A kind of preparation method of lignin-based resorcinol-phenol-formaldehyde resin adhesive

A technology based on resorcinol and formaldehyde resin, used in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., which can solve the problem of long curing time, low lignin activity and high curing temperature of phenolic resin. problems, to achieve the effect of reducing curing temperature, simple production process and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

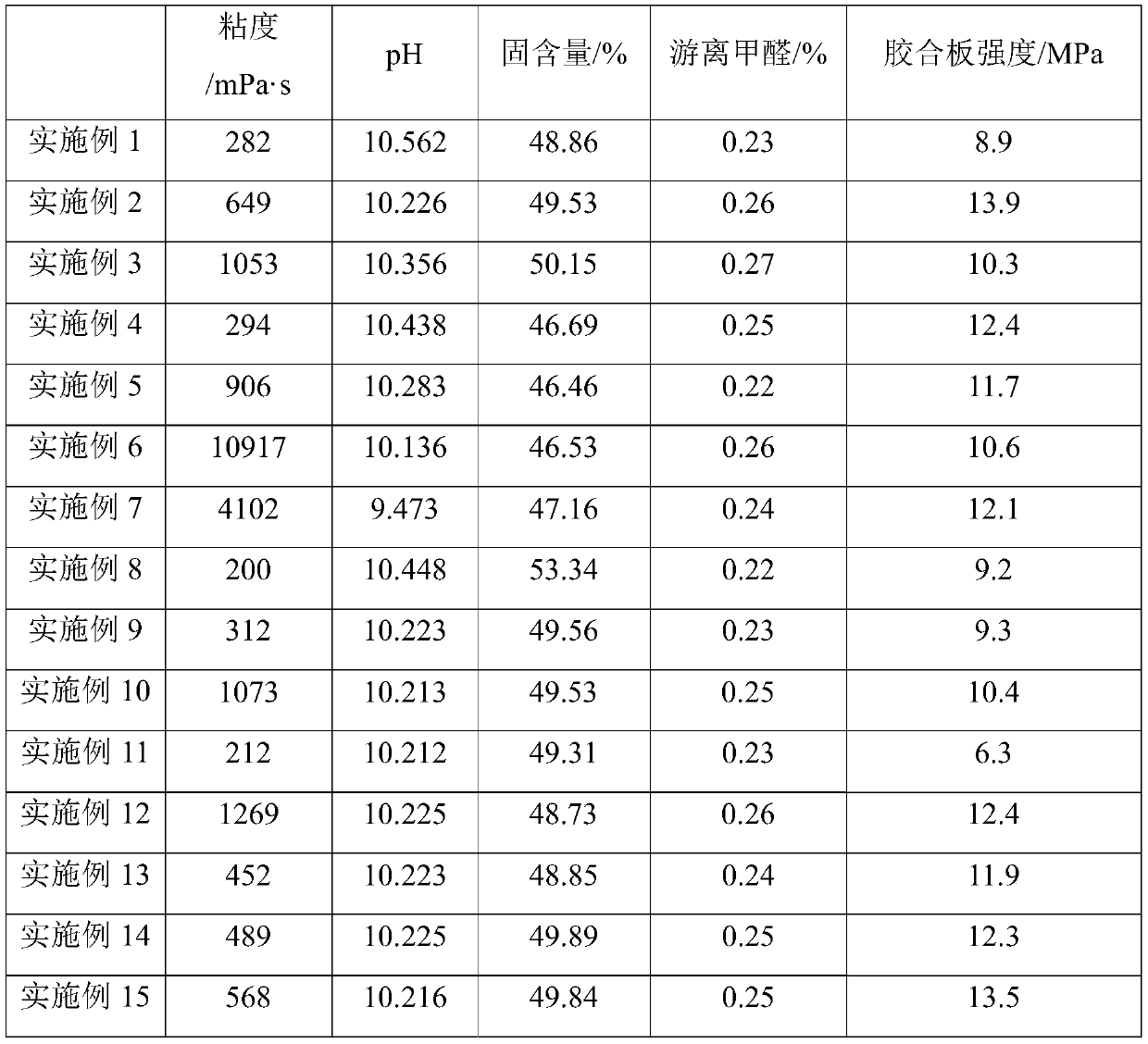

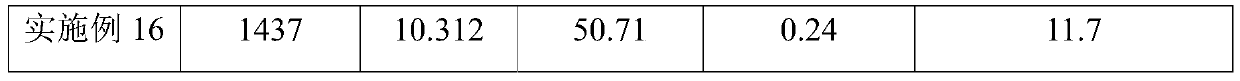

Examples

Embodiment 1

[0028] The ratio of enzymatic lignin, phenol, formaldehyde and resorcinol in this example is: enzymatic lignin 47g, phenol 47g, formaldehyde aqueous solution 59g (37wt%), resorcinol aqueous solution 28g (28.6wt%) .

[0029] Step 1: Add 12g of sodium hydroxide into a 500ml four-necked flask filled with 70ml of water, raise the temperature to 70°C, first add 20g of enzymatic lignin, after it is completely dissolved, add 47g of phenol, and mix it evenly, then The remaining 27 g of enzymatic lignin was added, the temperature was raised to 90° C., and the reaction was incubated at 90° C. for 1 hour.

[0030] Step 2: Cool down to 80°C, add 20g of sodium hydroxide solution (20wt%) and 59g of formaldehyde solution (37wt%) into the reaction system at an appropriate speed, and keep the reaction at 80°C for 60min.

[0031] Step 3: lower the temperature to 65°C, add 28g of resorcinol aqueous solution (28.6wt%) to the reaction system, keep the reaction at 65°C for 120min, cool to room tem...

Embodiment 2

[0033] The ratio of enzymatic lignin, phenol, formaldehyde and resorcinol in this example is: enzymatic lignin 47g, phenol 47g, formaldehyde aqueous solution 59g (37wt%), resorcinol aqueous solution 32g (37.5wt%) .

