Patents

Literature

49results about How to "Promote cross-linking and curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light curing material

InactiveCN102516866AIncrease profitPromote cross-linking and curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiluentUltraviolet lights

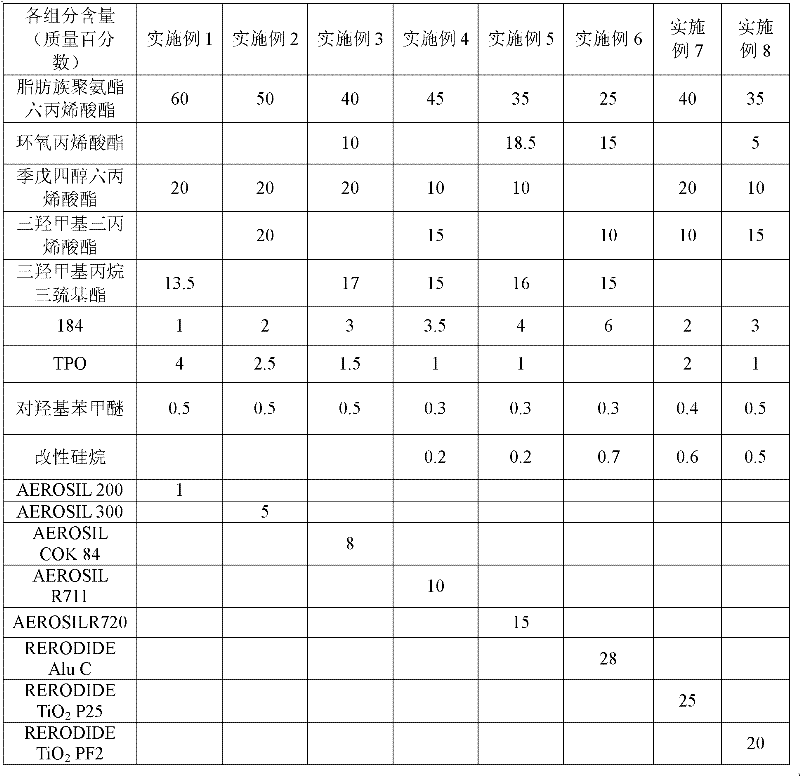

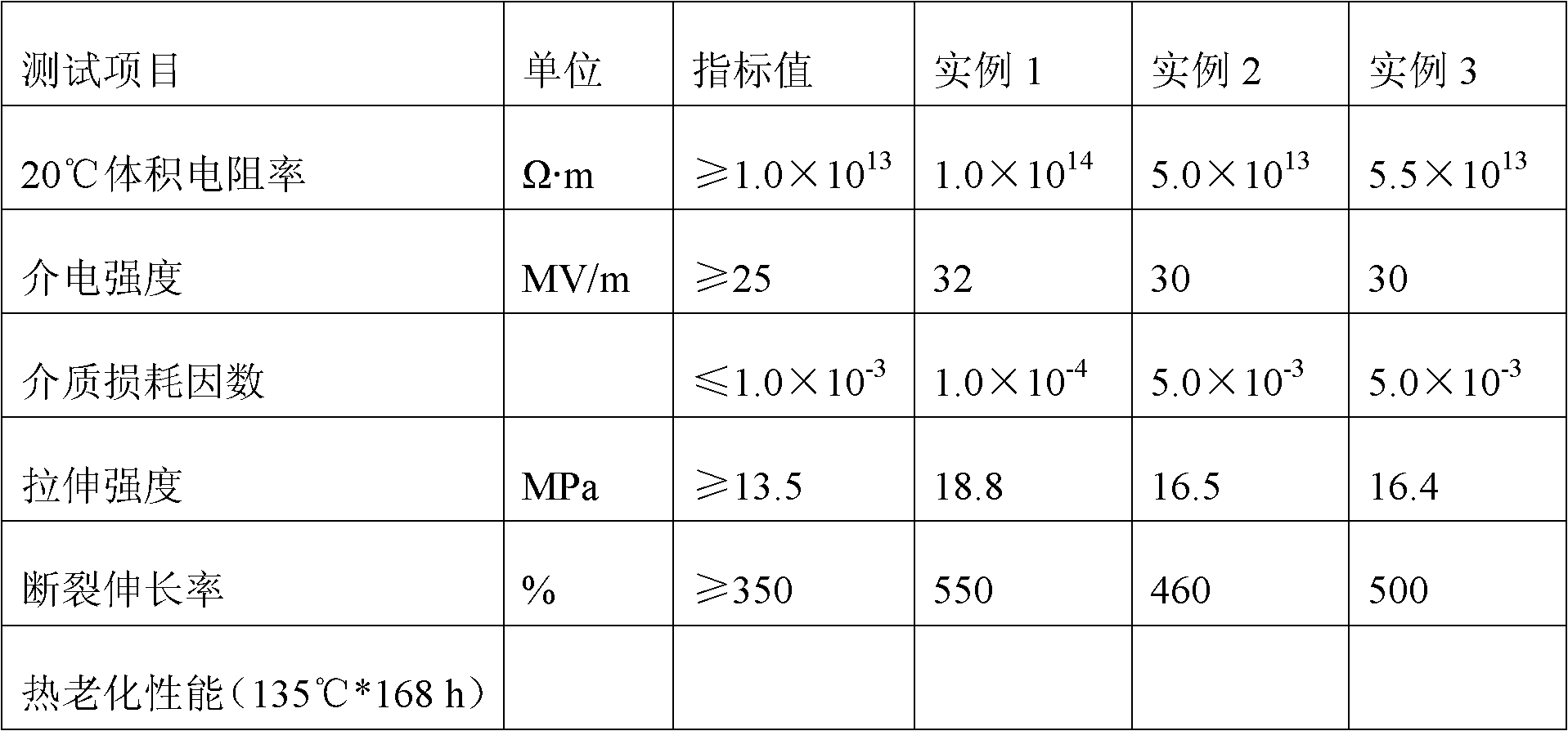

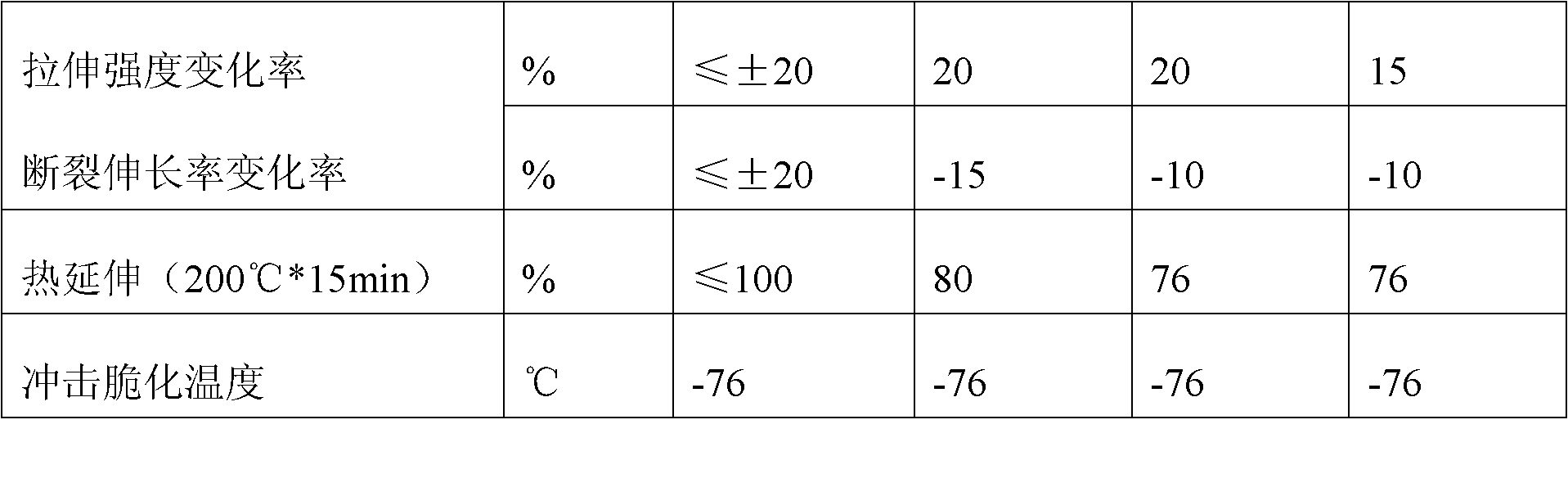

The present invention relates to an ultraviolet light curing material, which comprising the following components by weight percentage: 40-60%of light cured resin; 25-45% of light curing diluent; 2-10% of photoinitiator; 0-0.8% of ultraviolet storage stabilizer; 0.5-30%of nano filler; 0.2-1% of leveling agent. On the basis of addition of light cured resin, the light curing diluent and the photoinitiator in the ultraviolet light curing material, the nano filler is added, the ultraviolet light respectively reflects to all directions through small particles, so that the light is scattered, the utilization rate of the ultraviolet light can be increased, the crosslinking and curing speed can be accelerated, and the curing energy can be reduced.

Owner:YANTAI DARBOND TECH

Artificial lawn adhesive composition with excellent performances

ActiveCN106085290ALow costUniform particle sizeNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross linkerOrganic chemistry

The invention discloses an artificial lawn adhesive composition with excellent performance. The adhesive composition comprises, by mass, 50-100 parts of aqueous latex, 20-30 parts of phenolic resin, 6-30 parts of a filler, 6-9 parts of aqueous PUR dispersion, 10-15 parts of a color paste, 1-3 parts of a cross-linking agent, 0.1-2 parts of a coupling agent, 0.1-0.5 parts of a mildew inhibitor, 0.1-0.3 parts of an antioxidant, 0.2-0.4 parts of an ultraviolet absorbent, 0.1-0.2 parts of an antifoaming agent, 0.5-1 part of a dispersant, 5-15 parts of a thickener and 2-5 parts of zinc oxide. The adhesive composition has the advantages of uniform particle size, stable properties, good weatherability, good waterproof property, strong ageing resistance, simple and easy preparation method, and low cost.

Owner:江蘇聯創人造草坪股ふん有限公司

Easily processed and quickly crosslinked silane crosslinked polyethylene insulating material and preparation method thereof

ActiveCN102070812APromote cross-linking and curingImprove permeabilityPlastic/resin/waxes insulatorsAntioxidantSilanes

The invention discloses a preparation method of an easily processed and quickly crosslinked silane crosslinked polyethylene insulating material. The insulating material consists of a material A and a material B, wherein the material A comprises the following components in part by weight: 100 parts of polyethylene, 5 to 15 parts of ethylene-acrylate copolymer, 2 to 5 parts of silane and 0.1 to 0.5 part of initiator; and the material B comprises the following components in part by weight: 100 parts of ethylene-acrylate copolymer, 2 to 5 parts of catalyst, 2 to 10 parts of lubricating agent, 1 to 10 parts of silicon dioxide, 1 to 5 parts of antioxidant and 2 to 5 parts of copper inhibitor. A cable material prepared by the method has high natural crosslinking speed; and the required crosslinking can be achieved at room temperature in 2 to 3 days. Compared with the conventional natural crosslinked product, the material has the advantages of high crosslinking speed, wide processing temperature range, low corrosion to equipment, low probability of foaming and pre-crosslinking and the like, and can be used as the insulating material for wires and cables of 3kv or below.

