Patents

Literature

82 results about "Catalytic transfer hydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There is another process, called catalytic transfer hydrogenation (CTH), which avoids the use of hydrogen gas. Since addition of hydrogen to an alkene is reversible, CTH uses an organic compound as the source of hydrogen.

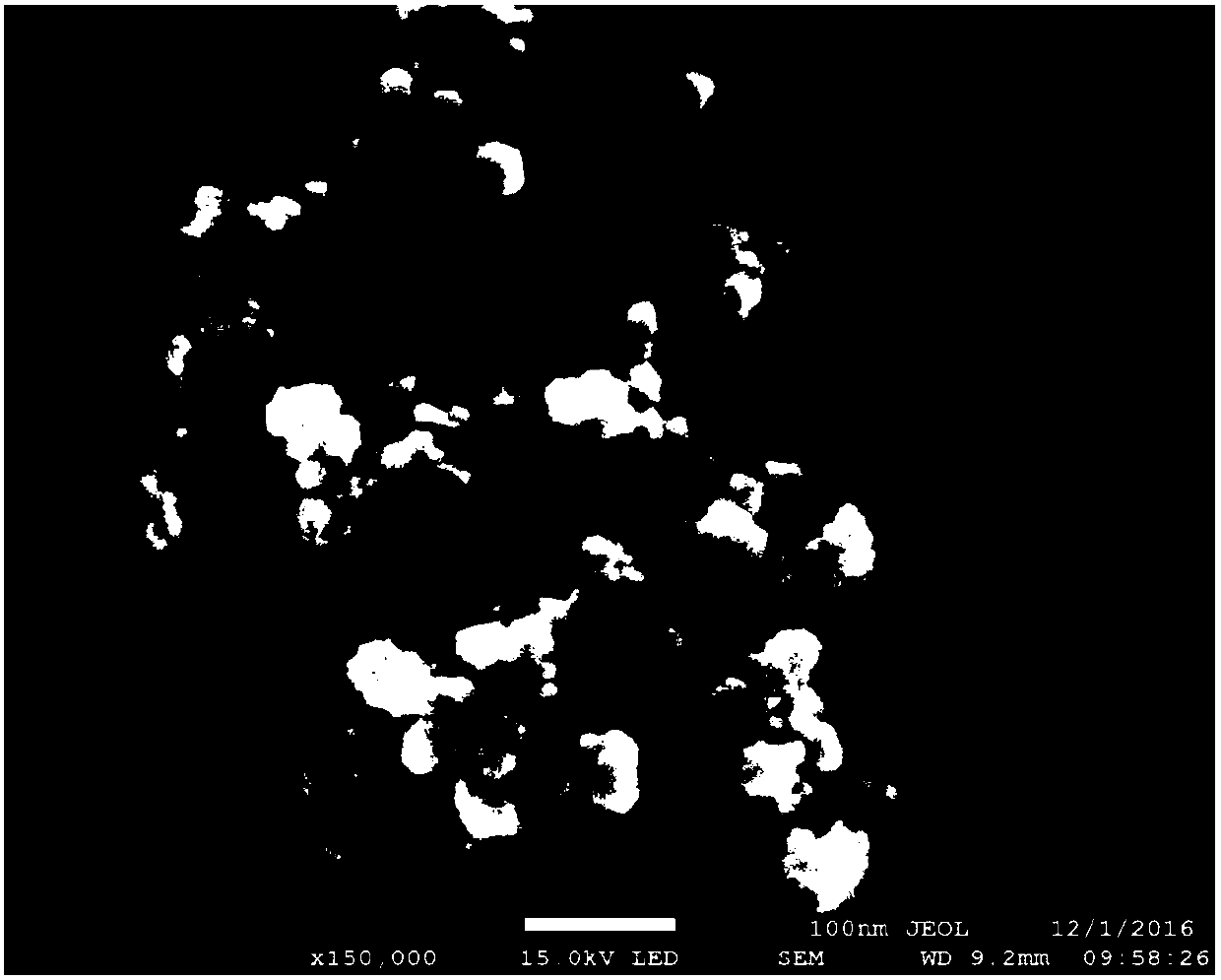

Catalyst for catalytic hydrogenation of p-nitrophenol and preparation method thereof

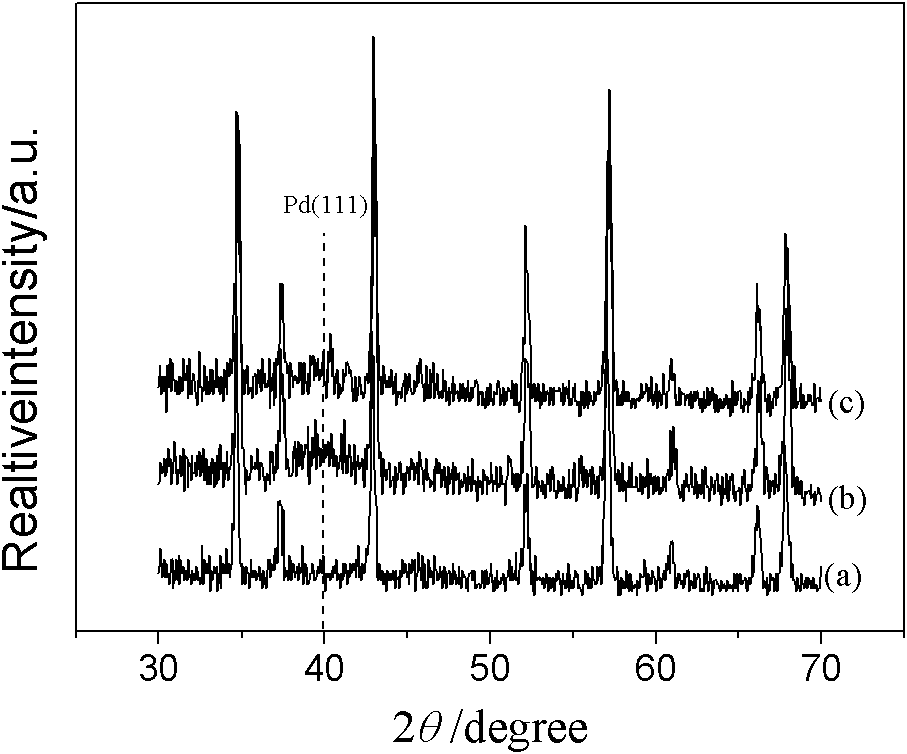

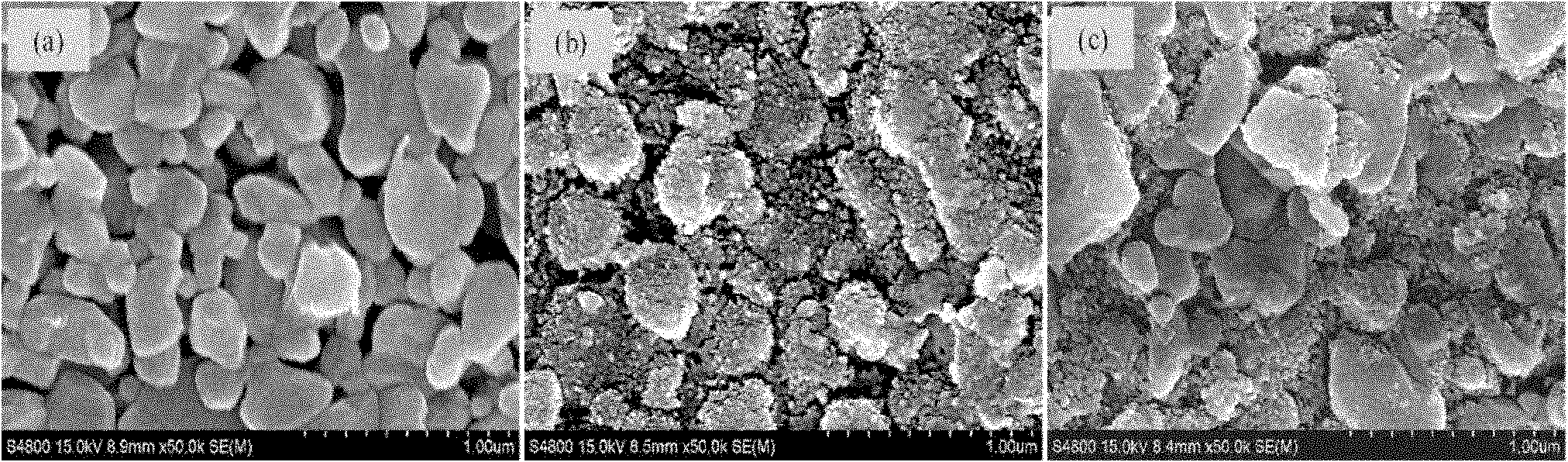

ActiveCN102091626AEasy to separateSimple production processCatalyst carriersOrganic compound preparationSilanesP-Aminophenol

The invention relates to a catalyst for preparing p-aminophenol through catalytic hydrogenation of p-nitrophenol, and a preparation method thereof, and belongs to the technical field of catalysis. The carrier of the catalyst is a ceramic membrane, and the preparation method comprises the following steps of: modifying the membrane surface by using aminosilane; immersing in salt solution of an active ingredient; and performing hydrazine hydrate reduction to prepare a catalytic membrane. The invention has the advantages that: nano-scale catalyst particles are supported on the surface of the ceramic membrane modified by silane, and the activity and stability of the catalyst are improved; moreover, a problem that the catalyst is hardly separated from the product subsequently is avoided. The catalyst is simple in preparation process and high in activity and stability and can be widely applied to preparing the p-aminophenol through catalytic hydrogenation of the p-nitrophenol.

Owner:NANJING UNIV OF TECH

Low temperature methods for hydrogen production

InactiveUS20050271579A1Nitrogen compoundsWaste based fuelHydrogenation reactionCatalytic transfer hydrogenation

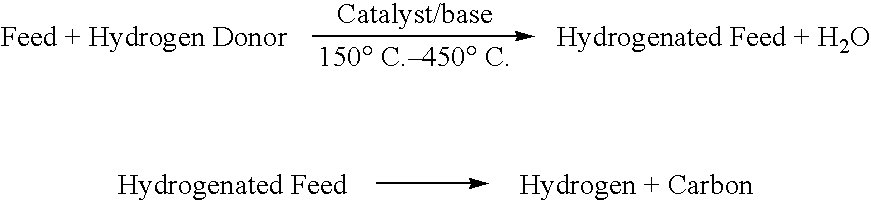

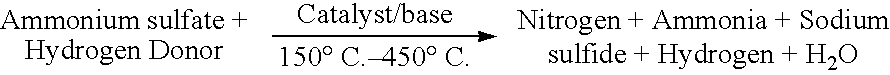

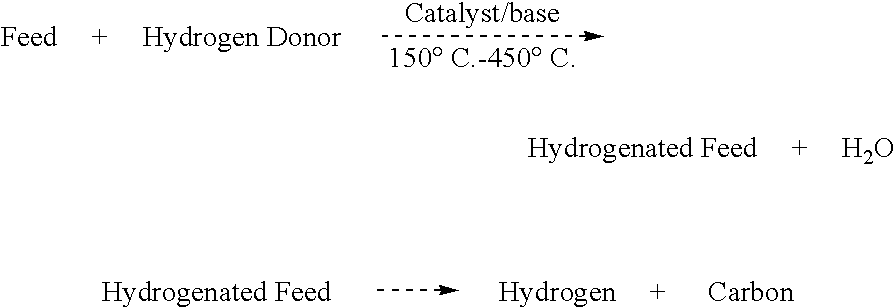

Methods for the production of hydrogen comprise heating a hydrogen-bearing feed material capable of undergoing a hydrogenation reaction in the presence of a hydrogen donor material, a catalyst promoting catalytic transfer hydrogenation, and a base at a temperature of from about 150° C. to about 450° C. for a time sufficient to hydrogenate the feed material and to dehydrogenate the hydrogenated feed material to produce hydrogen and carbon, and collecting the resulting hydrogen.

Owner:ROGERS FAMILY REVOCABLE LIVING TRUST

Nitrogen heterocycle ligand transition metal complex, and preparation and catalytic application thereof

ActiveCN102417523AThe synthesis method is simpleRuthenium organic compoundsOrganic compound preparationDiphosphinesKetone

The invention relates to a novel nitrogen heterocycle ligand / phosphine ligand transition metal complex, and preparation and application thereof in asymmetric catalytic hydrogenation and hydrogen transfer. The complex has the following structural formula: [MLnL' XY], wherein the transition metal M is Ru, Rh, Ir, Pd, Pt, Co, Ni or Os. The complex also contains a nitrogen heterocycle ligand, two monophosphine ligands or one diphosphine ligand, and the like. The transition metal compound, dinitrogen or mononitrogen ligand and diphosphine or monophosphine ligand react at 0-120 DEG C in an organic solvent for 0.5-20 hours to obtain the complex. The complex is used for asymmetric catalytic transfer hydrogenation or asymmetric hydrogenation reaction, and especially for asymmetric catalytic hydrogenation reaction of ketones, esters, hypnones and derivatives thereof, diphenyl ketones and derivatives thereof, beta-N,N-dimethylamino-alpha hypnones and derivatives thereof and other ketone compounds of which the alpha site is a large steric hindrance alkyl group.

Owner:ENANTIOTECH CORP

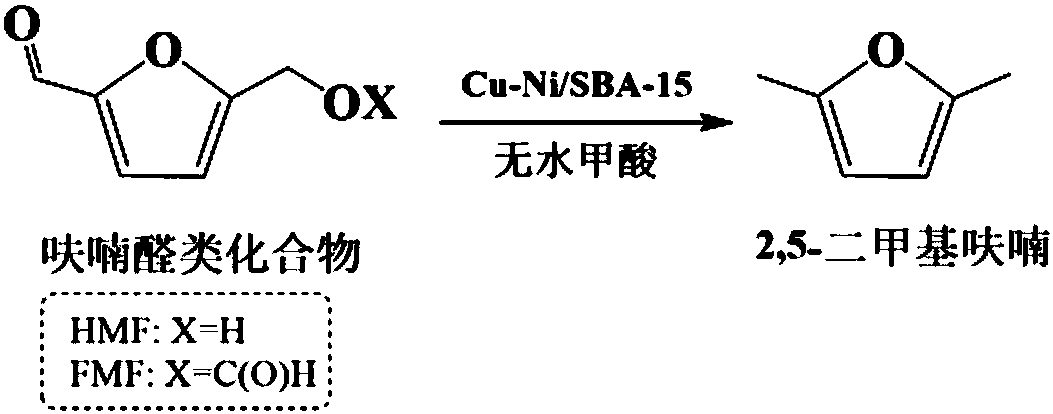

Preparation method of 2, 5-dimethylfuran

InactiveCN108047174AHigh activityHigh selectivityOrganic chemistryMolecular sieve catalystsSolubilityFuran

The invention discloses a preparation method of 2,5-dimethylfuran and relates to 2,5-dimethylfuran. A furan aldehyde compound serving as a substrate is added into an organic solvent to prepare a reaction substrate solution; the reaction substrate solution, anhydrous formic acid and a non-precious-metal catalyst are mixed and put into a reaction kettle, nitrogen gas is used for replacing dischargedair, heating and stirring are conducted for hydrodeoxygenation, and 2,5-dimethylfuran is obtained. The prepared supported non-precious-metal Ni-Cu / SBA-15 serves as a catalyst, formic acid serves as ahydrogen donor, and the furan aldehyde compound is subjected to catalytic transfer hydrogenation to synthesize DMF. The whole process is simple and easy to operate, the cost is low, the reaction system is green, the catalyst is high in activity, the selectivity of DMF is high, the yield is high, and the method has a wide industrial application prospect. Direct use of H2 is avoided, formic acid isused as a hydrogen source, 2,5-dimethylfuran is convenient to store and use, the requirement of a reaction solvent for the hydrogen solubility is reduced, the hydrogenation effect is good, the synthesis method is simple, the method is easy to operate, and energy consumption is low.

Owner:XIAMEN UNIV

Process for preparation of 2-phenyl ethanol

InactiveUS6979753B2Reduce usageEasy to separateOrganic compound preparationOxygen compounds preparation by reductionStyrene oxideSilicon dioxide

The present invention provides an improved process for preparation of 2-phenyl ethanol. More specifically, the present invention relates to a process for preparing 2-phenyl ethanol by catalytic transfer hydrogenation of styrene oxide, in the presence of a supported transition metal catalyst. The catalyst system comprises of a palladium supported on silica, alumina, clay or charcoal.

Owner:COUNCIL OF SCI & IND RES

Low temperature methods for hydrogen production

InactiveUS7520909B2Nitrogen compoundsWaste based fuelHydrogenation reactionCatalytic transfer hydrogenation

Methods for the production of hydrogen comprise heating a hydrogen-bearing feed material capable of undergoing a hydrogenation reaction in the presence of a hydrogen donor material, a catalyst promoting catalytic transfer hydrogenation, and a base at a temperature of from about 150° C. to about 450° C. for a time sufficient to hydrogenate the feed material and to dehydrogenate the hydrogenated feed material to produce hydrogen and carbon, and collecting the resulting hydrogen.