[0034] Step 1: Add 12g of sodium hydroxide into a 500ml four-necked flask filled with 70ml of water, raise the temperature to 70°C, first add 20g of enzymatic lignin, after it is completely dissolved, add 47g of phenol, and mix it evenly, then The remaining 27 g of enzymatic lignin was added, the temperature was raised to 90° C., and the reaction was incubated at 90° C. for 1 hour.

[0035] Step 2: Cool down to 80°C, add 15g of sodium hydroxide solution (30wt%) and 59g of formaldehyde solution (37wt%) into the reaction system at an appropriate speed, and keep the reaction at 80°C for 60min.

[0036] Step 3: lower the temperature to 65°C, add 32g of resorcinol aqueous solution (37.5wt%) to the reaction system, keep the reaction at 65°C for 120min, cool to room tem...

Embodiment 3

[0038] The ratio of enzymatic lignin, phenol, formaldehyde and resorcinol in this embodiment is: enzymatic lignin 47g, phenol 47g, formaldehyde aqueous solution 59g (37wt%), resorcinol aqueous solution 32g (50wt%).

[0039] Step 1: Add 12g of sodium hydroxide into a 500ml four-necked flask filled with 70ml of water, raise the temperature to 70°C, first add 20g of enzymatic lignin, after it is completely dissolved, add 47g of phenol, and mix it evenly, then The remaining 27 g of enzymatic lignin was added, the temperature was raised to 90° C., and the reaction was incubated at 90° C. for 1 hour.

[0040] Step 2: Cool down to 80°C, add 15g of sodium hydroxide solution (30wt%) and 59g of formaldehyde solution (37wt%) into the reaction system at an appropriate speed, and keep the reaction at 80°C for 60min.

[0041] Step 3: lower the temperature to 65°C, add 32g of resorcinol aqueous solution (50wt%) to the reaction system, keep the reaction at 65°C for 120min, cool to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com