Owner:上海新上化高分子材料有限公司

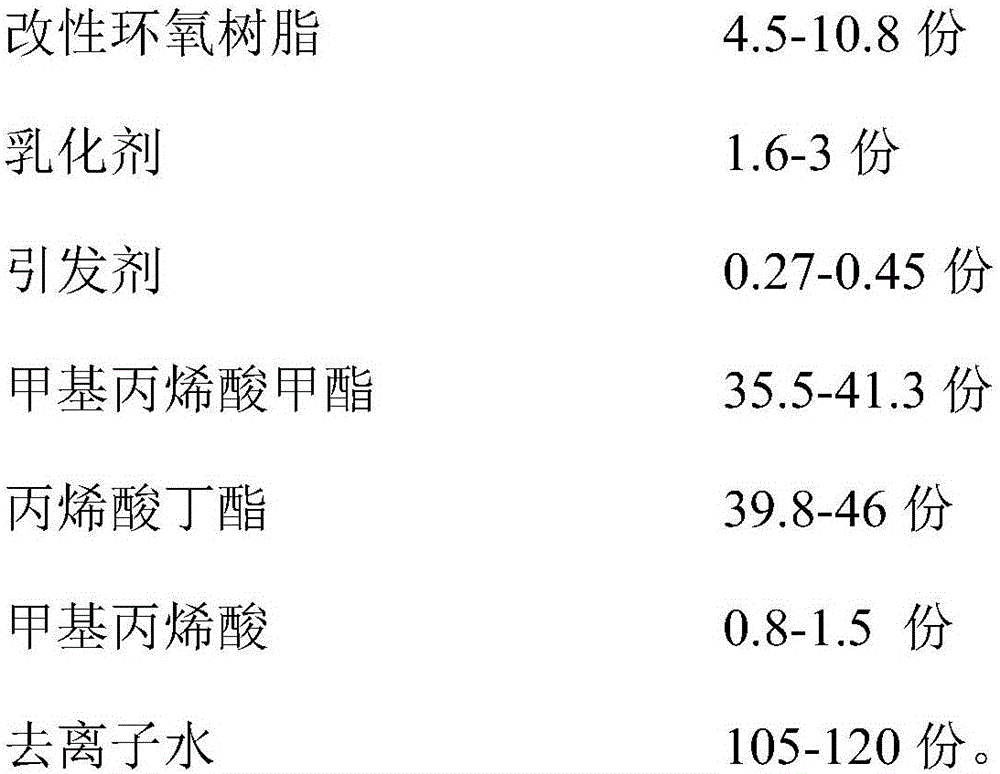

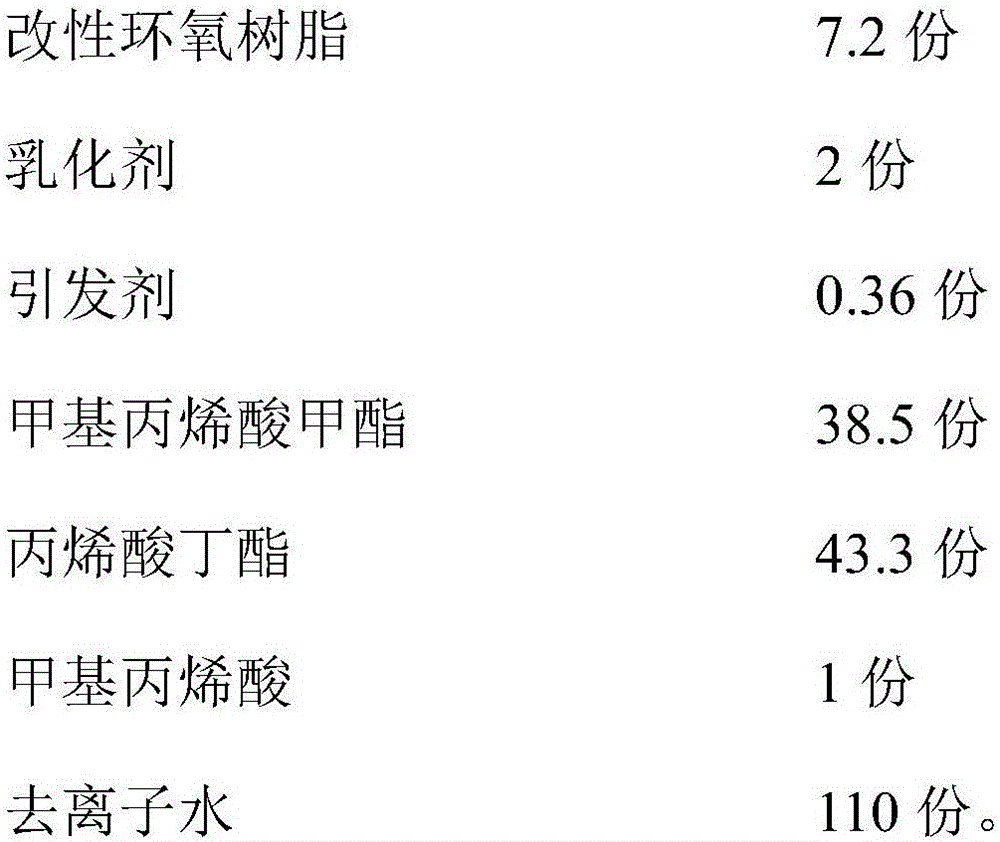

Epoxy-acrylate composite emulsion and preparation method therefor

The invention discloses a preparation method for an epoxy-acrylate composite emulsion. According to the preparation method, in step one, an acrylic monomer containing active hydrogen is adopted to modify epoxy resin, and the reaction ratio of the active hydrogen to epoxy groups is regulated and controlled, so that chain segments of the modified epoxy resin have double bonds, and part of the epoxy groups are reserved; and in step two, a high-epoxy-resin-content mono-component self-crosslinked stable aqueous epoxy-acrylate composite emulsion with an epoxy group acrylate polymer (core)-'inert' polyacrylate (intermediate layer)-carboxyl-containing (amino)acrylate polymer (shell) structure is prepared by adopting a core-shell emulsion polymerization method. The preparation method provided by the invention is simple in operation, and the problem that giving consideration to both the stability and the corrosion resistance of aqueous epoxy resin simultaneously is difficult is effectively solved.

Owner:HUBEI JIAJI SYNTHESIS MATERIALS CO LTD +1

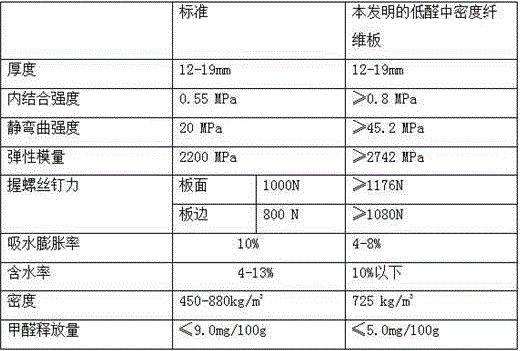

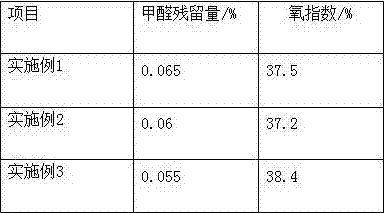

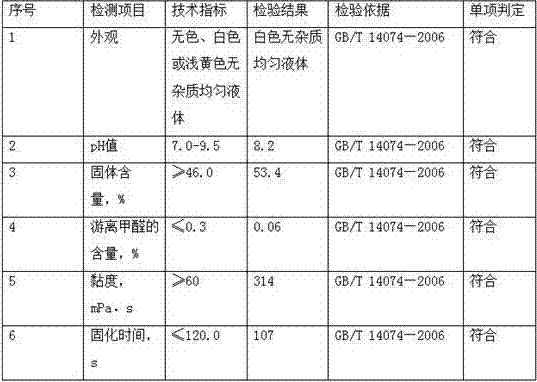

Method for producing low-formaldehyde medium-density fiberboard

ActiveCN105216086AImprove water resistanceGood alkali resistanceFlat articlesDomestic articlesEngineeringPulp and paper industry

The invention relates to a method for producing a low-formaldehyde medium-density fiberboard and belongs to the technical field of wood resource utilization. The method for producing the low-formaldehyde medium-density fiberboard comprises the technological steps of raw material slicing, impurity-removal and screening, boiling, waxing and hot grinding, gluing and drying, mat formation and hot pressing, and finished product obtaining. According to the method, residues, such as battens and waste veneer, generated during wood processing are used for producing the low-formaldehyde medium-density fiberboard, waste materials are recycled, and full utilization of wood resources is effectively achieved; the formaldehyde residual volume of low-formaldehyde urea formaldehyde resin adhesive used for producing the medium-density fiberboard is low, in this way, harm to the health of human bodies is reduced, and the bonding force is high; in addition, the fiberboard has good damp-proof performance and good water-proof performance, the internal structure of the board is uniform, the density is proper, the dimensional stability is high, the quality is stable, and the service life is long.