Owner:ROGERS FAMILY REVOCABLE LIVING TRUST

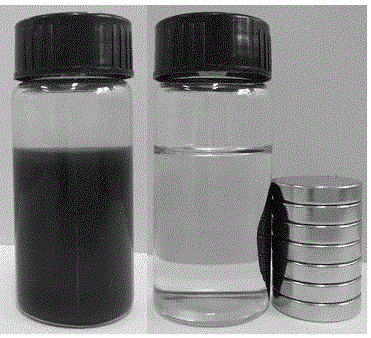

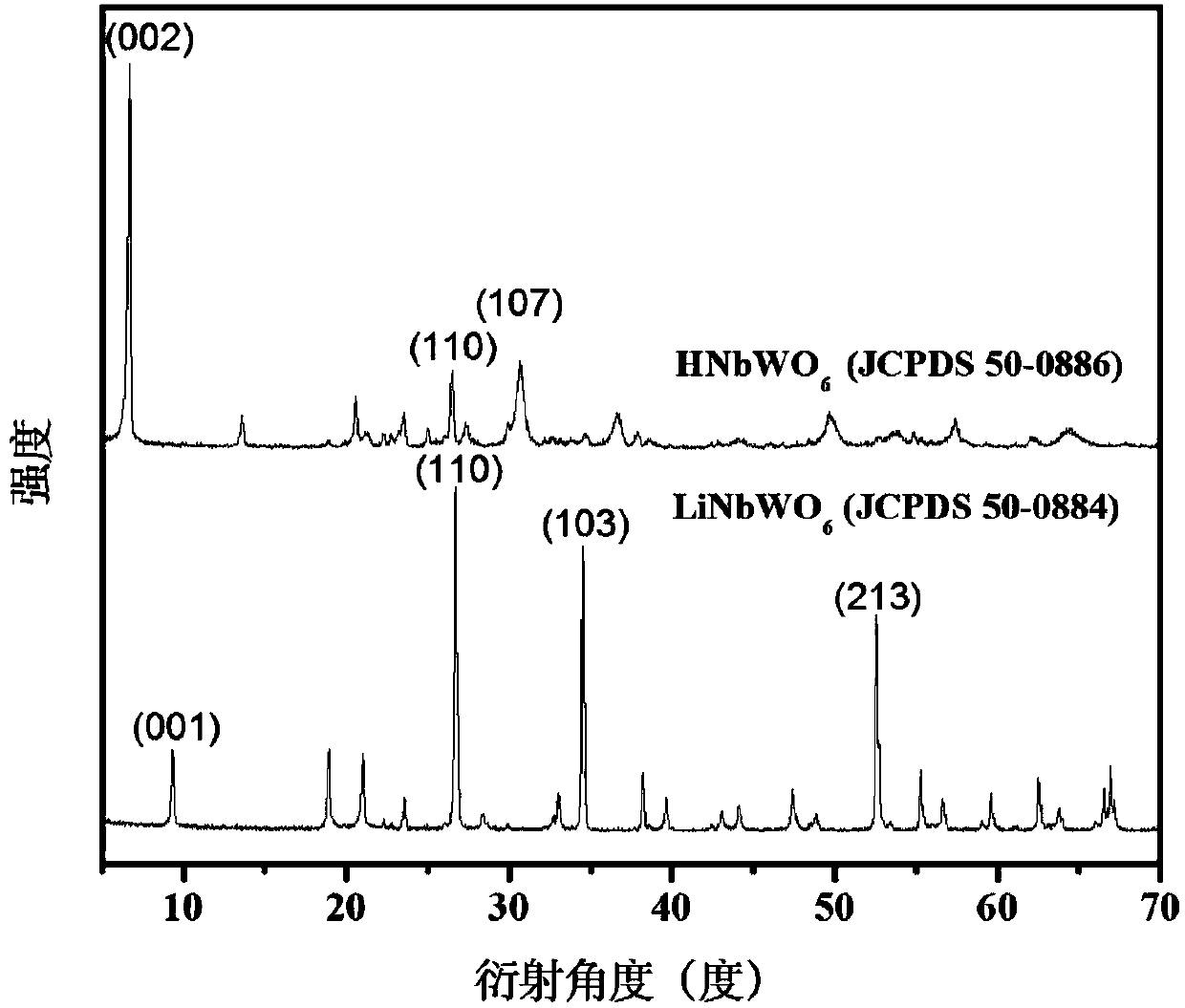

Method for preparing 2,5-dihydroxymethyl furan through 5-hydroxymethyl furfural catalytic transfer hydrogenation

The invention discloses a method for preparing 2,5-dihydroxymethyl furan through 5-hydroxymethyl furfural catalytic transfer hydrogenation. The method uses magnetic zirconium hydroxide as a catalyst, uses low carbon alcohol as a reaction solvent and a hydrogen donor, 5-hydroxymethyl furfural is selectively converted into the 2,5-dihydroxymethyl furan through Meerwein-Ponndorf-Verley (MPV) transfer hydrogenation reaction in a high-pressure reaction kettle, and the highest yield is up to 91.5%. The raw materials for the used catalyst are low in price, the preparation process is simple, and the catalytic performance is good. In addition, the 2,5-dihydroxymethyl furan has strong magnetism and is easy to separate, recycle and reuse. Furthermore, the used low carbon alcohol can serve as the in-situ hydrogen donor, hydrogen usage is omitted, and the safety of the reaction process is further improved. Moreover, the 2,5-dihydroxymethyl furan can also serve as a reaction solvent, introduction of exogenous substances is reduced, the production costs are further reduced, and the method has a high application value and a good industrialized prospect.

Owner:HUAIYIN TEACHERS COLLEGE

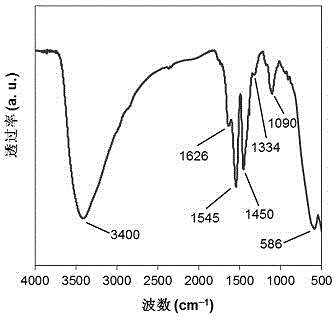

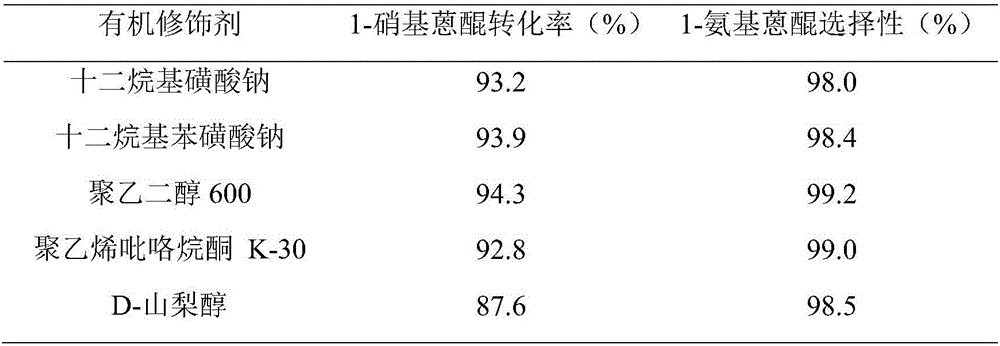

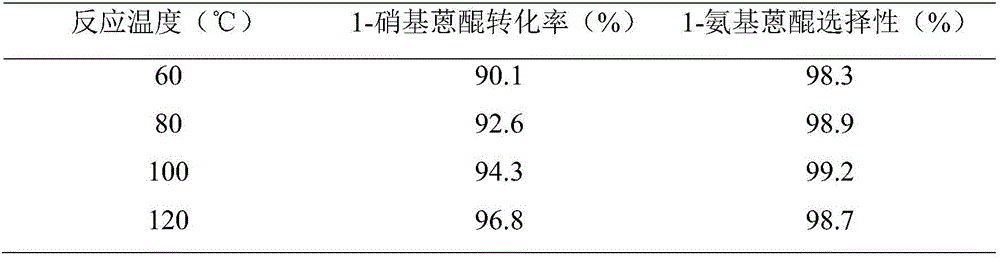

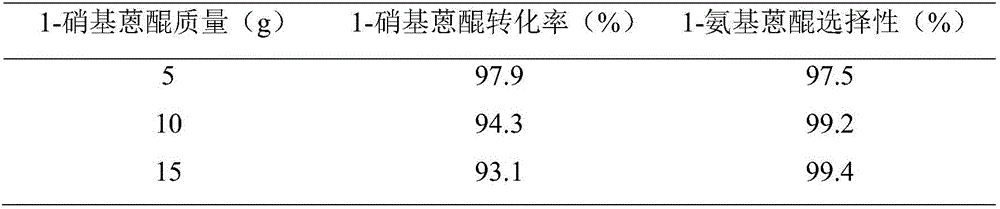

Method for preparing 1-amino-anthraquinone from 1-nitro-anthraquinone by catalytic hydrogenation

InactiveCN106242984ALess investmentSimple and safe operationOrganic chemistryOrganic compound preparationN dimethylformamideHigh pressure

The invention provides a method for preparing 1-amino-anthraquinone from 1-nitro-anthraquinone by catalytic hydrogenation. The method comprises the following steps: step 1, placing 1-nitro-anthraquinone and N,N-dimethylformamide into a high pressure reaction kettle; adding a certain amount of nano-copper / nickel binary alloy catalyst; mounting a reacting device well; feeding N2 to exhaust air; feeding high-purity hydrogen to exhaust the N2; and starting a stirring device; step 2, feeding a certain pressure of hydrogen into a system obtained in step 1 under a constant temperature condition for reacting; after the reaction is ended, reducing the temperature to be below 45 DEG C; diluting the reacting product 1-amino-anthraquinone; and finally analyzing and calculating a result by using high performance liquid chromatography. During a preparation procedure of a catalyst disclosed by the invention, different organic modifiers are used for controlling the size of particles; the nano-copper / nickel binary alloy catalyst of different structures and shapes is prepared; the catalytic performance of the catalyst is effectively improved.

Owner:JIANGSU UNIV

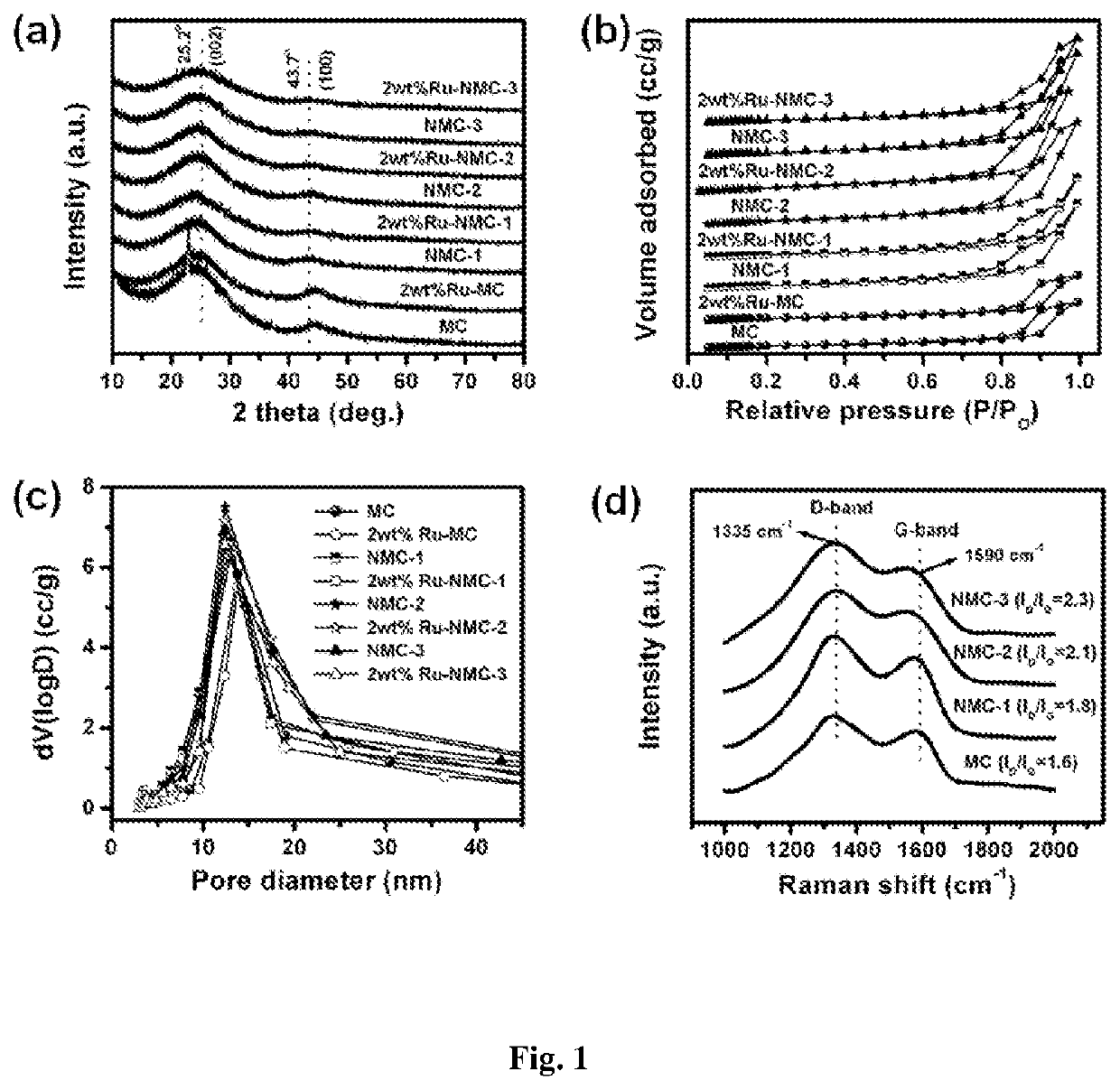

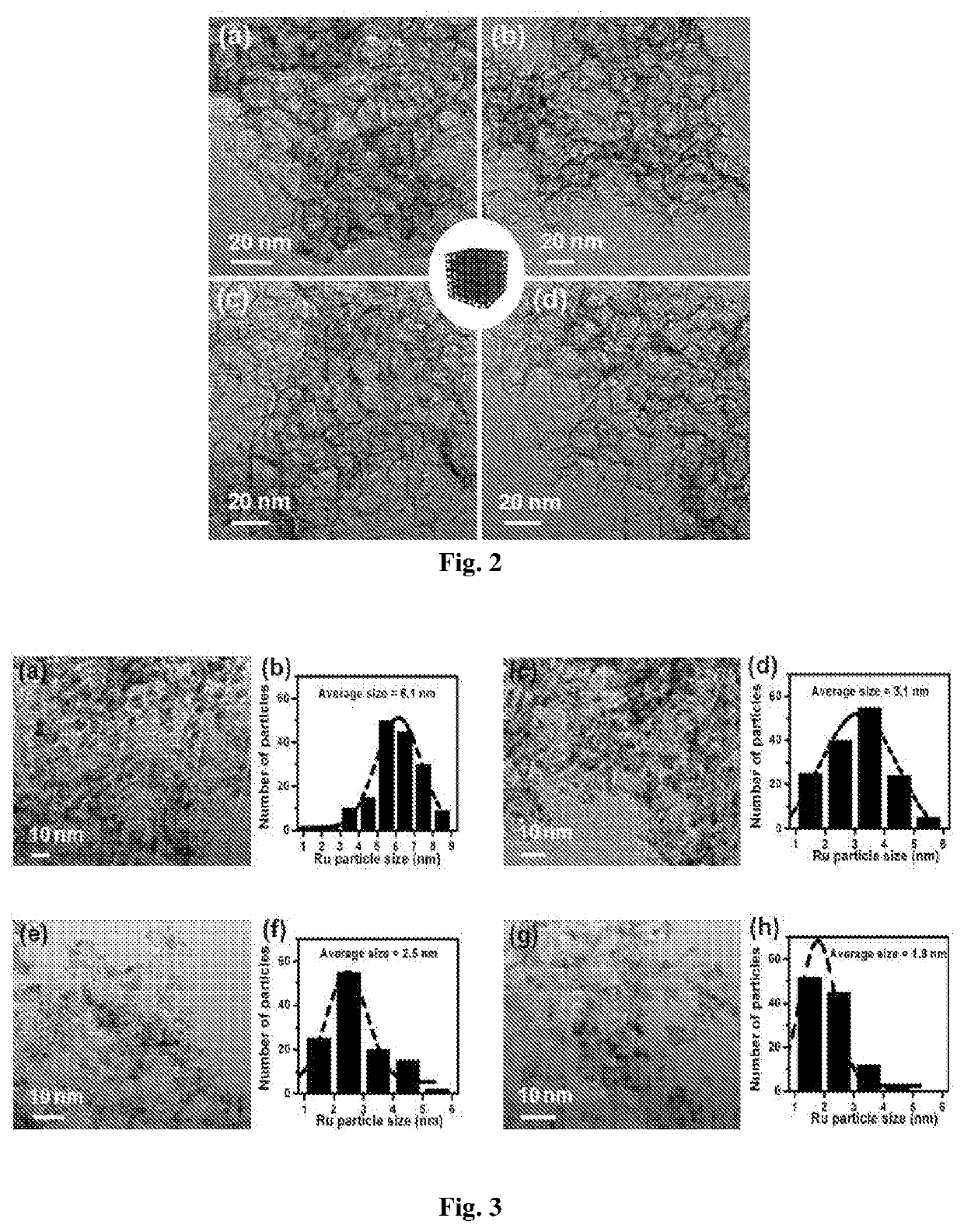

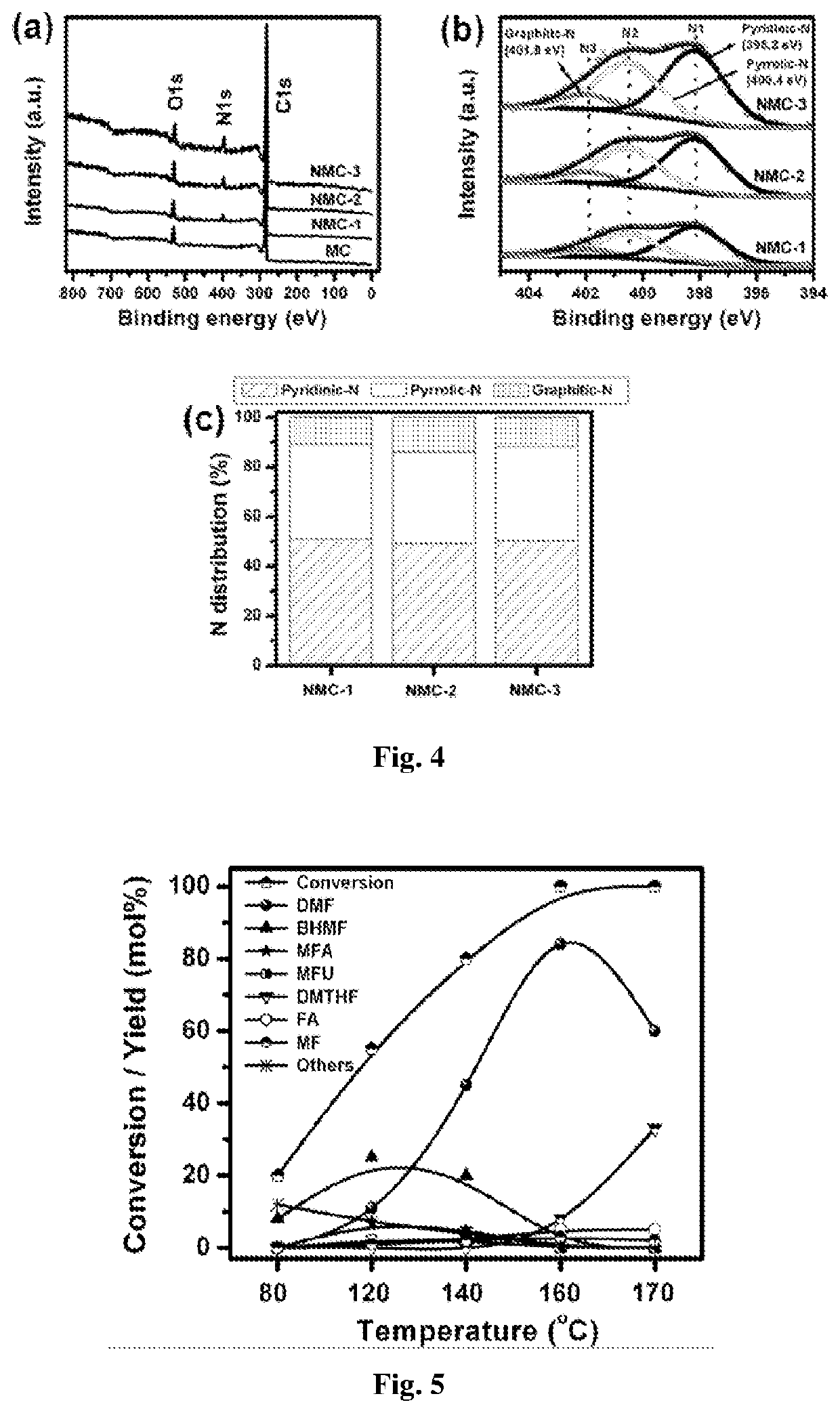

Transition metal(s) catalyst supported on nitrogen-doped mesoporous carbon and its use in catalytic transfer hydrogenation reactions

ActiveUS20200230578A1Good dispersionOrganic chemistryCatalyst activation/preparationFuranPtru catalyst

The present invention discloses a novel transition metal(s) catalyst supported on nitrogen-doped mesoporous carbon and a process for the preparation of the same. Further, the present invention discloses use of transition metal(s) supported on nitrogen-doped mesoporous carbon catalyst in catalytic transfer hydrogenation reaction. The invention also discloses an improved process for the synthesis of 2,5-Dimethylfuran (DMF) and 2-Methylfuran (MF) from 5-hydroxymethylfurfural (HMF) and furfural respectively, using alcohols as hydrogen donor over a transition metal supported on nitrogen-doped mesoporous carbon, especially ruthenium supported on nitrogen-doped mesoporous carbon without using any co-catalysts.

