Method for catalytic hydrogenation of heavy crude oil by using methane

A technology for heavy crude oil and catalytic hydrogenation, which is applied in the fields of hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems such as the industrial application of methane hydrogenation of heavy crude oil, etc., to improve the effect of hydrogenation reaction, The effect of reducing carbon dioxide emissions and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

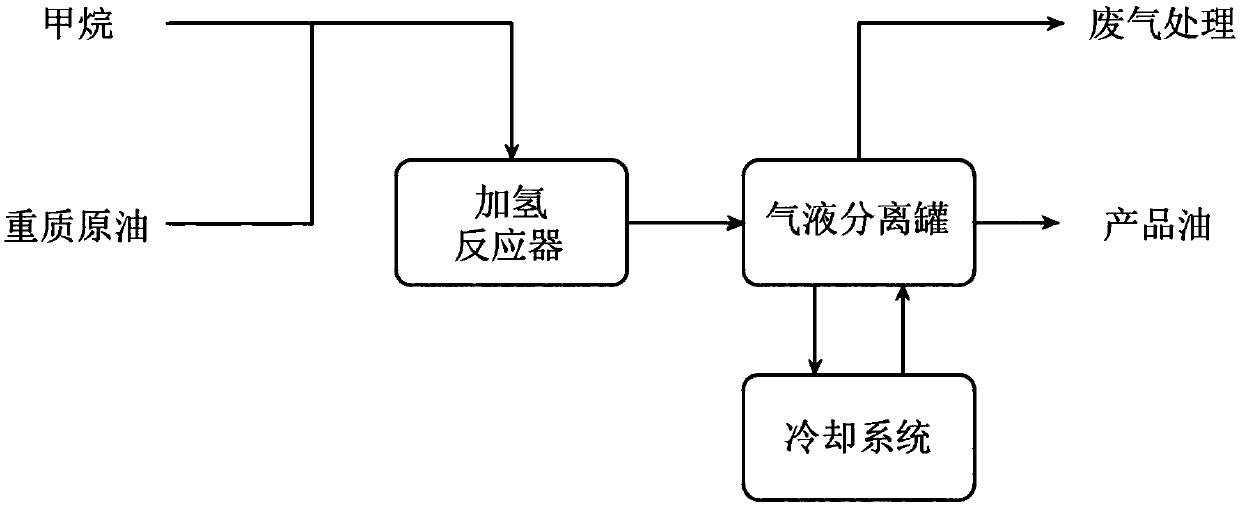

Method used

Image

Examples

Embodiment 1

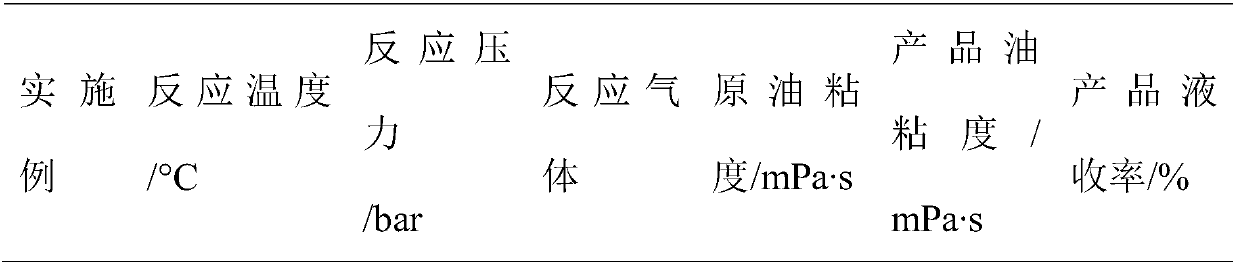

[0047] The heavy crude oil is preheated to 70°C in the raw material tank, and the preheated heavy crude oil is mixed with high-pressure methane in the pipeline and passed into the fixed-bed reactor filled with HOU2-2 catalyst. The reaction temperature is 400°C and the operating pressure is 50 atmospheres. The volume space velocity (LHSV) of heavy crude oil is 1h -1 , the volumetric space velocity of methane is 12h -1 ;Under the action of the catalyst, methane will undergo catalytic hydrogenation reaction with heavy crude oil; after the hydrogenation reaction is completed, the product oil flows out from the bottom of the reactor and is passed into the gas-liquid separation tank for gas-liquid separation; the gas-liquid separation tank is equipped with The cooling system reduces the temperature of the product oil to about room temperature; after the gas-liquid separation is completed, the tail gas flows into the after-treatment system, and the product oil flows into the product...

Embodiment 2

[0051] Preheat the heavy crude oil to 70°C in the raw material tank, mix the preheated heavy crude oil with high-pressure methane in the pipeline and pass it into the fixed bed reactor filled with HOU 2-3 catalyst; the reaction temperature is 430°C, The operating pressure is 50 atmospheres; the volume space velocity (LHSV) of heavy crude oil is 0.5h -1 , the volumetric space velocity of methane is 20h -1 . Under the action of the catalyst, methane will undergo catalytic hydrogenation reaction with heavy crude oil; after the hydrogenation reaction is completed, the product oil flows out from the bottom of the reactor and passes into the gas-liquid separation tank for gas-liquid separation; the gas-liquid separation tank is equipped with cooling The system lowers the temperature of the product oil to about room temperature; after the gas-liquid separation is completed, the tail gas flows into the after-treatment system, and the product oil flows into the product tank for collec...

Embodiment 3

[0056] Due to its good heat and mass transfer effect and uniform material dispersion, the slurry bed reactor has shown great development potential in petrochemical and other fields in recent years.

[0057] In this embodiment, a gas-liquid-solid three-phase slurry bed reactor is used to carry out the methane catalytic hydrogenation reaction of heavy crude oil, and the specific operations are as follows:

[0058] Preheat the heavy crude oil to 70°C in the raw material tank, mix the preheated heavy crude oil with the catalyst at a volume ratio of 1:1, and then pass it into the three-phase slurry bed reactor, and the catalyst is evenly dispersed in the liquid bed middle;

[0059] After the high-pressure methane is passed into the reactor, it passes through the bed in the form of bubbling, and reacts with heavy crude oil under the action of a uniformly dispersed catalyst. The reaction temperature is 410°C and the operating pressure is 50 atmospheres;

[0060] The volumetric space...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com