Owner:霸州市郭仕智能家居科技有限公司

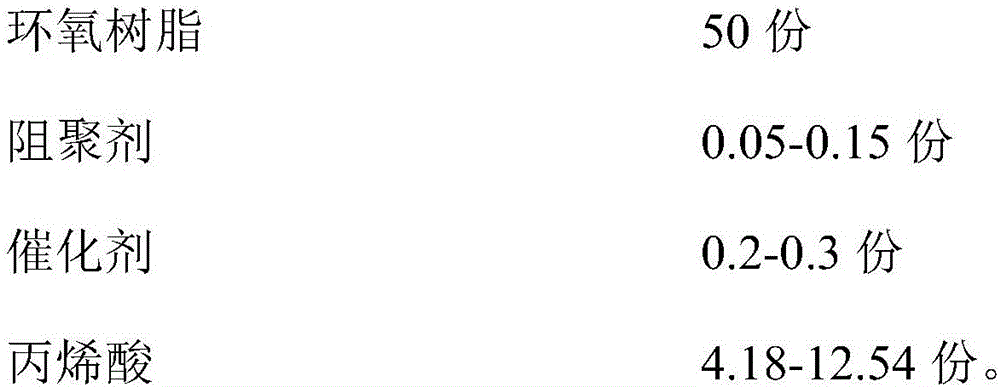

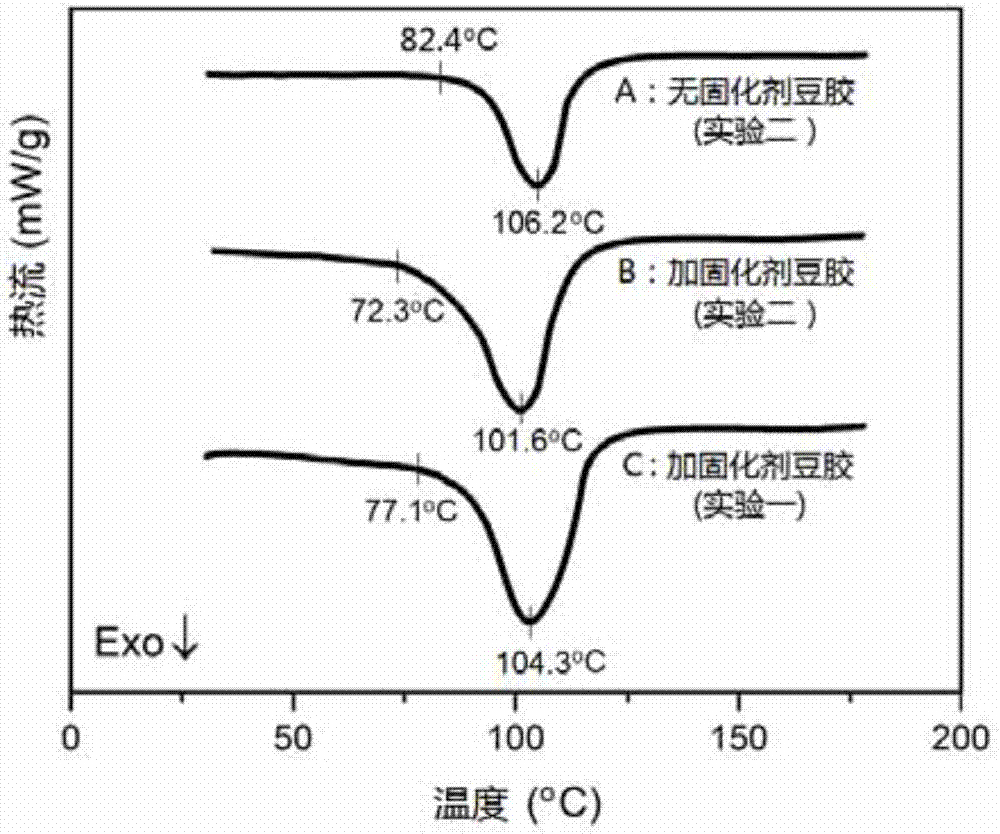

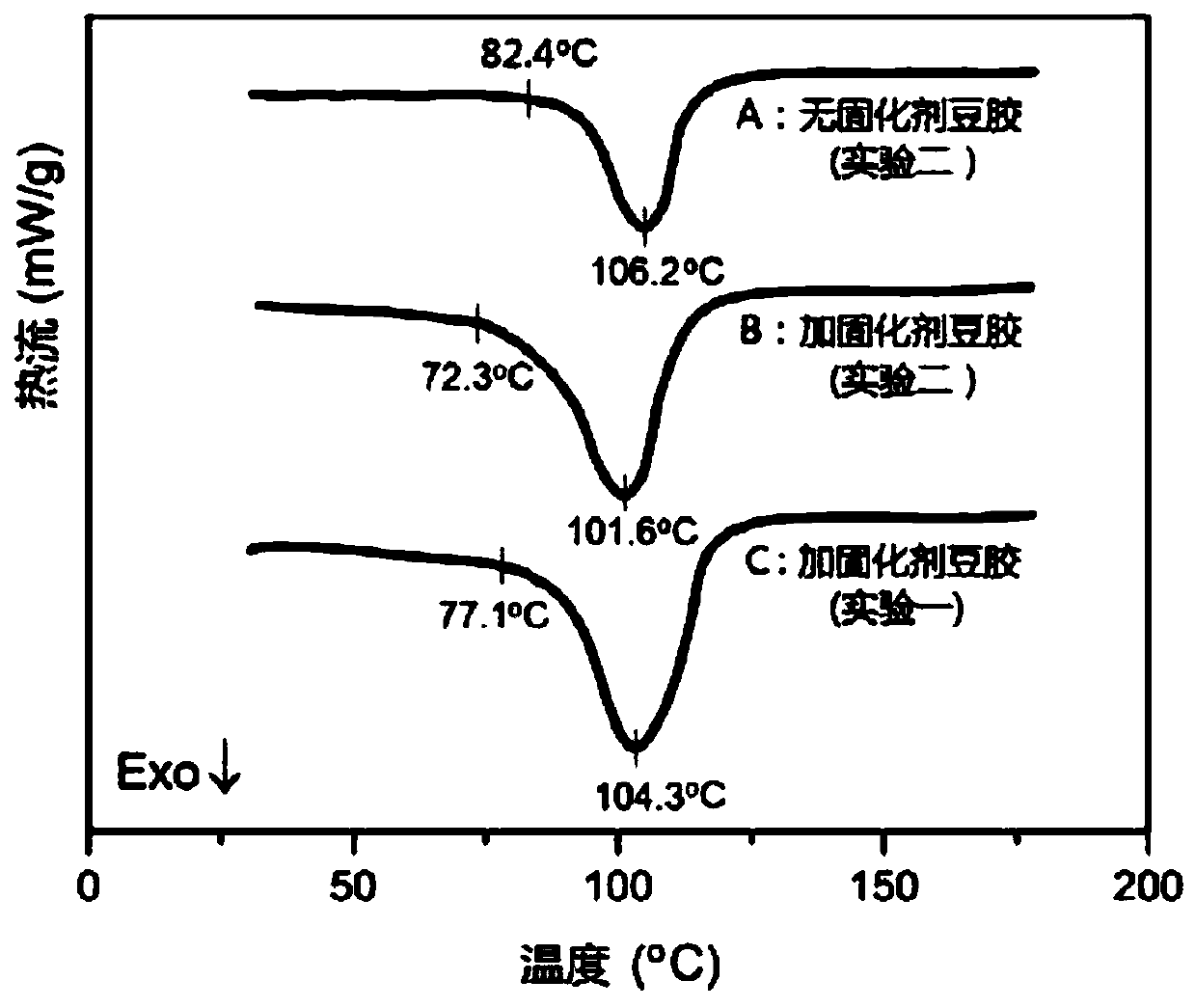

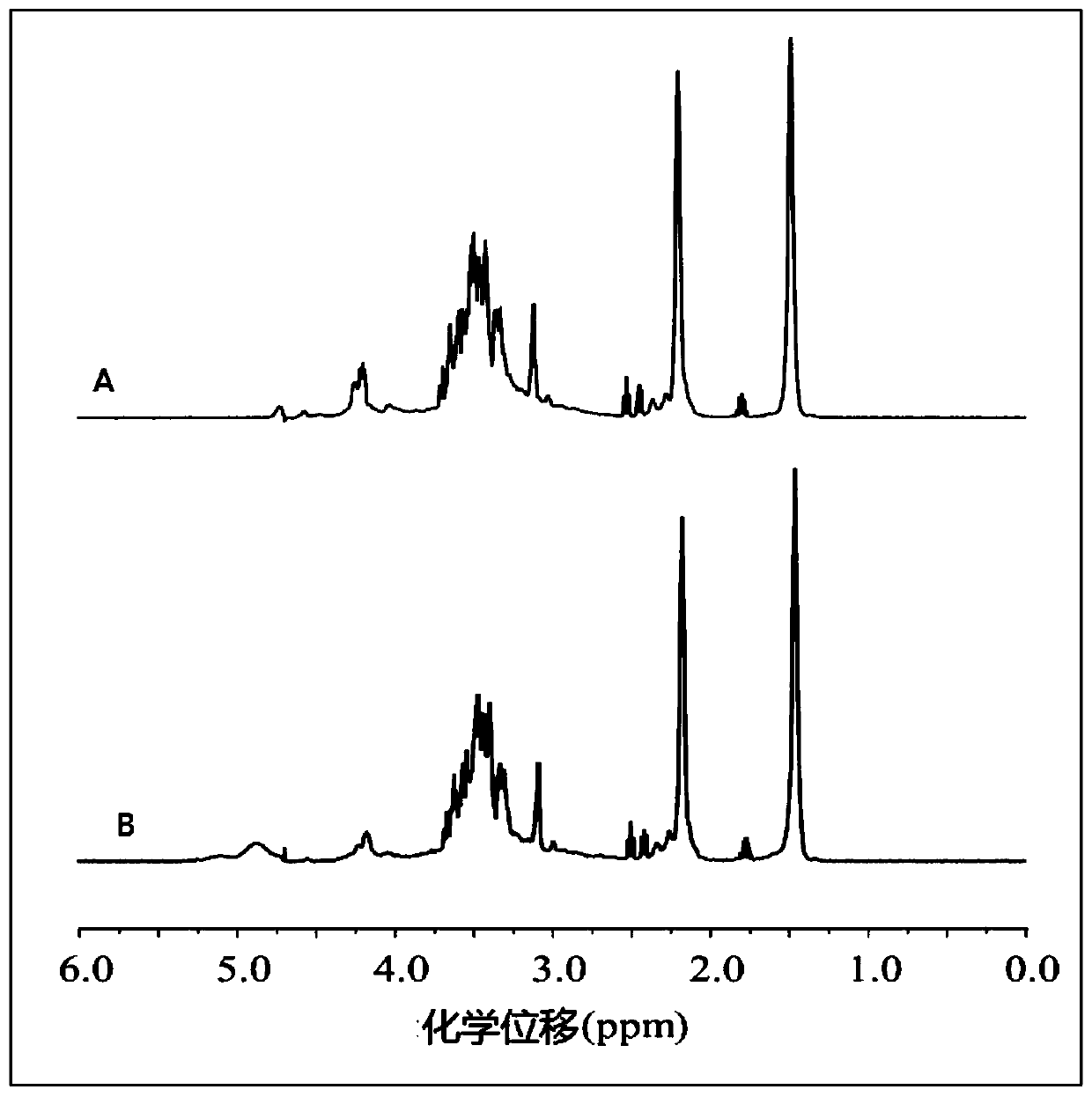

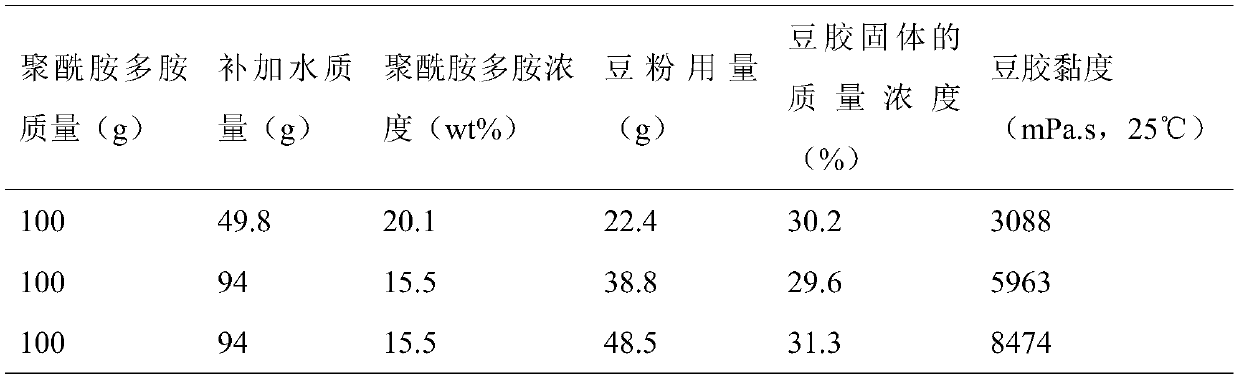

Soybean adhesive for water-resistant shaving board and preparation method thereof

ActiveCN107216849AMeet spraying requirementsEnsure water resistanceNon-macromolecular adhesive additivesProtein adhesivesProduction lineAdhesive

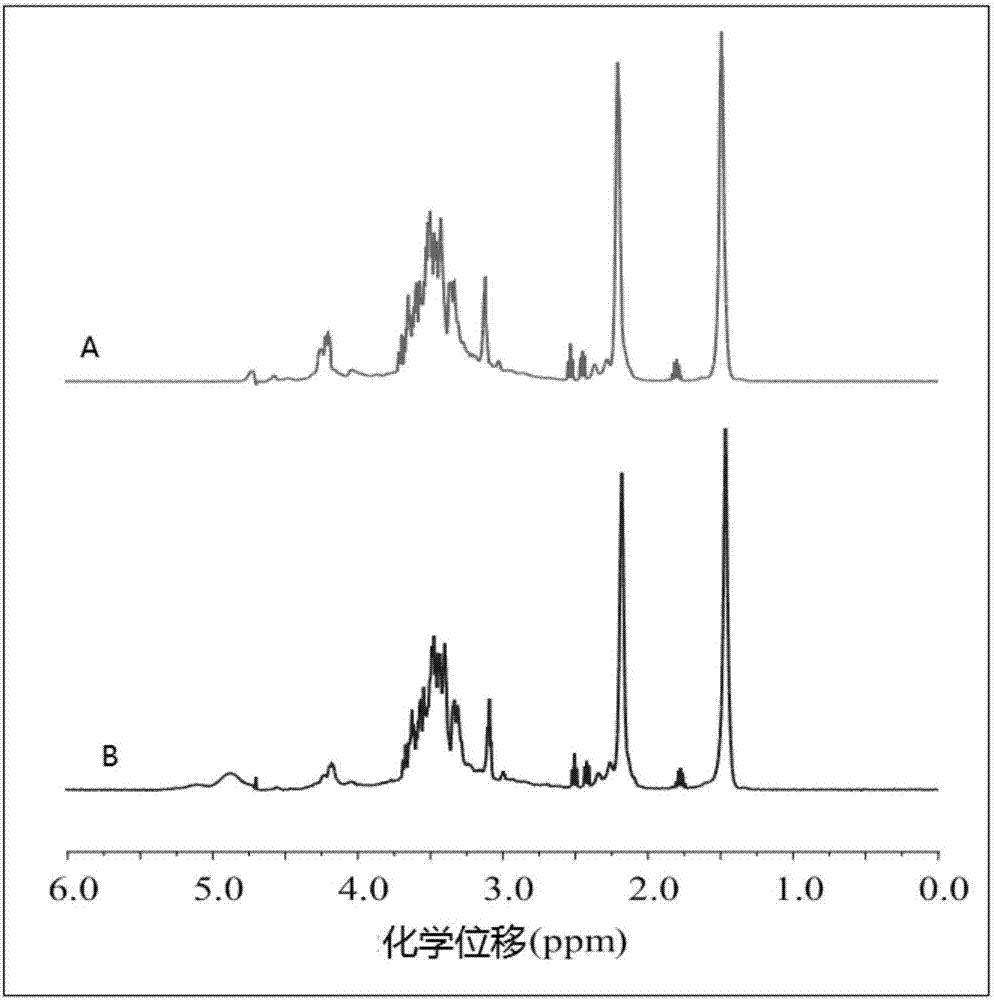

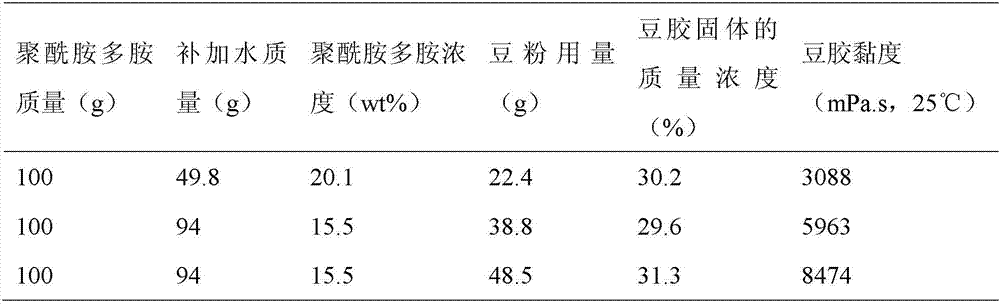

The invention discloses a soybean adhesive for a water-resistant shaving board and a preparation method thereof, and relates to an adhesive and a preparation method thereof, in particular to a modified soybean adhesive for production of boiling water boiling-resistant shaving boards, which aims at solving the technical problems of difficulty in adhesive applying in the production process of the shaving board due to large viscosity and difficulty in adapting to the production of the shaving board due to long hot pressing time in the existing soybean adhesive. The method comprises the following steps of 1, synthesizing of modified polyamide polyamine resin; 2, preparing of the adhesive. The prepared soybean adhesive for the water-resistant shaving board is prepared by adding 0.3 to 1.5% of curing agent and 10 to 25 parts of soybean meal into 100 parts of modified polyamide polyamine resin and mixing at room temperature. The soybean adhesive has the advantages that the viscosity is low, the adhesive is conveniently and uniformly sprayed onto the shaving board, the curing speed is high, the water-resistant property is good, and the soybean adhesive is especially suitable for preparing the boiling water boiling-resistant shaving board in the existing shaved board production line. The soybean adhesive belongs to the field of preparation of adhesives.

Owner:牡丹江恒源生化有限责任公司

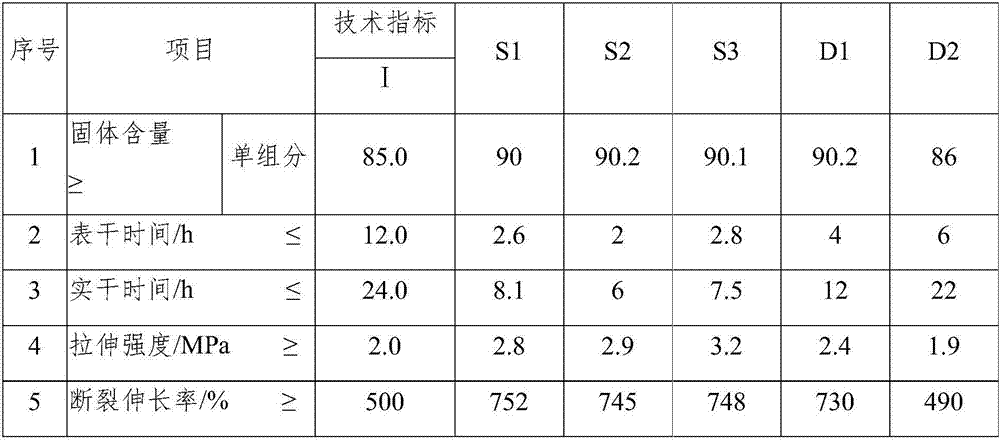

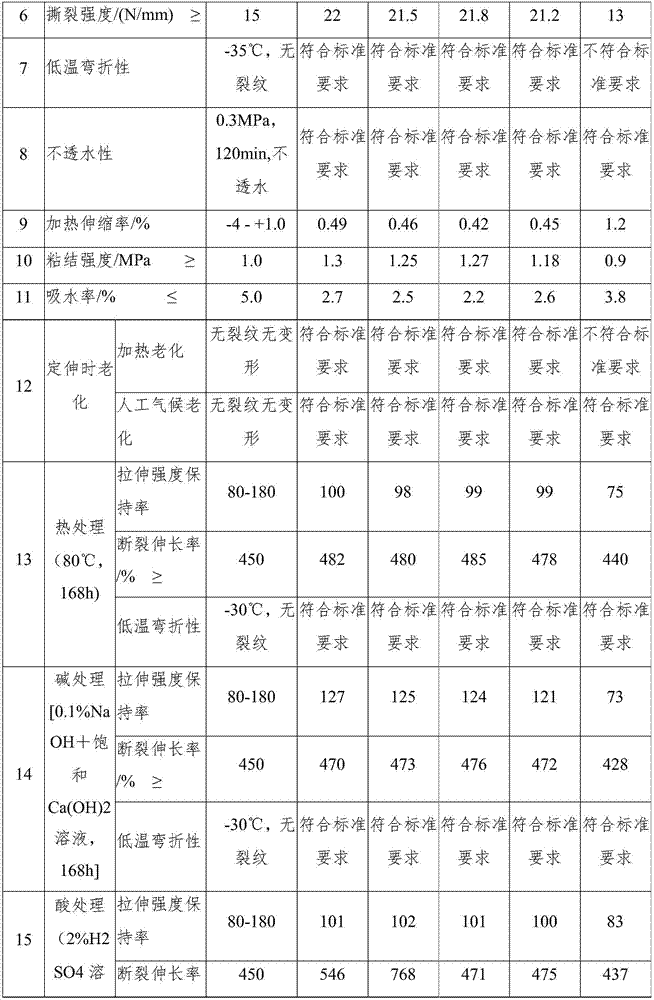

Single-component polyurethane waterproof coating and preparation method thereof

InactiveCN107573833AGuaranteed stabilityExtended storage timePolyurea/polyurethane coatingsSolventIsocyanate

In order to overcome the problem that the storage effect is affected by a catalyst in conventional simple-component polyurethane waterproof coating, the invention provides a single-component polyurethane waterproof coating, which is characterized by being prepared from the following components: polyether polyol, isocyanate, filler, catalyst microcapsules, chain extender and solvent; the catalyst microcapsule consists of a core and a shell wrapping the core, the core contains a palladium catalyst, and the melting point of the shell is between 50 DEG C and 70 DEG C. Moreover, the invention further discloses a preparation method for the single-component polyurethane waterproof coating. The single-component polyurethane waterproof coating provided by the invention can prevent the palladium catalyst from affecting unreacted isocyanate on a prepolymer in the process of storage, thus prolonging the storage time.

Owner:中油佳汇(广东)防水股份有限公司

Preparation method of rigid polyurethane foam heat insulation and energy saving material

The invention provides a preparation method of a rigid polyurethane foam heat insulation and energy saving material. The preparation method comprises the following steps of S1, preparing a black material and a white material with the weight ratio being (1.1-1.2) to 1, wherein the black material is isocyanate, and the white material is prepared by mixing the following raw materials in parts by weight: 70-95 parts of polyether polyol, 15-25 parts of deionized water, 6-9 parts of expanded vermiculite, 3-6 parts of acrylic resin, 2-3 parts of organosilicon oil foam stabilizer, 3-6 parts of rock wool fiber, 2-6 parts of bagasse fiber, 5-9 parts of nanometer calcium carbonate, 0.1-0.3 part of N,N-dimethyl cyclohexyl amine and 4-6 parts of modified tin catalyst; and S2, uniformly mixing the whitematerial in advance, then mixing the black material and the white material, foaming a mixture with a high-pressure foaming machine, injecting a foamed product into a die, and performing formation toobtain the rigid polyurethane foam heat insulation and energy saving material. The preparation method can reduce use of a chemical solvent and improves the heat insulation performance of a whole polyurethane material at the same time.