Owner:COUNCIL OF SCI & IND RES

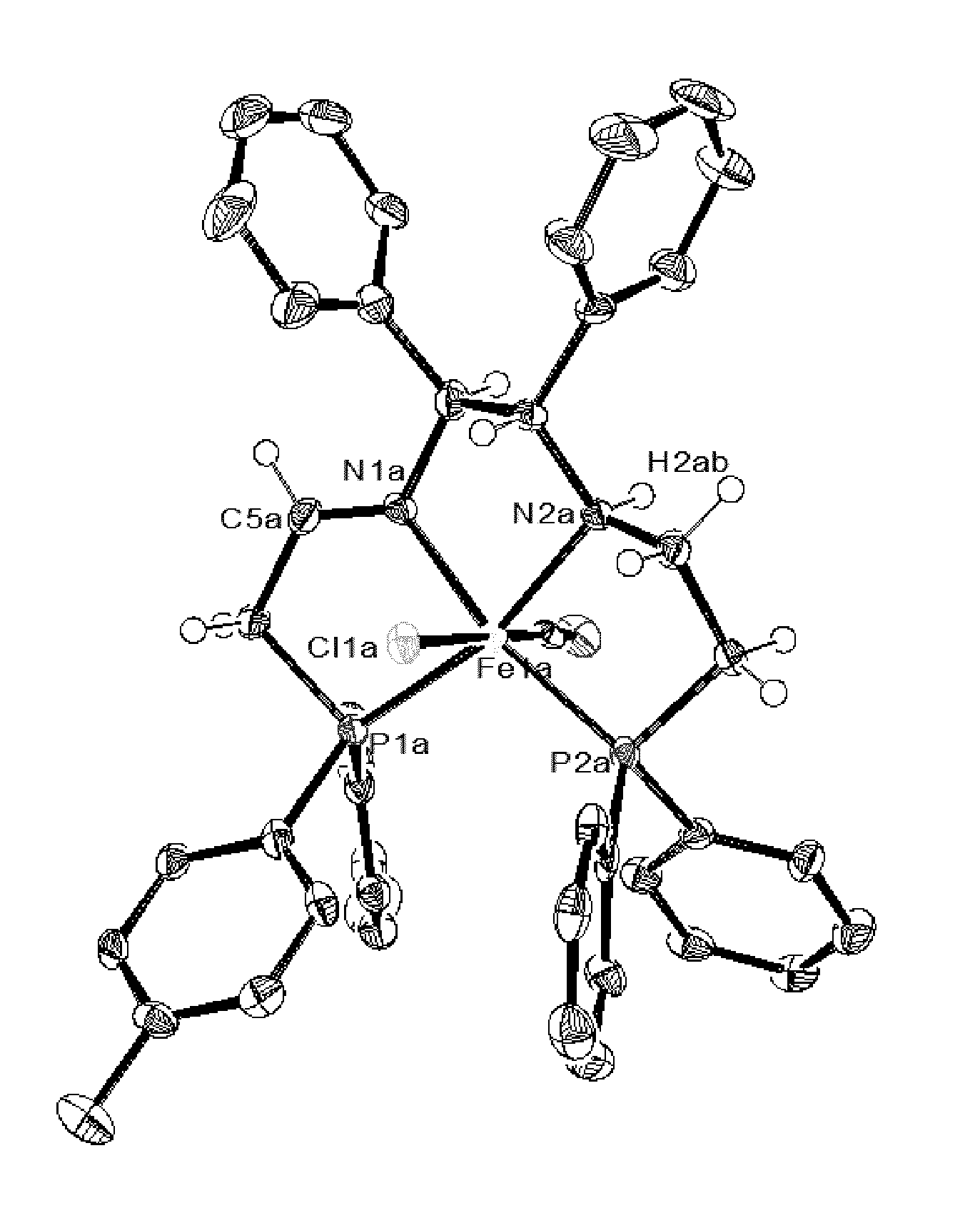

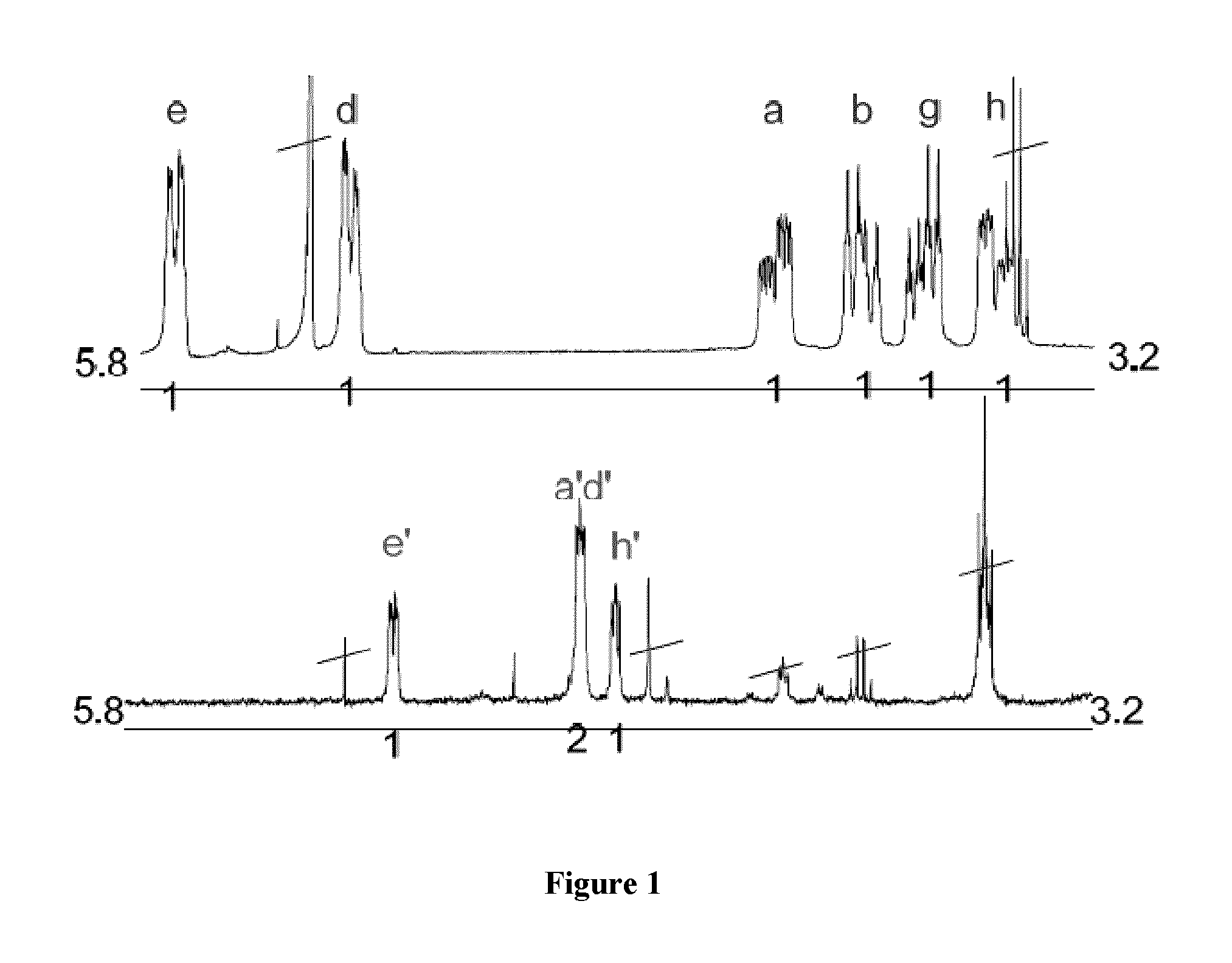

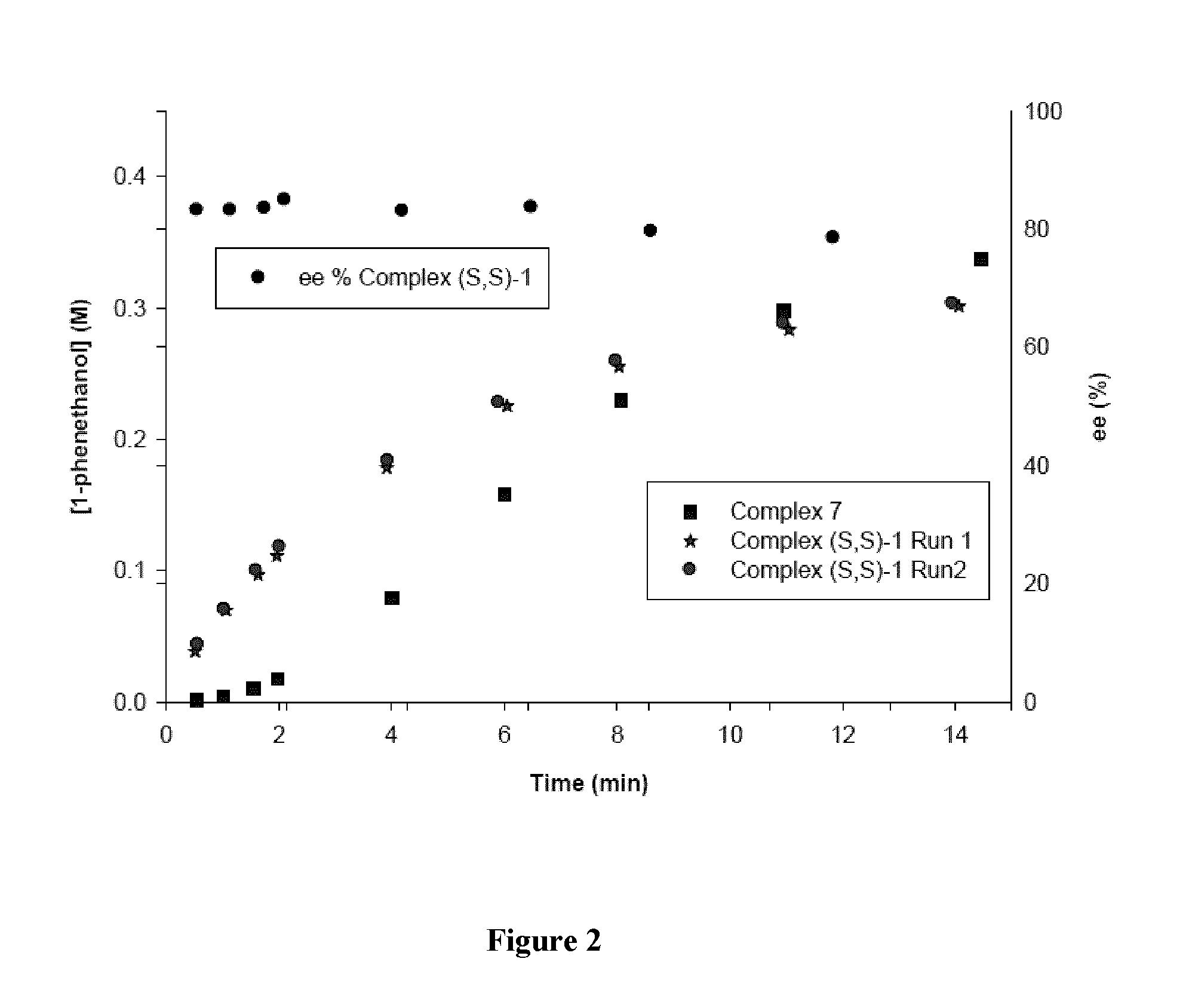

Iron catalysts with unsymmetrical pnn'p ligands

ActiveUS20150151289A1Easy to prepareHigh activityElectrolysis componentsOrganic compound preparationPolymer sciencePtru catalyst

The present invention relates to catalytic materials for hydrogenation or asymmetric hydrogenation. In particular, the invention relates to iron (II) complexes containing unsymmetrical tetradentate diphosphine (PNN′P) ligands with two different nitro gen donor groups useful for catalytic transfer hydrogenation or asymmetric transfer hydrogenation of ketones, aldehydes and imines.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

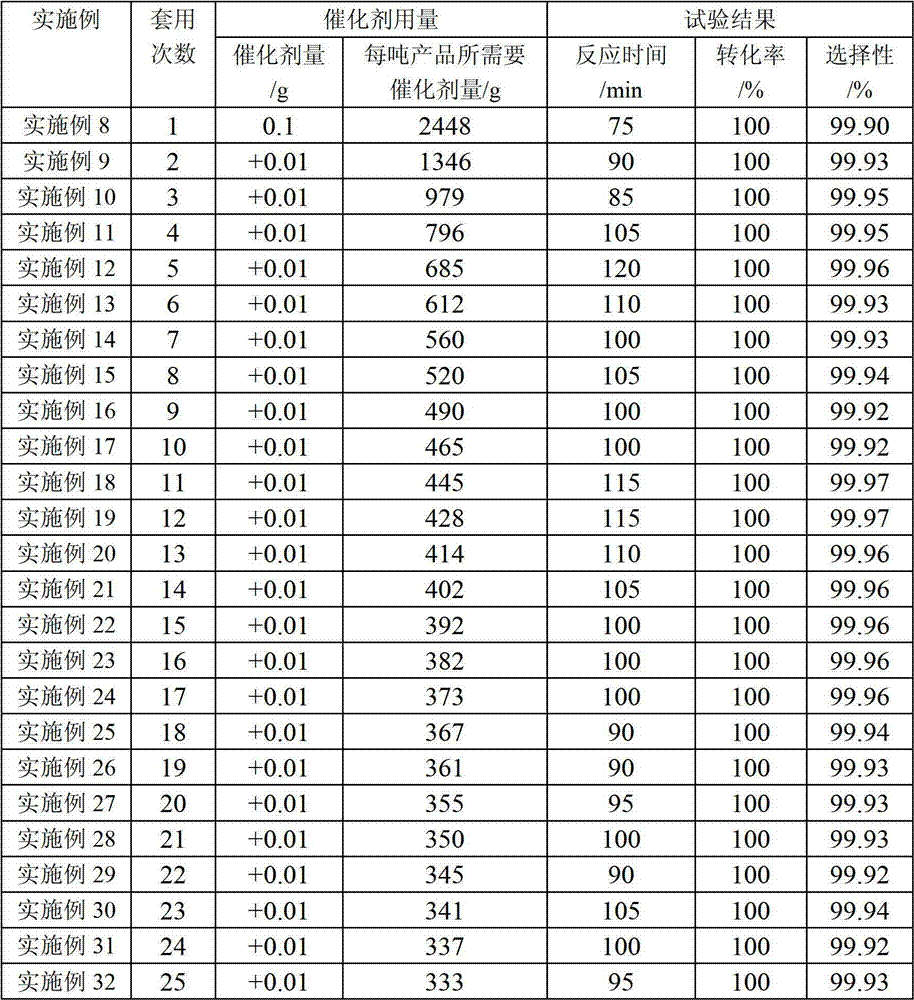

Method for preparing 3-chloro-4-methylaniline through catalytic hydrogenation

ActiveCN102786424AHigh activityHigh selectivityOrganic compound preparationAmino compound preparationMethylanilineAlcohol

The invention belongs to the field of organic synthesis and relates to a method for preparing 3-chloro-4-methylaniline through catalytic hydrogenation. The method comprises the steps of using 3-chloro-4-methylnitrobenzene as raw material and alcohol or alcohol-water as solvent, and performing hydrogenation reduction at the presence of a two component Pd-Fe / C catalyst to obtain the final product. The obtained 3-chloro-4-methylaniline has a selectivity of over 99.9% and a yield of over 99%. The method for preparing 3-chloro-4-methylaniline provided by the invention has the advantages of simple process, mild operating condition, little pollution, and high activity and selectivity of the used catalyst, and can effectively reduce production costs compared with the traditional process. The catalyst used can be used repeatably.

Owner:中国中化股份有限公司 +1

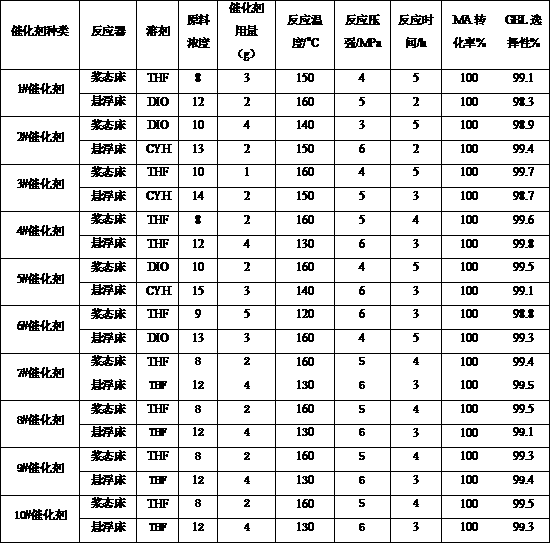

Modified nickel silicon catalyst and application thereof in preparation of gamma-butyrolactone (GBL) by means of catalytic hydrogenation of maleic anhydride

ActiveCN109529858AEffective control of decentralizationHigh catalytic activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsNickel saltCatalytic transfer hydrogenation

The invention discloses a modified nickel silicon catalyst and application thereof in preparation of gamma-butyrolactone (GBL) by means of catalytic hydrogenation of maleic anhydride. The active component of the catalyst is metal Ni, one or two of reducible metal oxides CeO2 ZnO and MoO3 is / are used as additive(s), and SiO2 is taken as a carrier, wherein the mass ratio of the metal Ni to the additive(s) to the SiO2 is equal to 1 to (0.04-0.7) to (2-3.2). A preparation method of the catalyst comprises the following steps: mixing a nickel salt with an additive precursor metal salt solution in proportion, and then adding ammonia water into the metal mixture to form a metal ammonia complex; then, dropwise adding alkaline silica sol into the complex mixed solution, and precipitating by using aheating ammonia distillation method; filtering the obtained precipitate, washing, drying and calcining to obtain the oxidized state modified nickel silicon catalyst which is abbreviated as a Ni-M-PS catalyst. The catalyst can be used for preparation of the GBL by means of the catalytic hydrogenation of the maleic anhydride, has higher catalytic activity and stability, and has a potential industrial application value.

