Patents

Literature

99results about How to "Improve bonding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

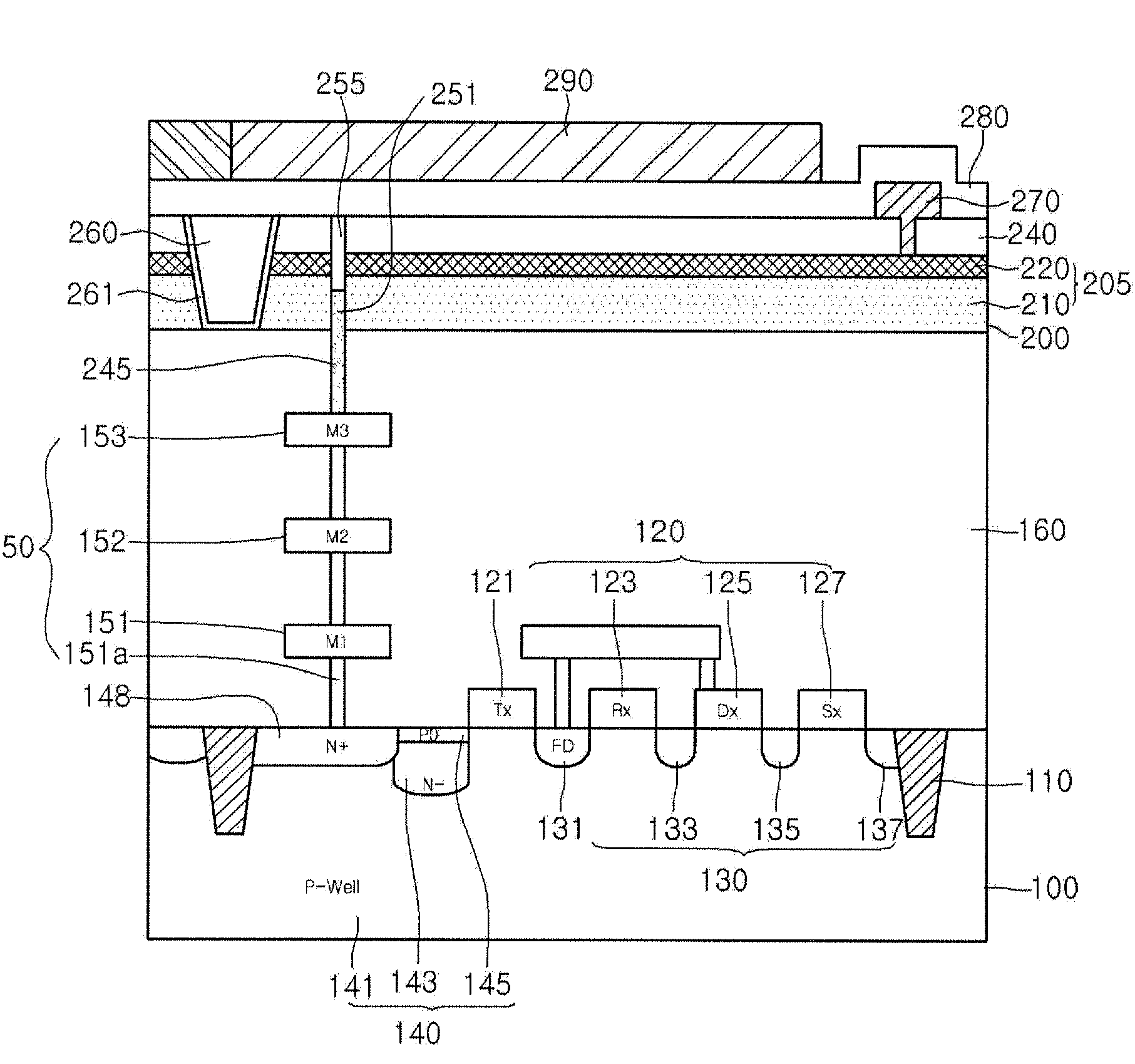

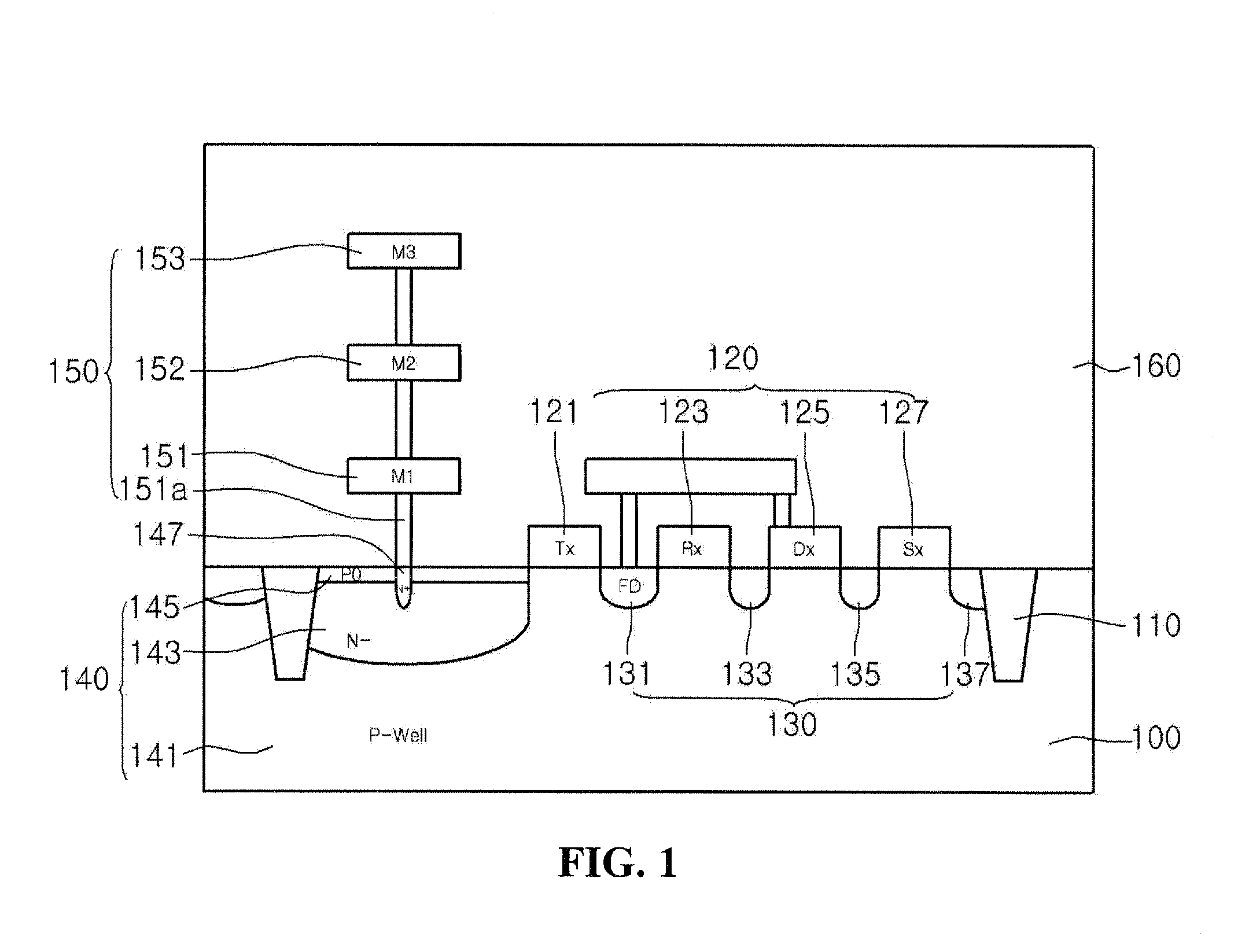

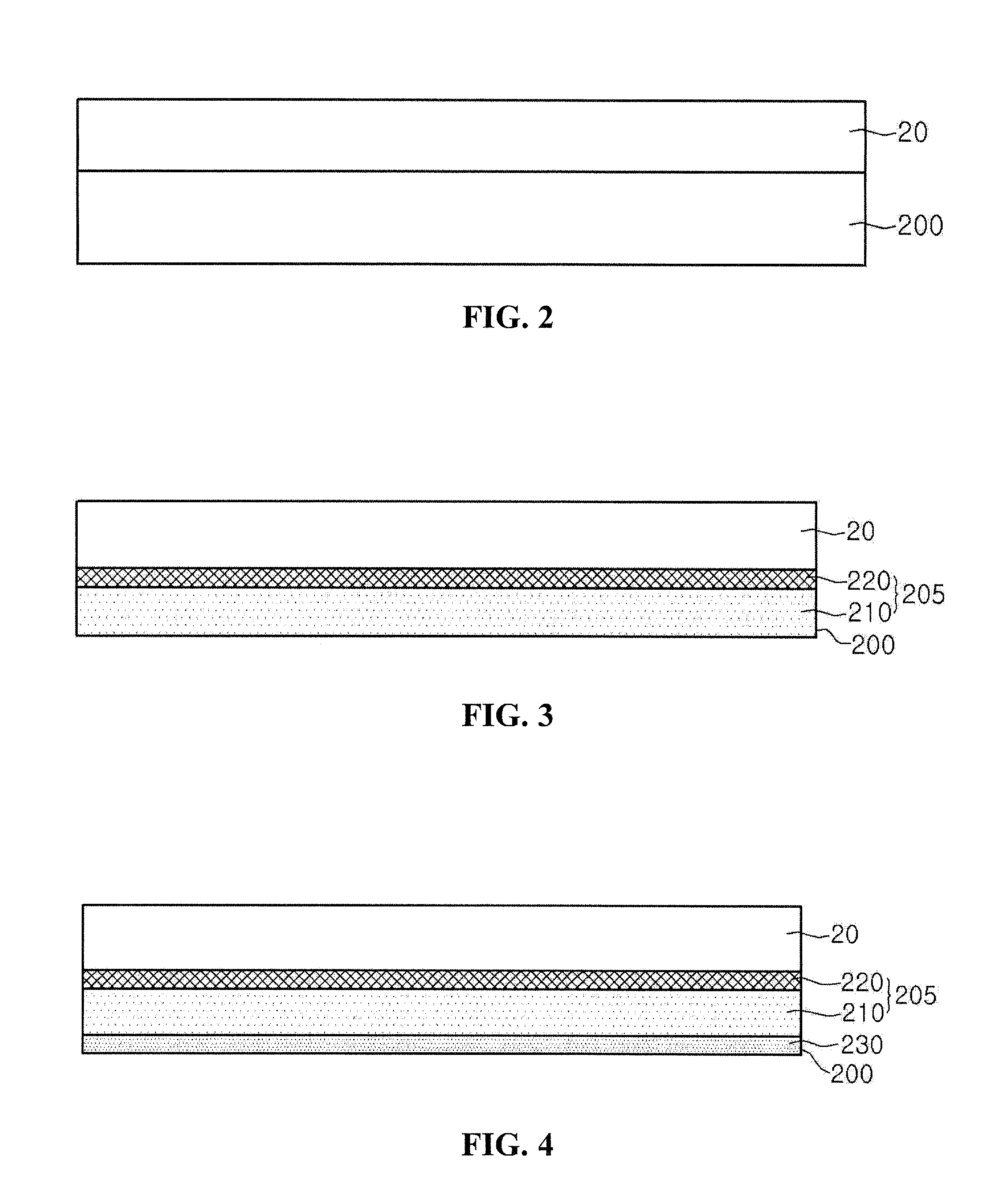

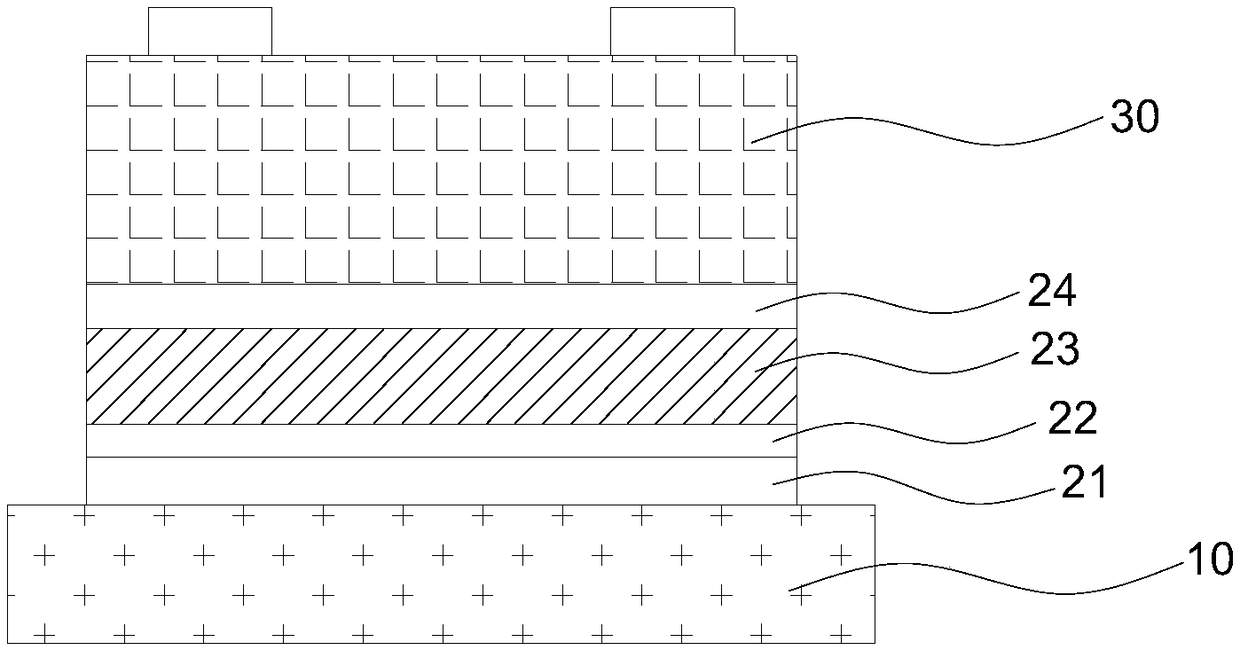

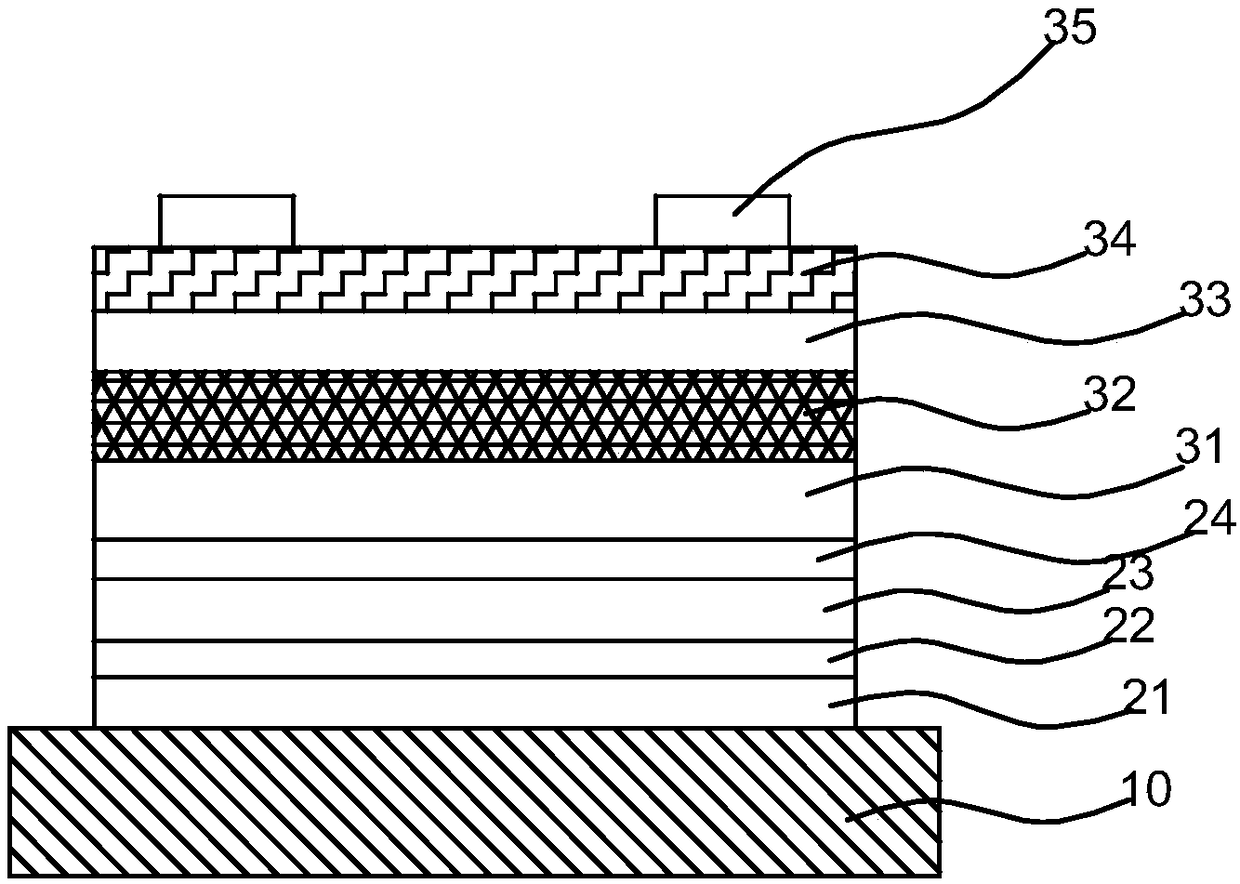

Image Sensor and Manufacturing Method Thereof

InactiveUS20090065827A1Improve bonding forceImprove the bonding force between layersSolid-state devicesSemiconductor/solid-state device manufacturingImage sensorDielectric

Provided is an image sensor. The image sensor can include a readout circuitry on a first substrate. An interlayer dielectric is formed on the first substrate, and comprises a lower line therein. A crystalline semiconductor layer is bonded to the interlayer dielectric. A photodiode can be formed in the crystalline semiconductor layer, and comprises a first impurity region and a second impurity region. A via hole can be formed passing through the crystalline semiconductor layer and the interlayer dielectric to expose the lower line. A plug is formed inside the first via hole to connect with only the lower line and the first impurity region. A device isolation region can be formed in the crystalline semiconductor layer to separate the photodiode according to unit pixel.

Owner:MARVELL ASIA PTE LTD

Double-component solvent-free polyurethane adhesive

ActiveCN105778847AHigh strengthImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesRefrigerator carPolyester

The invention relates to a double-component solvent-free polyurethane adhesive.The double-component solvent-free polyurethane adhesive is prepared from a component A and a component B at the mass ratio of (1-4):1.The component A is prepared from, by weight, 5-15% of polyether polyol, 20-40% of polyester polyol, 1-5% of an accelerant, 2-6% of a coupling agent, 30-60% of filler, 5-10% of a drying agent and 0.05-0.2% of a catalyst.The component B is prepared from, by weight, 50-80% of isocyanate, 10-30% of polyester polyol and 1-10% of a chain extender.A preparing method of the double-component solvent-free polyurethane adhesive includes the following first step of preparation of the component A, the second step of preparation of the component B and the third step of mixing of the component A and component B.The double-component solvent-free polyurethane adhesive is used for adhesion of compartment structural members in refrigerator car compartments and truck compartments, is capable of achieving long opening time, has high initial adhesion force and adhesion strength, high base material applicability and excellent adhesion force on various base materials, and is long in storage life and high in stability.

Owner:上海都昱新材料科技有限公司

Molybdenum-base alloy and its preparing method

This invention relates to a Mo-base alloy and its preparation method, and the components of the Mo-base alloy are: 0.1-0.8% hydrozirconium, 0.1-0.8% carbon, 0.4-2.2% titanium carbon with its grain size less than 0.6 micron, and 0.5-2.5% rare earth oxide with grain size less than 40 nm, and the rest is Mo. The above materials pass through homogeneity, pressing and agglomeration to form the Mo-base alloy. The Mo-base alloy can strength the solid solution and make it become dispersed carbonizing phase to improve the sticking strength of crystal lattices.

Owner:JINZHOU NEW CHINA DRAGON MOLY

Microfluidic surface-enhanced Raman scattering detector and its preparation method and use

