Polycarboxylate water reducer composition for self-compaction high-workability concrete

A self-compacting and concrete technology, applied in the field of concrete admixtures, can solve the problems of unstable concrete construction performance, inability to promote concrete self-compacting, poor workability of fresh concrete, etc., to solve the problem of easy deposition on the bottom layer of concrete and shorten the synthesis time , Improve the effect of mixing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

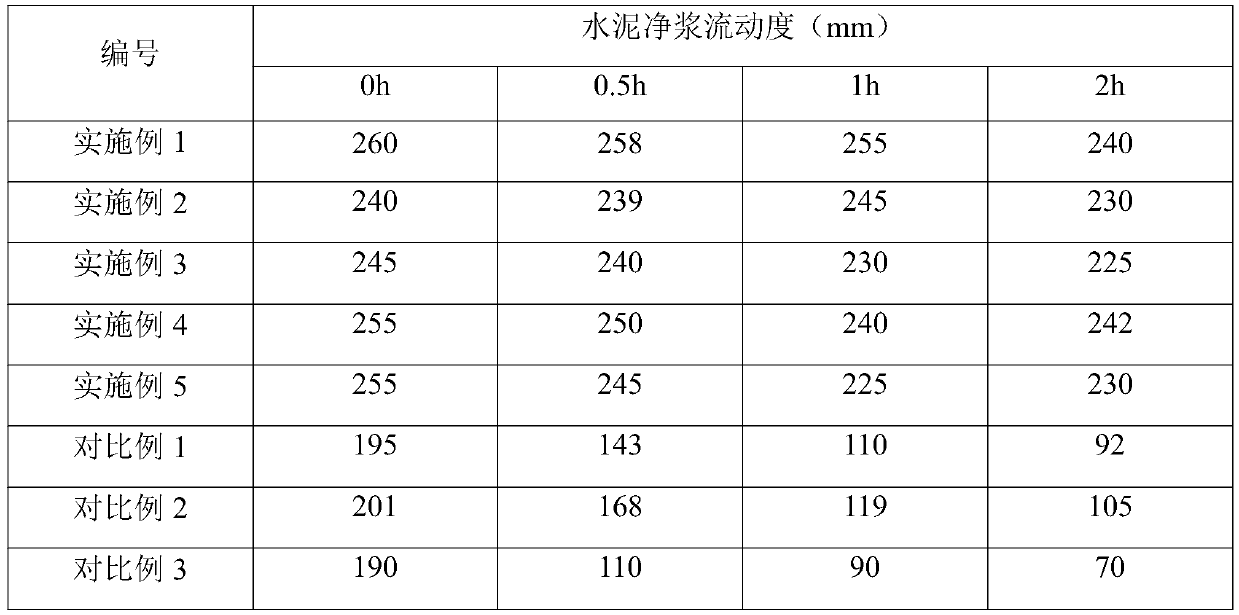

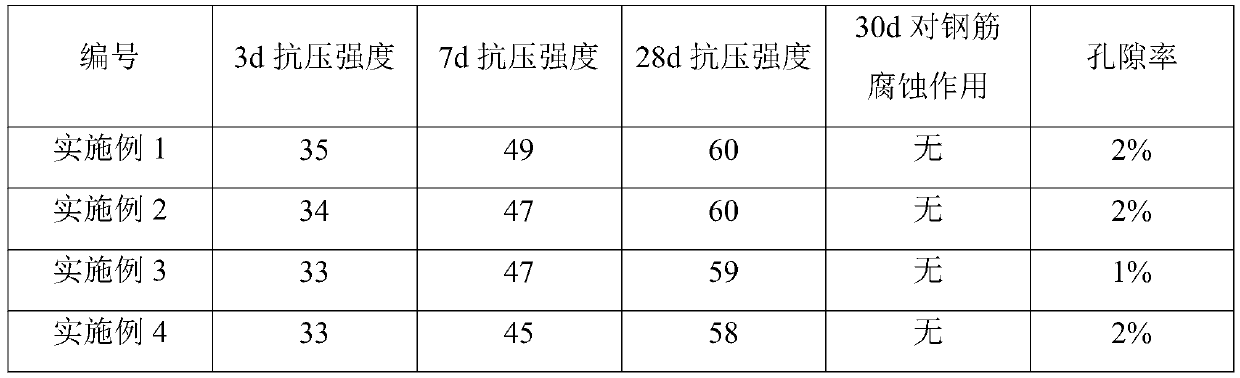

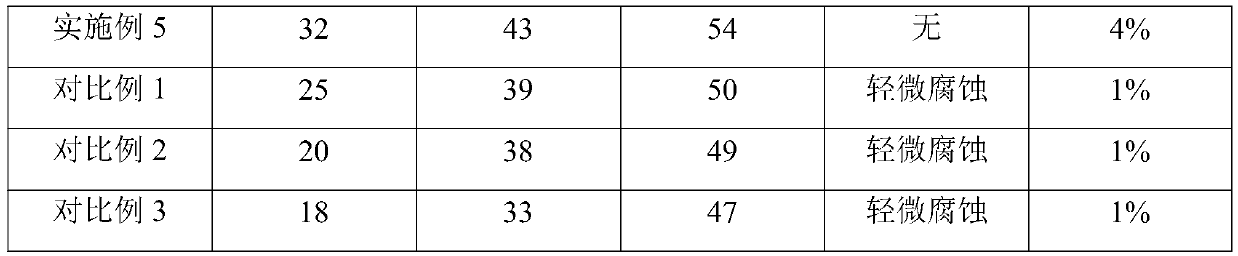

Examples

Embodiment 1

[0038] This example provides a polycarboxylate superplasticizer composition for self-compacting high workability concrete, which is composed of the following components: 60% allyl alcohol polyoxyethylene ether, 37% unsaturated acid, functional 1.5% monomer, 0.5% oxidizing agent, 0.3% reducing agent, 0.7% chain transfer agent;

[0039] The unsaturated acid is composed of citric acid, acetic anhydride, acrylic acid, and methacrylic acid in a mass ratio of 1:2:2:10;

[0040] The functional monomer is composed of nano diatomite and sulfonated melamine formaldehyde resin in a mass ratio of 1:1.

[0041] The oxidizing agent is ammonium persulfate; the reducing agent is sodium bisulfite; and the chain transfer agent is self-mercaptopropionic acid.

[0042] The present invention also provides a preparation method of a polycarboxylate superplasticizer composition for self-compacting high workability concrete, comprising the following steps:

[0043] A. In the reactor, dissolve allyl ...

Embodiment 2

[0048] This embodiment provides a polycarboxylate superplasticizer composition for self-compacting high workability concrete. Compared with Example 1, the difference is that the unsaturated acid is citric acid, acetic anhydride, acrylic acid, formic acid The mass ratio of base acrylic acid is 1:2:3:5.

[0049] The polycarboxylate superplasticizer composition was prepared by the preparation method described in Example 1.

Embodiment 3

[0051] This embodiment provides a polycarboxylate water reducer composition for self-compacting high workability concrete. Compared with Example 1, the difference is that the self-compacting high workability concrete uses polycarboxylate water reducer composition agent composition, a composition consisting of the following components: allyl alcohol polyoxyethylene ether 55%, unsaturated acid 40%, functional monomer 2%, oxidizing agent 1%, reducing agent 0.5%, chain transfer agent 1.5% .

[0052] The polycarboxylate superplasticizer composition was prepared by the preparation method described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com