Owner:SHANXI UNIV

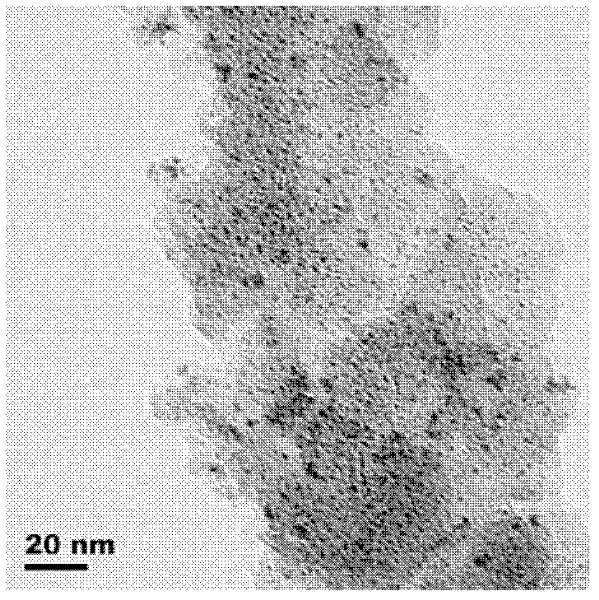

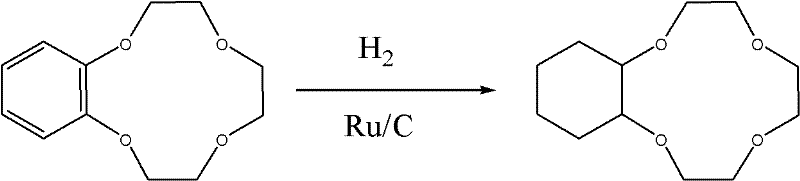

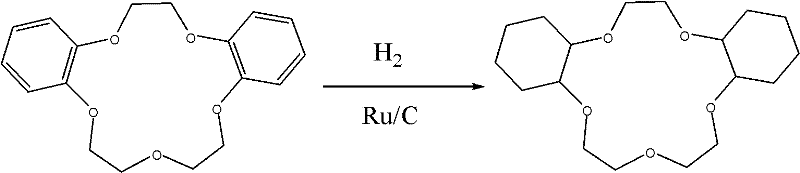

Method for preparing cyclohexyl crown ether by catalytic hydrogenation of carbon supported ruthenium catalyst

InactiveCN102516222ANon-flammableImprove securityOrganic chemistryChemical recyclingHydrogen pressureAsymmetric hydrogenation

The invention discloses a method for preparing cyclohexyl crown ether by catalytic hydrogenation of a carbon supported ruthenium catalyst. According to the method for preparing the cyclohexyl crown ether, a cyclohexyl substituted crown ether product is prepared by performing catalytic hydrogenation on benzo-crown ether which is used as raw materials under the action of the carbon supported ruthenium catalyst; and the mass ratio of the benzo-crown ether to the carbon supported ruthenium catalyst is 1:(0.01-1), the temperature in a reaction process is controlled to be 70 to 200 DEG C, and hydrogen pressure is 2 to 10 Mpa. The method for preparing the cyclohexyl crown ether has the advantages of high operability, and high safety; the catalyst is easy to recover; a carbon material with a large specific area is used as a catalyst carrier, so the dispersion degree of ruthenium is improved, and the using amount of ruthenium is reduced; and therefore, the method is low in cost.

Owner:TSINGHUA UNIV

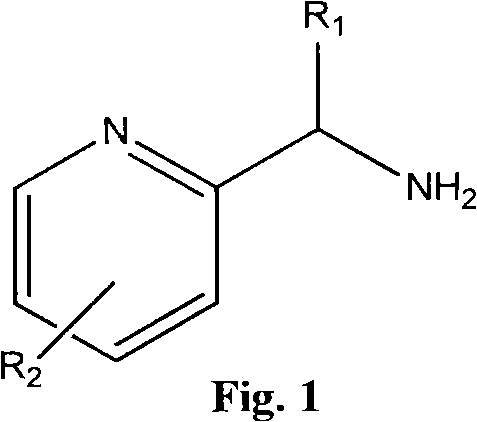

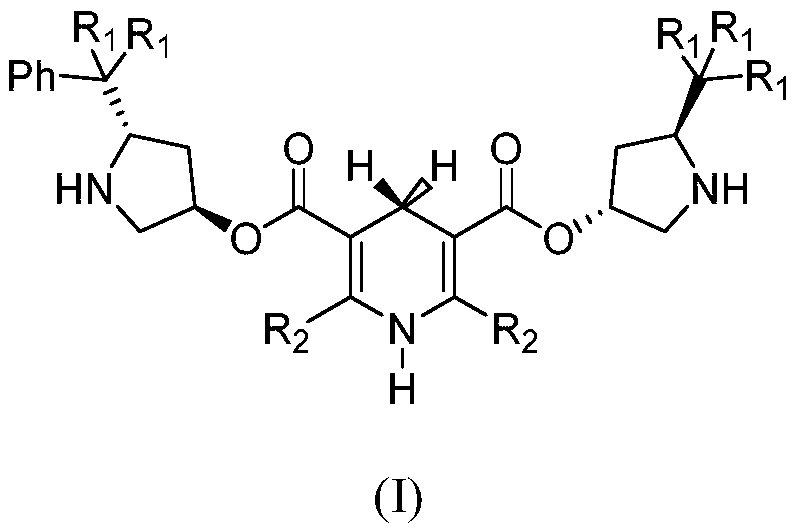

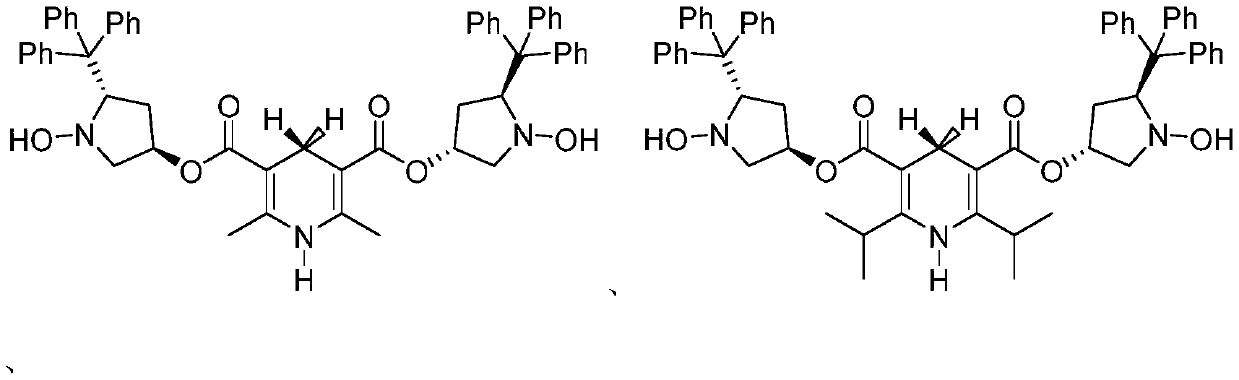

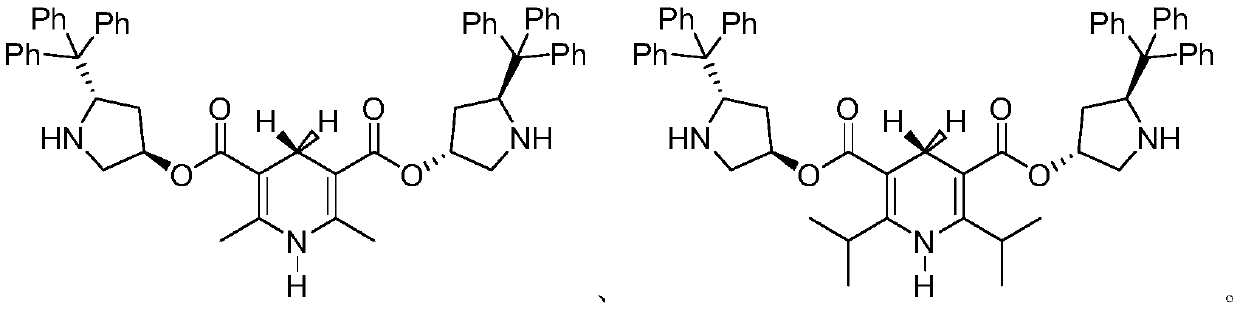

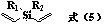

1, 4-dihydropyridine bifunctional chiral catalyst and preparation method and application thereof

InactiveCN109824652AAvoid residueReduce pollutionCarboxylic acid nitrile preparationOrganic compound preparationDihydropyridineBifunctional

The invention belongs to the field of organic catalysis, and discloses a novel 1, 4-dihydropyridine bifunctional chiral catalyst and a preparation method and application thereof. The general chemicalstructure formula of the chiral catalyst is shown in formula (I) as shown in specification. According to the invention, a 1, 4-dihydropyridine derivative and a chiral tetrahydropyrrole derivative areused as raw materials, and finally, the novel 1, 4-dihydropyridine bifunctional chiral catalyst is synthesized. The method has mild synthesis reaction conditions and high yield. The operation steps are simple, safe and reliable; the catalyst is environment-friendly, and can be applied to the fields of asymmetric catalytic transfer hydrogenation, chiral fine chemical synthesis, chiral drug or drugintermediate synthesis, chiral new materials, chiral functional molecule synthesis and the like; and the application prospect is wide.

Owner:广西九圣新材料有限公司

Method for preparing cyclohexanone oxime by catalysis of transferring and hydrogenating of nitrocyclohexane

ActiveCN109160887ALow costEasy to operateOximes preparationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonHydrogenation reaction

The invention discloses a method for preparing cyclohexanone oxime by catalysis of transferring and hydrogenating of nitrocyclohexane. The method comprises the following steps: adding catalyst cupper-nickel-loaded activated carbon, nitrocyclohexane and an amine borane compound in a reactor according to the mass ratio of 0.1-0.4 to 1 to 2-20.8; reacting for 6 to 12 hours at 50 to 80 DEG C under stirring conditions to obtain a reaction liquid; filtering and separating the obtained reaction liquid to obtain the cyclohexanone oxime. According to the method, hydrogenation reaction of the nitrocyclohexane is catalyzed by taking a hydrogen storage material as a hydrogen donor; a preparation process can be completed through a common glass instrument without the equipment, such as a high-pressure reaction kettle, so that the cost of a reaction device is reduced, the operation of the reaction is simplified, and the safety of a reaction process is improved.

Owner:HUNAN UNIV OF SCI & ENG

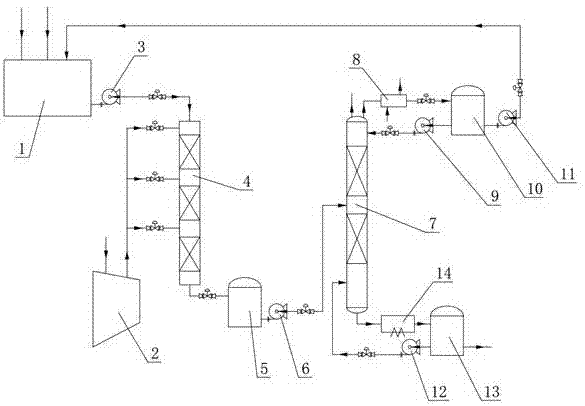

Process for preparing hexahydrophthalic anhydride (HHPA) by means of catalytic hydrogenation

ActiveCN107011304AReduce generationUniform and controllable response layoutOrganic chemistryHexahydrophthalic anhydrideMetal catalyst

The invention discloses a process for preparing hexahydrophthalic anhydride (HHPA) by means of catalytic hydrogenation. The process includes preparing Pd-NiO / SiO2 catalysts by the aid of impregnation processes by SiO2 used as a carrier; catalytically hydrogenating tetrahydrophthalic anhydride in a trickle-bed reactor to prepare the hexahydrophthalic anhydride (HHPA). The process has the advantages that the optimal reaction conditions and process parameters are explored; the SiO2-supported Pd and Ni binary-metal catalysts are adopted, the activity of the catalysts is appropriately deteriorated, the hydrogen partial pressures are increased, and accordingly the selectivity of the hexahydrophthalic anhydride (HHPA) which is a target product can be effectively improved; hydrogen can flow into the trickle-bed reactor from an upper location, a middle location and a lower location, accordingly, reaction layout is uniform and controllable, and side reaction can be reduced; heat generating reaction is carried out during catalyst hydrogenation, the internal circulation speed of the hydrogen in the reactor can be increased, the hydrogen is used as a heat transfer medium, accordingly, reaction heat can be timely transferred, local overheating phenomena can be effectively prevented, and the side reaction can be reduced.

Owner:PUYANG SHENGYUAN ENERGY TECH

Method used for high efficiency preparation of N,N'-dibenzylethylenediamine (DBE) through catalytic hydrogenation

ActiveCN108218718AReduced activityInhibition of hydrogenolysis reactionPhysical/chemical process catalystsOrganic compound preparationEthylenediamineSulfur

The invention discloses a method used for high efficiency preparation of N,N'-Bis(phenylmethyl)-1,2-ethanediamine (DBE) through catalytic hydrogenation. The method comprises a following step: in a reaction vessel, N,N'-dibenzylidene ethylenediamine is subjected to liquid phase catalytic hydrogenation under the catalytic effect of a nitrogen / sulfur codoped mesoporous carbon loaded noble metal catalyst so as to obtain DBE. The method is high in target product selectivity.