The invention discloses a microfluidic surface-enhanced Raman scattering detector and its preparation method and use. The microfluidic surface-enhanced Raman scattering detector comprises an active base and a microfluidic channel-containing structure layer. A microfluidic channel chamber is formed between the active base and the microfluidic channel-containing structure layer. The active base corresponding to the microfluidic channel chamber is provided with multiple nanoscale concave structures. The microfluidic channel-containing structure layer corresponding to the microfluidic channel chamber is provided with at least one pair of a liquid inlet and a liquid outlet communicated with the microfluidic channel chamber. A metal layer is coated on nanoscale concave structure surfaces and an active base surface located in the microfluidic channel chamber. The microfluidic surface-enhanced Raman scattering detector having a double-layer polydimethylsiloxane structure has a high yield, a low cost, good detection consistency and no noise interference and can realize real-time monitoring. The microfluidic surface-enhanced Raman scattering detector can be used for detection of an analyte in gas, colloid and liquid environments.

Owner:PEKING UNIV

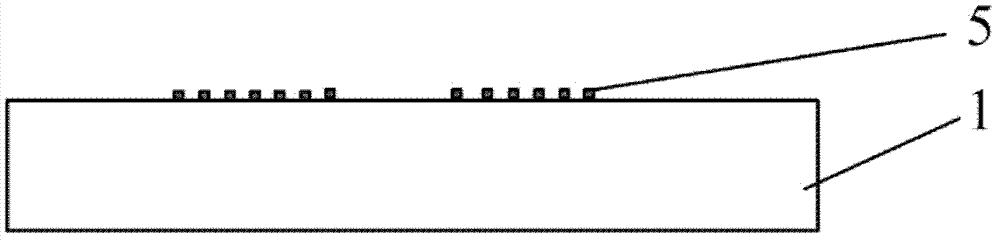

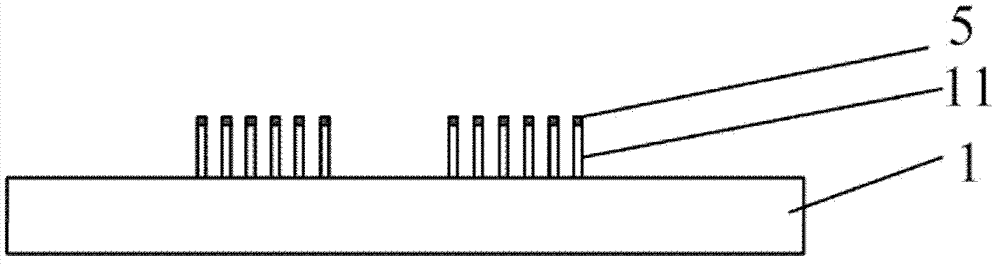

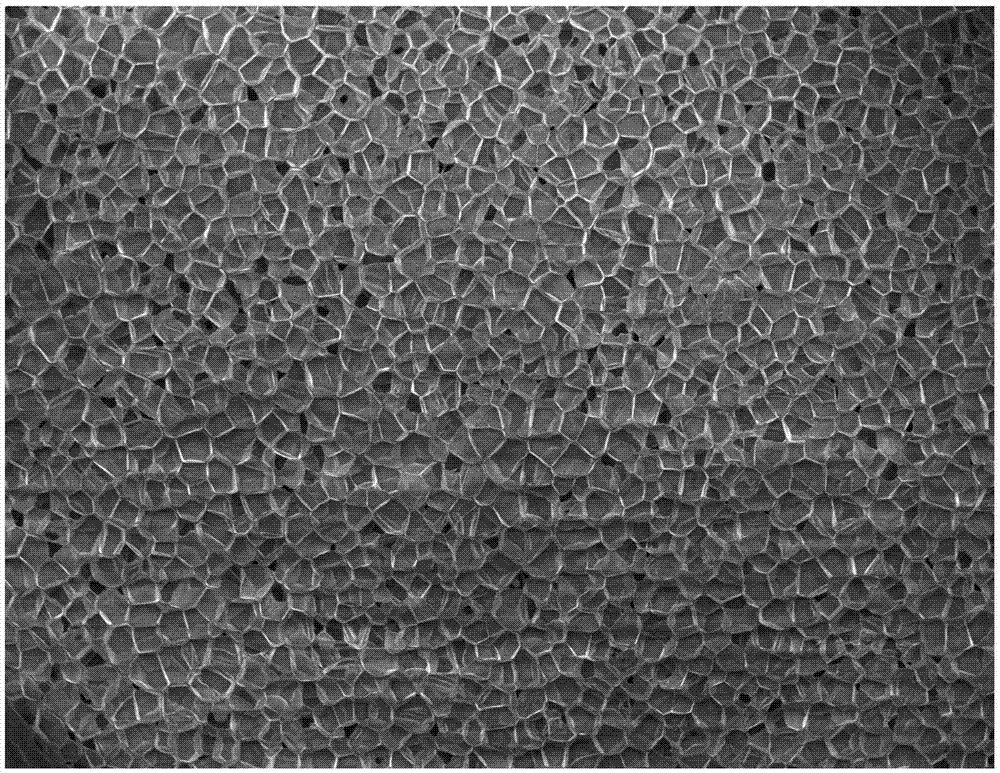

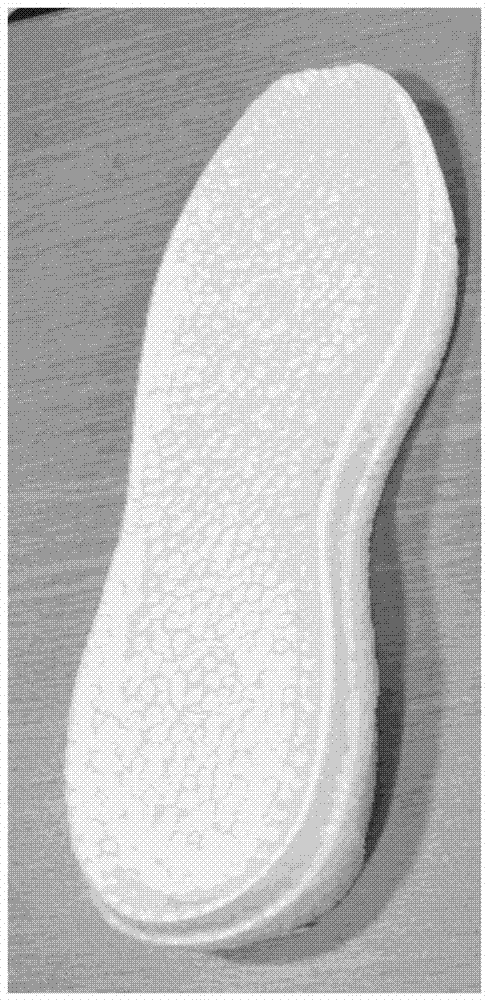

Preparation method for thermoplastic polyurethane elastomer foaming material

The invention discloses a preparation method for a thermoplastic polyurethane elastomer foaming material. The method comprises the following steps: (1) stirring and mixing 100 parts of TPU material, 0.5-10 parts of graphene material and 0.05-3 parts of lubricating agent, thereby acquiring a mixture; (2) adding the aggregates acquired in the step (1) and water into a reaction kettle and starting to stir; (3) introducing carbon dioxide or / and nitrogen into the reaction kettle, controlling the pressure and temperature in the reaction kettle and keeping the carbon dioxide or / and nitrogen in the reaction kettle under a super-critical state; (4) heating the reaction kettle and dissolving the super-critical carbon dioxide or / and nitrogen in thermoplastic polyurethane with uniformly doped graphene under the temperature of the reaction kettle; (5) continuously adding a foaming agent, a cross-linking agent, a lubricating agent and cross-linking auxiliaries into the reaction kettle, continuously stirring for 1-5h, and then connecting the reaction kettle with a pressure tank and enabling the materials in the reaction kettle to enter into the pressure tank under the pressure effect; and (6) foaming the materials in the pressure tank for 30-90min, and then reducing the pressure and reducing the temperature to below 70 DEG C, thereby acquiring the TPU foaming material.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

Tobacco sheet preparing method and tobacco sheet

ActiveCN103174052APromote moisture absorptionPromotes fibrosisTobacco treatmentNon-woody plant/crop pulpChemistrySmoke tobacco

The invention provides a tobacco sheet preparing method and a tobacco sheet. The method comprises the following steps: carrying out thread rolling on the fibrous wastes of plants, thereby obtaining plant crude fibers; spraying enzyme liquid on the plant crude fibers; soaking the enzyme-liquid-sprayed plant crude fibers in water, wherein the enzyme liquid is an aqueous suspension solution containing one or multiple of cellulase, xylanase, lipase, laccase, protease and pectinase; grinding the soaked plant crude fibers to form a plant fiber pulp; and sequentially performing pulping, primary drying, coating, secondary drying and sheet hitting on the plant crude fibers, thereby preparing the tobacco-smoking sheet. The invention further discloses the tobacco sheet prepared by using the method. According to the method, the various defects in the prior art are overcome effectively; the wastes are served as raw materials; and soaking and swelling of the fibers by using a great amount of water is not needed in the preparation process, so that the energy source is saved effectively and the preparation period of the tobacco sheet is shortened.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