Owner:GUANGXI JISHUN ENERGY TECH

Light-curing colored paint

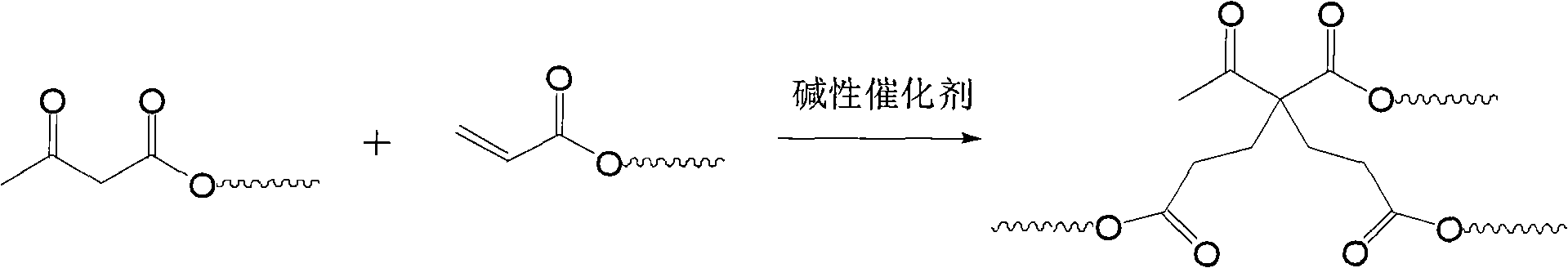

InactiveCN101967343AFast initial light curing effectCatalyzed Decomposition to AminesPolyurea/polyurethane coatingsEpoxy resin coatingsAcetoacetatesAcetic acid

The invention relates to a light-curing colored paint. The light-curing colored paint is technically characterized by comprising the following components in percentage by weight: 0.2 to 8 percent of light amine-producing agent, 0.5 to 10 percent of amine proliferation agent, 5 to 30 percent of acetoacetic ester compound, 30 to 65 percent of acrylate light-curing resin, 10 to 40 percent of acrylate activated thinner, 0.1 to 8 percent of photoinitiator and 4 to 8 percent of pigment. The light amine-producing agent contained in the system generates amine catalysts under ultraviolet irradiation, further catalyzes to start the amine-producing proliferation reaction of the amine proliferation agent, rapidly generates massive amines in a coating and automatically spreads to the whole coating system to generate amines along regional chemistry. Therefore, a crosslinked curing film is formed, and an invisible region on the surface or at the bottom of a film layer can be rapidly cured.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

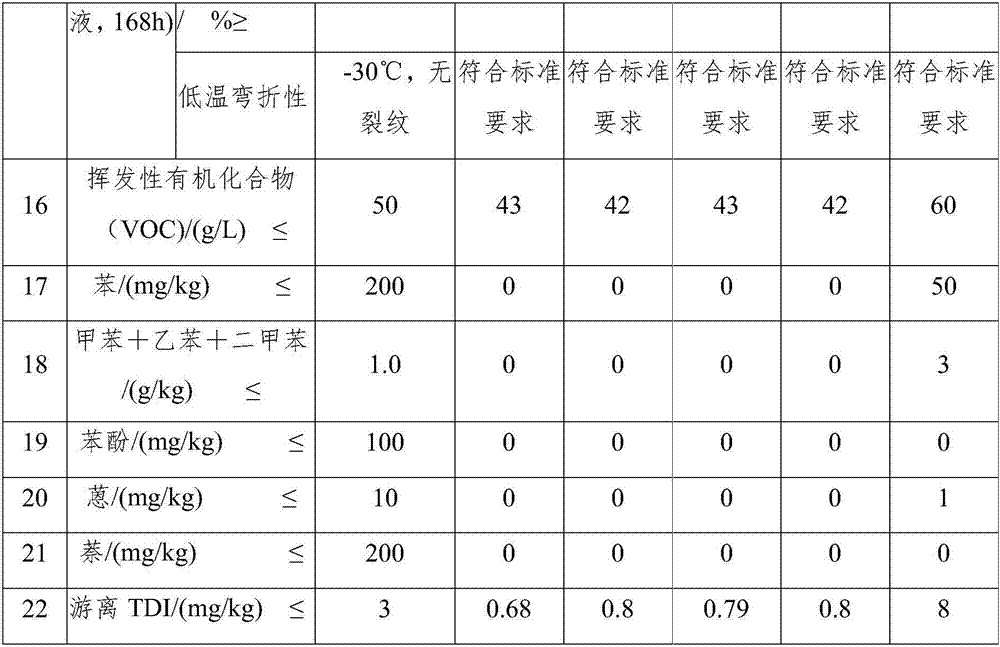

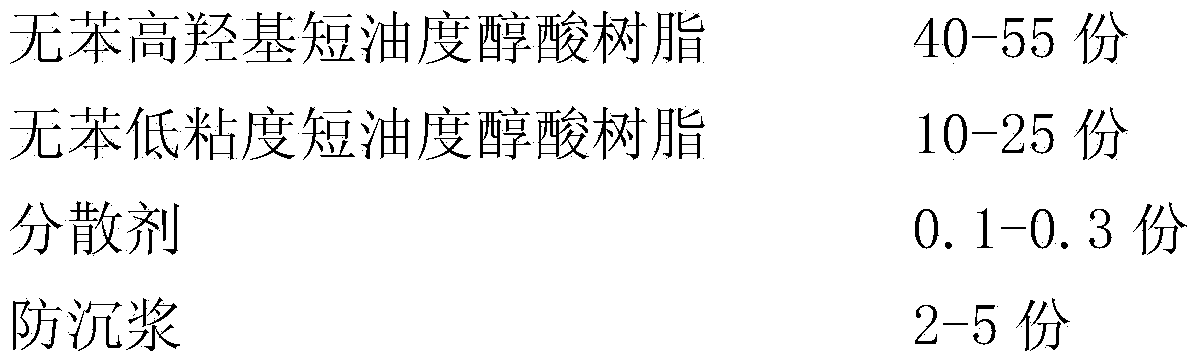

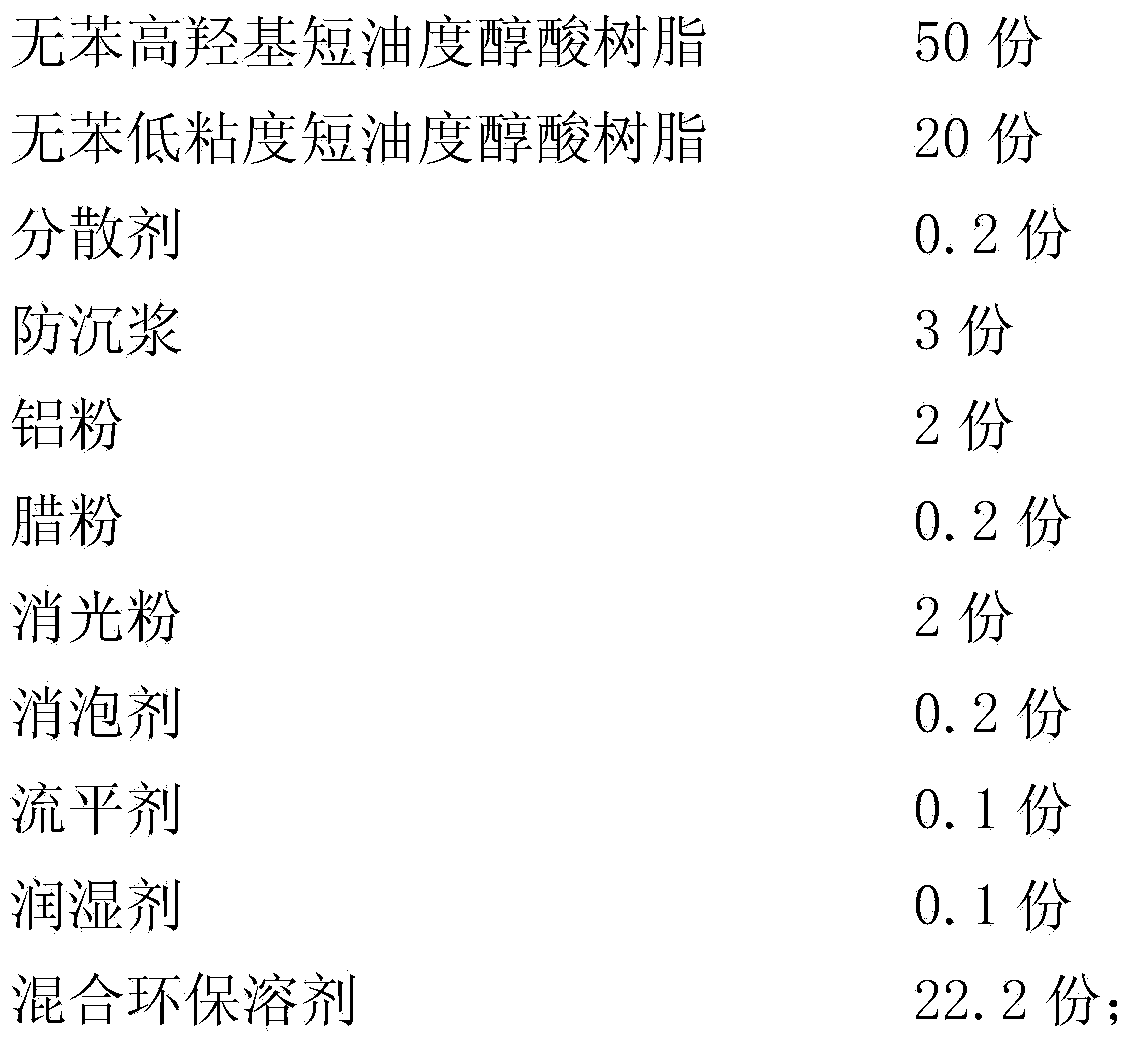

Healthy and environment-friendly dual-component wear-resisting floor paint and preparation method thereof

The invention relates to a dual-component floor paint and a preparation method thereof, in particular relates to a healthy and environment-friendly dual-component wear-resisting floor paint and a preparation method thereof, and belongs to the field of paints for construction and decoration. The healthy and environment-friendly dual-component wear-resisting floor paint is prepared from a main paint and an isocyanate curing agent at a mass ratio of 1:(0.8-1.2), wherein the main pant is prepared from the following raw materials in parts by weight: 40-55 parts of non-benzene high-hydroxyl short-oil alkyd resin, 10-25 parts of non-benzene low-viscosity short-oil alkyd resin, 0.1-0.3 parts of dispersing agent, 2-5 parts of anti-settling pulp, 1-3 parts of aluminum powder, 0.2-1 part of wax powder, 1-5 parts of matting agent, 0.1-0.5 parts of defoaming agent, 0.05-0.3 parts of flatting agent, 0.1-0.3 parts of wetting agent and 15-30 parts of mixed environment-friendly solvent.

Owner:SKSHU PAINT

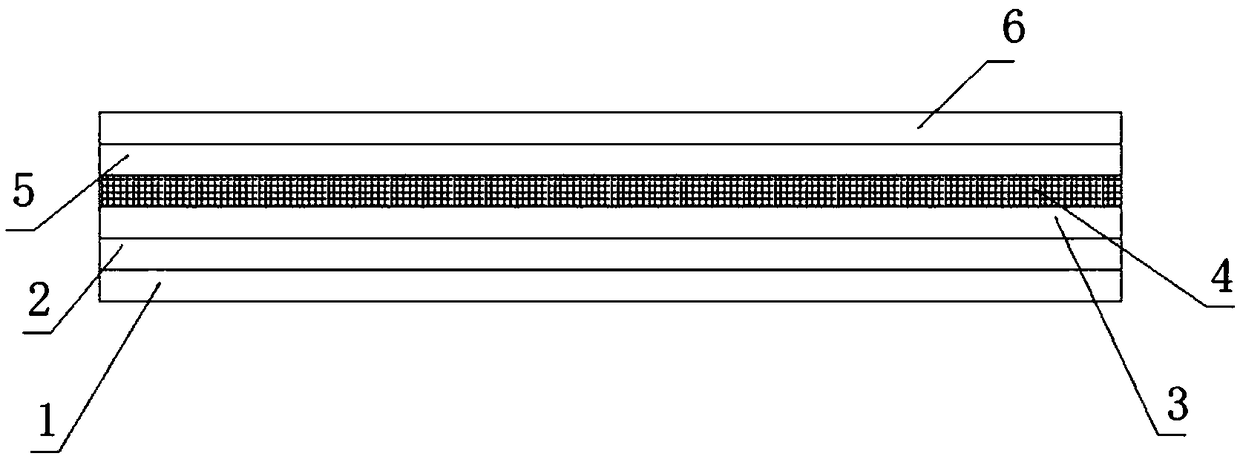

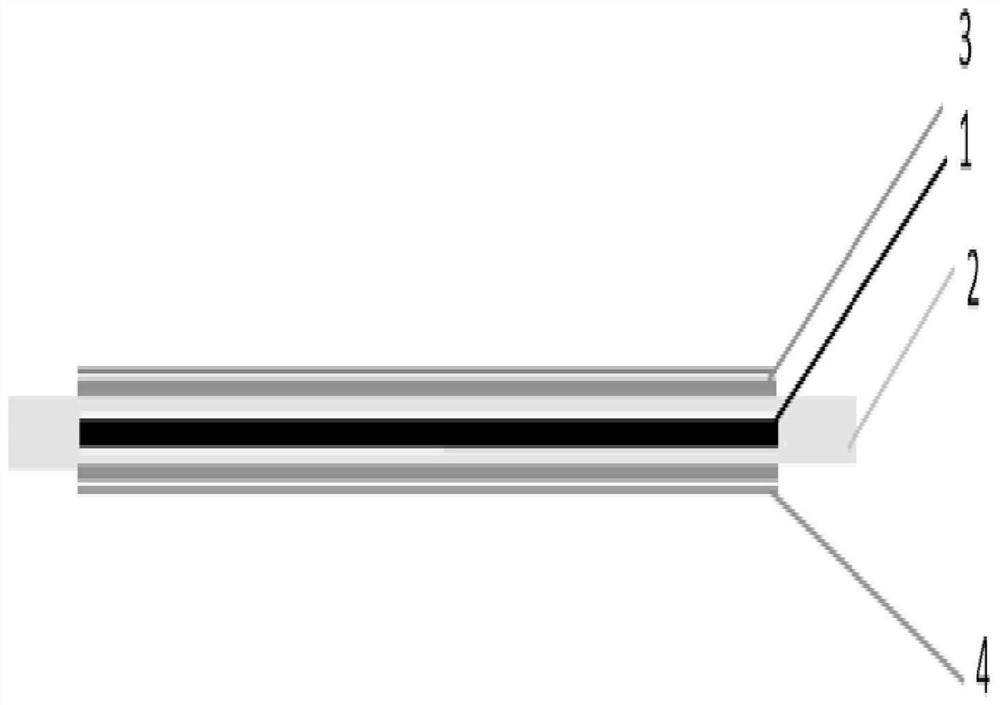

Water-based environmental-friendly sandpaper and production method thereof

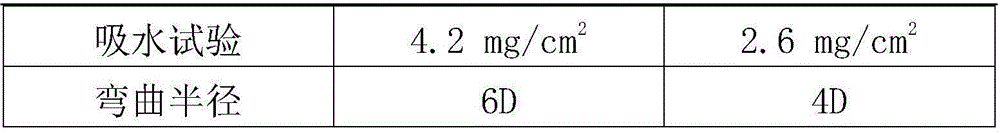

ActiveCN109290971AImprove water resistanceReduce cloggingAbrasion apparatusSandpaperFolding endurance

The invention provides water-based environmental-friendly sandpaper. The water-based environmental-friendly sandpaper comprises a base paper layer (1), a waterproof treatment layer (2), a bottom gluelayer (3), an abrasive layer (4), a compound glue layer (5) and an anti-blocking treatment layer (6) which are sequentially arranged from bottom to top. The waterproof treatment layer in the sandpaperimproves the waterproof capability, tensile strength, softness, folding endurance and smoothness of the base paper layer and effectively prevents base glue and compound glue from penetrating to the back of the base paper layer. The anti-blocking treatment layer in the sandpaper can make abrasive dust fall off and be not adhered to the sandpaper, so that the blocking phenomenon generated during the grinding of the sandpaper is reduced effectively, the service life of the sandpaper is greatly prolonged, and the grinding efficiency is improved.