Owner:浙江辰阳化工有限公司

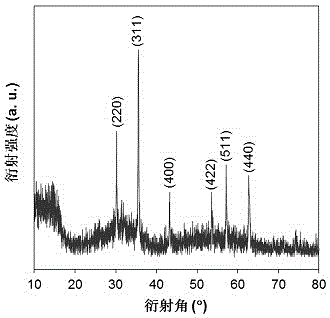

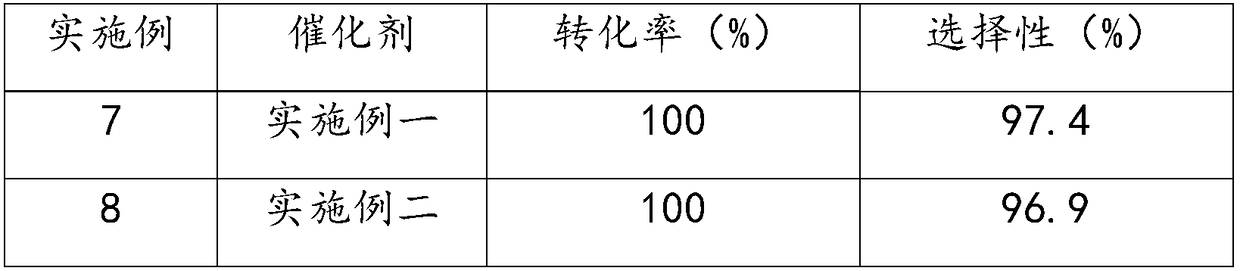

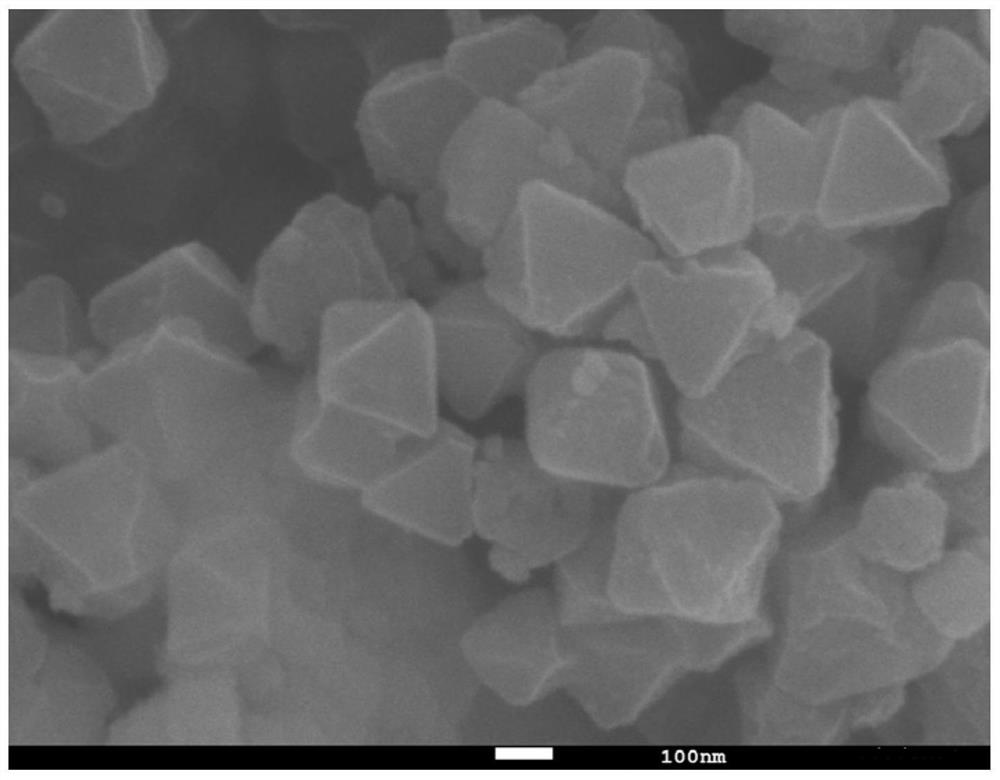

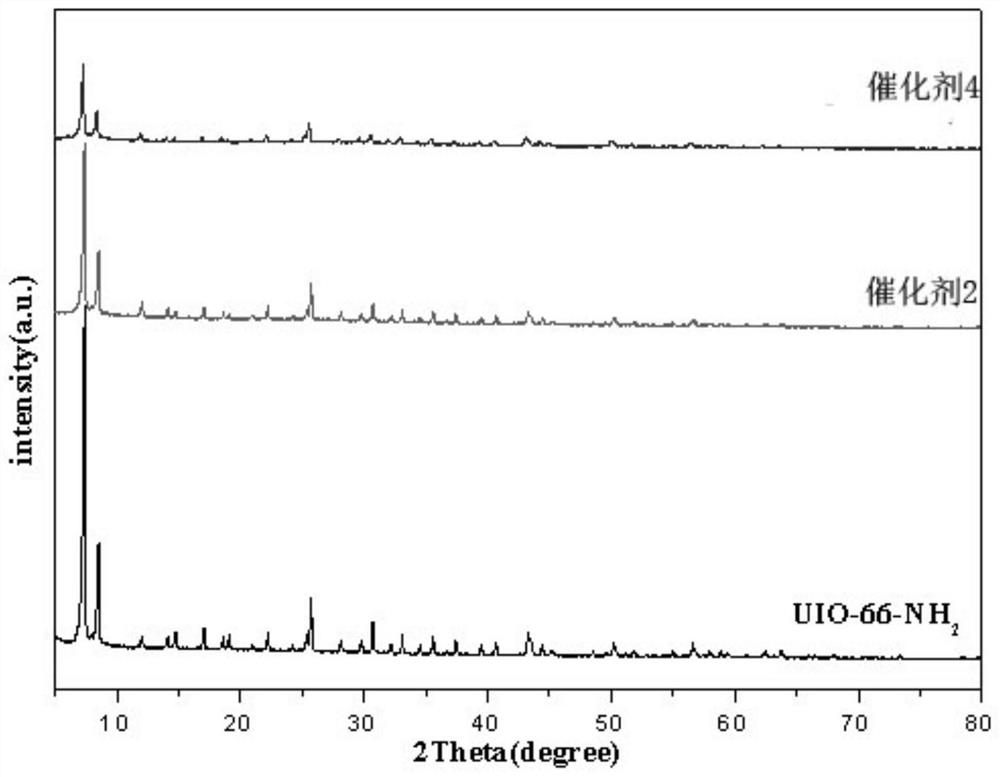

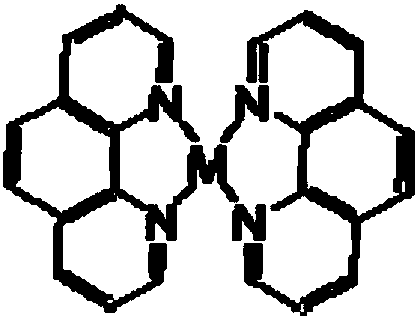

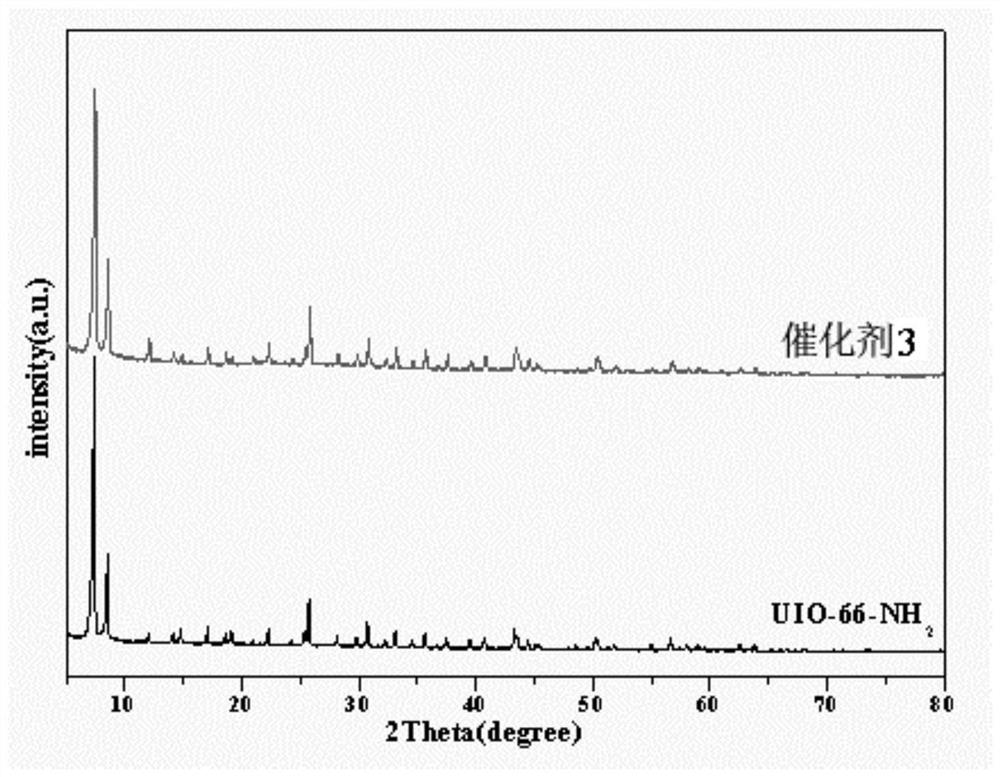

Catalyst for catalytic transfer hydrogenation and preparation method and application thereof

ActiveCN112121863AHigh catalytic transfer hydrogenation activityHigh activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsFuranPtru catalyst

The invention belongs to the technical field of catalyst material preparation, and discloses a catalyst for catalytic transfer hydrogenation and a preparation method and application thereof. The catalyst comprises a metal organic framework compound and metal cobalt loaded on the metal organic framework compound, and the loading capacity of the metal cobalt is 6%-35%. According to the catalyst provided by the invention, the MOFs material is selected to load metal cobalt, so that the catalyst has high activity and high selectivity; the catalyst has strong stability and a stable skeleton structure, and does not collapse to influence the catalytic effect. When the catalyst provided by the invention is used for catalyzing 5-hydroxymethyl furfural to prepare 2, 5-dihydroxymethyl furan, the catalyst still shows high activity when a solvent is used as a hydrogen donor, the reaction temperature is relatively low and the reaction time is relatively short, the conversion rate of HMF is as high as98.5%, and the selectivity of DHMF is as high as 95.6%. The preparation method of the catalyst provided by the invention is simple, easy to operate, low in equipment requirement and low in synthesiscost.

Owner:GUANGZHOU UNIVERSITY

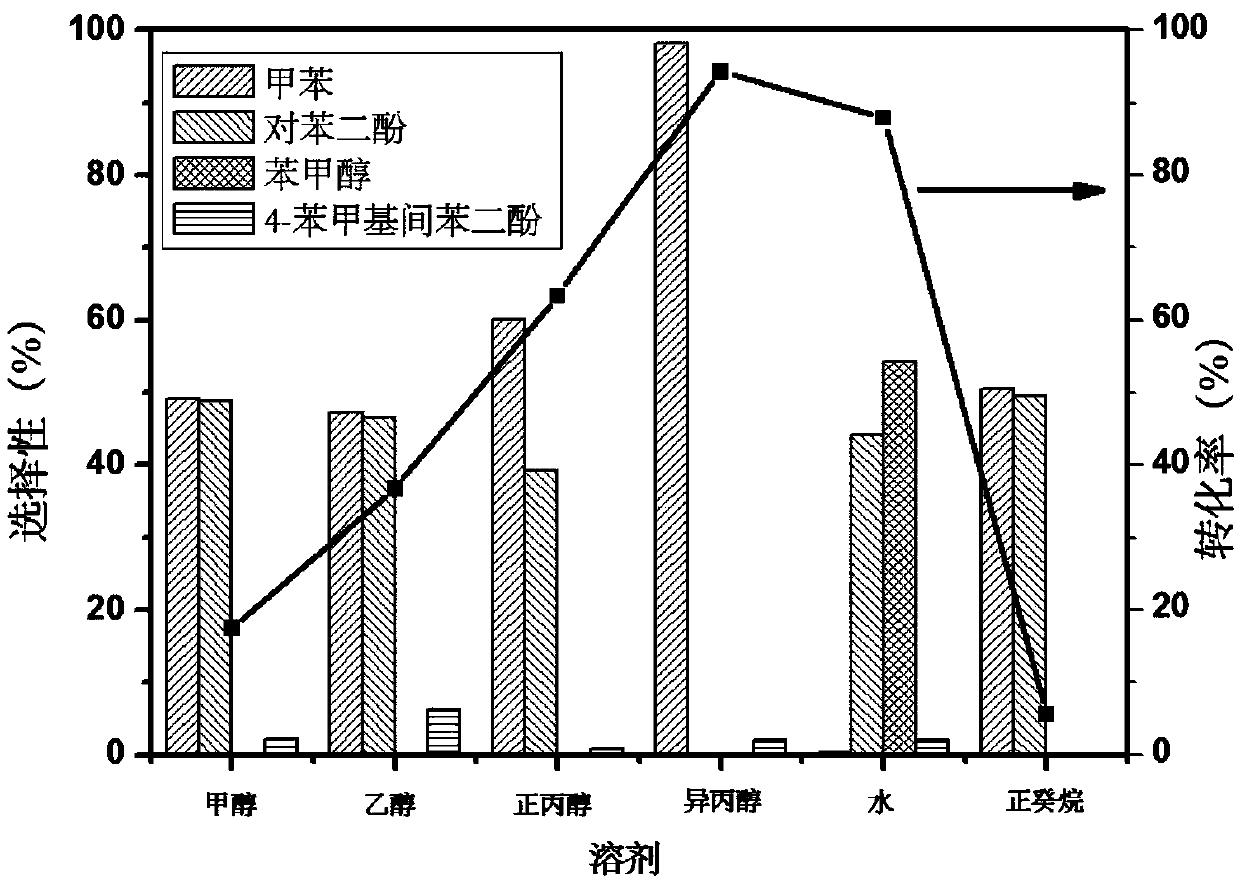

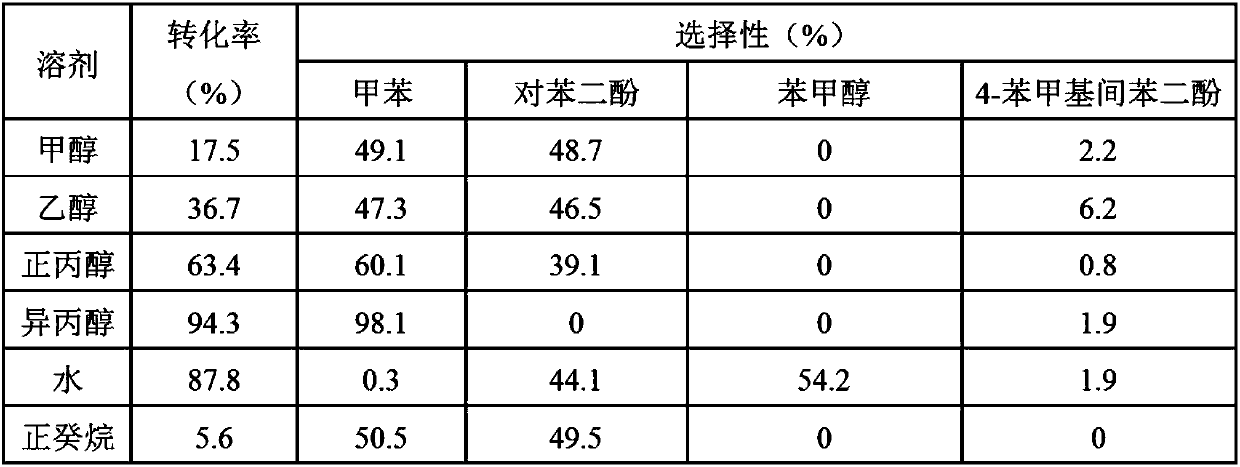

Method for preparing arene by carrying out high-selectivity catalytic transfer hydrogenation on lignin derivative

ActiveCN108048125AReduce restrictionsGood low temperature deoxidation activityHeterogenous catalyst chemical elementsLiquid hydrocarbon mixture productionAlkaneLiquid fuel

The invention discloses a method for preparing arene by carrying out high-selectivity catalytic transfer hydrogenation on a lignin derivative. Namely, the method is a process of carrying out catalyticdeoxidation by using an aromatic oxide compound which is the richest in a lignin structure to convert the aromatic oxide compound as a raw material into unsaturated arene liquid fuel. The method disclosed by the invention is applicable to a tank reactor and can reach 94% or more of feed stock conversion and saturated alkane selectivity. Moreover, reaction conditions are mild, a catalyst preparation process is simple and low in cost, and the arene has higher activity, selectivity and high stability. More importantly, in the process of preparing the unsaturated liquid arene fuel, which is disclosed by the invention, supply of outside hydrogen is not required, and a solvent provides hydrogen atoms. The aims of saving energy and reducing cost can be fulfilled. The technical scheme of the invention provides a new approach of efficiently preparing the unsaturated arene liquid fuel in an environment without consuming the outside hydrogen by downstream products derived from renewable resources with rich reserves; the method has a very wide application prospect.

Owner:DALIAN UNIV OF TECH

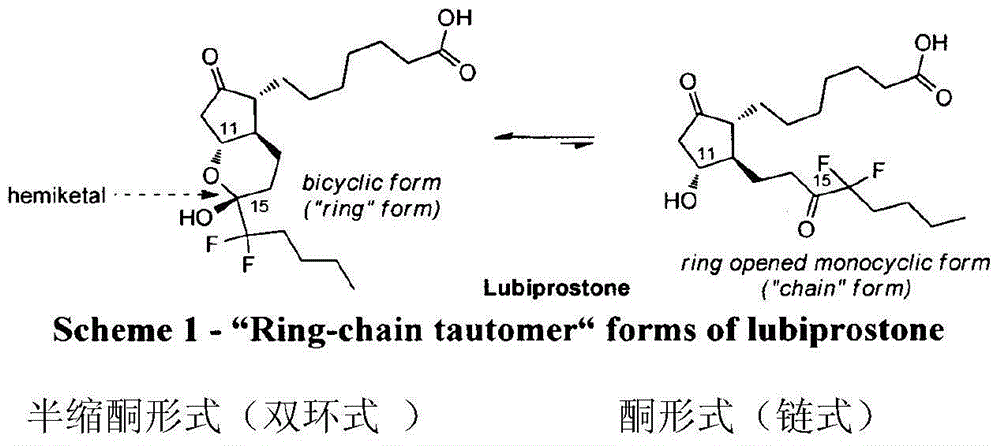

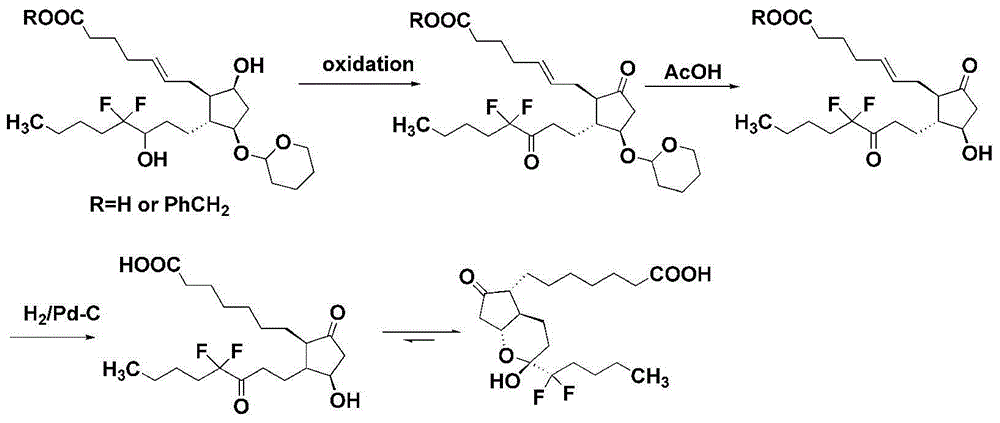

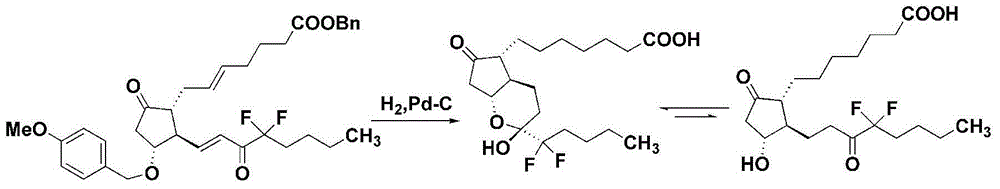

Method for preparing lubiprostone compound

ActiveCN104557845AShort reaction timeHigh reaction yieldOrganic chemistryBulk chemical productionHydrogenTriethylsilane

The invention relates to a method for preparing lubiprostone. The method comprises the following steps: by taking triethyl silicane as a hydrogen source, and taking palladium carbon or palladium hydroxide as a catalyst, performing catalytic transfer hydrogenation, removing the protecting groups, and reducing double bonds, thereby obtaining the product. Compared with a conventional catalytic hydrogenation reaction at present, the method has the advantages of simplicity in operation, mild reaction conditions, high yield and high purity, the reaction time and reaction period are obviously shortened, the production efficiency is greatly improved, the requirements on reaction equipment are reduced, and the method is suitable for industrial production.