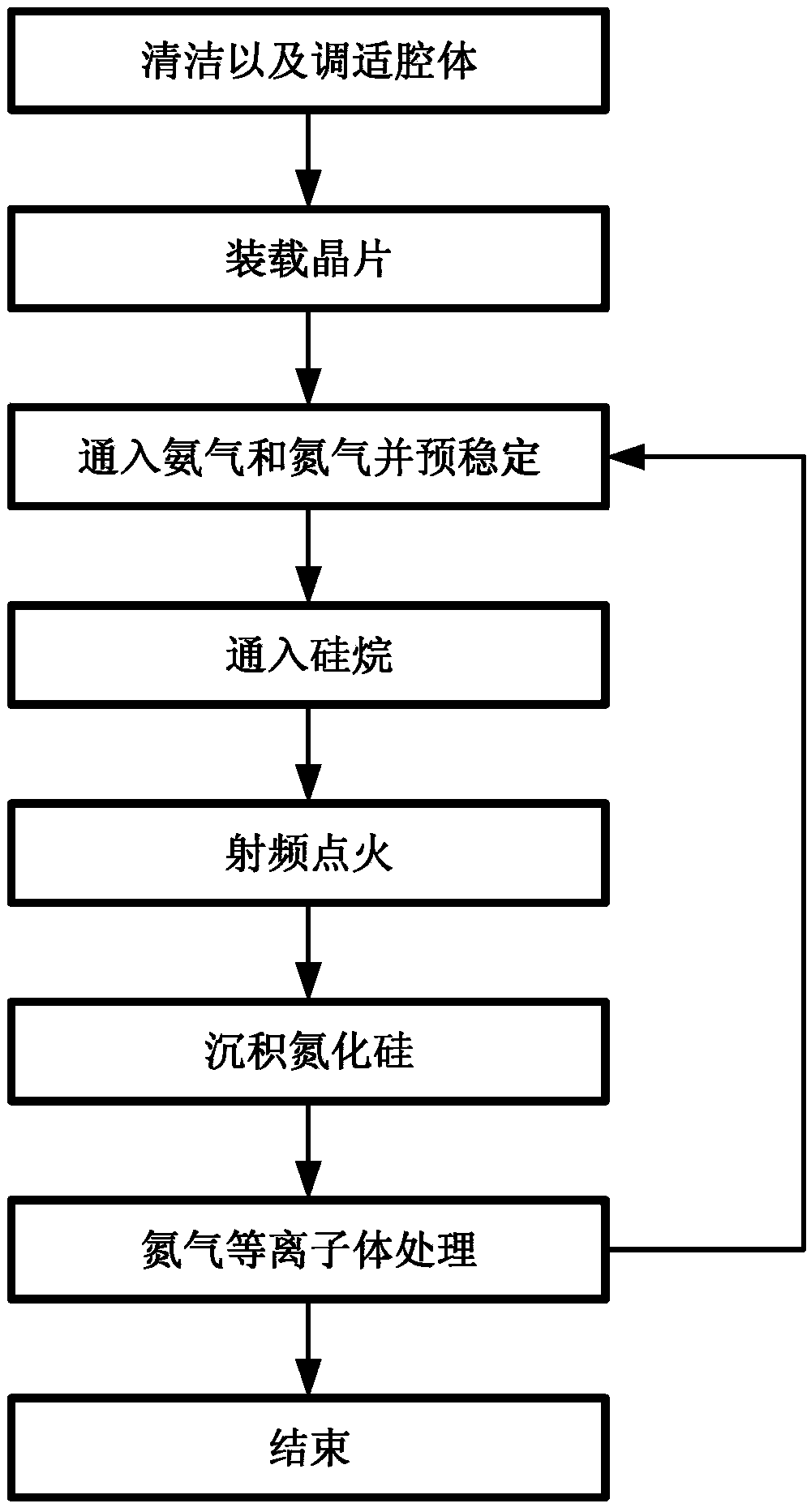

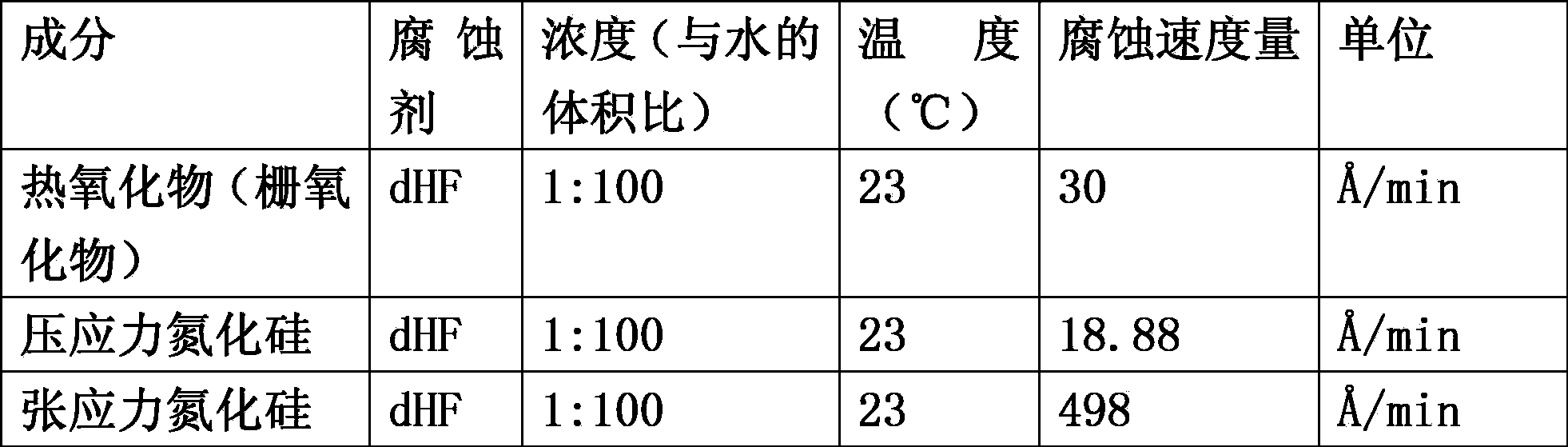

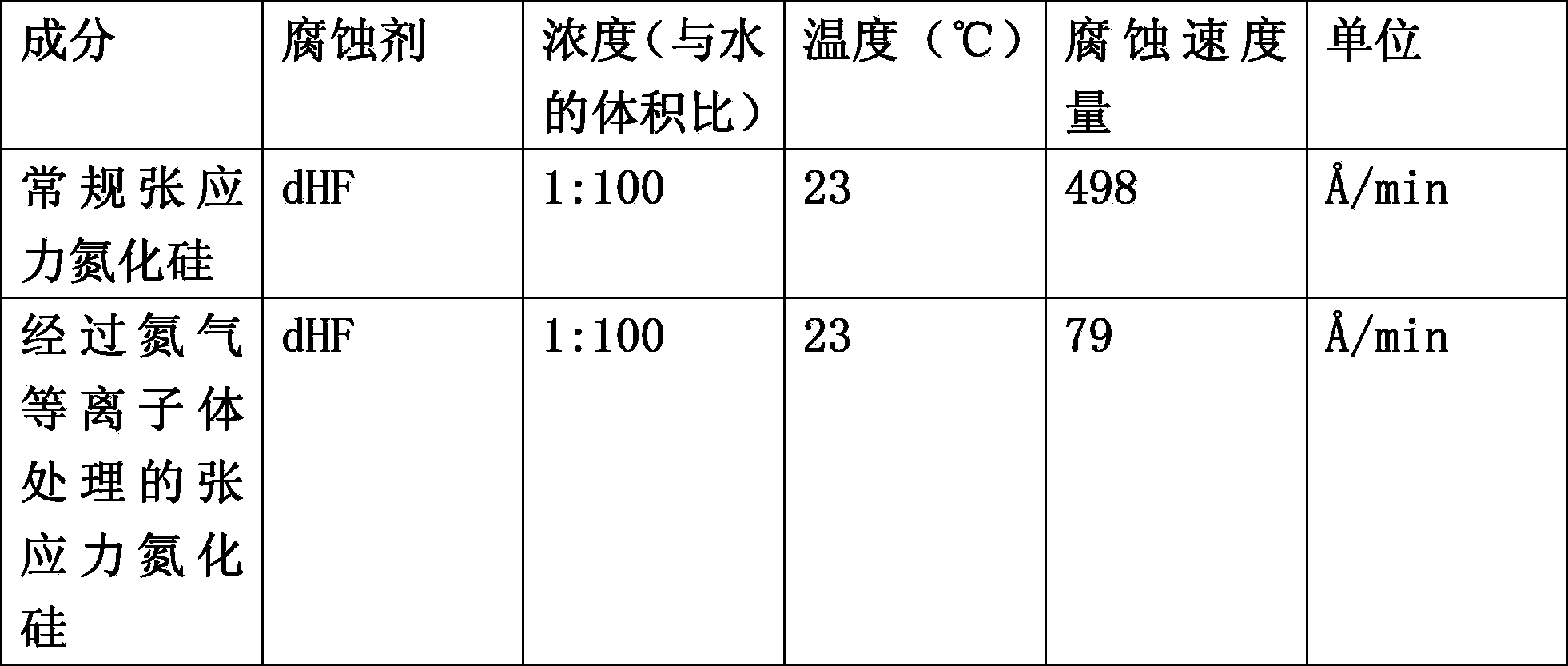

Silicon nitride manufacturing method

InactiveCN103839800AImprove acid resistanceImprove bonding forceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaMetallurgy

The invention discloses a silicon nitride manufacturing method. The method comprises the following steps: step c1, carrying out introduction of ammonia gas and nitrogen and carrying out pre-stabilization processing; step c2, carrying out silane introduction; step c3, carrying out radio frequency ignition; step c4, carrying out silicon nitride deposition; and step c5, using nitrogen plasma to carry out processing on the silicon nitride. According to the manufacturing method, nitrogen plasma bombardment is used for strengthening the Si-N binding force, thereby enhancing the film density. The acidoresistance of the silicon nitride with the tensile stress is improved, so that the silicon nitride with the tensile stress can be applied to the dual-stress lining layer rear grid process. And thus the performance and reliability of the device are effectively enhanced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

EVA film for packaging high-transmittance solar cell and preparation method thereof

InactiveCN102408841AHigh light transmittanceImprove photoelectric efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAntioxidant

The invention relates to an EVA (Ethylene Vinyl Acetate) film and a preparation method thereof. The purpose of the invention is to provide the film having higher transmittance and high stability. The technical proposal adopted is as follows: the EVA film for packaging a high-transmittance solar cell comprises an ethylene-vinylacetate copolymer, wherein the EVA film comprises the following components according to part by weight: 100 parts by weight of ethylene-vinylacetate copolymer, 0.1-6 parts by weight of cross-linking curing agent, 0.05-5 parts by weight of nucleating transparent agent, 0.02-3 parts by weight of light stability, 0.05-5 parts by weight of antioxidant and 0.01-4.0 parts by weight of tackifier. The preparation method comprises the following steps of: (1) mixing the nucleating transparent agent with the tackifir; (2) evenly mixing the light stability with the antioxidant; (3) evenly mixing the cross-linking curing agent with the ethylene-vinylacetate copolymer particles; and (4) adding the mixtures obtained in the steps (1) and (2) to the mixture obtained in the step (3), and evenly mixing the mixtures together and then performing blending extrusion.

