Ultraviolet light curing material

A curing material and ultraviolet light technology, applied in the direction of epoxy resin coating, polyurea/polyurethane coating, coating, etc., can solve the problems of instability, inconvenient transportation, difficult storage, etc., to reduce curing energy and accelerate crosslinking The effect of curing and improving the utilization rate

Inactive Publication Date: 2013-12-04

YANTAI DARBOND TECH

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] There are also some problems when using UV-curable materials. For example, traditional photo-curable materials need to be at 600mj / cm 2 ~2000Mj / cm 2 It can only be cured under high strength, which requires high energy consumption and relatively high requirements for ultraviolet light sources, so that traditional ultraviolet curing materials cannot be used in environments that are in contact with the human body and require low energy.

At present, the way to reduce the curing energy is mainly by increasing the functionality of the photocurable resin and the monomer, which is partially cured to reduce the curing energy, and also by using a special structure, such as mercapto resin, which has high reactivity, but its Unstable, difficult to store, inconvenient to transport and other issues, so providing a low-energy UV-curable material is a technology that the industry has been longing for

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] The principles and features of the present invention will be described below, and the examples given are only used to explain the present invention, not to limit the scope of the present invention.

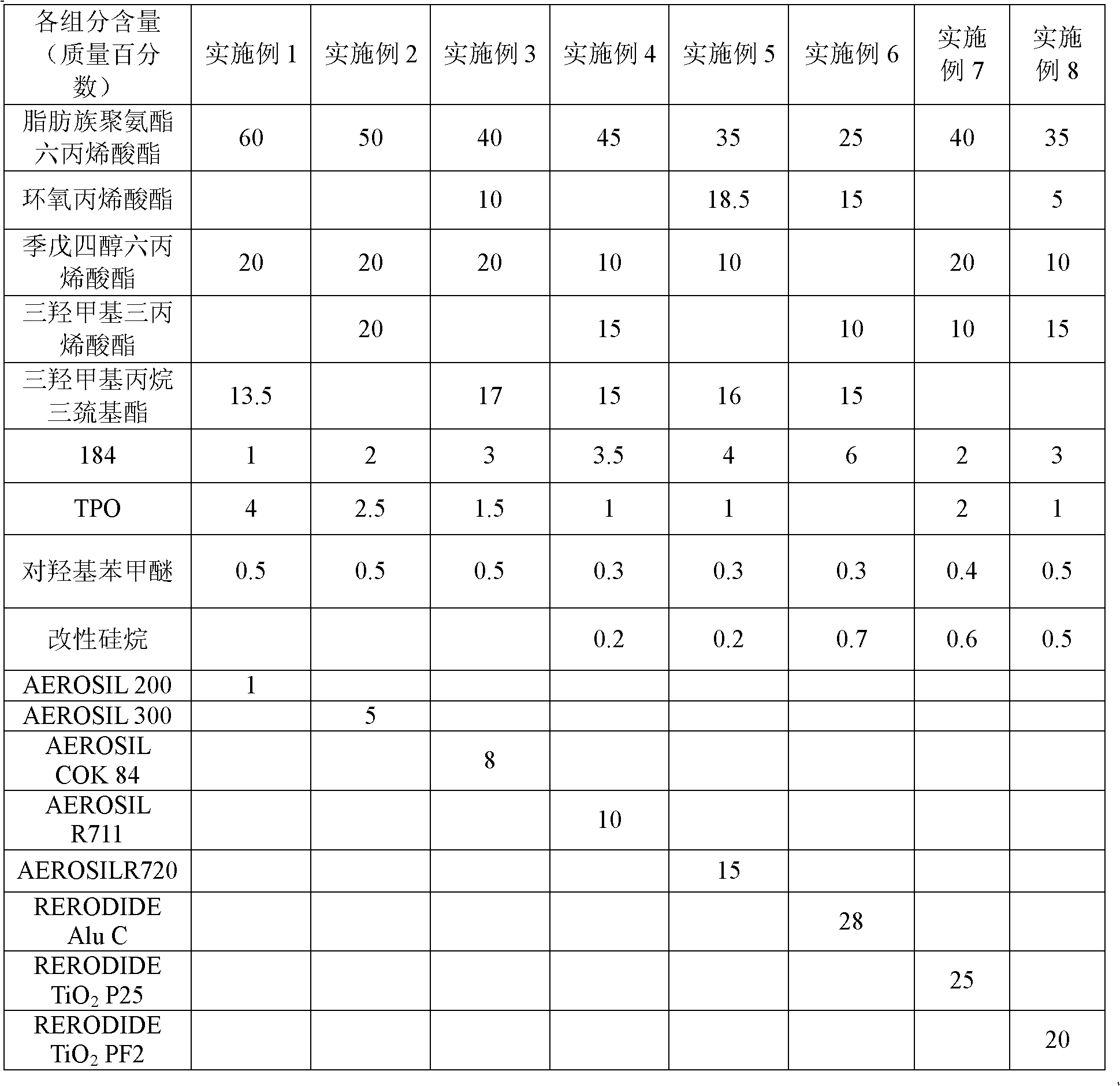

[0028] The present invention will be further illustrated by the following examples.

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to an ultraviolet light curing material, which comprising the following components by weight percentage: 40-60%of light cured resin; 25-45% of light curing diluent; 2-10% of photoinitiator; 0-0.8% of ultraviolet storage stabilizer; 0.5-30%of nano filler; 0.2-1% of leveling agent. On the basis of addition of light cured resin, the light curing diluent and the photoinitiator in the ultraviolet light curing material, the nano filler is added, the ultraviolet light respectively reflects to all directions through small particles, so that the light is scattered, the utilization rate of the ultraviolet light can be increased, the crosslinking and curing speed can be accelerated, and the curing energy can be reduced.

Description

Technical field [0001] The invention relates to an ultraviolet light curing material, in particular to an ultraviolet light curing material that can be cured under low energy. Background technique [0002] Light-curing materials are also called photosensitive materials, and those that use ultraviolet light as a material for curing energy are called ultraviolet-curing materials. Ultraviolet (UV) curing materials do not need to be heated, and can be quickly cured into a film by ultraviolet radiation. The UV curing material is mainly composed of light curing resin, photoinitiator and diluent, and some additives are added at the same time. [0003] Light-curing resins are generally low-molecular-weight resins with unsaturated bonds, such as unsaturated polyesters and acrylic oligomers; photoinitiators are compounds that generate active free radicals by absorbing ultraviolet light, such as benzophenone and benzoin Base ethers; the main function of the diluent is to adjust the viscosit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D175/14C09D163/10C09D7/12C09J175/14C09J163/10C09J11/04

Inventor 马其祥王建斌陈田安

Owner YANTAI DARBOND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com