Owner:QILU PHARMA CO LTD

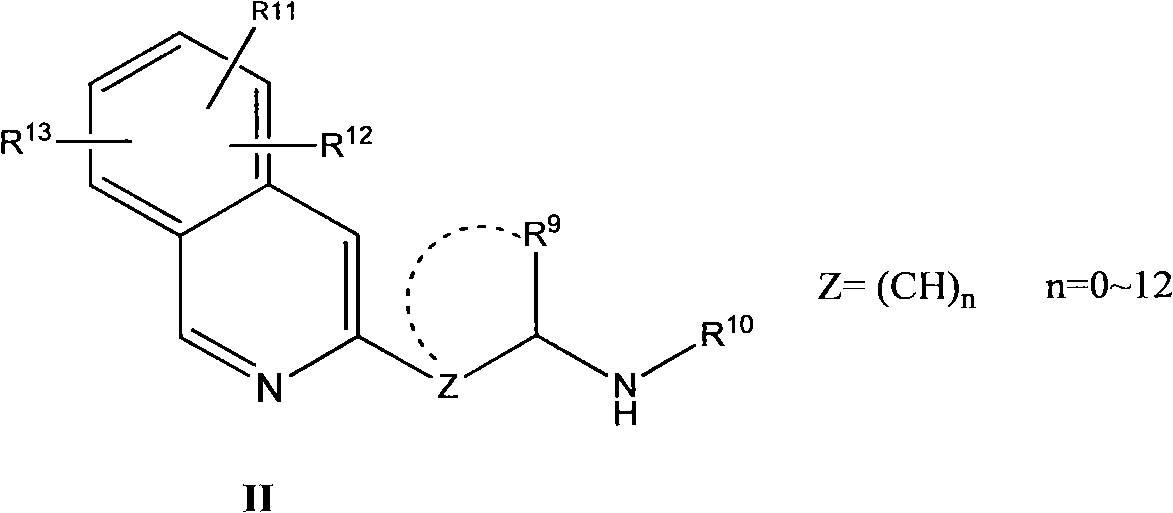

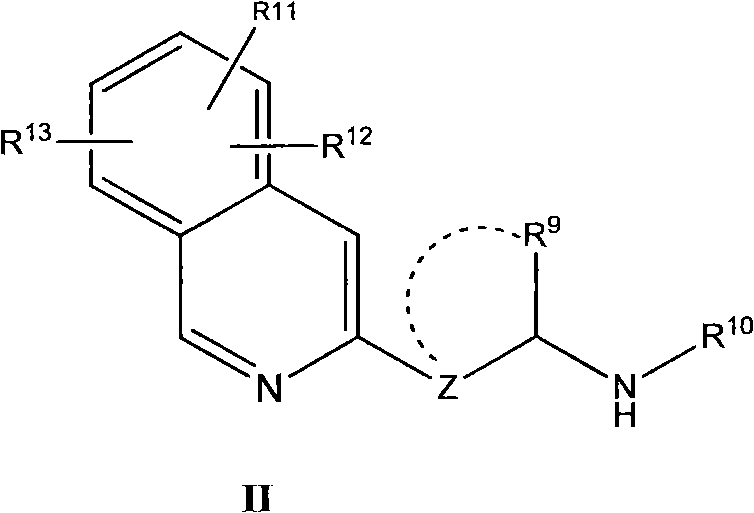

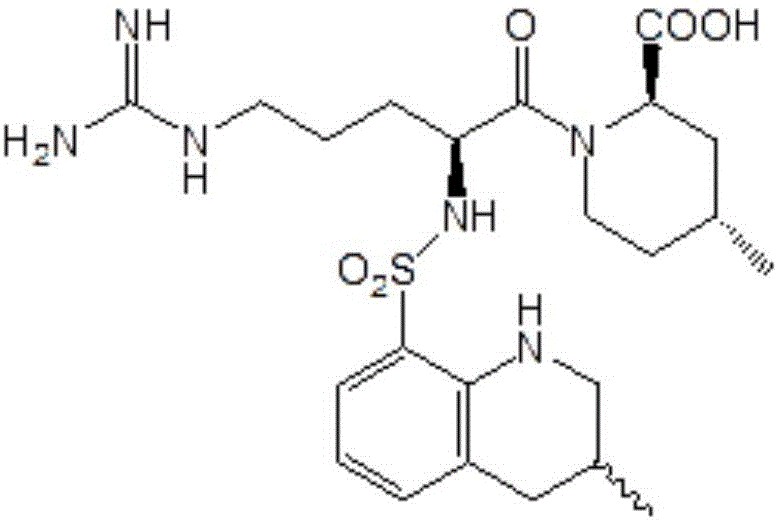

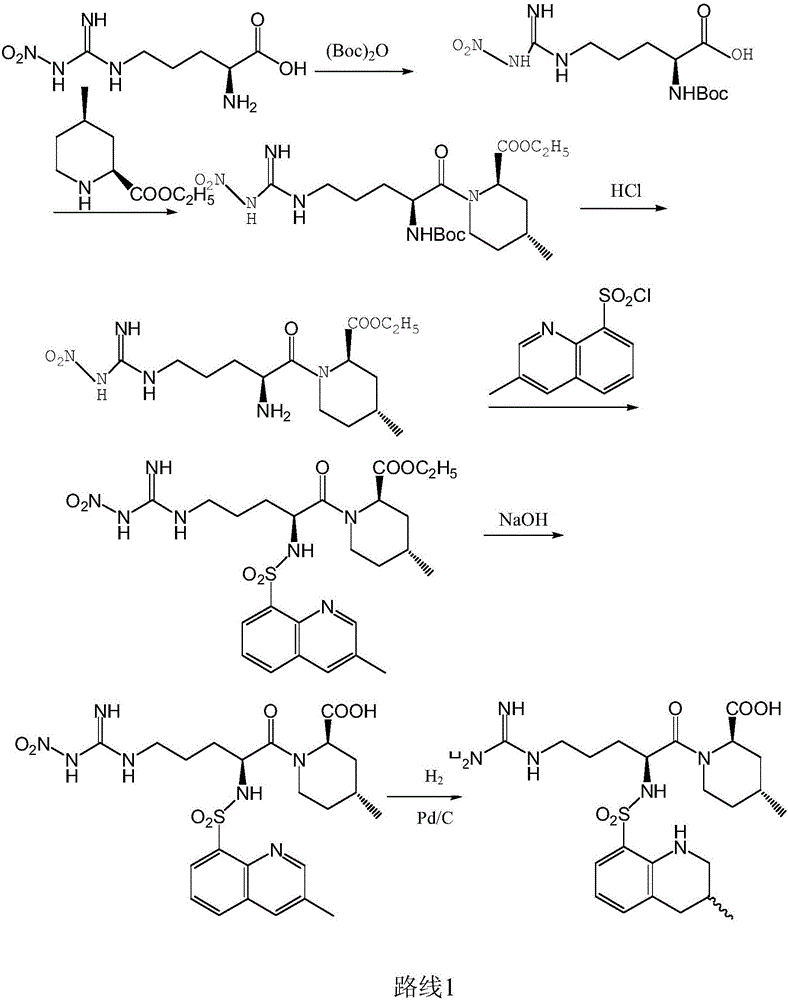

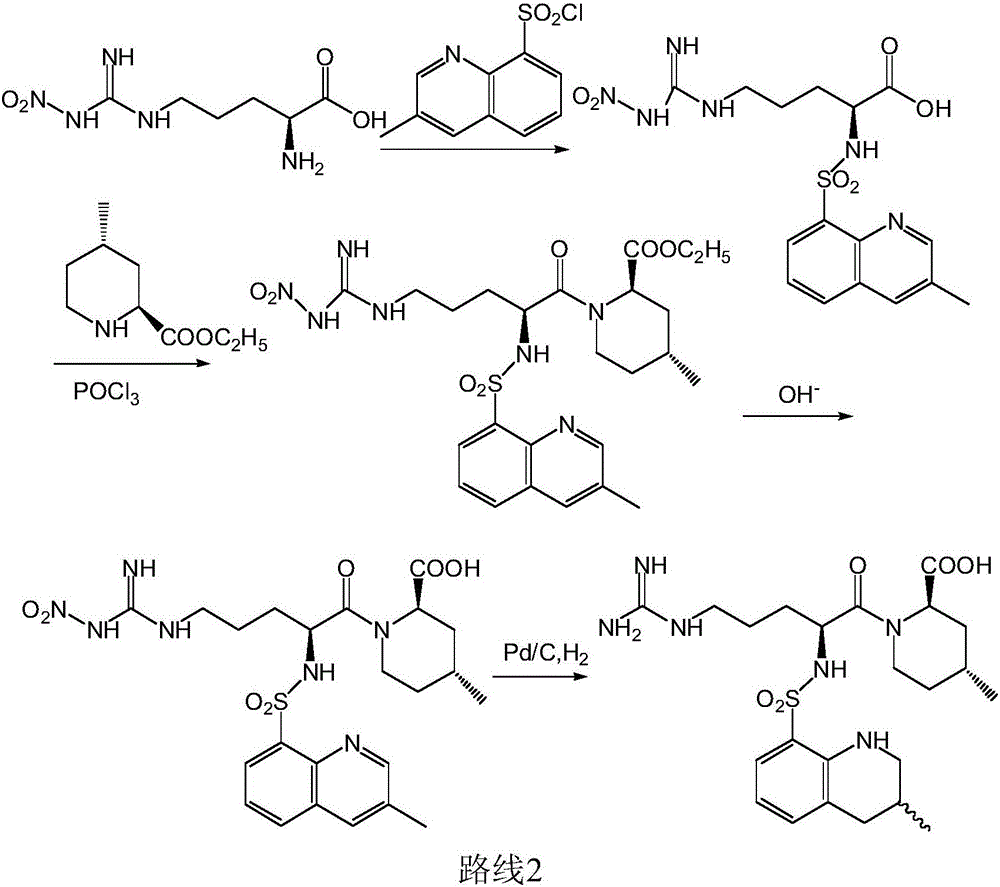

Synthesis method of argatroban

ActiveCN105837658ASuitable for industrial scale-up productionReduce riskPeptide preparation methodsHydrogenSynthesis methods

The invention discloses a synthesis method of argatroban .The method includes the step of making a compound II of a structure shown in the formula II make contact with and react with a hydrogen donor under the catalytic transfer hydrogenation conditions through the catalyst to obtain an argatroban rough product, wherein the hydrogen donor is formic acid or formate, and the formula II can be seen in the description .By means of the method, formic acid or formate serves as the hydrogen donor, the compound II is subjected to hydrogenation and reduction to obtain argatroban .By means of the method, in the hydrogenation and reduction process of the compound II, catalytic transfer hydrogenation reaction replaces catalytic hydrogenation reaction, operation steps are simplified, the problems on the aspects of technology and safety caused by hydrogen application are solved, reaction dangerousness is reduced, reaction conditions are mild and easy to control, and the method is more suitable for industrial application and production of argatroban.

Owner:河北广祥制药有限公司

Process for preparation of 2-phenyl ethanol

InactiveUS20050131258A1Reduce usageEasy to separateOrganic compound preparationOxygen compounds preparation by reductionStyrene oxideSilicon dioxide

The present invention provides an improved process for preparation of 2-phenyl ethanol. More specifically, the present invention relates to a process for preparing 2-phenyl ethanol by catalytic transfer hydrogenation of styrene oxide, in the presence of a supported transition metal catalyst. The catalyst system comprises of a palladium supported on silica, alumina, clay or charcoal.

Owner:COUNCIL OF SCI & IND RES

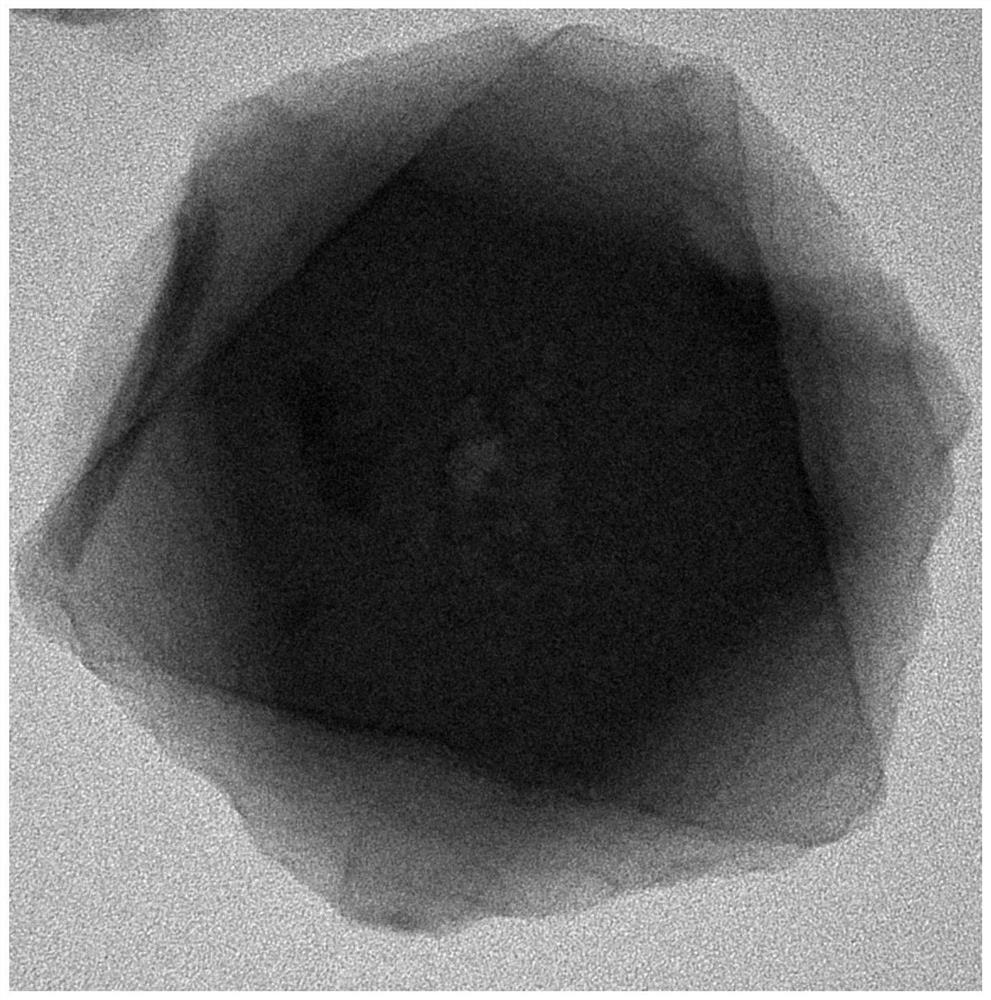

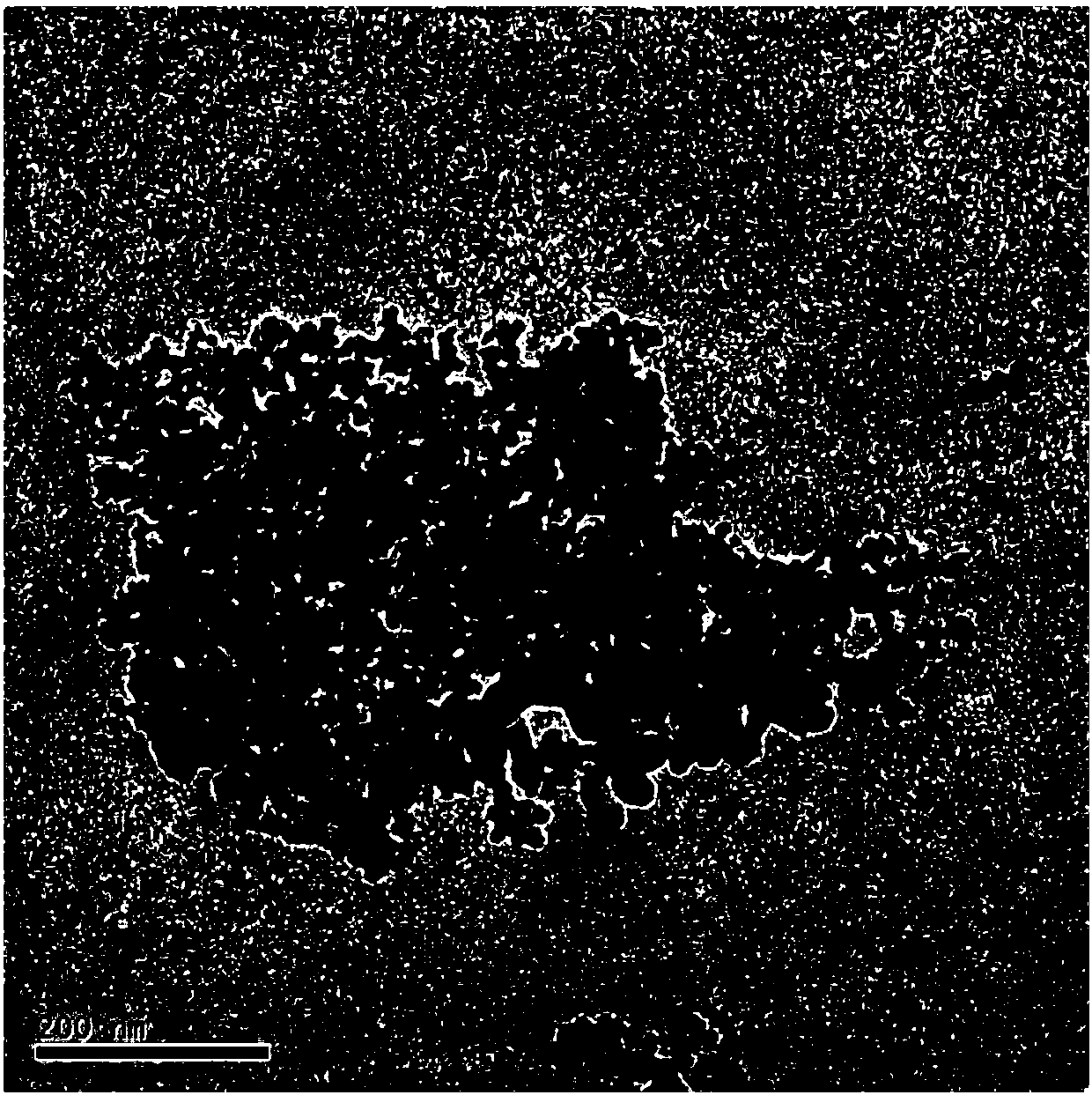

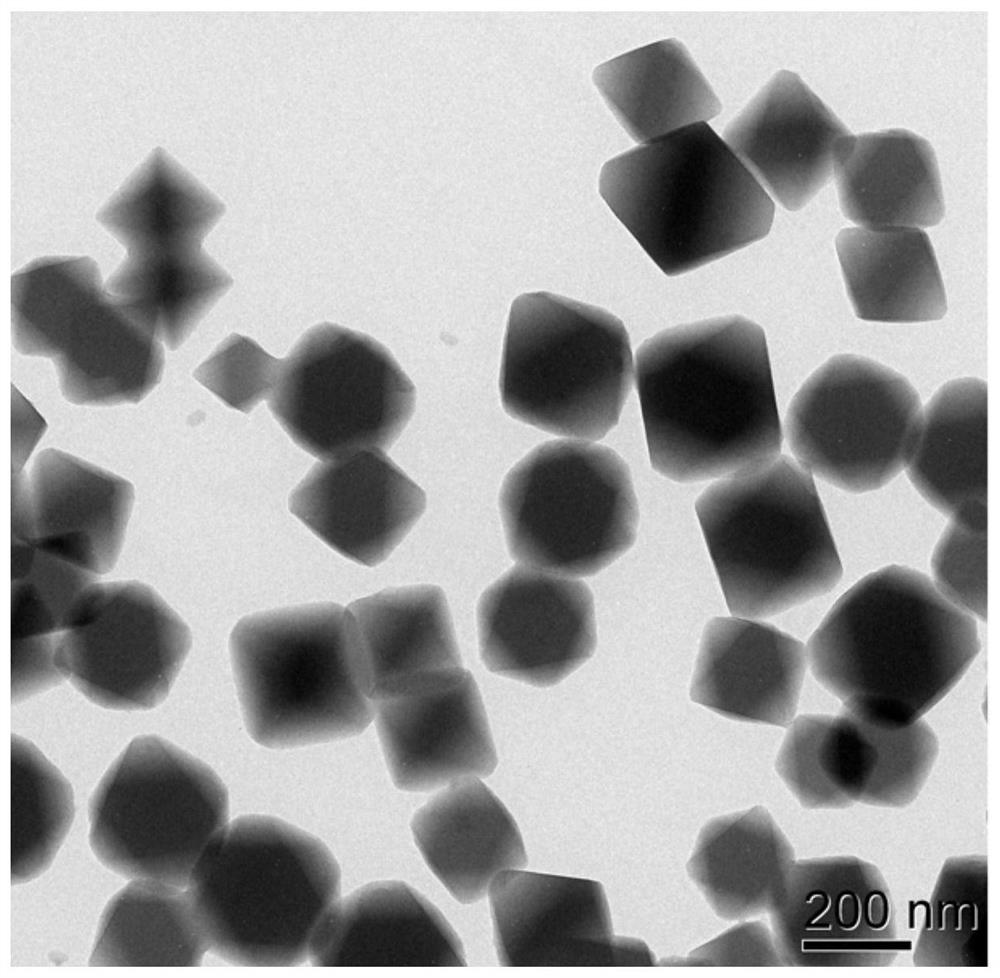

Preparation method of silica-supported carbon-nitrogen-coated cobalt-ruthenium catalyst and method for catalytic transfer hydrogenation of unsaturated compound through silica-supported carbon-nitrogen-coated cobalt-ruthenium catalyst

InactiveCN107597160ANot easy to loseNo separationOrganic reductionPhysical/chemical process catalystsEnvironmental resistanceDecomposition

The invention discloses a preparation method of a silica-supported carbon-nitrogen-coated cobalt-ruthenium catalyst. The preparation method comprises uniformly mixing a ruthenium salt, a cobalt salt,an organic ligand and a solvent in a mass ratio of 2.945 to 3.354: 47.5 to 570: 198.2: 19.725, heating the mixture for some time to obtain a solution A, adding nano-silica into the solution A, carrying out uniform mixing to obtain a solution B, removing the solvent in the solution B, carrying out drying to obtain solids, calcining the solids and cooling the solids to obtain the silica-supported carbon-nitrogen-coated cobalt-ruthenium catalyst. The invention also discloses a method for catalytic transfer hydrogenation of an unsaturated compound through the catalyst. The method has simple processes, utilizes easily available raw materials and is suitable for promotion and application. The bimetallic cobalt and ruthenium are respectively chelated with o-phenanthroline and the chelate is supported on nano-silica particles so that carbon-nitrogen-coated metal is formed. The catalyst reduces a metal loss, resists acid corrosion and toxicity of CO obtained by decomposition of formic acid, isfree of high-pressure hydrogen and is economic and environmentally friendly.