Owner:陈光伟

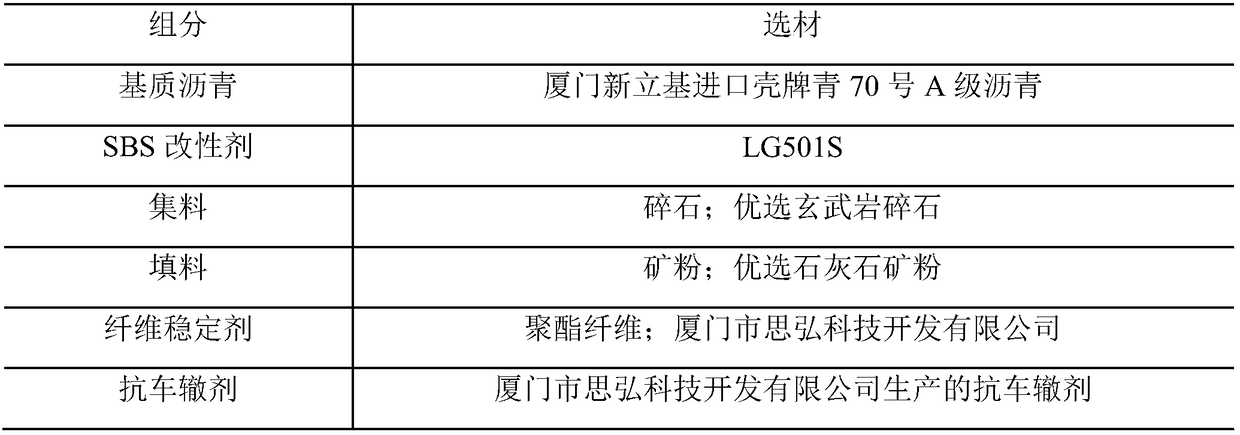

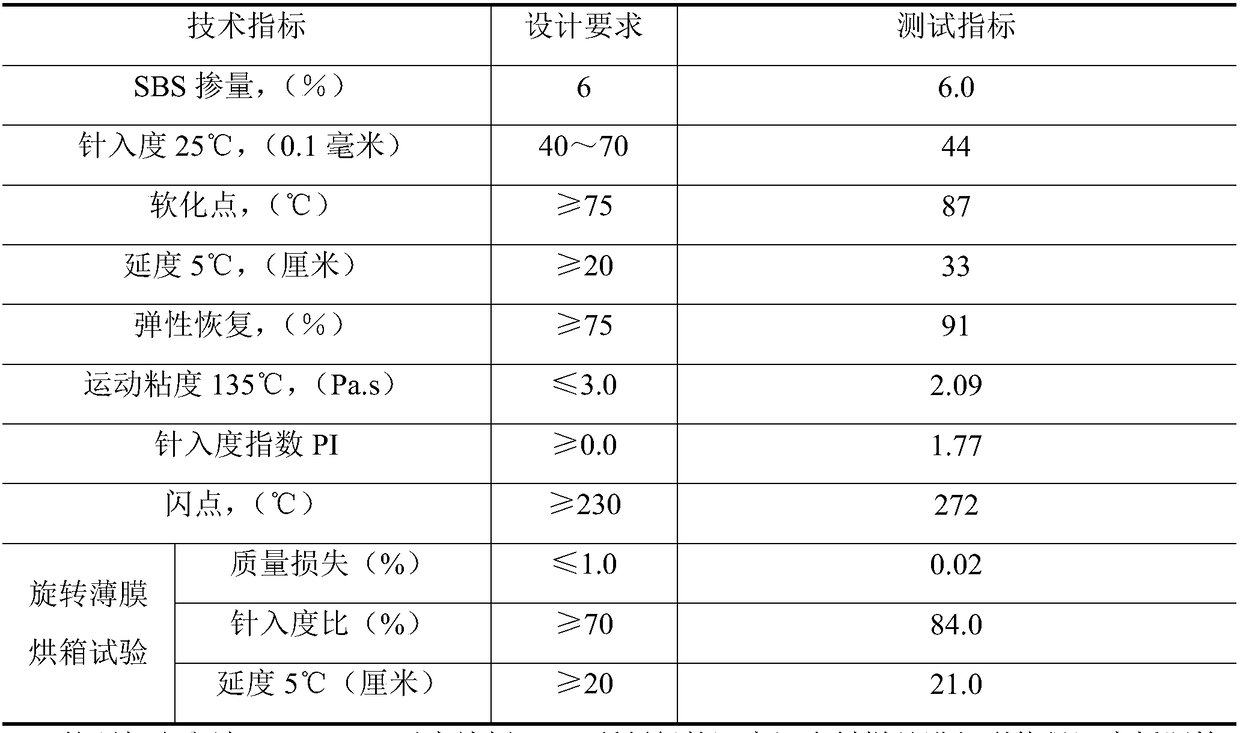

Asphalt mixture and production method thereof

ActiveCN109180077AImproves rutting resistanceImprove stress resistanceBuilding insulationsAsphaltPolymer chemistry

The invention discloses an asphalt mixture and a production method thereof and relates to the field of building materials. The asphalt mixture solves the problem that the existing asphalt mixture forthe airport runway has poor stability and anti-rutting ability, and comprises 4 to 12 wt% of modified asphalt, 72 to 88 wt% of aggregate, 5 to 10 wt% of a filler, 0.5 to 3 wt% of a fiber stabilizer and 0.5 to 3 wt% of an anti-rutting agent and has an asphalt-aggregate ratio of 5.6 to 14%. The modified asphalt comprises matrix asphalt and SBS and the weight of the SBS is 5-8 wt% that of the matrixasphalt. The asphalt mixture has the advantages of high dynamic stability, high temperature stability, strong rutting resistance and good water stability, and is suitable for airport runways.

Owner:厦门市政沥青工程有限公司 +2

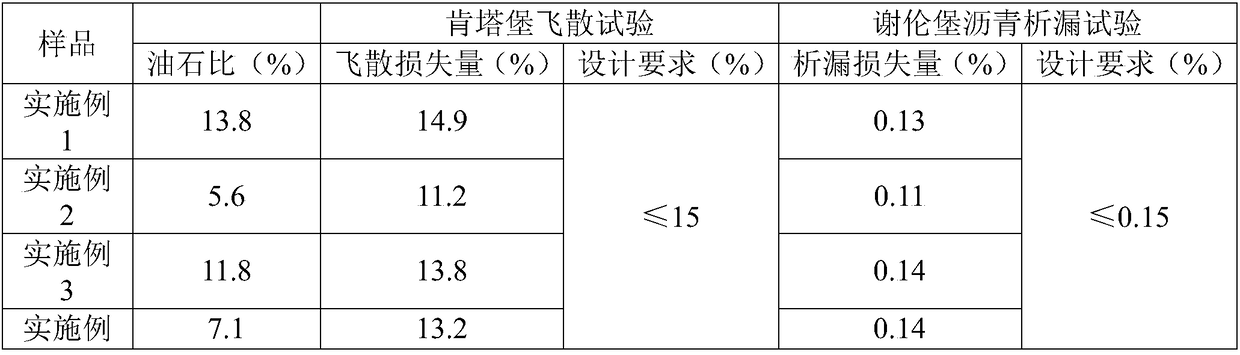

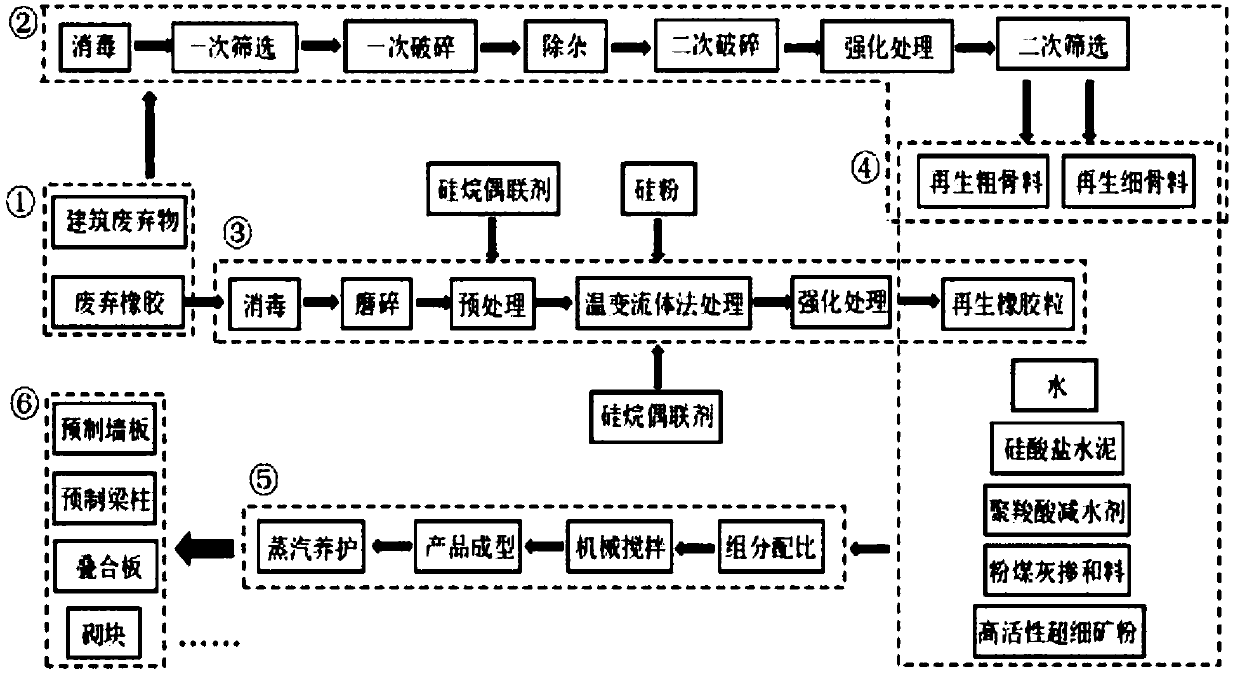

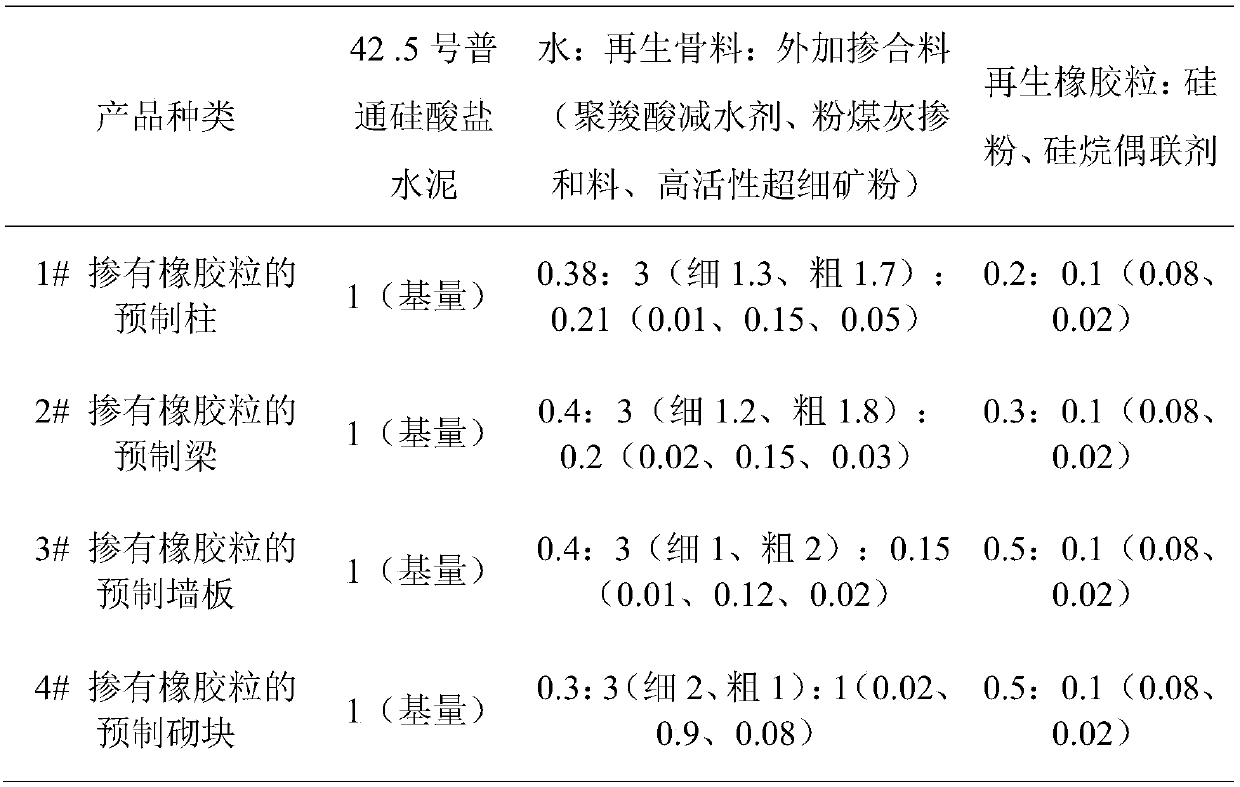

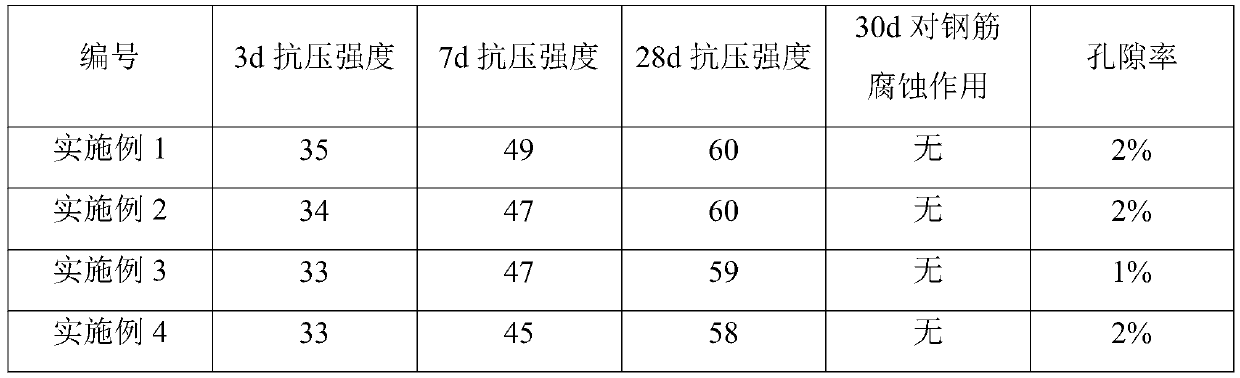

Recycled concrete doped with rubber particles as well as preparation method and application thereof

The invention provides recycled concrete doped with rubber particles as well as a preparation method and application thereof. Construction garbage is disinfected, broken, decontaminated, sieved, strengthened and the like to prepare recycled aggregates; abandoned rubber tyres and the like are used for preparing rubber particles through technologies including disinfection, breaking, preprocessing, temperature change fluid method processing, strengthening processing and the like; the obtained recycled composite aggregates, silicate cement, water and other mineral admixture are mixed to prepare different concrete products, including recycled concrete prefabricated wall panels, building blocks and the like doped with rubber particles, through a subsequent technology by controlling different proportions. The concrete prepared with the method has the advantages of environment protection, low price, stable mechanical property, good durability and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

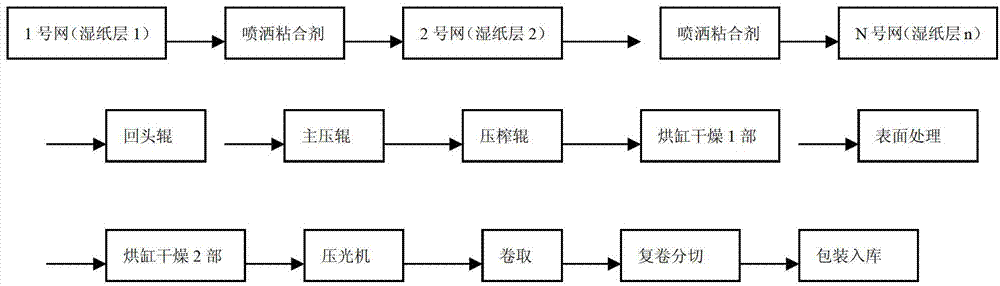

Preparation method of thick paperboard with high bonding strength between paperboards

ActiveCN102877357AImprove interlayer bond strength effectHigh bonding strengthNon-fibrous pulp additionPaper/cardboardFiberPaperboard

The invention relates to a preparation method of a thick paperboard, in particular to a preparation method of a thick paperboard with high bonding strength between paperboards. In the preparation method, a fog-like adhesive water solution is sprayed between wet paper layers before the wet paper formed on a net by pulp with beating degree of 20-35oSR are mutually bonded; the adhesive water solution is one of starch, polyacrylamide modified substance or a mixture of starch and the polyacrylamide modified substance; and the concentration of the adhesive water solution is 0.5-6.0%. The preparation method has following advantages that: 1, manufacturing paper with pulp is easy, and energy can be saved; and 2, the effect of improving bonding strength is notable, and a certain effect in improving retention of the pulp and chemical materials is realized. In addition, the preparation method increases bonding point and bonding force between the adhesive and pulp fibers so as to greatly improve bonding strength between the paperboards.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