Owner:湖北重泰研磨工具有限公司

Method for manufacturing moth-proof and low-formaldehyde wardrobe plate

ActiveCN105108841AResidue reductionImprove water resistanceLaminationLamination apparatusAdhesiveMoisture resistance

The invention relates to a building material for home furnishing, in particular to a method for manufacturing a moth-proof and low-formaldehyde wardrobe plate. The method for manufacturing the moth-proof and low-formaldehyde wardrobe plate is characterized by comprising the steps of lathing a plank into pieces, conducting drying, trimming edges, applying adhesive, conducting prepressing, conducting hot-pressing, sanding cut edges, conducting moth proofing treatment, attaching abrasion resistant paper, conducting decoration veneering and sealing the edges. According to the method for manufacturing the wardrobe plate, the formaldehyde residual amount is small, an aluminum alloy frame is inlaid at the periphery of the wardrobe plate, moisture in the air can be effectively prevented from permeating the plate, the moisture resistance and water resistance of the wardrobe plate are improved, the wardrobe plate obtained through the manufacturing method has good moth prevention performance, mold prevention performance, moisture protection performance and abrasion resistant performance, the formaldehyde residual amount is small, damage to a human body is reduced, the obtained wardrobe plate is stable in quality, the dimension stability is good, the plate is not prone to being cracked, damaged or deformed, and the service life is long.

Owner:广州市艾依格家居制品有限公司

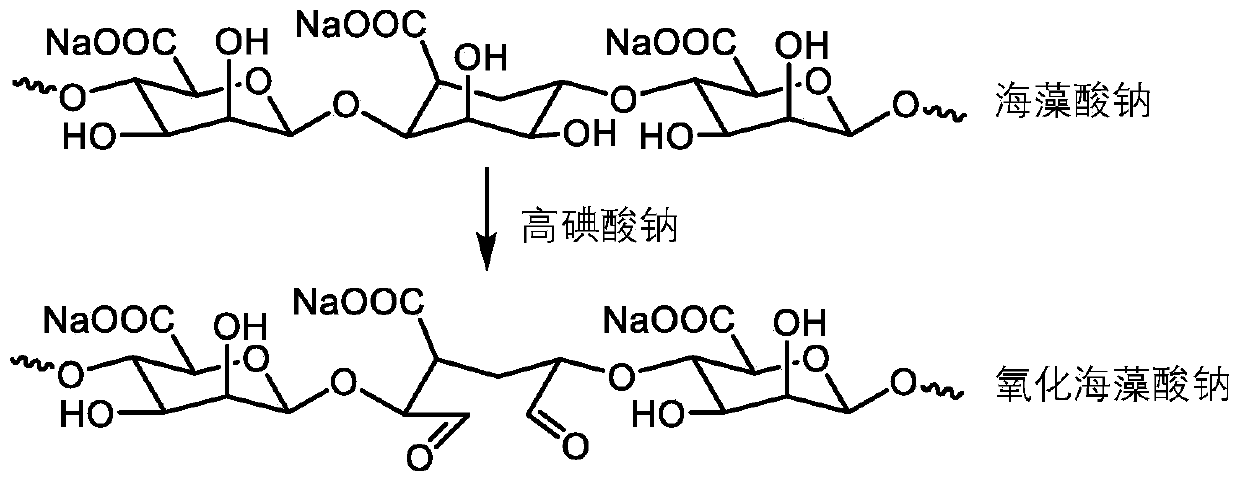

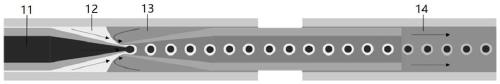

Degradable core-shell type oxidized calcium alginate gel microsphere, and preparation method and application thereof

ActiveCN111569798AUniform size and structureGood monodispersityMicroballoon preparationMicrocapsule preparationOrganic acidMicrosphere

The invention belongs to the technical field of materials, and particularly relates to a degradable core-shell type oxidized calcium alginate gel microsphere, and a preparation method and applicationthereof. According to the preparation method disclosed by the invention, the degradable core-shell type oxidized calcium alginate gel microsphere is prepared on the basis of micro-fluidic control; andan inner oil-phase fluid, a water-phase fluid and an outer oil-phase fluid form oil / water / oil double emulsion droplets, an acidic oil phase fluid containing organic acid is introduced into the downstream position of the oil / water / oil double emulsion droplets, calcium hydrochloride nanoparticles in a water phase of the oil / water / oil double emulsion droplets are rapidly dissolved, and free calciumions are released, so oxidized alginate in a water phase and the calcium ions are initiated to undergo rapid cross-linking so as to form a gelatinous oxidized alginate layer, and the degradable core-shell type oxidized calcium alginate gel microsphere is obtained. The degradable core-shell type oxidized calcium alginate gel microsphere prepared by the preparation method has the advantages that a size structure is uniform and monodispersity is high.

Owner:SUN YAT SEN UNIV

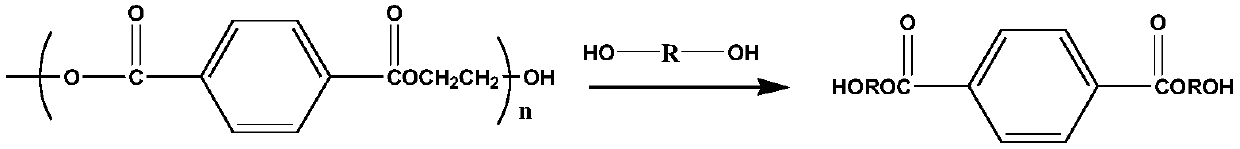

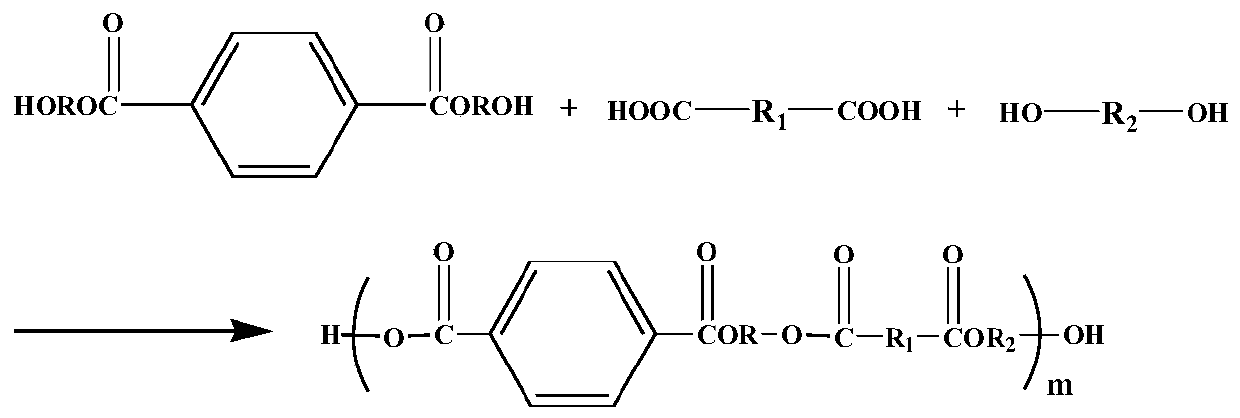

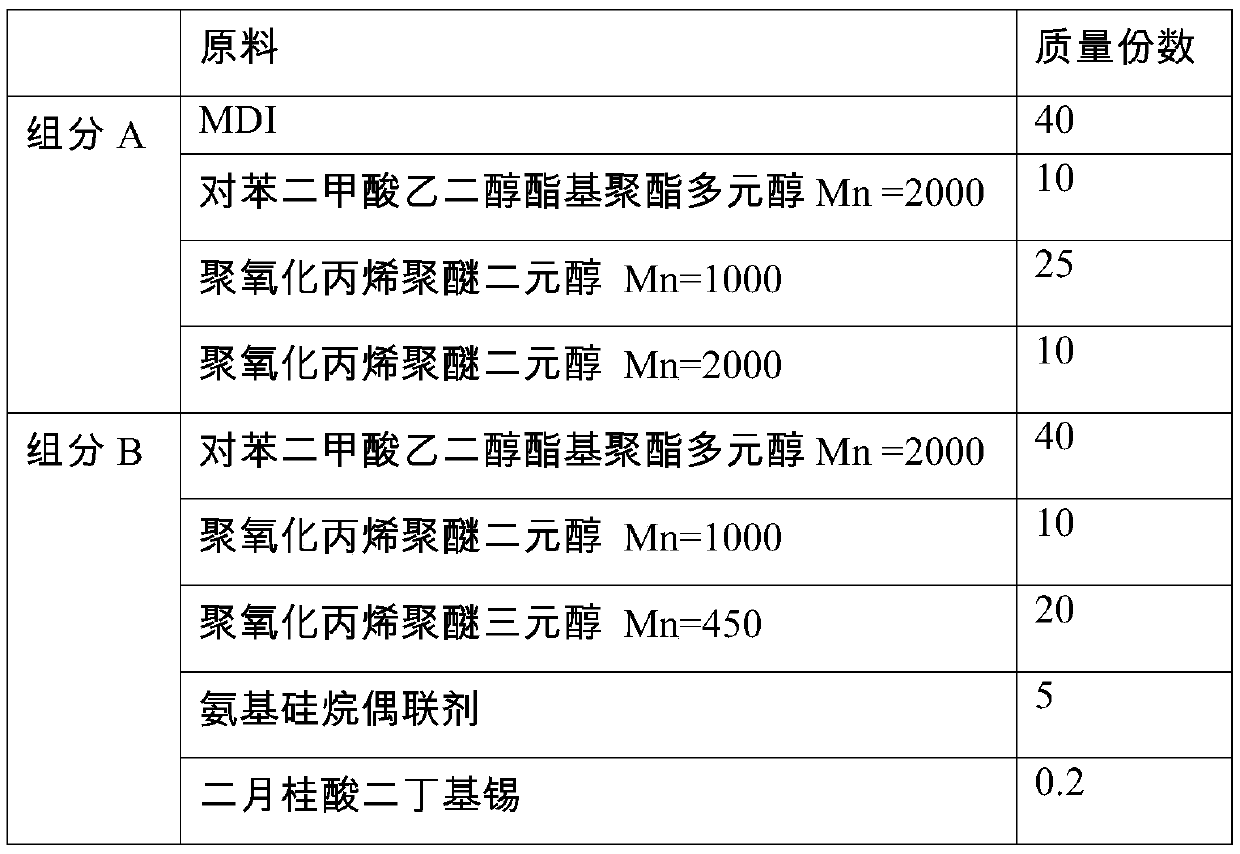

Two-component solvent-free polyurethane adhesive and preparation method thereof

InactiveCN111234757AEnable recyclingReduce manufacturing costPolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention discloses a bi-component solvent-free polyurethane adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The paint is composed of a component A anda component B according to a mass ratio of 1-2:1. The component A is prepared from the following raw materials in parts by weight: 30 to 80 parts of polyisocyanate, 10 to 50 parts of polyether polyoland 5 to 15 parts of polyester polyol; the component B is prepared from the following raw materials in parts by weight: 5 to 40 parts of polyether polyol, 20 to 50 parts of polyester polyol, 2 to 6 parts of a coupling agent and 0.05 to 0.5 part of a catalyst. The preparation method comprises the following steps: preparing the component A; preparing the component B; and preparing the polyurethane adhesive. The polyester polyol adopted by the invention is prepared by alcoholysis and esterification of recycled PET, so that the production cost of the polyester polyol is reduced. The obtained two-component solvent-free polyurethane adhesive has the advantages of low viscosity, reduced production energy consumption, high bonding strength and high temperature resistance.

Owner:BEIJING HUATENG NEW MATERIAL CO LTD

High-strength weather-resistant modified acrylonitrile-butadiene rubber material and preparation method thereof

The invention discloses a high-strength weather-resistant modified acrylonitrile-butadiene rubber material. The acrylonitrile-butadiene rubber material comprises the following raw materials in parts by weight: 45-48 parts of acrylonitrile-butadiene rubber 2707, 30-33 parts of prefabricated fluoropolymer, 12-15 parts of ethylene-propylene rubber, 8-12 parts of para-aramid fiber, 1-3 parts of castor oil, 0.6-1 part of sulfur powder, 1.4-1.8 parts of an accelerator AA, 1.6-2 parts of an accelerator MZ, 13-16 parts of coal gangue powder, 15-18 parts of calcined clay, 7-10 parts of magnesium hydroxide, 4-8 parts of zinc borate, 1.4-1.8 parts of a titanate coupling agent, 2.2-2. 6 parts of an anti-aging agent BLE and 3-5 parts of an anti-aging agent OD. The invention also provides a preparation method of the high-strength weather-resistant modified acrylonitrile-butadiene rubber material. The high-strength weather-resistant modified acrylonitrile-butadiene rubber material has the advantages of high oil resistance, high strength, excellent oxidation resistance and weather resistance and good mechanical properties.

Owner:ANHUI SPECIAL CABLE GRP

High-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material and preparation method thereof

InactiveCN104558867AGood flexibilityImprove solubilityRubber insulatorsPlastic/resin/waxes insulatorsPolymer scienceAntimony trioxide

The invention discloses a high-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material which is prepared from the following raw materials in parts by weight: 48-54 parts of ethylene propylene diene monomer rubber, 28-34 parts of preformed fluorine-containing polymer, 20-23 parts of styrene-butadiene rubber, 10-12 parts of hard clay, 3-5 parts of monoalkoxy titanate coupling agent, 5-8 parts of aluminum hydroxide, 6-7 parts of red phosphorus master batch, 4-5 parts of antimony trioxide, 0.5-0.8 part of sulfur, 0.4-0.6 part of dicumyl peroxide, 1.1-1.4 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1.4-1.5 parts of trimethylolpropane trimethylacrylate, 1.6-2 parts of anti-aging agent H and 1.2-1.5 parts of anti-aging agent DFC-34. The invention also discloses a preparation method of the high-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material. The high-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material has the advantages of high elasticity, high strength, excellent flame retardancy, excellent wear resistance, excellent ozone erosion resistance and excellent weather resistance.