Owner:HUBEI UNIV

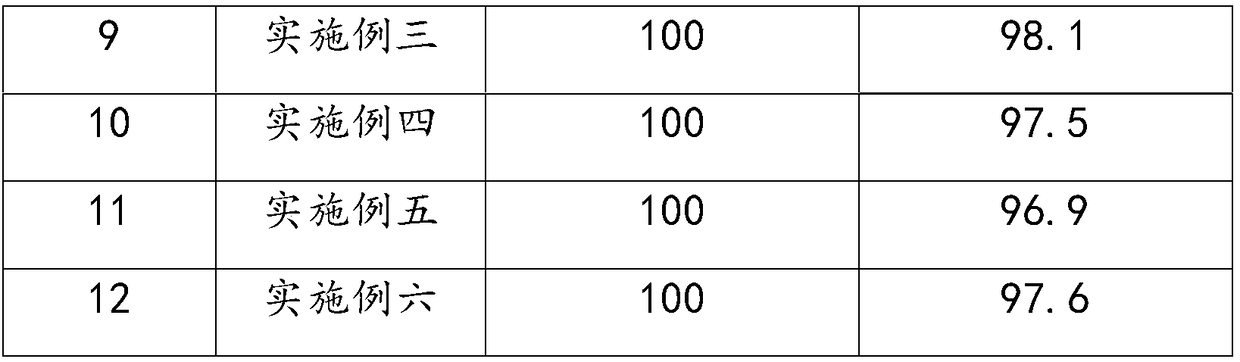

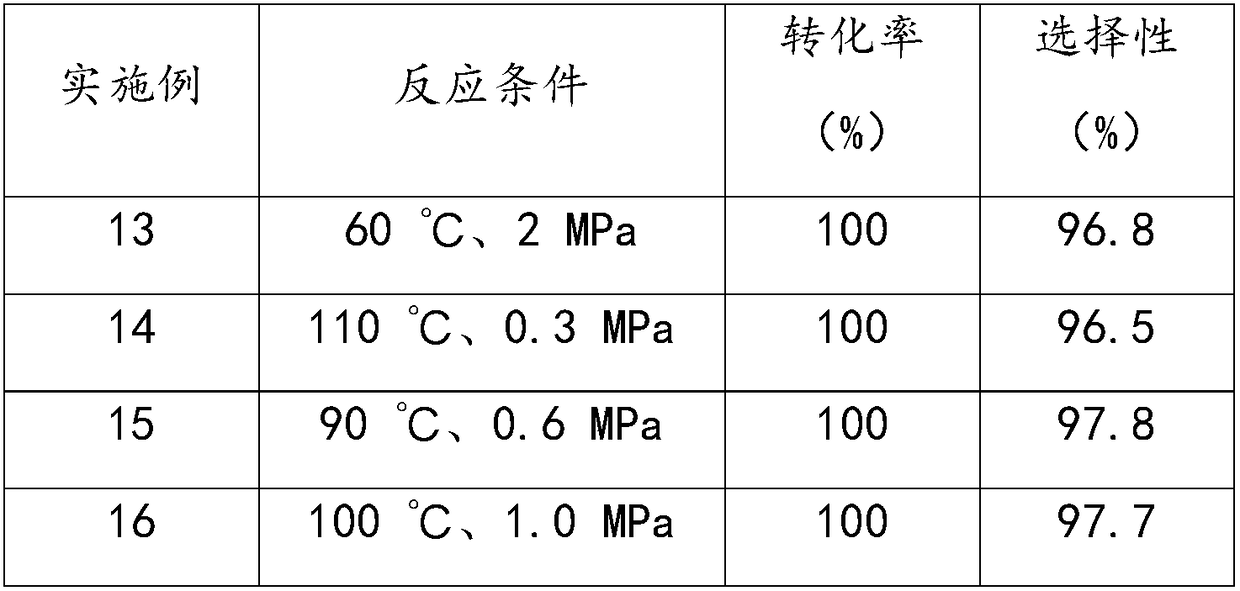

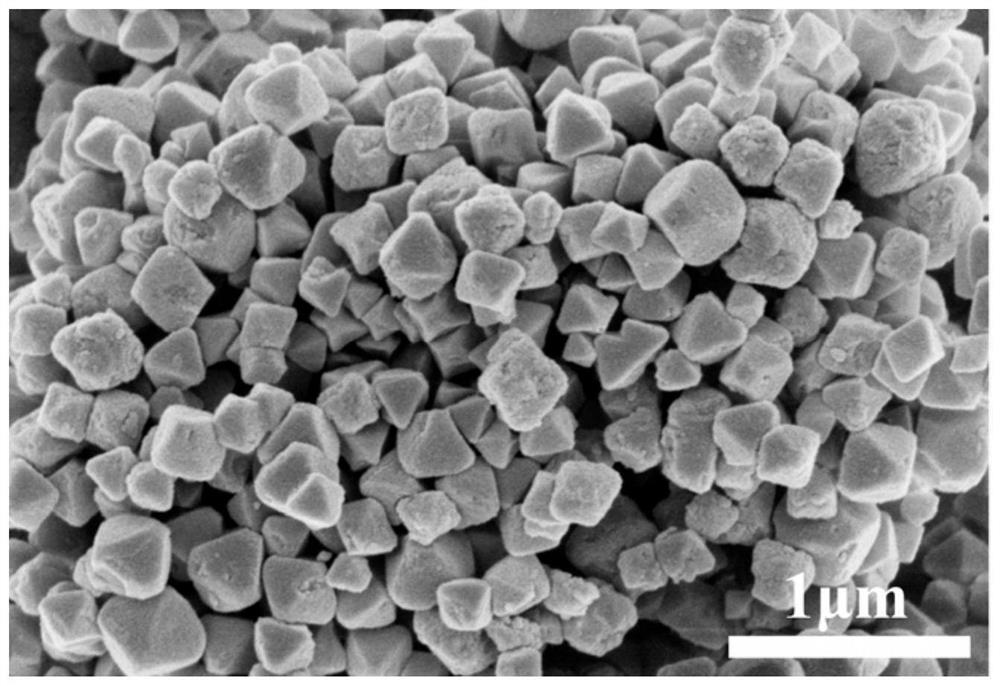

Catalytic hydrogenation catalyst and preparation method and application thereof

ActiveCN112742482AHigh catalytic transfer hydrogenation activityImprove conversion rateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMeth-

The invention belongs to the technical field of catalyst material preparation, and discloses acatalytic hydrogenationcatalyst and a preparation method and application thereof. The catalyst comprises a metal organic framework compound and two metals doped on the metal organic framework compound, and the two metals are copper and cobalt. The catalyst has high catalytic transfer hydrogenation activity under mild conditions, and shows high conversion rate and high selectivity. The catalyst is applied to catalysis of 5-hydroxymethylfurfural to prepare 2, 5-dimethylolfuran, and the conversion rate of 5-hydroxymethylfurfural is greater than 97% and is as high as 99.5%; and the selectivity of 2, 5-dimethylolfuran is greater than 95% and is as high as 97.7%. The catalyst also has good stability and recyclability. The catalyst is synthesized through a solvothermal reaction and a one-step method, and the preparation method is simple, easy and convenient to operate and high in preparation efficiency.

Owner:GUANGZHOU UNIVERSITY

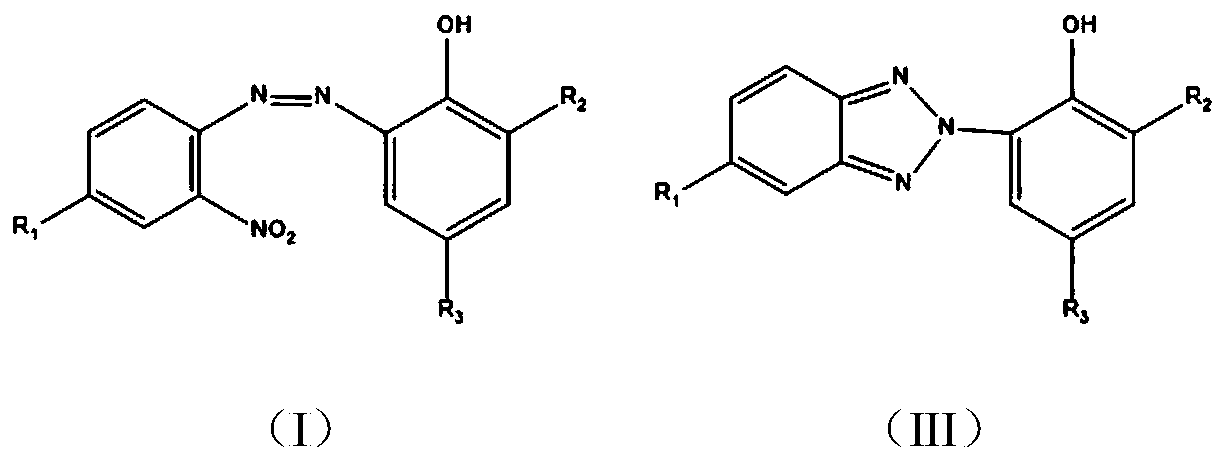

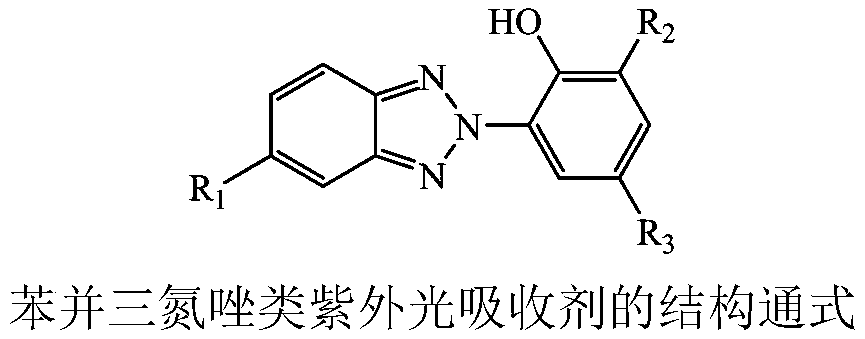

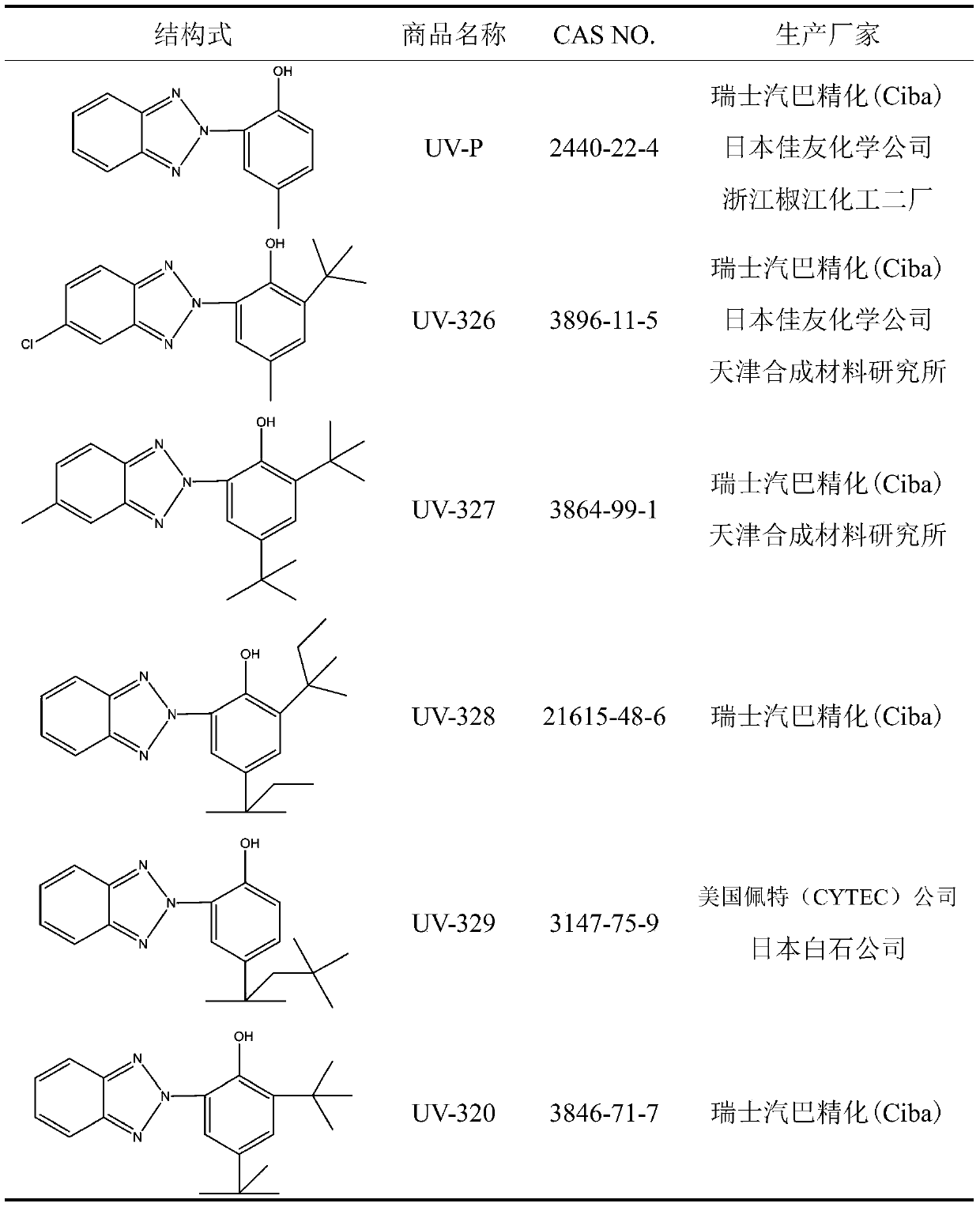

Carbon-supported basic ionic liquid-metal catalyst as well as preparation and application thereof in catalytic transfer hydrogenation reaction

ActiveCN111282592AEasy to prepareEasy to operateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonPlatinum

The invention discloses a carbon-supported basic ionic liquid-metal catalyst as well as preparation and application thereof in catalytic transfer hydrogenation reaction. The carbon-supported basic ionic liquid-metal catalyst is composed of an activated carbon carrier, basic ionic liquid and metal, wherein the basic ionic liquid and the metal are loaded on the carrier. The metal is palladium or platinum. The catalyst can be prepared by the following steps: performing alkali treatment on an activated carbon carrier to weaken acidic groups on the surface of the activated carbon carrier, loading ametal precursor salt and an alkaline ionic liquid onto the surface of the pretreated activated carbon by wet impregnation, performing drying, and reducing with a reducing agent to obtain the carbon-supported alkaline ionic liquid-metal catalyst. The invention provides an application of the basic ionic liquid-metal catalyst in a reaction for synthesizing a benzotriazole ultraviolet absorbent shownin a formula (II) through catalytic transfer hydrogenation of an azo intermediate shown in a formula (I) (the formulas are shown in the specification), and the selectivity of a target product can beremarkably improved under the condition that an alkaline auxiliary agent is not added.

Owner:ZHEJIANG UNIV OF TECH +1

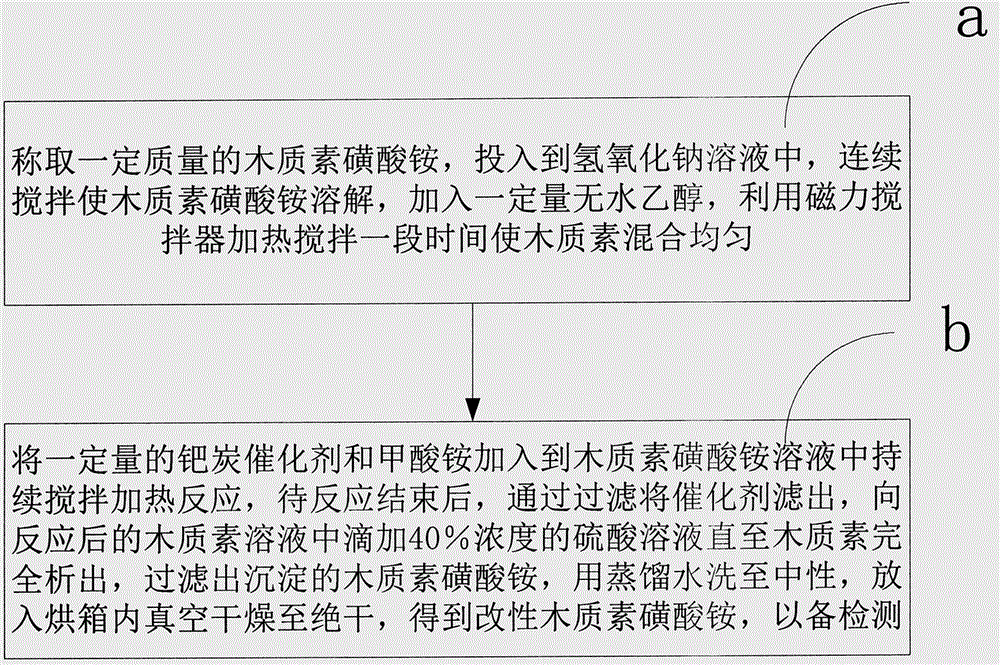

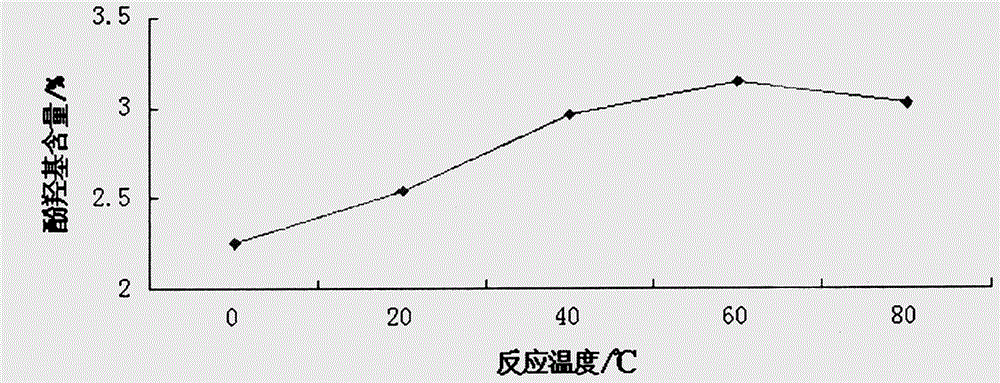

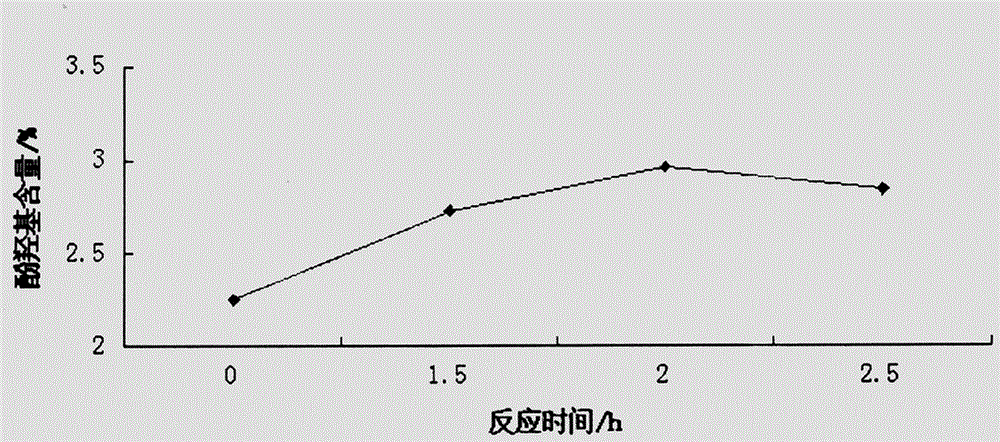

Modification method for improving industrial lignin activity

The invention relates to a modification method for improving industrial lignin activity. According to the invention, ammonium formate and palladium carbon catalysts are utilized; and with a catalytic transfer hydrogenation method, industrial lignin is subjected to a modification treatment. The adopted reagents are environment-friendly and non-toxic. Mainly, the industrial lignin phenolic hydroxyl group content is improved, such that lignin activity is improved, and the lignin added value is increased. With the method, the industrial lignin phenolic hydroxyl group content is improved by approximately 40% when compared with the content before modification.