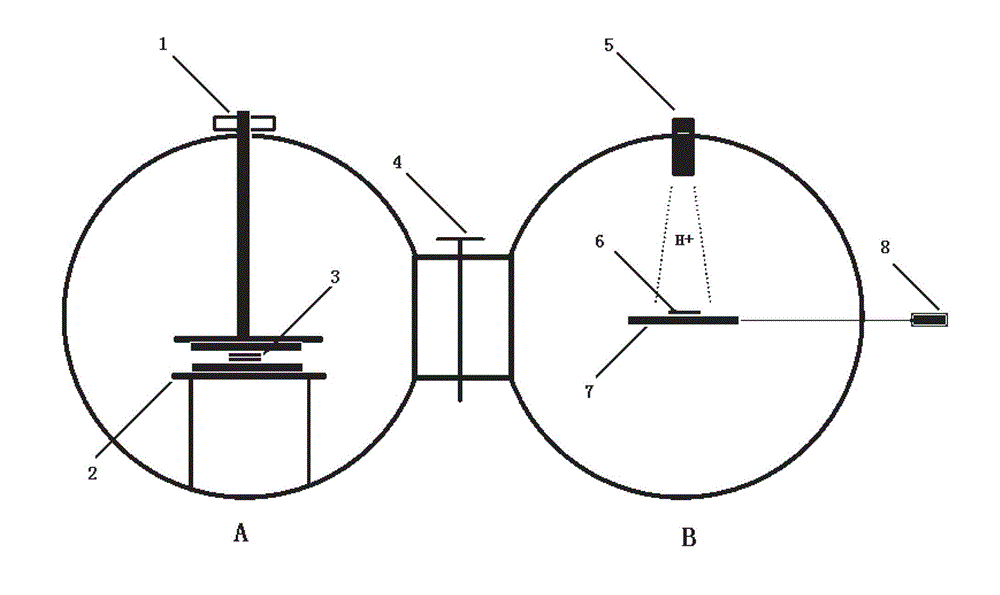

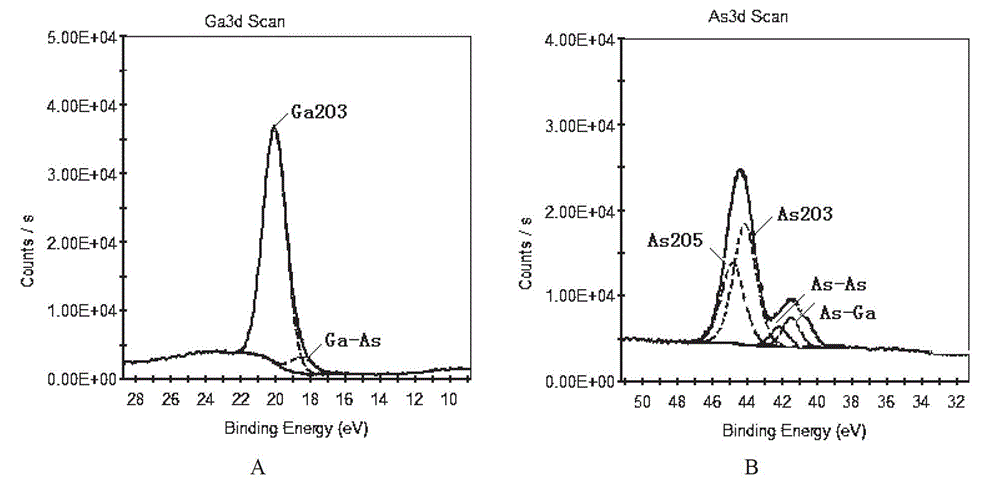

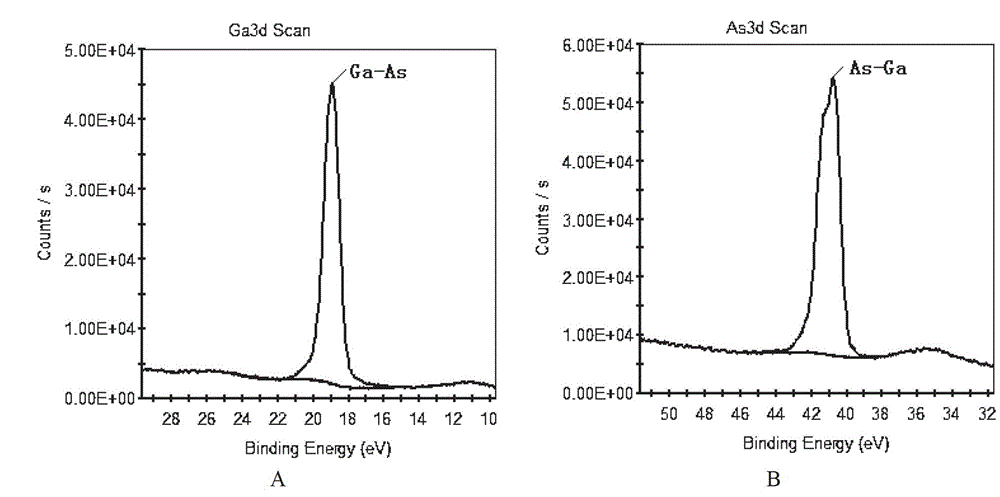

Bonding method for improving bonding force and optical properties of bonding crystal

InactiveCN102912449AGood optical performanceEliminate surface oxidesAfter-treatment detailsNonlinear optical crystalBond interface

The invention relates to a bonding method for improving the bonding force and the optical properties of a bonding crystal, which can be applied to preparing a quasi-phase-matched nonlinear crystal, belongs to the field of nonlinear optical crystals and mainly solves the problems that the quasi-phase-matched crystal obtained through conventional bonding is large in optical loss and small in bonding force. According to the bonding method, a gallium arsenide crystal is selected as a bonding material, ultrahigh vacuum ion source cleaning equipment is utilized, and the loss of a bonding interface is reduced and the bonding force of the bonding crystal is improved by solution cleaning, ion cleaning, ultrahigh vacuum low-temperature bonding, low-pressure heat treatment and other technologies. The bonding method for improving the bonding force and the optical properties of the bonding crystal is mainly used for preparing the quasi-phase-matched gallium arsenide crystal with nonlinear frequency conversion in an infrared band.

Owner:BEIJING UNIV OF TECH

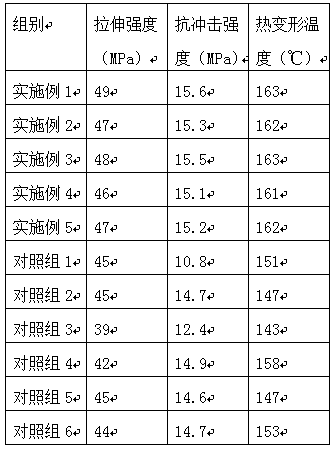

Polypropylene composite material and preparation method thereof

ActiveCN103113665AImprove heat resistanceImprove mechanical propertiesGlass fiberPolypropylene composites

The invention relates to a polypropylene (PP) composite material and a preparation method thereof. The polypropylene composite material comprises the components in parts by weight as follows: 50-80 parts of polypropylene, 5-20 parts of graphite powder, 8-20 parts of glass fiber, 1-3.6 parts of surface treating agent, 0.4-7.4 parts of unsaturated carboxylic acid and polypropylene graft phase solvent, 0.6-1.6 parts of maleic anhydride phase solvent, 0.4-3 parts of coupler and 1-4 parts of antioxidant. The preparation method comprises the following steps of: firstly, carrying out surface treatment on graphite powder and glass fiber; then, mixing polypropylene, unsaturated carboxylic acid, polypropylene graft phase solvent, antioxidant and graphite powder after surface treatment at high speed to obtain a graphite / PP mixture; and then, melting, cutting, mixing, homogenizing, extruding, cooling and prilling the graphite / PP mixture and dried glass fiber by a double-screw extruder to obtain graphite modified and reinforced PP composite material. The PP composite material provided by the invention is better in heat resistance and chemical corrosion resistance, and meanwhile, the tensile strength and impact strength are further remarkably improved.

Owner:江苏苏东化工机械有限公司

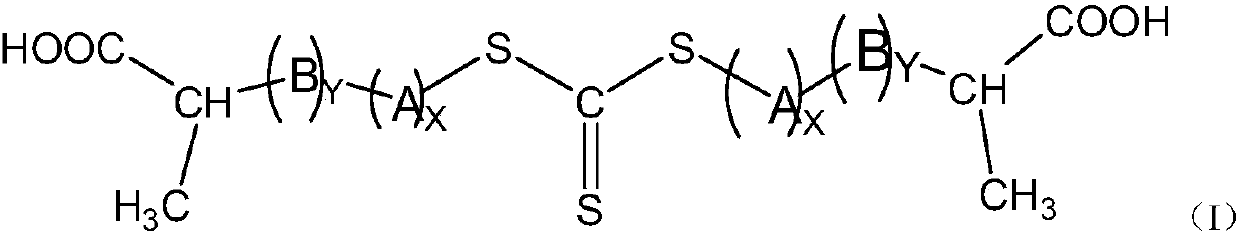

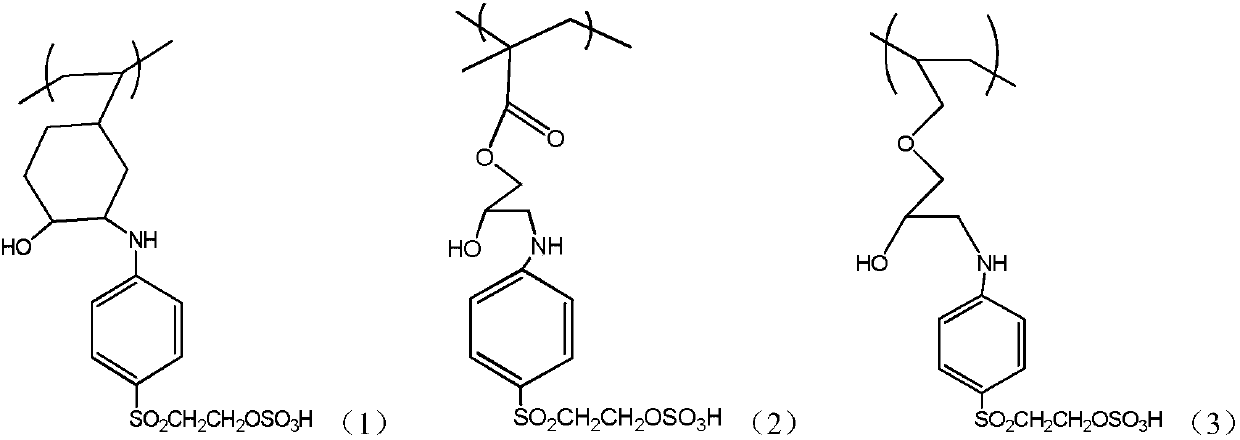

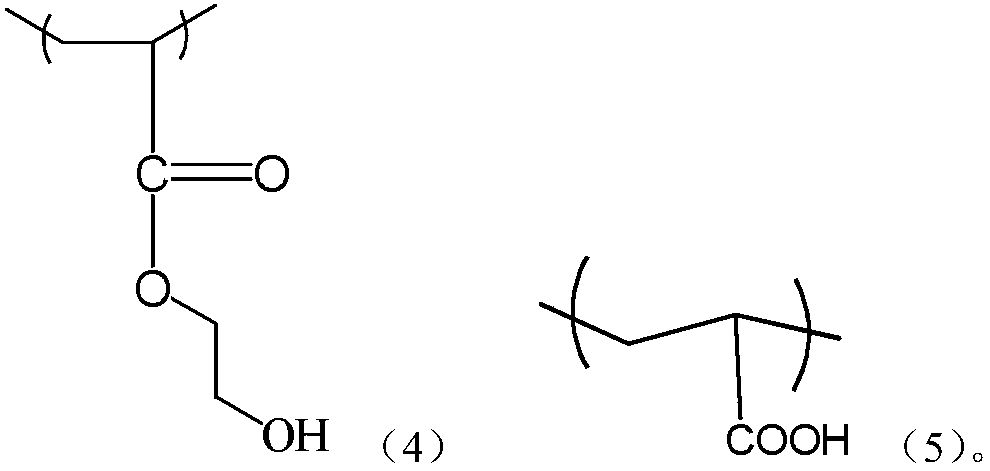

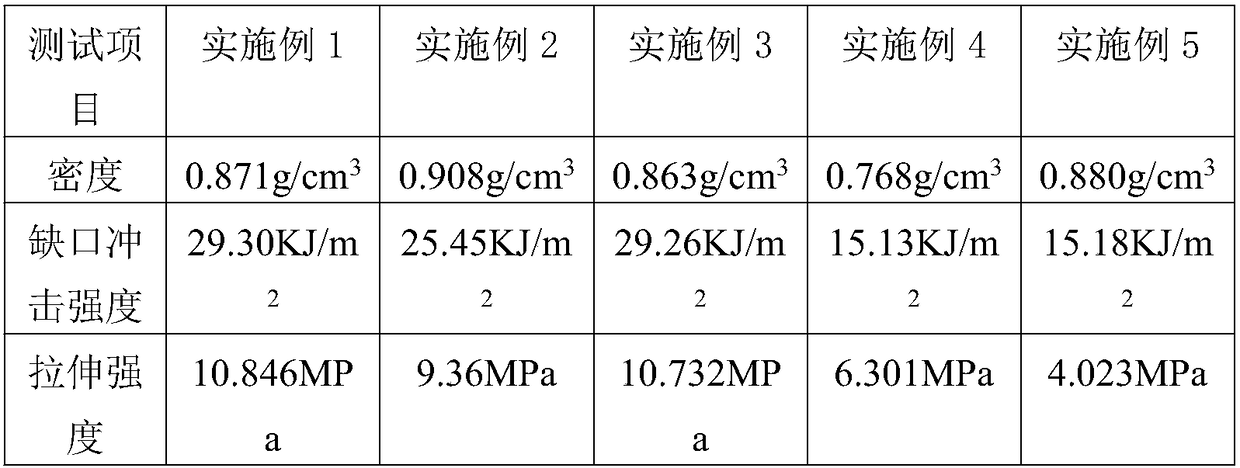

Highly washable and friction-resistant ink for cotton fabrics and preparation method thereof

The invention discloses highly washable and friction-resistant ink for cotton fabrics. The ink is composed of the following components in parts by weight: 3-5 parts of pigments, 2.5-6.5 parts of macromolecular trisulfide carbonate compounds, 0.8-1.0 part of lauryl sodium sulfate, 0.8-1.0 part of n-hexadecane, 15-18 parts of soft monomers, 2-5 parts of hard monomers, 0.03-0.05 part of a water-soluble initiator and 65-80 parts of deionized water. Compared with the traditional non-structured or non-block structure type adhesive film, the block 'core-shell' structure coated ink designed in the invention has excellent mechanical property after film forming, and an RAFT living polymerization technology is adopted when a basic molecular chain structure of the adhesive film is designed, so that each macromolecular chain is directionally and quantitatively grafted with active groups that can carry out characteristic reactions with the cotton fabrics, binding force between the adhesive layer ofthe ink and fibers of the cotton fabrics is greatly enhanced on a molecular level, and macroscopic performances such as washable property and fastness to rubbing of the ink are improved.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

Carbon fiber reinforced composite material and preparation method thereof

The invention discloses a carbon fiber reinforced composite material. The composite material is prepared from, by weight, 10-40 parts of short carbon fibers, 40-60 parts of polypropylene, 10-30 partsof compatilizer, 0.1-4 parts of surface treating agent, 5-15 parts of modifying agent, 1-5 parts of lubricating agent and 5-20 parts of fire retardant. Compared with the prior art, by adding the different compatilizer, the short carbon fibers which are treated through liquid state oxidation, and other auxiliary modifiers, the carbon fiber reinforced composite material is prepared, through the formula, the intermolecular binding force can be increased to promote binding of polymers, and then the blends are high in strength, high in mechanical property, low in cost, environmentally friendly andhigh in flame retardant property. The composite material can be used for parts of a car, various indexes are higher than those of existing parts, the security coefficient of the car can be greatly improved, and the composite material is wide in market development prospect.