Owner:ANHUI SPECIAL CABLE GRP

Epoxy resin based anti-static coating

InactiveCN109054477AGood dispersionWell dispersed and surroundedElectrically-conductive paintsEpoxyCalcium bicarbonate

The invention discloses an epoxy resin based anti-static coating and belongs to the technical field of high polymer materials. The epoxy resin based anti-static coating is prepared by the following steps: putting epoxy resin and a diluent in a mixer; stirring and mixing for 40-60min at a rotation speed of 400-600r / min; adding low-melting-point alloy, silver nanowire, a curing agent, drying oil, acoupling agent, coated sodium peroxide, calcium bicarbonate, alkaline phenolic resin and dry soybean oil into the mixer; stirring and mixing for 40-60min at a rotation speed of 400-600r / min to obtainthe epoxy resin based anti-static coating. The epoxy resin based anti-static coating provided by the invention has excellent anti-static property and mechanical property.

Owner:杨帮燕

Ultraviolet light curing material

InactiveCN102516866BIncrease profitPromote cross-linking and curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiluentUltraviolet lights

The present invention relates to an ultraviolet light curing material, which comprising the following components by weight percentage: 40-60%of light cured resin; 25-45% of light curing diluent; 2-10% of photoinitiator; 0-0.8% of ultraviolet storage stabilizer; 0.5-30%of nano filler; 0.2-1% of leveling agent. On the basis of addition of light cured resin, the light curing diluent and the photoinitiator in the ultraviolet light curing material, the nano filler is added, the ultraviolet light respectively reflects to all directions through small particles, so that the light is scattered, the utilization rate of the ultraviolet light can be increased, the crosslinking and curing speed can be accelerated, and the curing energy can be reduced.

Owner:YANTAI DARBOND TECH

Environment-friendly anti-radiation photovoltaic cable used for solar energy power generation

InactiveCN106221264AGood water solubilityHigh reactivityInsulated cablesOrganic insulatorsBenzoyl peroxideEngineering

The invention discloses an environment-friendly anti-radiation photovoltaic cable used for solar energy power generation, which includes a cable core and a sheath layer coating the cable core, wherein the sheath layer includes, by weight, 20-40 parts of EVA resin, 15-25 parts of chloroprene rubber, 15-30 parts of hydrogenated nitrile butadiene rubber, 15-35 parts of micro powder of silicon carbide, 8-12 parts of bentonite, 10-20 parts of zeolite powder, 10-20 parts of lignin, 45-65 parts of rice hull powder, 10-20 parts of barite powder, 15-22 parts of modified sodium lignin sulfonate, 1-1.5 parts of white oil, 0.8-1.6 parts of an anti-aging agent 2246, 0.8-1.6 parts of an anti-aging agent SP, 3-6 parts of benzoyl peroxide, 2-5 parts of an anti-coking agent CTP, 0.4-0.8 parts of an accelerator PZ, 0.3-0.7 parts of an accelerator TMTD, 1-1.8 parts of zinc oxide, 1.5-2.2 parts of disproportionated rosin, 1.5-3.5 parts of a softener DOP, 1.5-2.5 parts of epoxy soybean oil and the like.

Owner:吴显峰

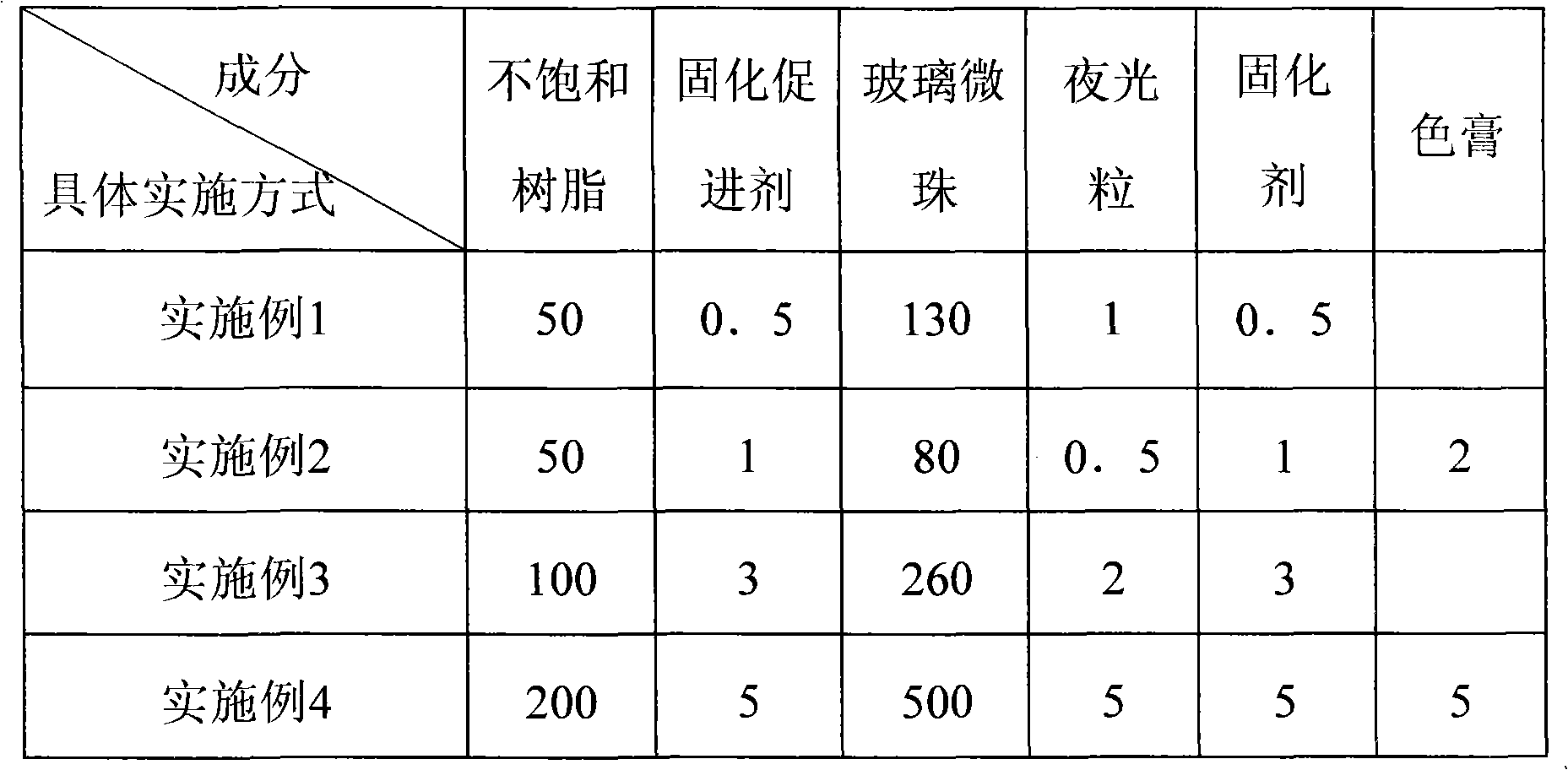

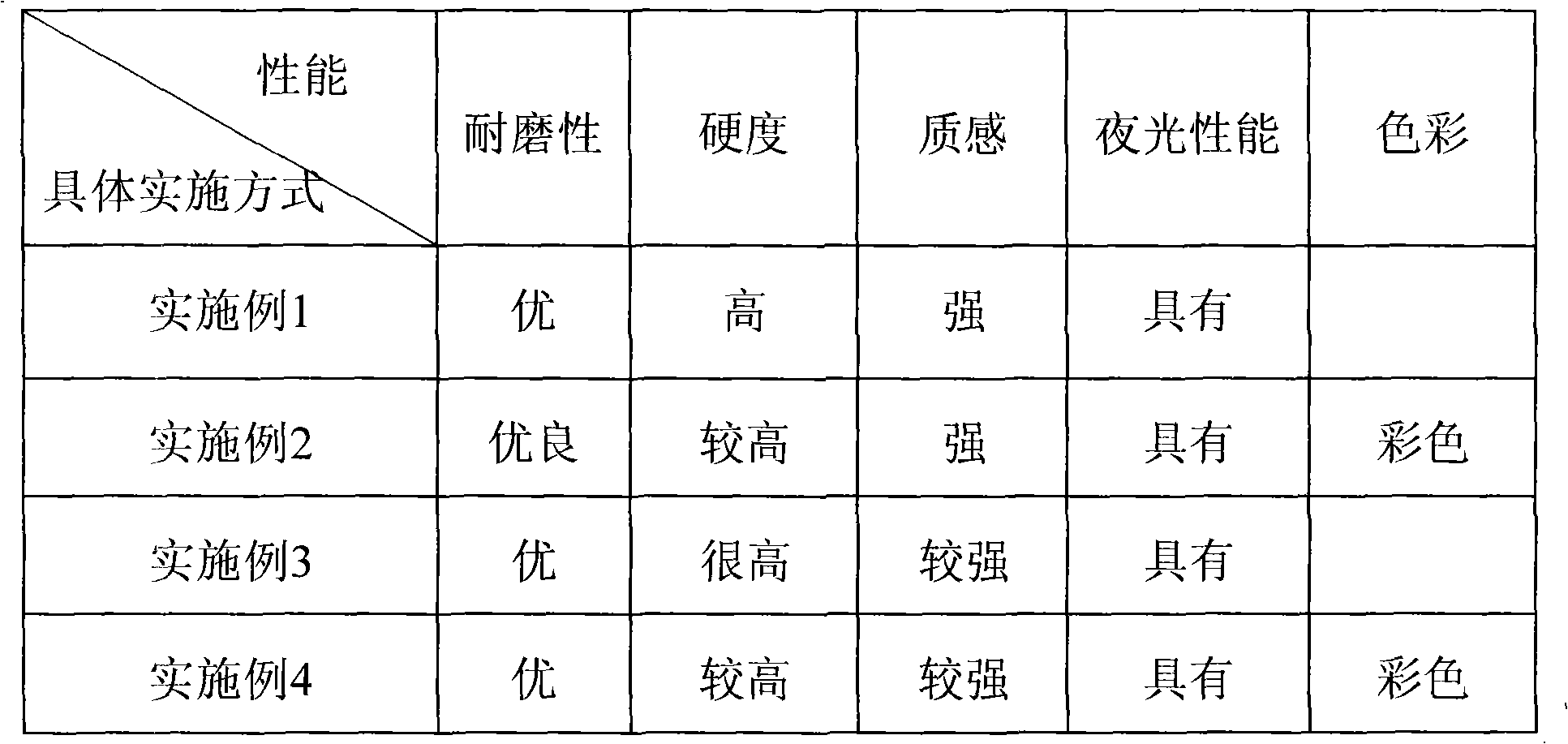

Luminous sandstone imitating decorating material and manufacturing method thereof

InactiveCN101293758APromote cross-linking and curingHigh strengthWear resistantUltimate tensile strength

The invention relates to a noctilucent imitated sandstone decorative material and a preparation method thereof. The noctilucent imitating sandstone decorative material is prepared by the following components with the weight parts as follows: 50 to 200 parts of unsaturated resin; 0.1 to 5 parts of solidified accelerant; 50 to 500 parts of glass microballoons; 0.1 to 20 parts of inorganic luminous grains; and 0.1 to 5 parts of solidifying agent; the grain diameter of each glass microballoon is 10 to 50 meshes; the decorative material not only has the tactile sensation, the strength and the wear resistant property of natural sandstone, but also has artistic effects different from the yellow color of the sandstone; the decorative material is semitransparent and has the snow white, special artistic effect and the luminous effect, representing a novel decorative material which not only has the artistic quality, but also has the luminous performance.

Owner:陈伟刚

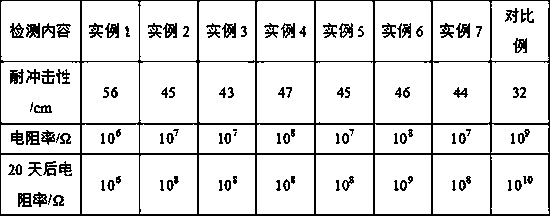

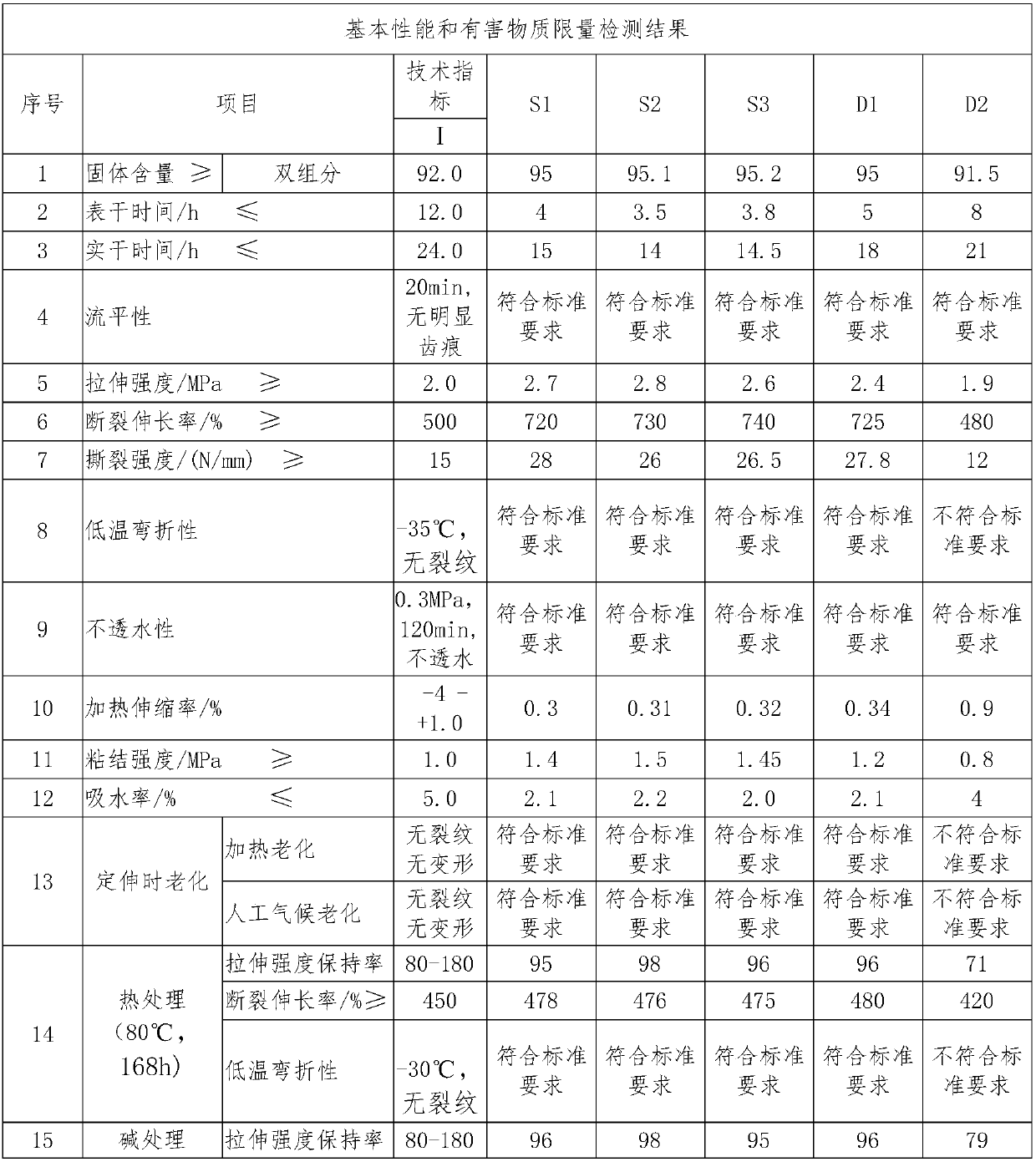

Two-component waterproof polyurethane coating and preparation method thereof

InactiveCN107629671APromote cross-linking and curingAvoid contactPolyurea/polyurethane coatingsPolyolPalladium catalyst

