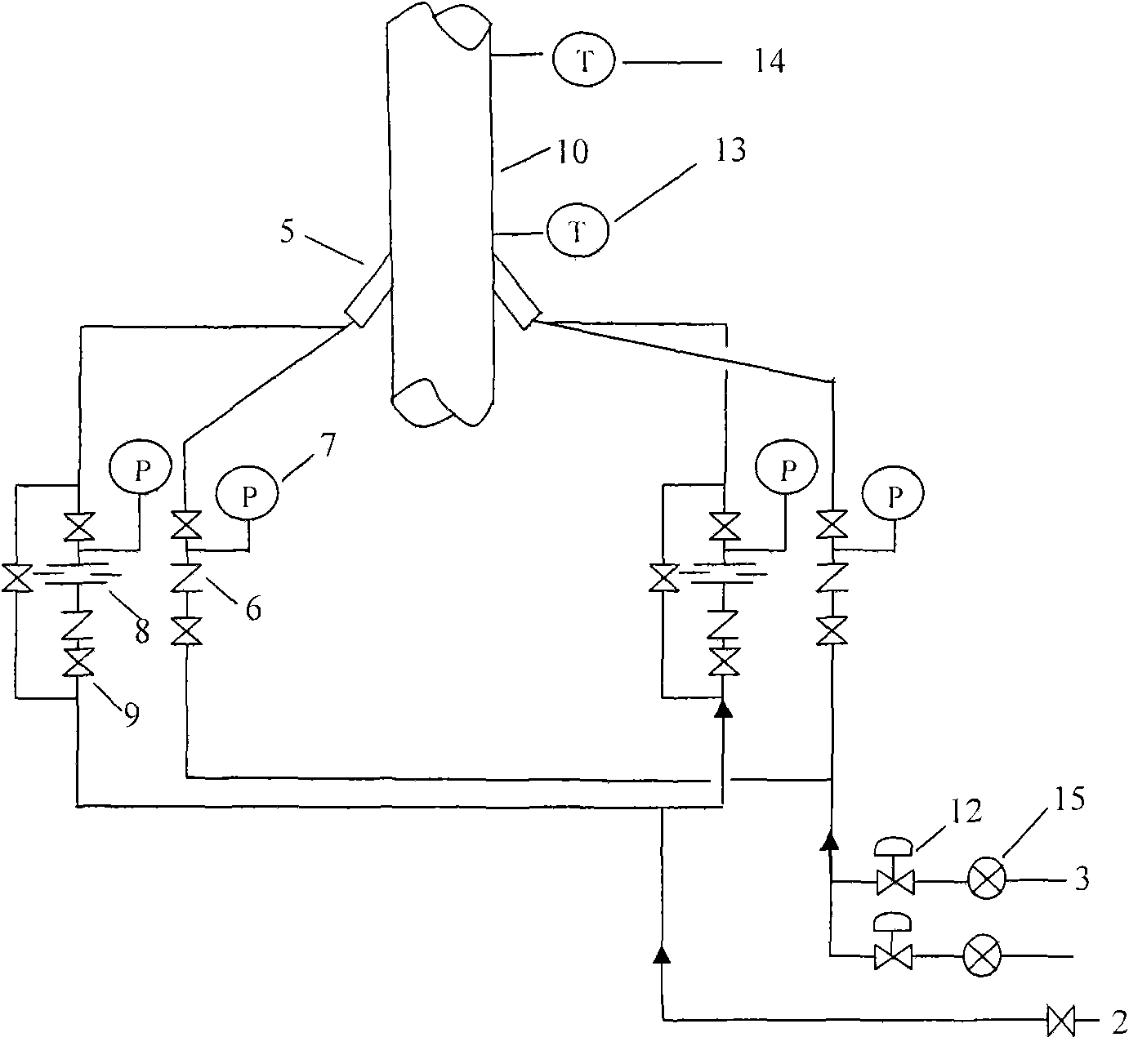

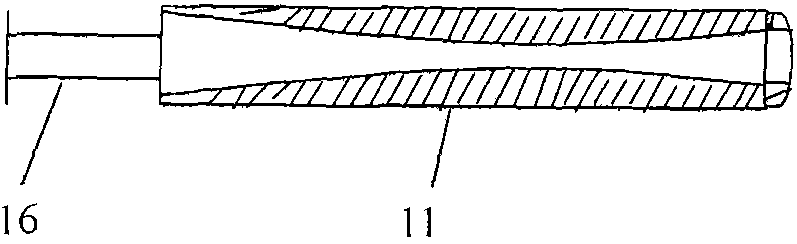

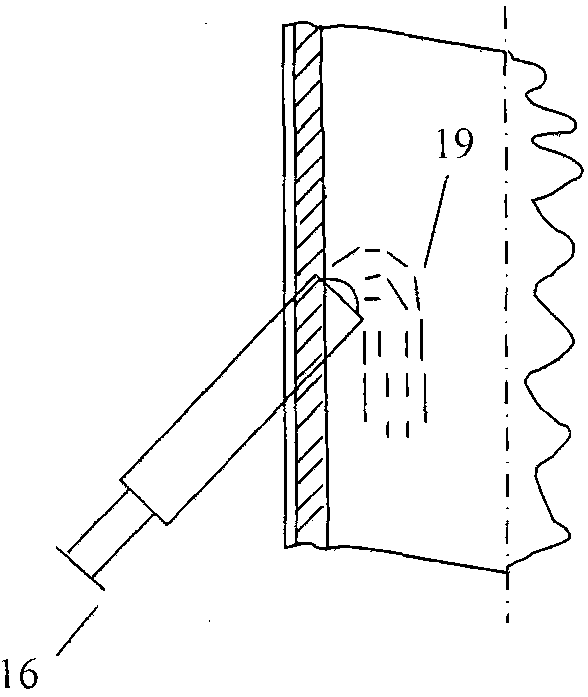

[0027] attached figure 2 It is one of the processes for controlling the temperature of the upper part of the riser in the present invention, and it is a process for injecting a terminator into the upper part of the riser. The temperature of the mixture of the light oil product 3 and the acidic water 4 is 40 °C and the pressure is above 1.0 MPa (G), From the catalytic cracking fractionation zone, it passes through the regulating valve and then enters the nozzle 11 in two ways; the steam 2 with a pressure of 1.0 MPa (G) comes from the steam pipe network, divides into two ways in front of the nozzle, and then passes through the one-way valve 6 and the flow-restricting orifice 8 After throttling; the dry gas with a pressure of 1.1MPa(G) is divided into two paths and passes through the one-way valve 6, the flow-restricting orifice 8 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com