Bonding method for improving bonding force and optical properties of bonding crystal

A technology of optical properties and bonding force, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve problems such as small bonding force, large optical loss, and increase the bonding force of gallium arsenide diffusion bonded crystals, etc., to achieve Effect of eliminating surface oxide and improving optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After the surface of the wafer is polished, the surface of the wafer is cleaned with a chemical solution. The solution used for cleaning is: carbon tetrachloride, acetone, ethanol, and deionized water. After cleaning, the wafer is soaked in deionized water for subsequent processes. All operations Performed in a clean room.

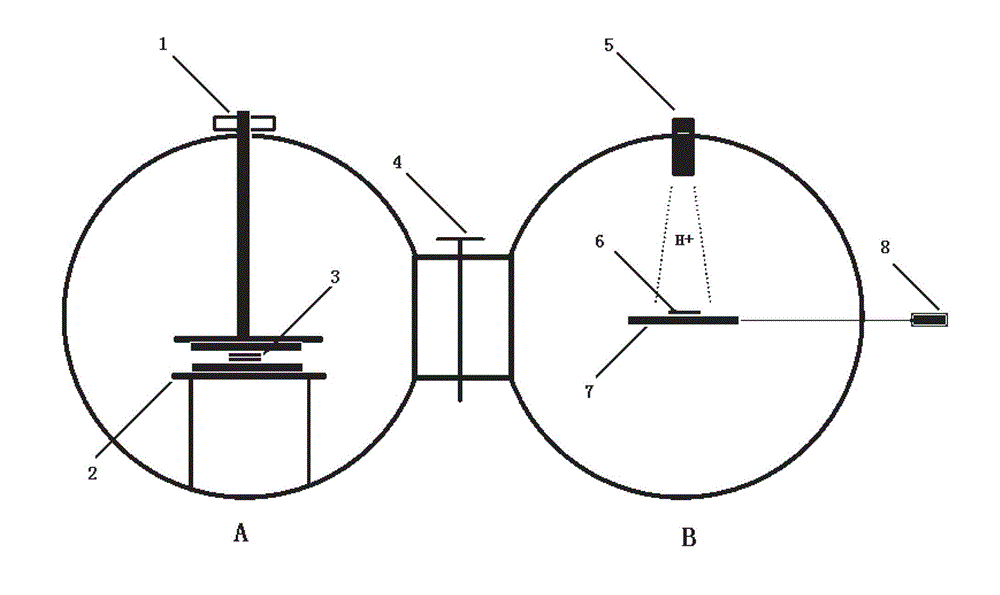

[0022] After the samples are blown dry with nitrogen, use the ultra-high vacuum hydrogen ion cleaning device (CN201010279377.7, ultra-high vacuum ion source wafer cleaning system, authorization date: 2012-05-02) to complete the cleaning and pre-bonding process, such as figure 1 shown. Place the sample on the sample holder 7 and place it in the sputtering vacuum chamber B until the vacuum degree reaches 10 -5 At Pa, the hydrogen ion beam is generated by the hydrogen ion source 5, and the sample 6 to be cleaned is started to be cleaned by hydrogen ions. The ion beam current energy is set to 350eV, and the ion beam current density is 10 μA / cm 2 , bom...

Embodiment 2

[0029] After the surface of the wafer is polished, the surface of the wafer is cleaned with a chemical solution. The solution used for cleaning is: carbon tetrachloride, acetone, ethanol, and deionized water. After cleaning, the wafer is soaked in deionized water for subsequent processes. All operations Performed in a clean room.

[0030] After the sample was blown dry with nitrogen, the sample was placed on the sample holder 7 and placed in the sputtering vacuum chamber B until the vacuum degree reached 10 -5 Pa, the hydrogen ion beam is generated by the hydrogen ion source 5, and the sample 6 to be cleaned is started to be cleaned with hydrogen ions. The ion beam current energy is set to 500eV, and the ion beam current density is 5 μA / cm 2 , bombarded at room temperature for 15 min to reduce most of the oxides, and heated room B to 150 °C as a whole, and bombarded for 5 min.

[0031] After the bombardment is over, use the transfer rod 8 to transfer the cleaned wafer 6 to th...

Embodiment 3

[0035] After the surface of the wafer is polished, the surface of the wafer is cleaned with a chemical solution. The solution used for cleaning is: carbon tetrachloride, acetone, ethanol, and deionized water. After cleaning, the wafer is soaked in deionized water for subsequent processes. All operations Performed in a clean room.

[0036] After the sample was blown dry with nitrogen, the sample was placed on the sample holder 7 and placed in the sputtering vacuum chamber B until the vacuum degree reached 10 -5 Pa, the hydrogen ion beam is generated by the hydrogen ion source 5, and the sample 6 to be cleaned is started to be cleaned with hydrogen ions, and the ion beam current energy is set to 300eV, and the ion beam current density is 10μA / cm 2 , bombarded at room temperature for 15 min to reduce most of the oxides, and heated room B to 150 °C as a whole, and bombarded for 5 min.

[0037] After the bombardment is over, use the transfer rod 8 to transfer the cleaned wafer 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com