Owner:NORTHEAST FORESTRY UNIVERSITY

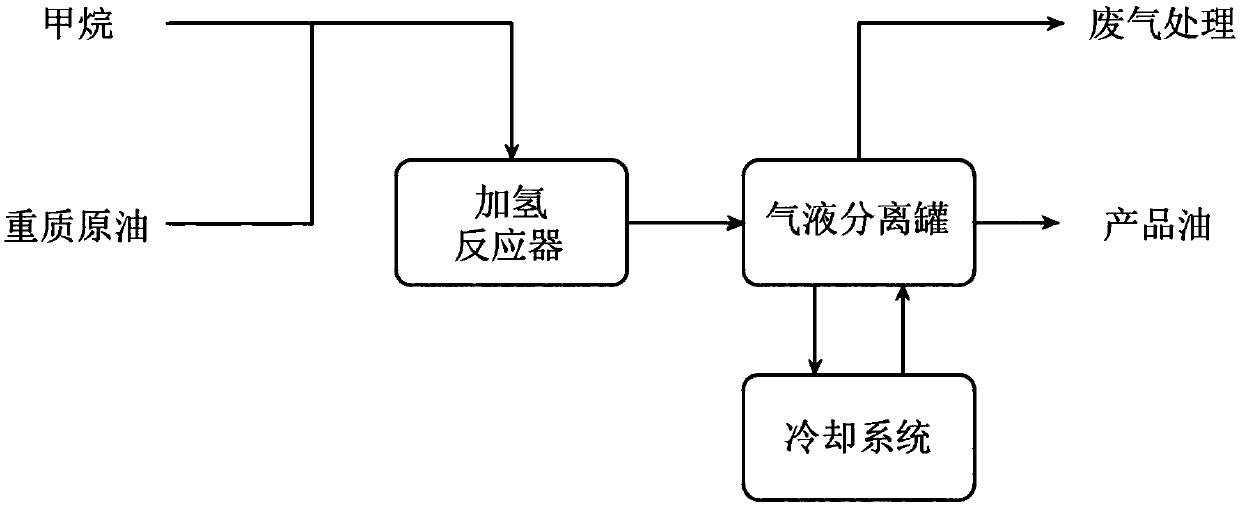

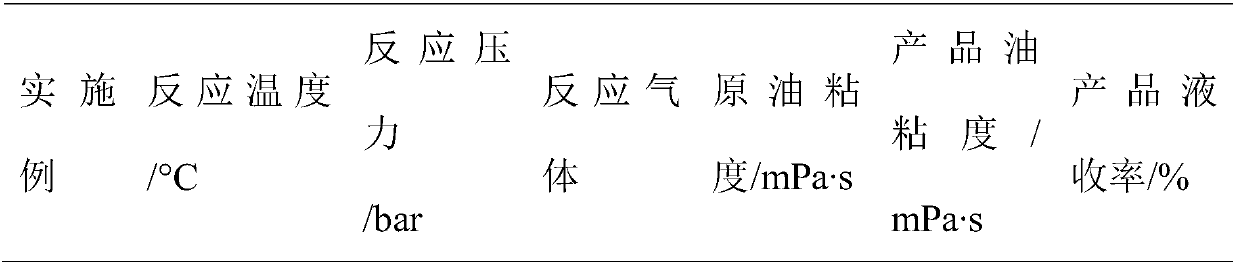

Method for catalytic hydrogenation of heavy crude oil by using methane

InactiveCN109517624ARealize green operationEliminate the step of reforming to produce hydrogenTreatment with hydrotreatment processesAlkaneHydrogenation reaction

The invention discloses a method for catalytic hydrogenation of heavy crude oil by using methane. Heavy crude oil is pumped into a hydrogenation reactor containing catalysts; methane is used as reaction gas for catalytic hydrogenation reaction; macromolecules in the heavy crude oil are decomposed into alkane and light-weight aromatic compounds; product oil flows out from a lower side of the hydrogenation reactor and is introduced into a gas-liquid separation tank for gas-liquid separation; tail gas flows out from the pipeline from the top of the gas-liquid separation tank and is used for subsequent treatment; product oil flows into a product tank from the bottom of the gas-liquid separation tank to be collected; the gas liquid separation tank is connected with a cooling system for reducingthe temperature of the product oil; the viscosity of the obtained product oil is 107 to 379 mPa.s; the density is 0.9511 to 0.9642 g / ml; the total acidity is 0.02 to 1.55 mg KOH / g; the average molecular weight is 172 to 210 g / mol; the water content is 0.21 to 0.30 weight percent; the product liquid yield is 96.9 to 104 percent. The operation cost of the technical flow process is reduced; the hydrogenation reaction effect is effectively improved; the operation pressure is reduced; a green and environmental-friendly process is achieved.

Owner:广西华大骄阳能源环保科技有限公司

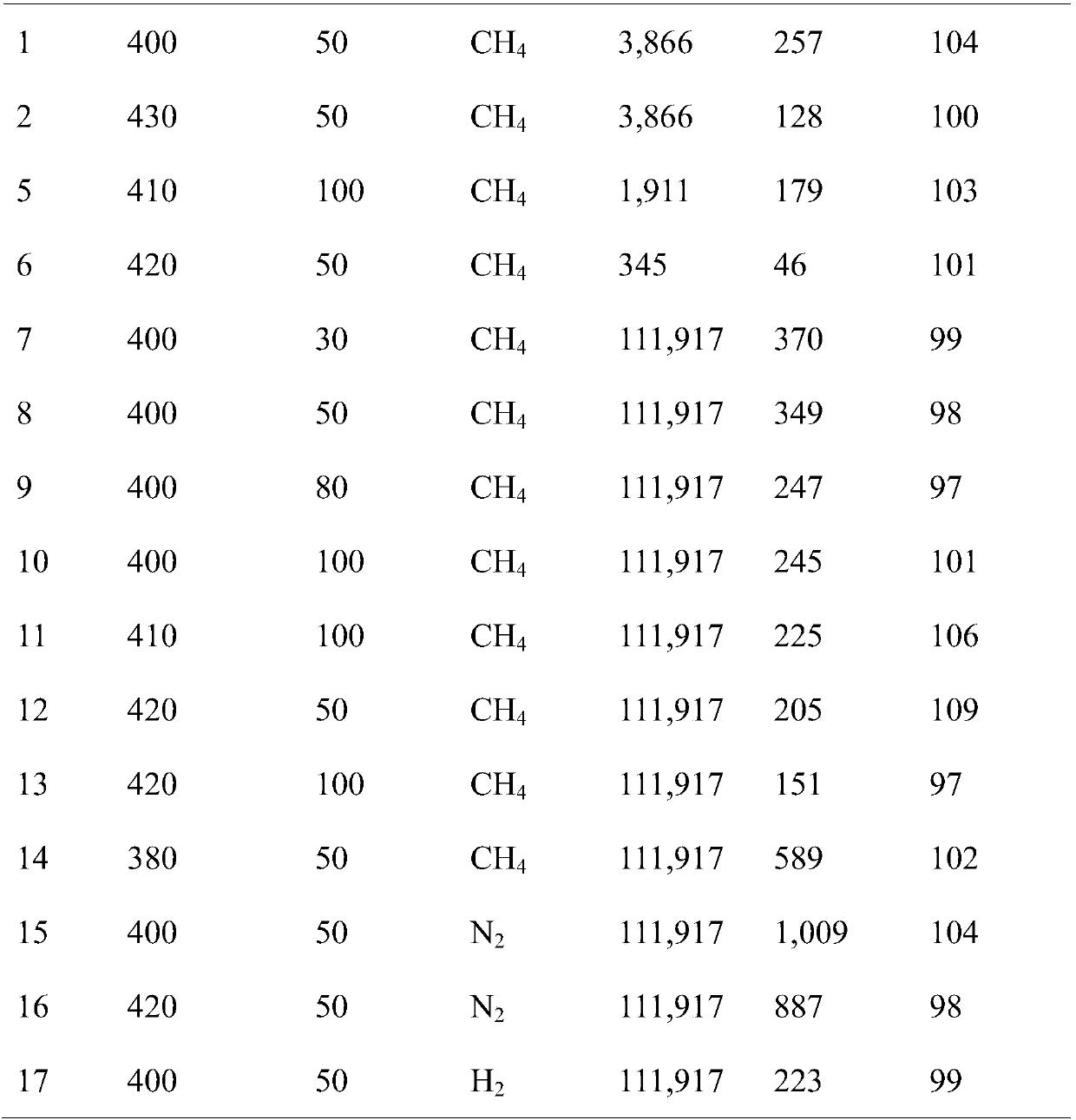

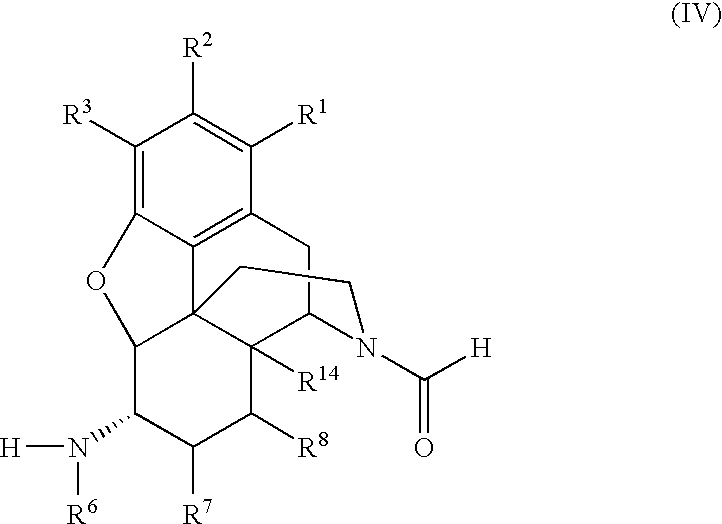

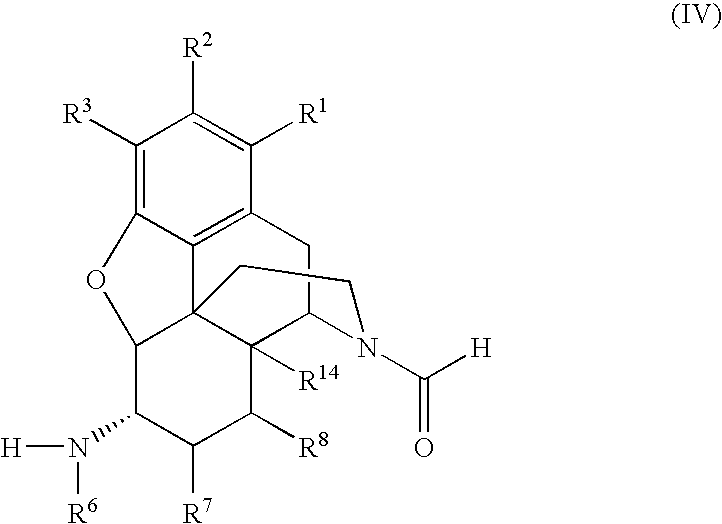

Reductive amination of 6-keto normorphinans by catalytic hydrogen transfer

The present invention provides processes for the stereoselective synthesis of 6-alpha-amino morphinans. In particular, the invention provides processes for the reductive amination of 6-keto normorphinans by catalytic transfer hydrogenation.

Owner:SPECGX LLC

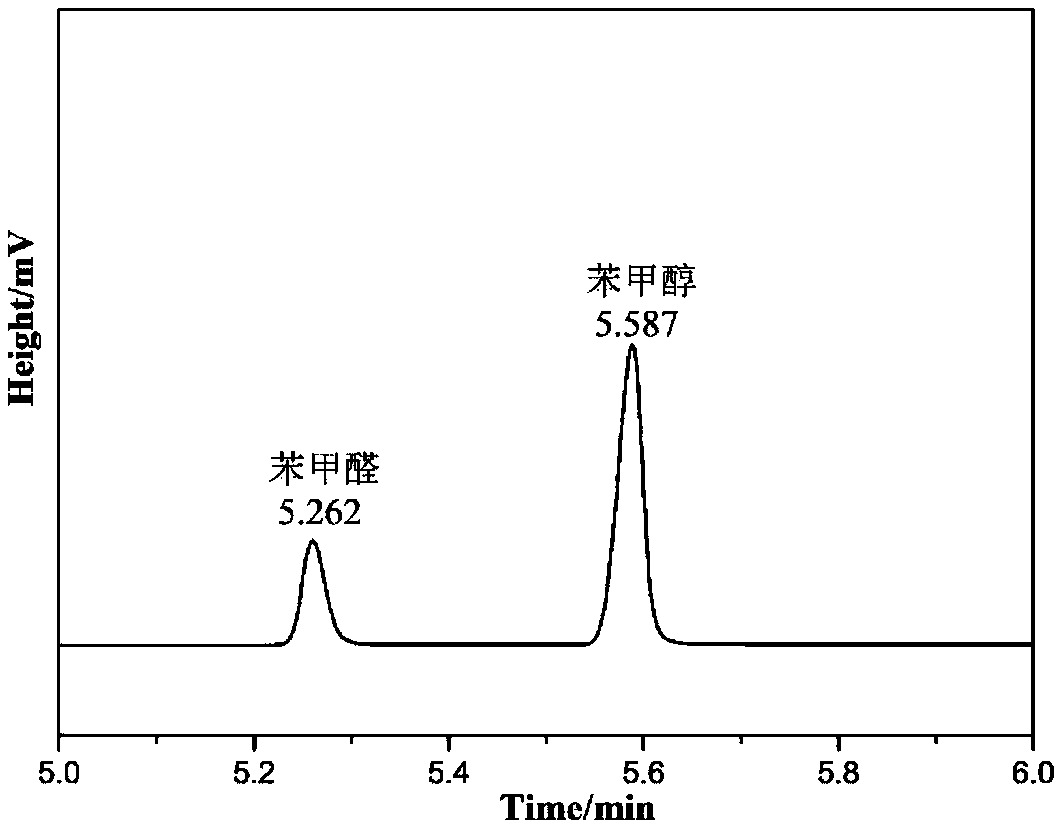

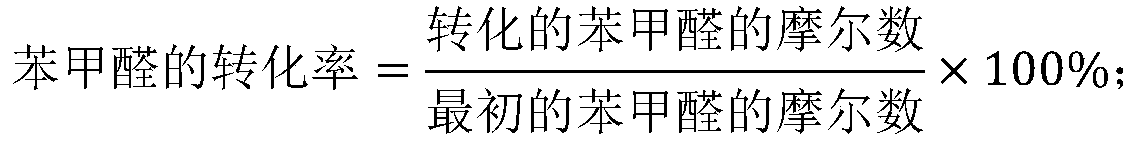

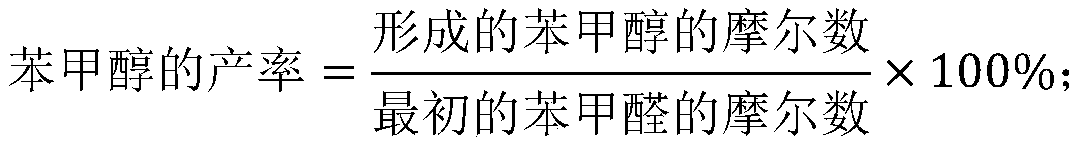

Application of ferro-nickel hydrotalcite catalyst in preparation of benzyl alcohol

The invention discloses application of a ferro-nickel hydrotalcite catalyst in preparation of benzyl alcohol, and belongs to the technical field of synthesis of benzyl alcohol. In the application, thebenzyl alcohol is prepared by catalyzing benzaldehyde via a catalytic transfer hydrogenation reaction under the own pressure condition in a hydrothermal reaction kettle by taking alcohol compounds asa solvent and a hydrogen donor and taking Ni-Fe(2 / 1)LDH, Ni-Fe(3 / 1)LDH or Ni-Fe(4 / 1)LDH as a catalyst, the reaction temperature is 110-160 DEG C, and the reaction time is 6-11 hours. A method for preparing the benzyl alcohol is simple in process and convenient in operation and is safe and environmentally friendly. The ferro-nickel hydrotalcite catalyst is prepared from common non-noble metals, islow in cost and is easy to obtain; the ferro-nickel hydrotalcite catalyst can be also used for reducing other compounds containing C=O bonds and is beneficial for commercial application.

Owner:JIANGNAN UNIV

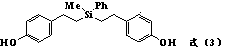

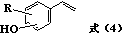

Silicon-containing diphenol and preparation method thereof

InactiveCN104817581AEasy to manufactureRaw materials are easy to getSilicon organic compoundsPolymer scienceSilanes

The invention provides a silicon-containing diphenol and a preparation method thereof, wherein a structure of the silicon-containing diphenol is represented as the formula (I). The preparation method includes following steps: (A) with di-substituted divinyl silane as a raw material, performing a catalytic olefin double-decomposition reaction with vinylphenol to obtain an intermediate, di-substituted bis(hydroxylstyryl)silane; (B) performing catalytic hydrogenation and catalytic transfer hydrogenation to obtain di-substituted bis(hydroxylphenethyl)silane, which is the silicon-containing diphenol in the invention. The silicon-containing diphenol represented in the formula (I) is excellent in toughness, flame resistance and heat resistance. The preparation method is simple in operation, is mild in conditions, is high in product yield, is low in cost, is green and environment-friendly, and is high in industrialization value.

Owner:QUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com