Owner:JINLING INST OF TECH

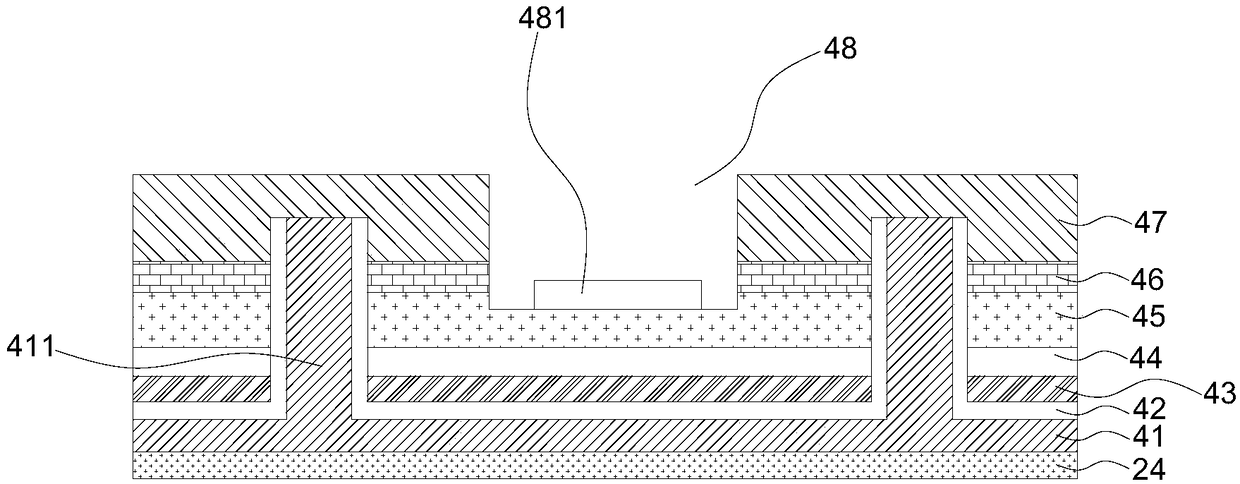

Superstructure LED chip and preparation method thereof

ActiveCN108389954AImprove stabilityLow eutectic pointSemiconductor devicesOptoelectronicsSuperstructure

The invention discloses a superstructure LED chip, comprising a bonded substrate and a light emitting hierarchical structure; a first adhesion layer, a barrier layer, a bonded layer and a second adhesion layer are arranged between the bonded substrate and the light emitting hierarchical structure in sequence; the first adhesion layer is adhered to the bonded substrate; the second adhesion layer isadhered to the light emitting hierarchical structure, wherein the first adhesion layer is a Cr adhesion layer, Pt adhesion layer or a Cr / Pt adhesion layer; the barrier layer is a Ti barrier layer; the bonded layer is formed by multiple Ni / Sn bonded layers in a stacked manner; in the Ni / Sn bonded layers, the thickness of the Sn layer is 1-8 times of that of the Ni layer; and the second adhesion layer is a Ti adhesion layer. The invention also discloses a preparation method of the superstructure LED chip. According to the superstructure LED chip disclosed in the invention, the bonded substrateand the light emitting hierarchical structure are high in bonding, so that an electrode and the substrate are high in contact, and long service life can be achieved.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

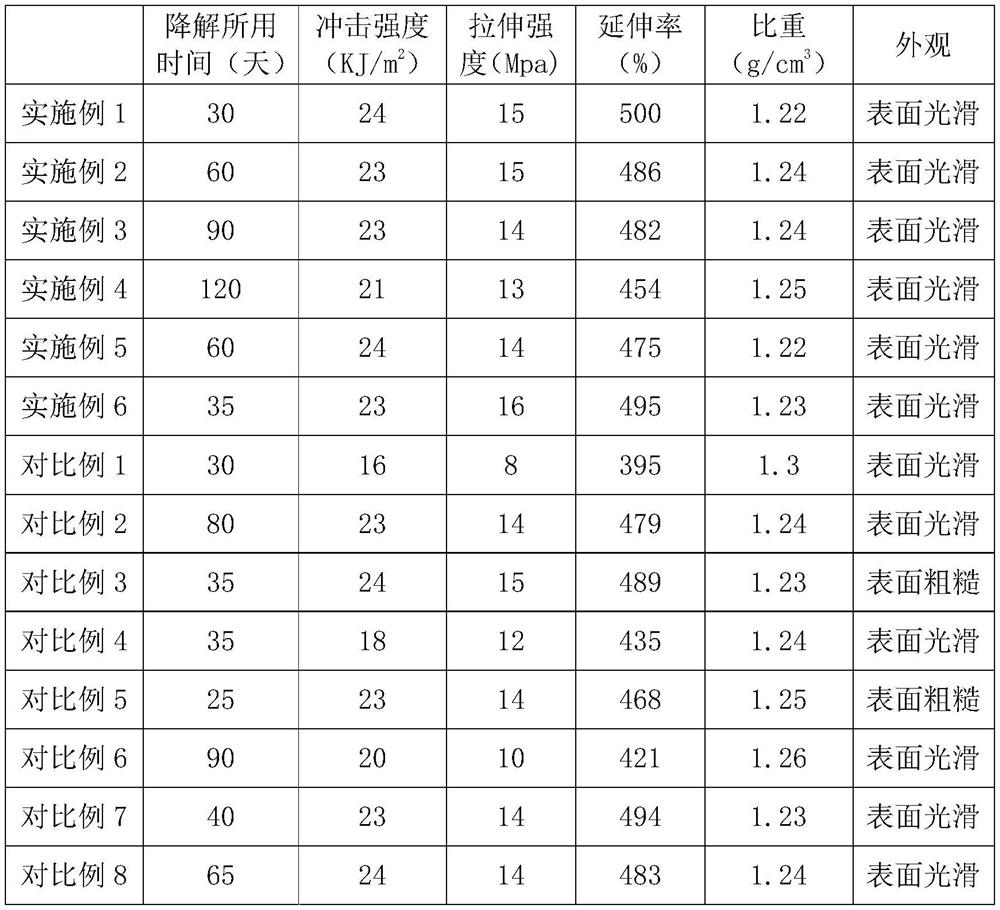

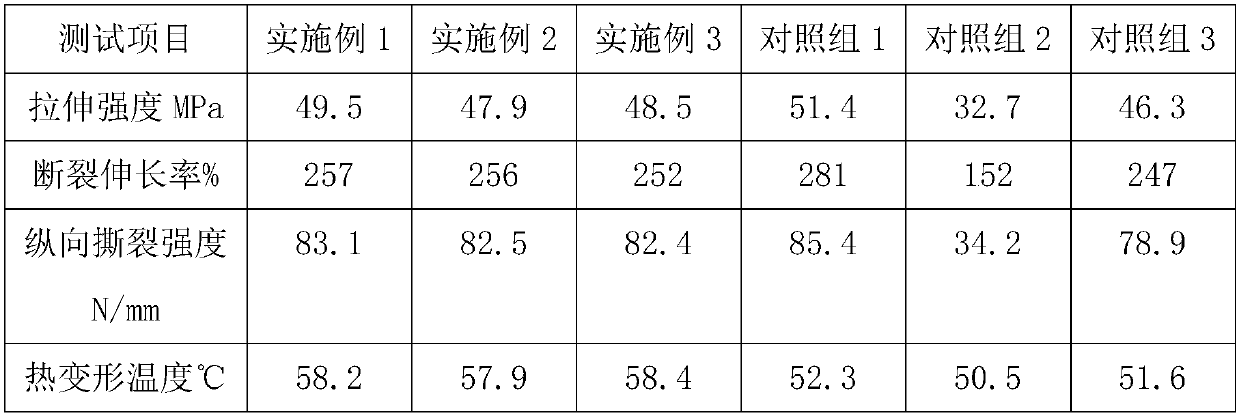

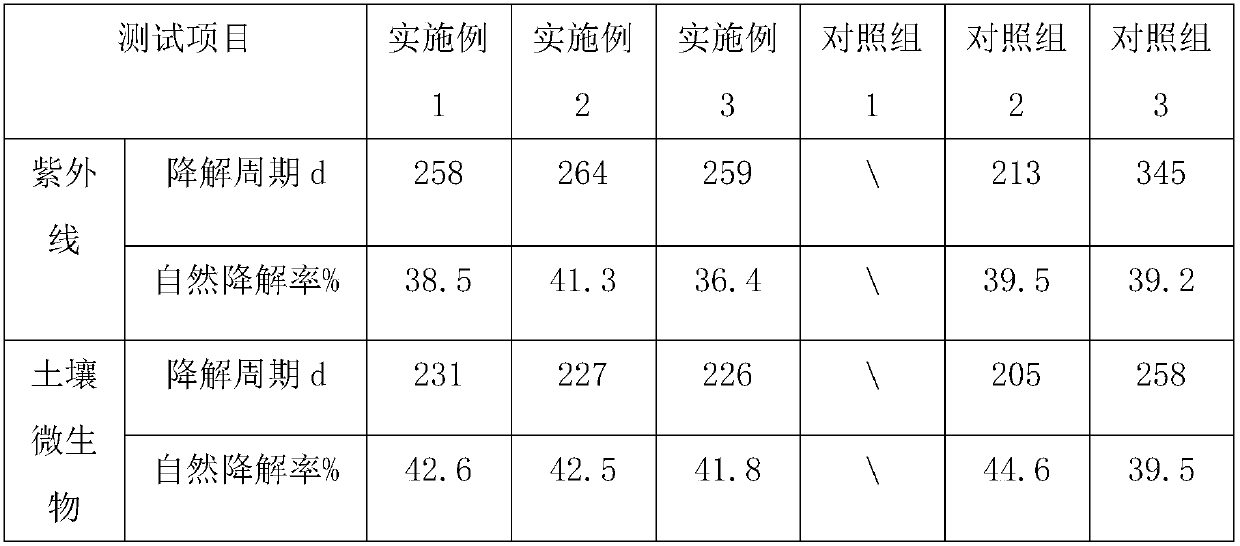

Functional degradable material with controllable degradation period and preparation method thereof

The invention relates to a degradable material, in particular to a functional degradable material with a controllable degradation period and a preparation method thereof. The functional degradable material with the controllable degradation period is prepared from the following raw materials in parts by weight: 30-50 parts of polybutylene terephthalate, 58 parts of a carbon dioxide copolymer, 10-40parts of polybutylene succinate, 3-5 parts of a compatilizer, 0.2-0.5 part of a lubricant, 3-5 parts of a plasticizer and 0.2-0.5 part of an antioxidant. Raw materials of the functional degradable material with the controllable degradation period further comprise a mixture of modified starch, polyglycolic acid and poly (p-dioxocyclohexanone). By controlling the ratio of the modified starch to thepoly (butylene succinate), the ratio of the mixture of the polyglycolic acid and the poly (p-dioxanone) and the addition amount of the antioxidant, the full-biodegradable material with different degradation periods can be prepared under the composting conditions of the same temperature, humidity, pH value, flora and the like; the material is suitable for products with different degradation periods.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

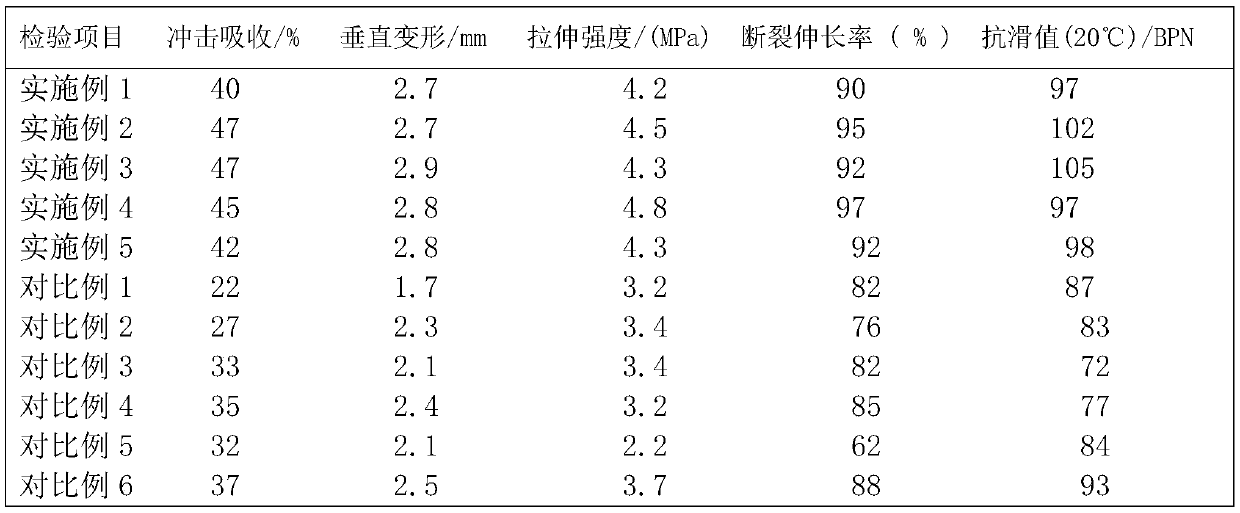

Antislip impact-resistant prefabricated surface material for PVC (polyvinyl chloride) plastic tracks and preparation method thereof

The invention discloses an antislip impact-resistant prefabricated surface material for PVC (polyvinyl chloride) plastic tracks and a preparation method thereof. The antislip impact-resistant prefabricated surface material for PVC plastic tracks is made from 10-30 parts of a modified paper-plastic compound, 100 parts of PVC resin, 2.5-5 parts of a stabilizer, 65-90 parts of plasticizer DOTP, 5-10parts of plasticizer DOA, 7-15 parts of an anti-impact modifier, 0.3-3.5 parts of an antioxidant, 0.5-1.5 parts of an ultraviolet absorbent, 2-9 parts of an ionomer forming agent, 7-15 parts of a wear-resistant nonslip agent, 2-7 parts of an expander, 5-12 parts of nano zinc oxide, 0.3-3 parts of silicone powder, 40-90 parts of a filling material, and 0.5-3.5 parts of a pigment. The antislip impact-resistant prefabricated surface material for PVC plastic tracks, prepared herein, is green, provides good comfort and safety, and shows good slip resistance, impact resistance, tensile strength andelongation at break.