The invention provides a two-component waterproof polyurethane coating in order to solve the problems of poor catalysis effect and short shelf life of existing two-component waterproof polyurethane coatings. The two-component waterproof polyurethane coating comprises a component A and a component B; the component A comprises first polyether polyol, isocyanate, a catalyst microcapsule and a first solvent, the catalyst microcapsule comprises a capsule core and a capsule shell coated outside the capsule core, the capsule core comprises a palladium catalyst, and the melting point of the capsule shell is 50-70 DEG C; and the component B comprises second polyether polyol, chlorinated paraffin, a filler and a second solvent. The invention also discloses a preparation method of the two-component waterproof polyurethane coating. The two-component waterproof polyurethane coating can avoid the influences of the palladium catalyst on unreacted isocyanate radicals in a prepolymer during storage andprolong the storage time.

Owner:中油佳汇(广东)防水股份有限公司

Soybean Adhesive for Water Resistant Particleboard

ActiveCN107216849BMeet spraying requirementsEnsure water resistanceNon-macromolecular adhesive additivesProtein adhesivesAdhesivePolyamide

The invention discloses a soybean adhesive for a water-resistant shaving board and a preparation method thereof, and relates to an adhesive and a preparation method thereof, in particular to a modified soybean adhesive for production of boiling water boiling-resistant shaving boards, which aims at solving the technical problems of difficulty in adhesive applying in the production process of the shaving board due to large viscosity and difficulty in adapting to the production of the shaving board due to long hot pressing time in the existing soybean adhesive. The method comprises the following steps of 1, synthesizing of modified polyamide polyamine resin; 2, preparing of the adhesive. The prepared soybean adhesive for the water-resistant shaving board is prepared by adding 0.3 to 1.5% of curing agent and 10 to 25 parts of soybean meal into 100 parts of modified polyamide polyamine resin and mixing at room temperature. The soybean adhesive has the advantages that the viscosity is low, the adhesive is conveniently and uniformly sprayed onto the shaving board, the curing speed is high, the water-resistant property is good, and the soybean adhesive is especially suitable for preparing the boiling water boiling-resistant shaving board in the existing shaved board production line. The soybean adhesive belongs to the field of preparation of adhesives.

Owner:牡丹江恒源生化有限责任公司

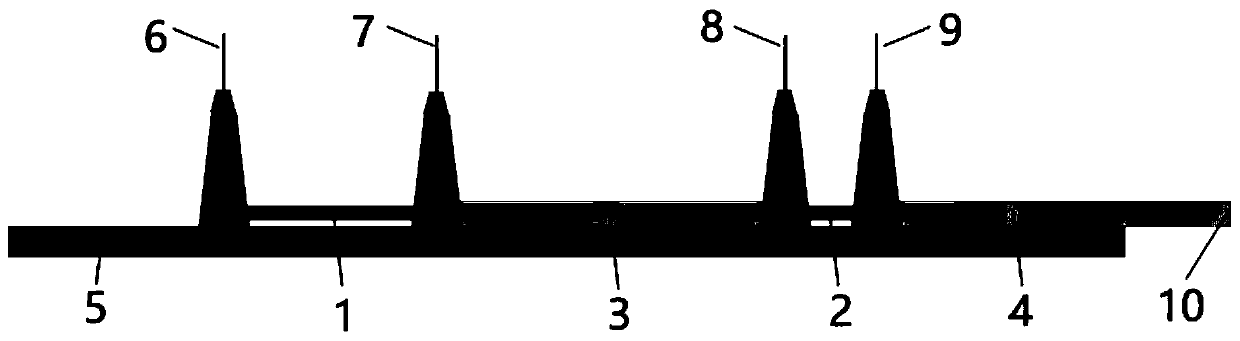

Novel negative electrode current collector, negative electrode composed of novel negative electrode current collector and lithium ion battery

ActiveCN112952104AReduce weightImprove conductivityElectrode carriers/collectorsSecondary cellsPhysical chemistryLithium-ion battery

The invention discloses a novel negative electrode current collector, a negative electrode composed of the novel negative electrode current collector and a lithium ion battery. A negative electrode piece comprises a substrate layer, a conductive metal layer, a porous conductive layer and a composite binder layer. The invention further discloses a preparation method of the negative plate and a lithium ion secondary battery manufactured by using the negative plate. The weight and the size of the negative plate are reduced, the energy density of the lithium ion secondary battery is improved, the conductivity of the negative plate is relatively good, the problem that lithium ions are separated out and deposited under the high power of the battery is solved, and finally, the safe and reliable lithium ion battery with ultrahigh energy density is obtained.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

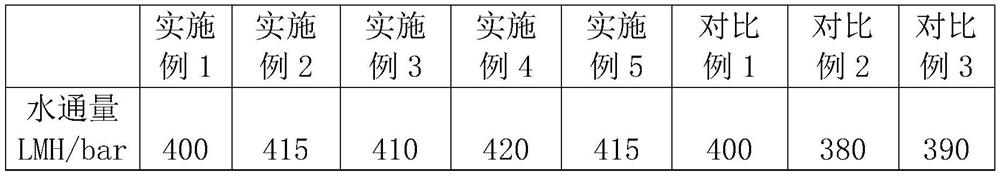

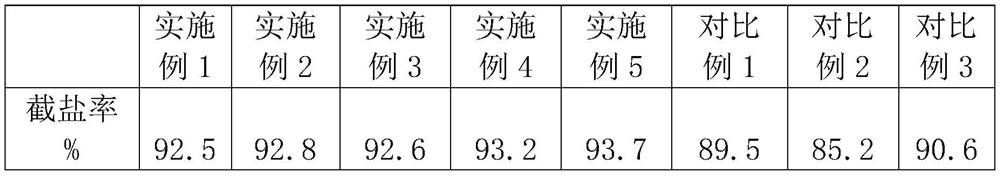

Hydrophilicity improvement method of PP film

PendingCN113499692AHydrophilic permanent and stableSimple processSemi-permeable membranesMembranesPolymer scienceOrganic solvent

The invention relates to the field of PP film material preparation methods, and discloses a PP film hydrophilicity improvement method comprising the following steps: 1, taking a PP film, and taking an organic solvent to infiltrate the PP film for 30 min; 2, taking clear water, cleaning the PP film with clear water, soaking the PP film in the clear water for 10 minutes, taking a water-soluble high-molecular polymer solution, and soaking the PP film in the water-soluble high-molecular polymer solution for 30-60 minutes; 3, fishing out the PP film, and soaking the PP film in a cross-linking agent solution for 5-10 minutes; and 4, fishing out the PP film, and draining off the liquid on the surface to obtain the hydrophilic improved PP film. The method for improving the hydrophilicity of the PP film has the advantages of being simple in process and low in cost, and the PP film with the improved hydrophilicity can be applied to microfiltration or ultrafiltration and has excellent water flux and good salt rejection rate.

Owner:苏诺特(苏州)材料科技有限公司

Artificial turf adhesive composition

InactiveCN109486442ALow costUniform particle sizeNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedWeather resistance

The invention discloses an artificial turf adhesive composition. The artificial turf adhesive composition is prepared from the following components in parts by weight: 45-100 parts of water-based latex, 20-30 parts of phenolic resin, 1-30 parts of filler, 6-9 parts of aqueous polyurethane (PUR) dispersion, 1-3 parts of cross-linking agent, 0.1-2 parts of coupling agent, 0.1-0.3 part of anti-ageingagent, 0.2-0.4 part of ultraviolet absorbent, 0.1-0.2 part of defoaming agent, 0.5-1 part of dispersing agent, and 2-5 parts of zinc oxide. The artificial turf adhesive composition provided by the invention is uniform in particle size, stable in property, good in weather resistance and water resistance, strong in ageing resistance, simple and feasible in preparation method and low in cost.

Owner:陆欣瑜

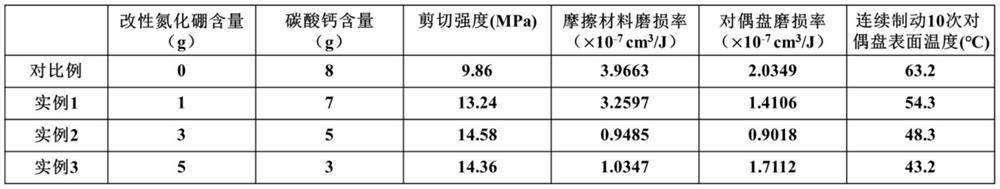

Soft metal-friendly resin-based friction material and preparation method thereof

The invention relates to a soft metal-friendly resin-based friction material and a preparation method thereof, dopamine hydrochloride and hexagonal boron nitride are added into a buffer solution with PH of 8.5 for mixing, and modified boron nitride with the surface uniformly coated with a polydopamine nano-film is obtained. And by uniformly mixing the modified boron nitride serving as a filler with fibers and a resin binding agent, and carrying out hot-pressing curing, the soft metal-friendly resin-based friction material is obtained. The resin-based friction material has the beneficial effects that the anti-attrition lubricating property, the heat-conducting property and the anti-shearing property of the resin-based friction material are improved. The wear rate of the resin-based friction material is reduced by 76%, the wear rate of the soft metal dual disc is reduced by 55.6%, and the surface temperature of the dual disc in the friction process is obviously reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

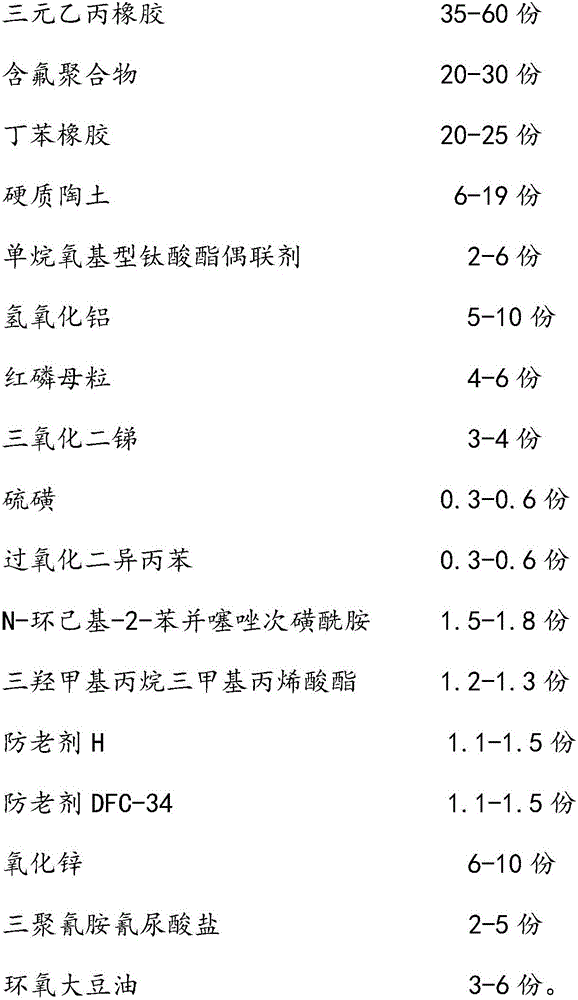

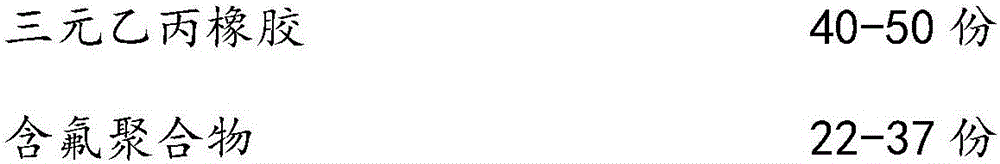

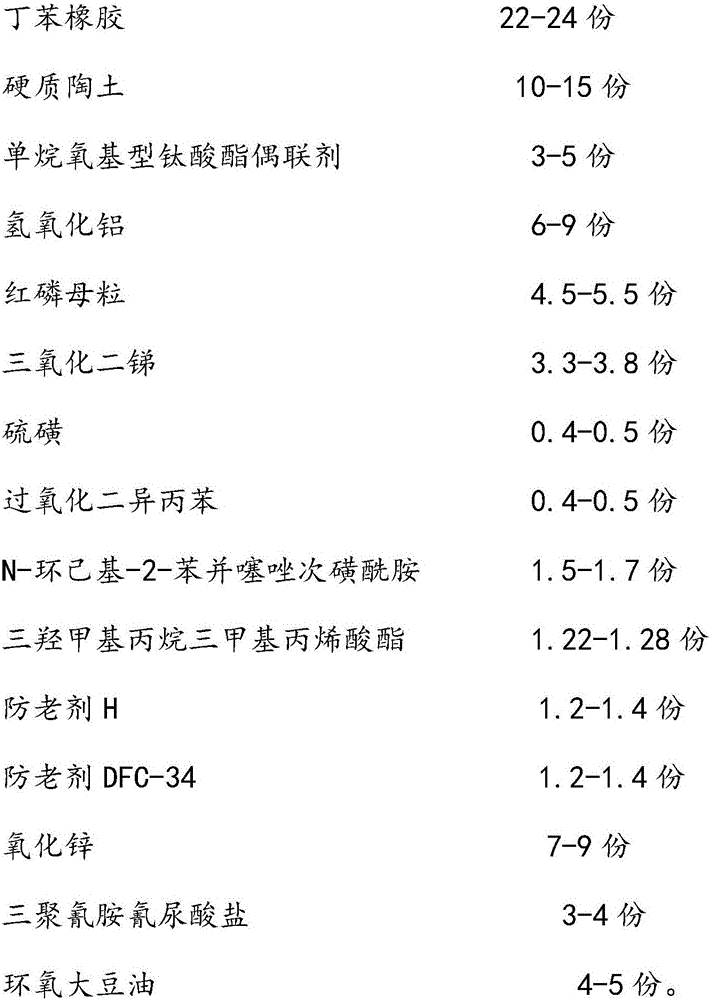

High-elasticity and high-strength weather-resistant and flame-retardant cable material for wind power generation

InactiveCN106243522AGood flexibilityImprove solubilityRubber insulatorsInsulated cablesAntimony trioxidePolymer

The invention discloses a high-elasticity and high-strength weather-resistant and flame-retardant cable material for wind power generation. The cable material comprises the following raw materials in parts by weight: 35-60 parts of ethylene propylene diene monomer rubber, 20-30 parts of fluorine-containing polymer, 20-25 parts of styrene-butadiene rubber, 6-19 parts of hard clay, 2-6 parts of a monoalkoxy titanate coupling agent, 5-10 parts of aluminum hydroxide, 4-6 parts of red phosphor masterbatch, 3-4 parts of antimony trioxide, 0.3-0.6 parts of sulfur, 0.3-0.6 parts of dicumyl peroxide, 1.5-1.8 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1.2-1.3 parts of trimethylolpropane trimethacrylate, 1.1-1.5 parts of an antioxidant H, 1.1-1.5 parts of an antioxidant DFC-34, 6-10 parts of zinc oxide, 2-5 parts of melamine cyanurate and 3-6 parts of epoxidized soybean oil. The cable material provided by the invention has high elasticity, high strength, and excellent flame retardancy, wear resistance, ozone erosion resistance and weather resistance.

