Modification method for improving industrial lignin activity

A technology for industrial lignin and lignin, which is applied in the field of modification treatment of industrial lignin by catalytic transfer hydrogenation, can solve the problems of low activity, waste of resources, unfavorable industrial utilization, etc. Added value and activity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

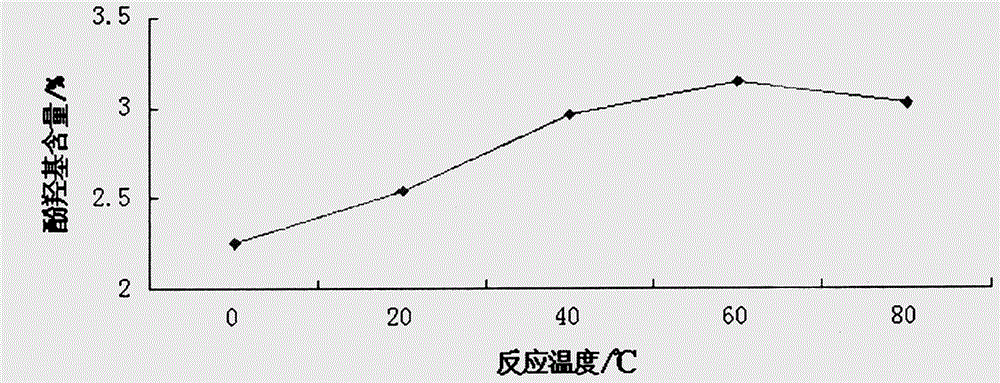

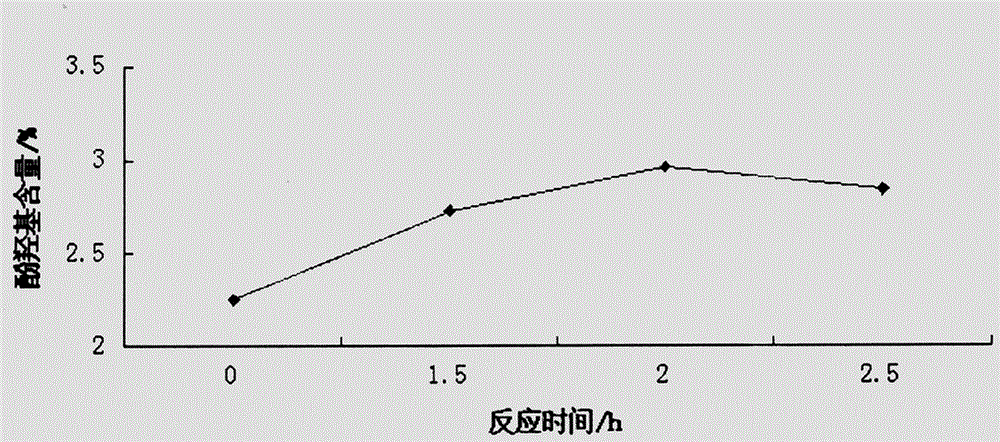

[0025] In the present invention, ammonium formate and palladium carbon catalysts are used to modify industrial lignin by catalytic transfer hydrogenation method. The process parameters are set as temperature: 20-80°C, time: 1.5-2.5h, catalyst dosage: modified industrial 20%-40% of lignin mass, pH: 10-13, ammonium formate addition amount is 200%-400% of modified lignin.

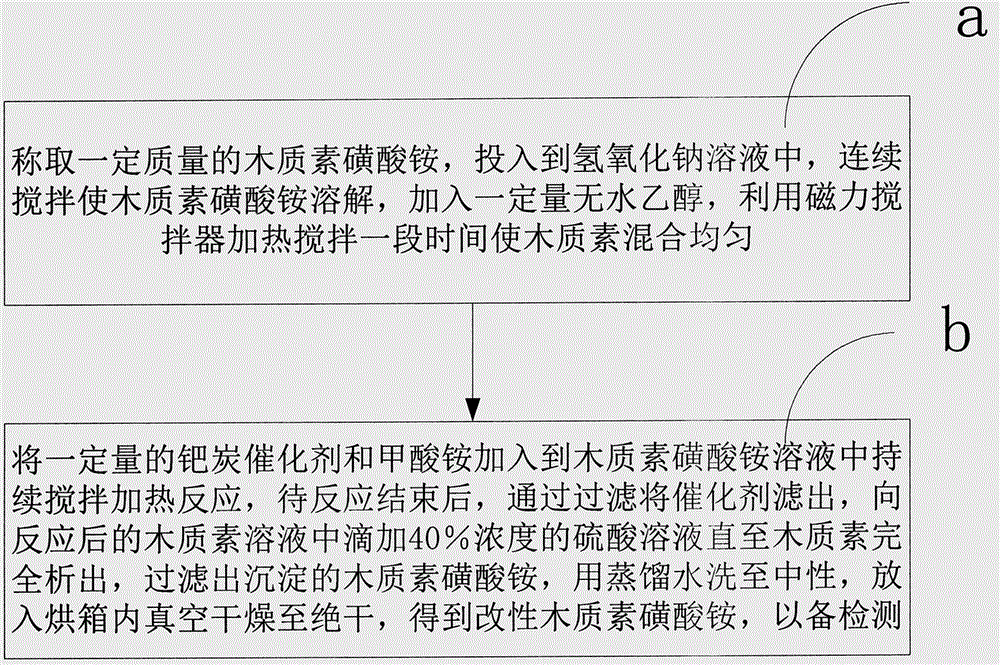

[0026] The specific process of catalytic transfer hydrogenation method of Pd / C catalyst and ammonium formate hydrogen donor system is as follows:

[0027] Step a, weigh a certain amount of ammonium lignosulfonate, put it into the sodium hydroxide solution, stir continuously to dissolve the ammonium lignosulfonate, add a certain amount of absolute ethanol, heat and stir with a magnetic stirrer for a period of time to make the lignin well m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com