Owner:DONGGUAN JISU PLASTIC TECH

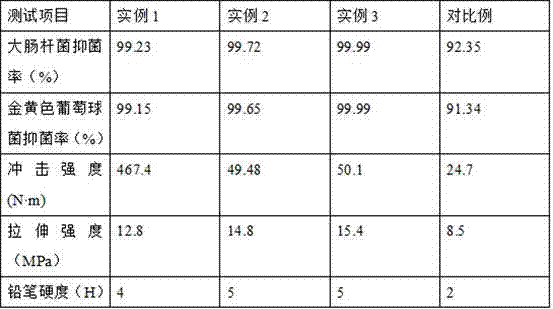

Preparation method of antibacterial paperboard high in bonding strength

InactiveCN107881846AHigh bonding strengthImprove operating conditionsPaper/cardboardInorganic compound additionCrosslinked chitosanPaperboard

The invention discloses a preparation method of antibacterial paperboard high in bonding strength, and belongs to the technical field of board preparation. An amphoteric polyacrylamide emulsion servesas a bridge and is combined and linked with silver-loaded zeolite and paper pulp, gaps between layers are filled with cationic starch and modified chitosan, and the antibacterial paperboard high in bonding strength is obtained; zeolite of a porous structure is modified through a silver nitrate solution, a catalytic reaction is utilized for sterilization, water molecules and oxygen in the air areactivated with nanometer particles, and then the antibacterial effect of the paperboard is improved, the very good retention effect is achieved for the starch, and the bonding strength, between the layers, of the paperboard is further improved; crosslinked chitosan resin is prepared by mixing the chitosan with epichlorohydrin, formalin and acetic acid, the crosslinked chitosan resin can control loss of the chitosan and enhance adsorptive selectivity of the chitosan, and then the effect of killing bacteria is achieved; the bacterial effect of the paperboard is further improved, and a wide application prospect is achieved.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

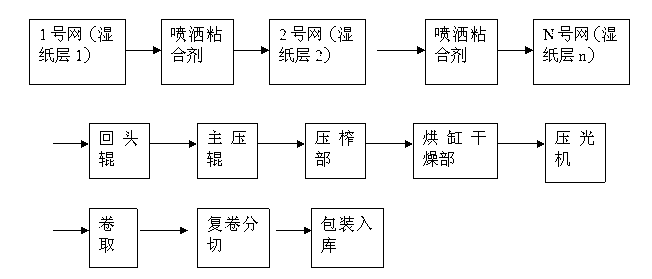

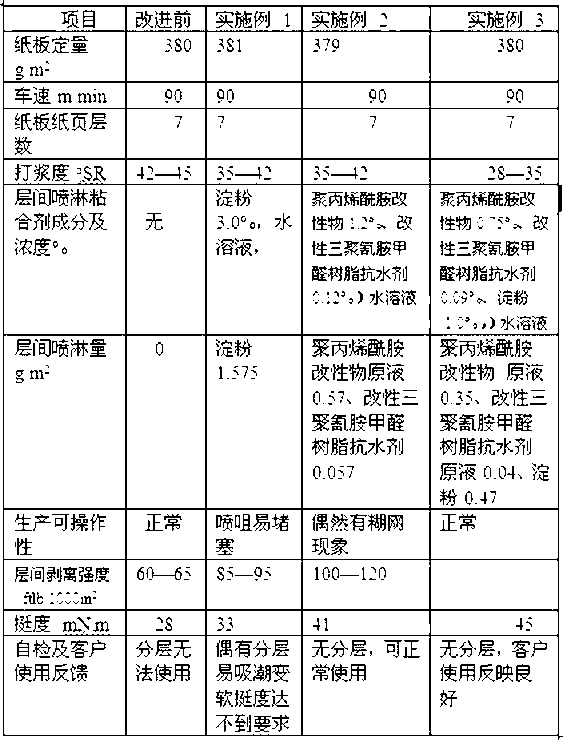

Manufacturing method of high-interlayer bonding strength high-deflection thin paperboard

ActiveCN103225239AEasy to copyCopying energy savingSpecial paperStarch adhesivesPolyacrylamideBonding strength

The invention discloses a manufacturing method of a high-interlayer bonding strength high-deflection thin paperboard. The manufacturing method is characterized in that a compound binder aqueous solution is sprayed between two adjacent wet paper sheets so that the high-interlayer bonding strength high-deflection thin paperboard is formed; the compound binder aqueous solution is prepared by orderly dissolving a polyacrylamide modifier and a modified melamino-formaldehyde resin water repellent agent in clear water in a tank to form an aqueous solution; a mass concentration of the aqueous solution is in a range of 0.35 to 2.0%; the aqueous solution comprises 0.3 to 1.8wt% of the polyacrylamide modifier and 0.05 to 0.20wt% of the modified melamino-formaldehyde resin water repellent agent; a spray amount of the polyacrylamide modifier stoste between the two adjacent wet paper sheets is in a range of 0.15 to 0.95g / m<2>; a spray amount of the modified melamino-formaldehyde resin water repellent agent stoste is in a range of 0.025 to 0.10g / m<2>; the compound binder aqueous solution sprayed between the two adjacent wet paper sheets is in a mist state; and the sprayed compound binder aqueous solution mist is covered on the whole wet paper sheets. The manufacturing method increases bonding points and bonding force between paper pulp fibers, and improves interlayer bonding strength, deflection and moisture resistance of the paperboard.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

Two-component solvent-free polyurethane adhesive and preparation method thereof

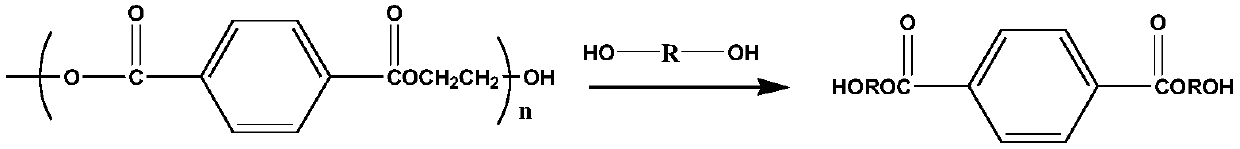

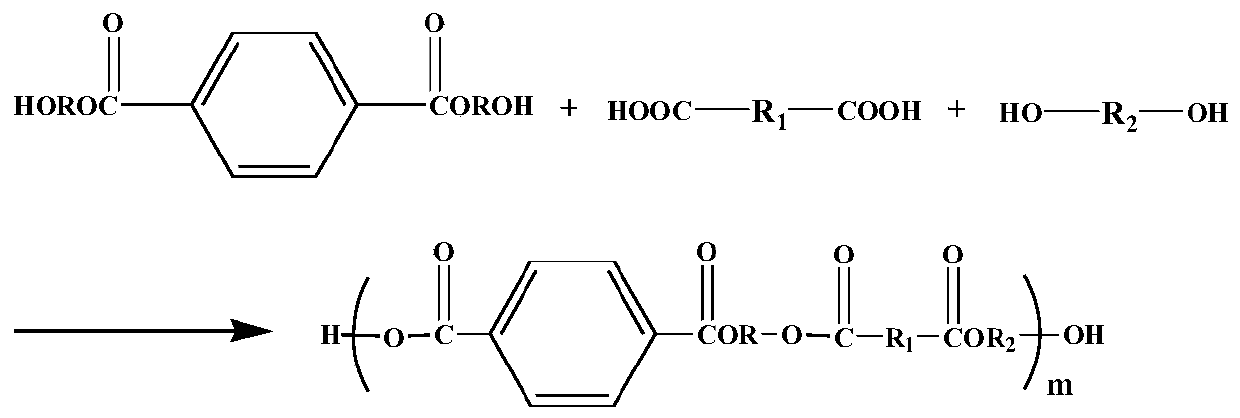

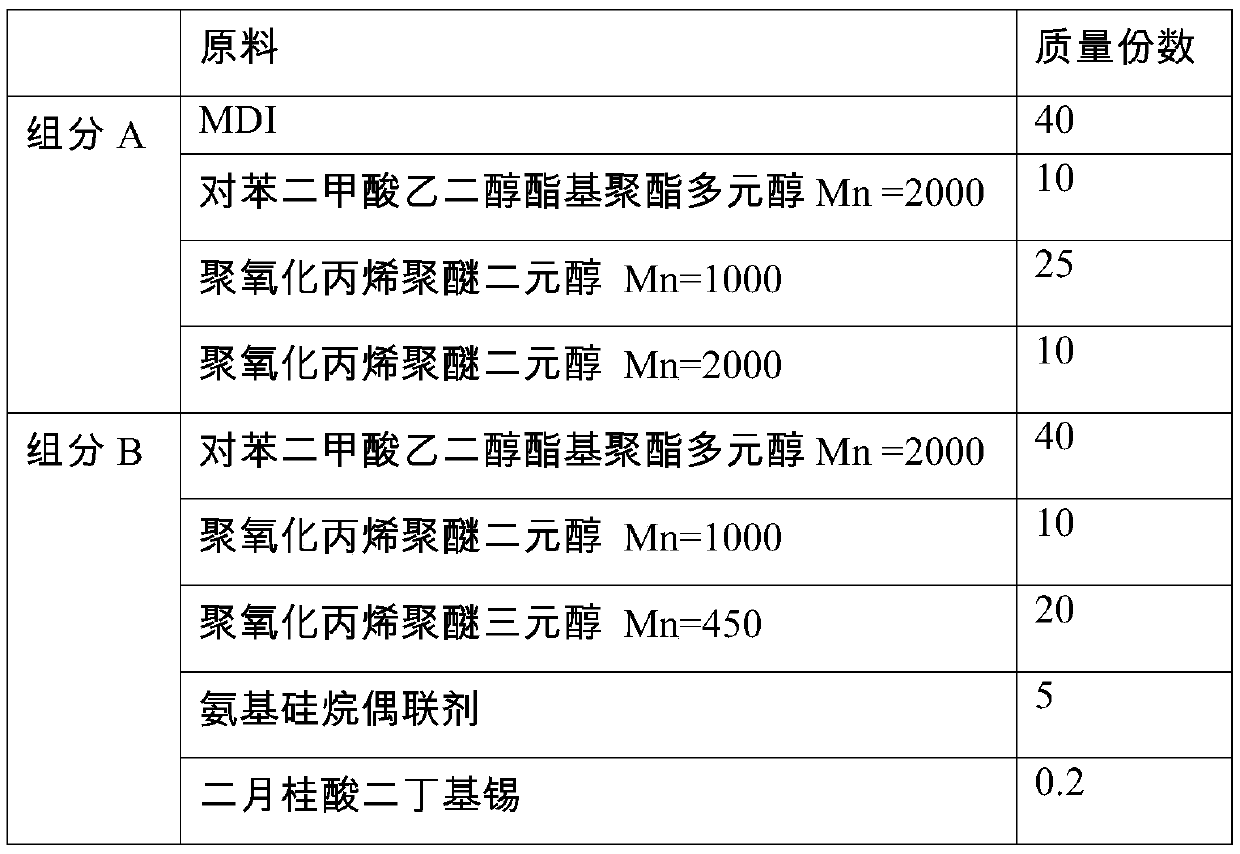

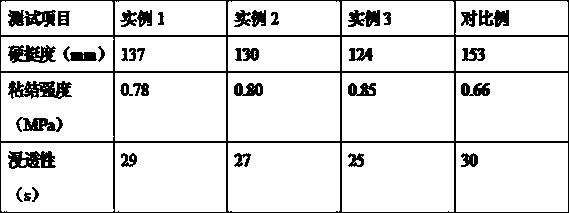

InactiveCN111234757AEnable recyclingReduce manufacturing costPolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention discloses a bi-component solvent-free polyurethane adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The paint is composed of a component A anda component B according to a mass ratio of 1-2:1. The component A is prepared from the following raw materials in parts by weight: 30 to 80 parts of polyisocyanate, 10 to 50 parts of polyether polyoland 5 to 15 parts of polyester polyol; the component B is prepared from the following raw materials in parts by weight: 5 to 40 parts of polyether polyol, 20 to 50 parts of polyester polyol, 2 to 6 parts of a coupling agent and 0.05 to 0.5 part of a catalyst. The preparation method comprises the following steps: preparing the component A; preparing the component B; and preparing the polyurethane adhesive. The polyester polyol adopted by the invention is prepared by alcoholysis and esterification of recycled PET, so that the production cost of the polyester polyol is reduced. The obtained two-component solvent-free polyurethane adhesive has the advantages of low viscosity, reduced production energy consumption, high bonding strength and high temperature resistance.