Owner:安徽顺驰电缆股份有限公司

A kind of production method of low-aldehyde flame-retardant plywood

ActiveCN105235025BImprove flame retardant performanceQuality assuranceLaminationLamination apparatusCell wallResin adhesive

The invention relates to a plywood, in particular to a production method of a low-aldehyde flame-retardant plywood. The process steps of its production include: plank rotary blade—primary drying—repair—vacuum impregnation treatment—secondary drying—gluing—prepressing—hot pressing—edge trimming and sanding. The invention uses a flame retardant solution to vacuum impregnate the veneer. After the impregnation process, the flame retardant penetrates into the cell cavity, cell wall and intercellular space of the wood to obtain a flame retardant veneer, which is used to produce plywood. The flame retardant performance of the produced plywood has been improved; by improving the urea-formaldehyde resin adhesive used, the residual amount of formaldehyde in the adhesive is reduced, thereby reducing the residual amount of formaldehyde in the plywood; The burning agent borax solution improves the flame retardancy of the urea-formaldehyde resin adhesive used. Using this adhesive to produce plywood not only reduces the residual amount of formaldehyde in the plywood but also further improves the flame retardancy of the plywood.

Owner:广州皕吉装饰材料有限公司

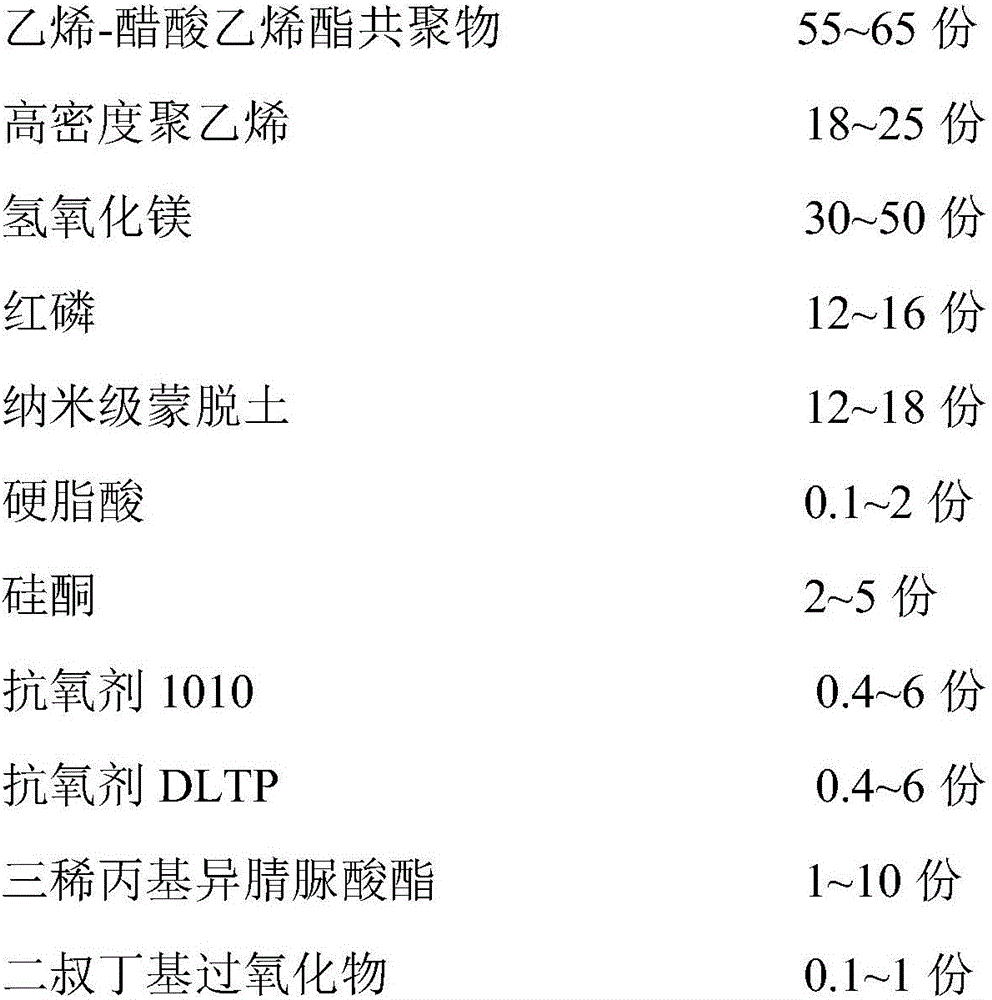

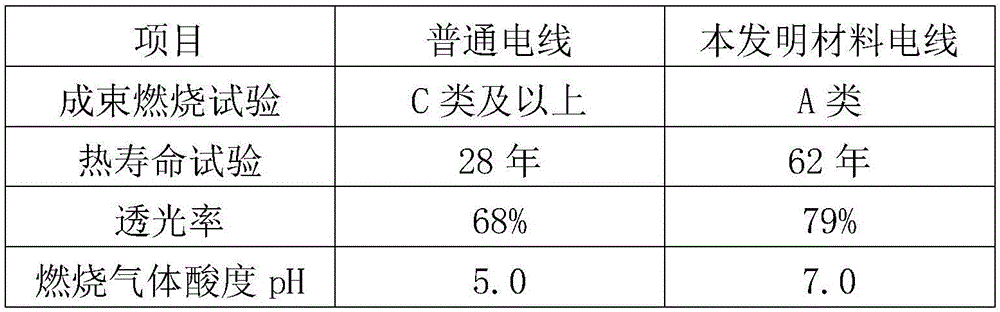

Irradiation cross-linked polyolefin cable material and preparation method thereof

InactiveCN106397957AAccelerated agingExtended service lifePlastic/resin/waxes insulatorsCross-linkPolyolefin

Belonging to the technical field of cable material manufacturing, the invention in particular relates to an irradiation cross-linked polyolefin cable material and a preparation method thereof. The irradiation cross-linked polyolefin cable material comprises the following components by weight: 55-65 parts of an ethylene-vinyl acetate copolymer; 18-25 parts of high density polyethylene; 30-50 parts of magnesium hydroxide; 12-16 parts of red phosphorus; 12-18 parts of nano montmorillonite; 0.1-2 parts of stearic acid; 2-5 parts of silicone; 0.4-6 parts of an antioxidant 1010; 0.4-6 parts of an antioxidant DLTP; 1-10 parts of triallyl isocyanurate; and 0.1-1 part of di-tert-butyl peroxide. The invention also discloses a preparation method of the irradiation cross-linked polyolefin cable material. After being extruded in a conductive wire core, the irradiation cross-linked polyolefin obtained according to the components, weight parts and manufacturing method has the characteristics of excellent aging performance, long service life, better mechanical and physical properties, and higher safety coefficient, etc.

Owner:西安飞机工业(集团)亨通航空电子有限公司

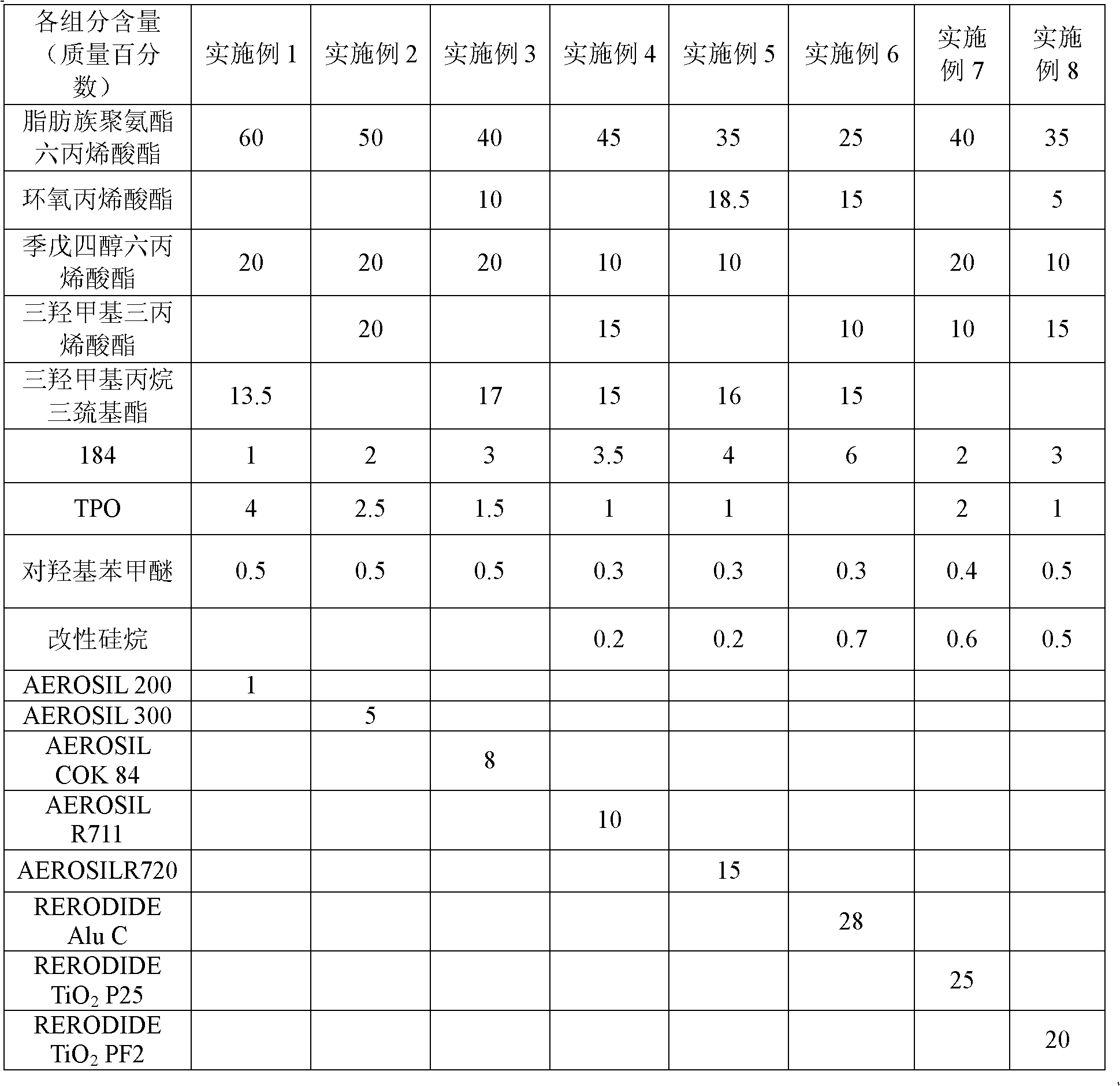

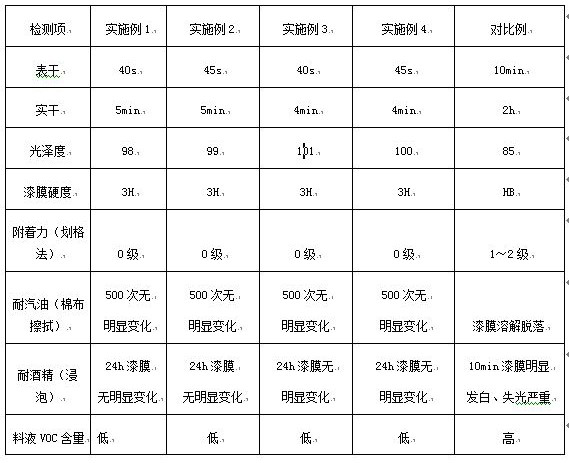

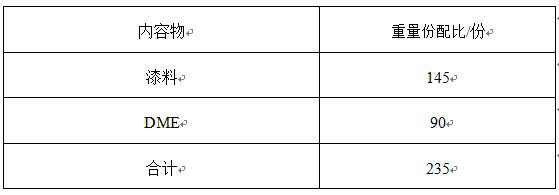

Aerosol type UV coating and preparation method thereof

InactiveCN112300685APromote cross-linking and curingLow VOC contentPolyurea/polyurethane coatingsEpoxy resin coatingsSolventComposite material

The invention discloses an aerosol type UV coating which comprises a component A paint vehicle and a component B propellant, the component A paint vehicle comprises the following components in parts by weight: 50-70 parts of oligomer, 20-30 parts of a reactive diluent, 1-3 parts of a photoinitiator, 0.1-1 part of a defoamer, 0.1-1 part of a leveling agent, 0-5 parts of filler, 0-8 parts of pigmentand 0.1-1 part of a polymerization inhibitor, and the filling ratio of the component A paint vehicle to the component B propellant is (1.2-2.0): 1. The aerosol paint adopting the technical scheme hasthe advantages that volatile organic solvents are not added into the paint vehicle; after the product is sprayed, the product is cured under ultraviolet radiation, all the components of the paint vehicle participate in cross-linking film formation, and VOC is greatly reduced; under ultraviolet radiation, a paint film is rapidly cross-linked, the drying speed is high, and the construction efficiency is greatly improved; and a paint film is of a three-dimensional net structure after being cured, the hardness, adhesive force, abrasion resistance, weather resistance and solvent resistance are superior to those of traditional aerosol paint, and the use field of the product is further widened.

Owner:GUANGDONG SANVO CHEM IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com