Two-component solvent-free polyurethane adhesive and preparation method thereof

A solvent-free polyurethane and adhesive technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of limited application fields, unstable product performance, imperfect application technology, etc., to reduce production. cost, promoting cross-linking and curing, and improving the effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

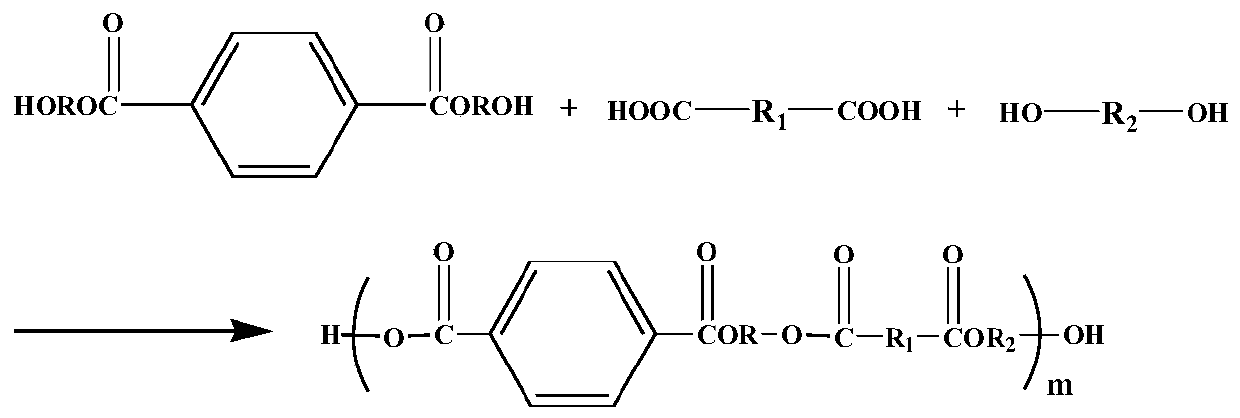

Embodiment 1

[0054]

[0055] (1) Preparation of component A: Polyoxypropylene polyether diol is mixed with ethylene terephthalate-based polyester polyol, and at 120° C., vacuum dehydration until the moisture is 420 ppm, adding MDI, and React at 80°C for 2 hours, then test the percentage of NCO every half hour, and stop the reaction when the NCO content decreases and tends to be stable, to obtain component A;

[0056] (2) Preparation of component B: mix polyoxypropylene polyether diol, triol with ethylene terephthalate-based polyester, vacuum dehydrate at 120°C until the water content is 410ppm, and cool down to At 50°C, add aminosilane coupling agent and dibutyltin dilaurate and stir evenly to prepare component B;

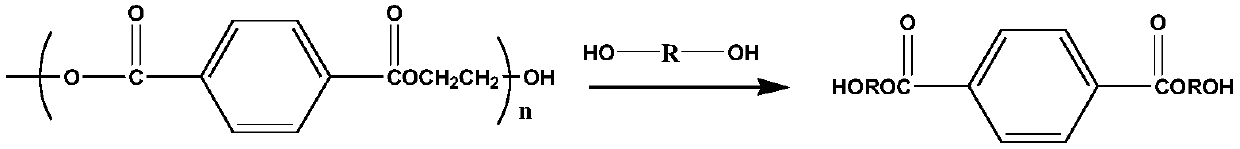

[0057] Wherein, the above-mentioned ethylene terephthalate-based polyester polyol is prepared by the following method:

[0058] Take 10 parts of recovered PET bottle flakes after washing and drying, add 0.05 parts of stannous chloride and 25 parts of ethylene glycol in sequ...

Embodiment 2

[0062]

[0063] (1) Preparation of component A: Polyoxypropylene polyether diol is mixed with diethylene glycol terephthalate-based polyester polyol, and at 120° C., vacuum dehydrated until the moisture is 439ppm, adding MDI, and React at 80°C for 2 hours, then test the percentage of NCO every half hour, and stop the reaction when the NCO content decreases and tends to be stable, to obtain component A;

[0064] (2) Preparation of component B: Polyoxypropylene polyether diol, triol and diethylene glycol terephthalate-based polyester are mixed, and at 120° C., vacuum dehydration until the water content is 420 ppm, and the temperature is lowered to At 50°C, add aminosilane coupling agent and dibutyltin dilaurate and stir evenly to prepare component B;

[0065] Wherein, above-mentioned diethylene glycol terephthalate base polyester polyol is prepared by following method:

[0066] Take 10 parts of recovered PET bottle flakes after washing and drying, add 0.1 parts of zinc aceta...

Embodiment 3

[0070]

[0071] (1) Preparation of Component A: Mix polyoxypropylene polyether diol with propylene terephthalate-based polyester polyol, vacuum dehydrate at 120°C until the water content is 456ppm, add TDI, and heat at 60°C Lower the reaction for 2 hours, then test the NCO percentage content every half an hour, and stop the reaction when the NCO content decreases and tends to be stable, and component A is obtained;

[0072] (2) Preparation of component B: mix polyoxypropylene polyether diol and triol with propylene terephthalate-based polyester, vacuum dehydrate at 120°C until the water content is 458ppm, and cool down to 60°C , adding epoxy silane coupling agent and dibutyltin dilaurate and stirring evenly to prepare component B;

[0073] Wherein, the above-mentioned propylene glycol terephthalate-based polyester polyol is prepared by the following method:

[0074] Take 10 parts of recovered PET bottle flakes after washing and drying, add 0.1 parts of zinc acetate and 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com