Owner:BEIJING HUATENG NEW MATERIAL CO LTD

Method for preparing modified starch-type glass fiber impregnating compound

The invention discloses a method for preparing a modified starch-type glass fiber impregnating compound, which belongs to the field of glass fiber production. The method comprises the following steps:isoamylase is used for performing enzymatic hydrolysis on buckwheat starch, an etherification reaction is carried out, modified starch is taken as a film forming agent, the viscosity is enhanced, thecaking degree is also increased, an auxiliary film forming agent is added, the bonding cluster force is increased, the modified starch and amylose are mixed, so that the dispersion degree of the filmforming agent on the glass fiber and intensity of the glass fiber are increased, a silane coupling agent is used for modification of quartz sand, microbe is used for decomposition of plant oil to generate a lipophilic ester group, the self-crosslinking effect on the microbe is generated, the compatibility between the quartz sand and a polymer is enhanced, the uniform dispersion intensity is improved, the bonding intensity of the film forming agent on the glass fiber is increased, a proper amount of an emulsifier is added, the surface tension is effectively reduced, the glass fiber surface iseasily wetted by the impregnating compound, and the mechanical strength and caking property of the modified starch-type glass fiber impregnating compound are enhanced.

Owner:周荣

Reinforced composite rubber filter plate material

The invention relates to a preparation method of a novel reinforced composite rubber filter plate material with good pressure-resistant property, anti-corrosion property and sealing property for a press filter and a filter plate. The preparation method comprises the following steps of firstly, activating the surfaces of graphite powder and fiber, and coating glue; mixing the graphite powder with fiber after surface treatment at high speed to form a graphite mixture; adding into a waterborne surface treatment solvent, dispersing and mixing; adding natural adhesive slurry, stirring, removing liquid, and drying the adhesive-coated fiber under the vacuum condition for standby use; mixing: respectively plasticizing the rubber, then uniformly mixing, and sequentially adding the surface-treated fiber, a scorch retarder, an accelerant and other additives, graphite, carbon black, a processing additive, and a vulcanizer to mix; thinning the uniformly mixed rubber material, and drawing into sheets for standby use; performing high-temperature and high-pressure compounding on a welded steel skeleton after surface treatment and a fiber enhancing rubber sheet on a die of a vulcanizing machine, vulcanizing and forming. The preparation method has the advantages that the property of the filter plate of the press filter is good, the service life is long, and the application range of the press filter is broadened.

Owner:江苏苏东化工机械有限公司

High-strength and easily-degradable composite material for garbage bag

The invention relates to the technical field of polymer materials, and in particular to a high-strength and easily-degradable composite material for a garbage bag. The composite material comprises thecomponents of polyvinyl chloride resin, polyamide resin, a TPVC (Thermoplastic Polyvinyl Chloride) elastomer, metamorphic starch, a compatibilizer, a plasticizer, a reinforcing agent, a degradation catalyst and a stabilizer, wherein the compatibilizer is maleic anhydride grafted polyethylene; the stabilizer is a calcium-zinc composite stabilizer; the reinforcing agent is carbon black; and the plasticizer is dibutyl phthalate, isosorbide diester or butyl triacetate; a photocatalyst is a compound formed by mixing nano zinc oxide, anatase titanium dioxide and polylactic acid in a mass ratio of 2:5:10. The composite material has high strength, good toughness and remarkable weather resistance and has the characteristics of high degradation rate and fast degradation speed.

Owner:合肥易美特建材有限公司

Method for improving toughness of heat-resisting phenolic resin

The invention belongs to the technical field of processing of heat-resisting phenolic resin and specifically relates to a method for improving the toughness of the heat-resisting phenolic resin. The method comprises the following steps: preparation for raw materials, processing of modified sepiolite fibers, preparation of pre-mixed solution and preparation of the heat-resisting phenolic resin. Compared with the prior art, the method has the following advantages: the sepiolite fibers are processed by butyl titanate-ethanol mixed solution, and the processed sepiolite fibers are matched with (methyl) acrylate-hydroxy ester, so that the internal binding force of a composite material can be enhanced, and the impact energy can be effectively absorbed; through reasonable match of the raw materials, the mechanical strength, fire resistance and aging resistance of the material are enhanced, the heat fading is obviously improved; therefore, the heat-resisting phenolic resin can be used for the fields of fireproof interior and exterior wallboards, equipment materials suffering from high impact, base materials of brake pads and clutch plates, aerospace and the like.

Owner:合肥绿普包装材料有限公司

Environment-friendly warm mix asphalt mixture and preparation method thereof

ActiveCN111499272AIncrease viscosityIncreased resistance to shear deformationClimate change adaptationEngineeringMaterials science

The invention discloses an environment-friendly warm mix asphalt mixture and a preparation method thereof. The asphalt mixture comprises the following raw materials in parts by weight: 10-15 parts ofpretreated asphalt, 80-90 parts of aggregate, 5-8 parts of mineral powder, 2-3 parts of silica fume, 2-3 parts of fly ash, 3-7 parts of a modified warm mixing agent, 8-12 parts of a first additive and8-10 parts of a second additive. The invention discloses an environment-friendly warm mix asphalt mixture and a preparation method thereof. . The preparation method has reasonable process design andproper component ratio; by pretreating a warm mixing agent and SBS modified asphalt, the mixing performance and the stability of the asphalt mixture are synergistically improved. According to the modified asphalt mixture, the mixing and construction temperature of the modified asphalt mixture can be obviously reduced, the bonding acting force between modified asphalt and aggregate is improved, themechanical property and aging resistance of the asphalt mixture are effectively improved, the high-temperature rutting resistance, low-temperature fatigue resistance and water damage resistance are excellent, and high practicability is achieved.

Owner:SHANDONG HUITONG CONSTR GRP CO LTD

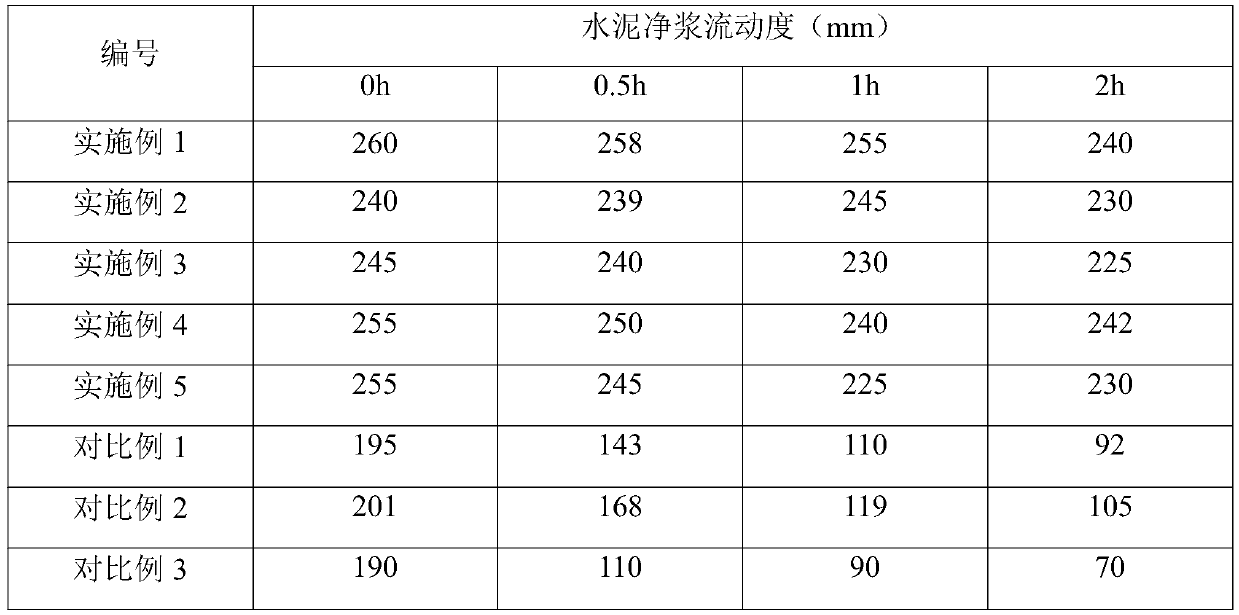

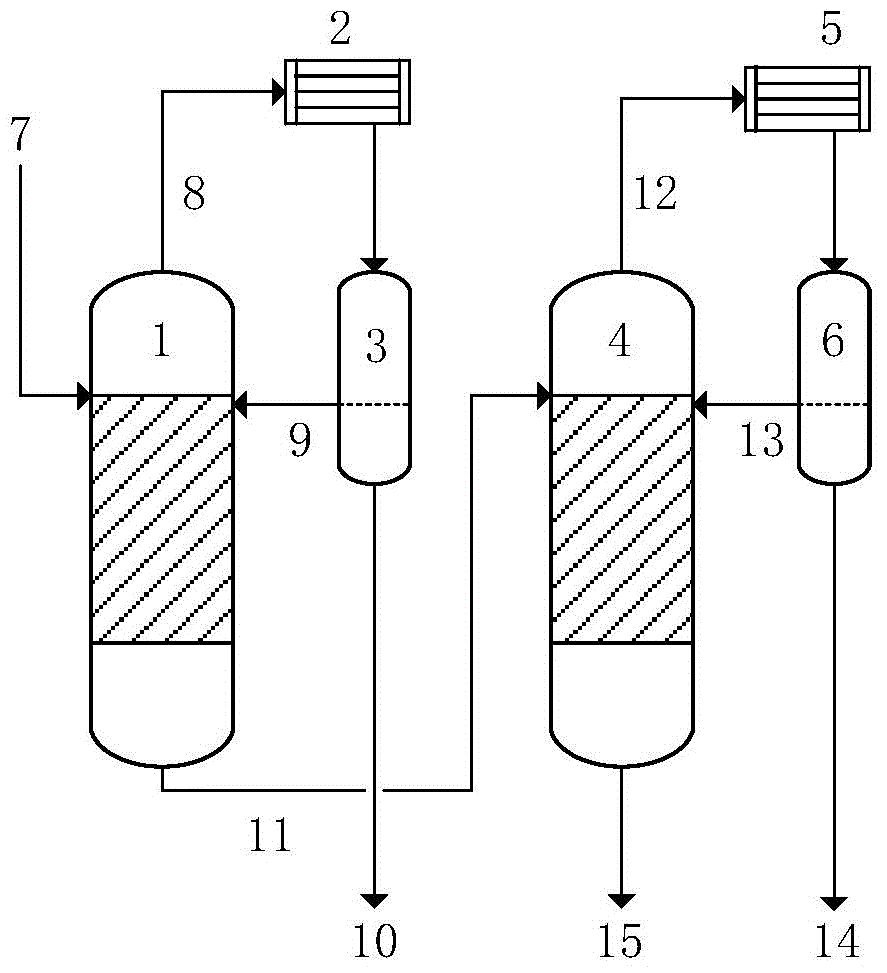

Polycarboxylate water reducer composition for self-compaction high-workability concrete

The invention discloses a polycarboxylate water reducer composition for self-compaction high-workability concrete. The polycarboxylate water reducer composition is composed of the following components: allyl alcohol polyoxyethylene ether, an unsaturated acid, functional monomers, an oxidizing agent, a reducing agent and a chain transfer agent, wherein the unsaturated acid consists of citric acid,acetic anhydride, acrylic acid and methacrylic acid according to a mass ratio of (1-3):(1-2):(2-3):(5-10), and the functional monomers are nano-diatomaceous earth and sulfonated melamine formaldehyderesin. According to the invention, the water reducer is synthesized by the allyl alcohol polyoxyethylene ether and the unsaturated acid, so that mixing performance of concrete can be improved, meanwhile, steel bars can be prevented from rusting, and the service life of the concrete is prolonged. Mutual reactions between cementing materials can be promoted through the functional monomers, and workability of the concrete is enhanced.

Owner:武汉优城科技有限公司

High-temperature-resistant yellowing-resistant high-hardness vinyl acetate-acrylic emulsion and preparation method thereof

InactiveCN106832085AIncrease chemical bond energyIncrease dry film hardnessMonocarboxylic acid ester polymer adhesivesFunctional monomerAcrylic resin

The invention discloses a high-temperature-resistant yellowing-resistant high-hardness vinyl acetate-acrylic emulsion which comprises the following components in parts by mass: 100 parts of water, 2-8 parts of butyl acrylate, 100-150 parts of vinyl acetate, 1-5 parts of functional monomer, 5-10 parts of N-hydroxymethyl acrylamide, 1-5 parts of emulsifier and 0.1-1 part of persulfate. The high-temperature-resistant yellowing-resistant high-hardness vinyl acetate-acrylic emulsion has the advantages of favorable yellowing resistance, favorable high-temperature resistance and higher hardness.

Owner:上海巴德富实业有限公司

Method for preparing LFT-D dropping board by means of PP original materials and waste materials

InactiveCN105199222AImprove toughnessExtended service lifeFlat articlesTemperature controlGlass fiber

The invention discloses a method for preparing an LFT-D dropping board by means of PP original materials and waste materials. According to the method, through the combination of temperature control, material improvement and a special technical formula, modified PP plastic and waste material particles are added to Y2600 original material particles in proportion and stirred and fused through double screws, and then glass fiber is added to obtain the finished product. The weather resistance and adverse environment resistance of the Y2600 original materials are poor, tenacity, weather resistance, aging resistance and the like can be improved greatly by adding modified plastic, so that the defect of poor strength is overcome and aging time is prolonged, tests on various mechanical performances of each machined product can meet the relevant dropping board inspection standards, and the purposes of improving the tenacity of the LFT-D dropping board and prolonging the service life of the LFT-D dropping board are realized. Recycling is achieved, and the method has great significance for environment protection.

Owner:陕西新智汇科技股份有限公司

Method for preparing tetrahydrofuran acrylate through continuous esterification reaction and method for preparing catalyst

ActiveCN106518815AExtended service lifeGood filling effectOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIon-exchange resinTetrahydrofuran

The invention discloses a method for preparing tetrahydrofuran acrylate through a continuous esterification reaction. The method comprises the following steps: taking acrylic acid and tetrahydrofurfuryl alcohol as raw materials, adopting a composite catalyst composed of a metal ion modified solid acid catalyst and graphite, adding submicron order silicon carbide whiskers, nanoscale tungsten oxide, nanoscale zirconium oxide, metal ions and the like into the catalyst for modifying an ion exchange resin, and realizing a two-stage continuous esterification reaction. According to the method, continuous production of the tetrahydrofuran acrylate is realized by controlling the temperature, reaction pressure and the like, the conversion rate can reach 100%, the monoester selectivity is 97%, the overall product yield is 97%, and the method disclosed by the invention is simple in operation, capable of obviously improving the production efficiency, reducing the production cost and greatly reducing the wastewater discharge, and has excellent large-scale industrial application value.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com