Method for preparing modified starch-type glass fiber impregnating compound

A technology of glass fiber and sizing, which is applied in the field of preparation of modified starch-type glass fiber sizing, which can solve the problems of poor film-forming properties, poor cohesiveness, and low shear strength, and achieve improved cohesiveness and enhanced mechanical strength and cohesiveness, the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

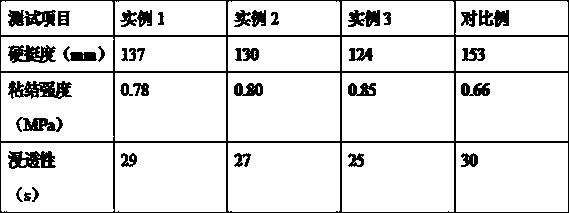

Examples

example 1

[0021] Weigh 30 g of buckwheat starch, add 100 mL of water to the buckwheat starch, mix and stir at 85°C for 1 hour, and obtain a starch paste after stirring. Cool the starch paste to 40°C, and adjust the pH to 5 with a mass fraction of 1% hydrochloric acid. Obtain the starch mixture, and then add 3g isoamylase to the starch mixture for enzymatic hydrolysis at 25°C for 1 h. After the enzymolysis is completed, filter and remove the filter residue, and the filtrate is the starch reaction solution. Add 25 mL mass fraction to the starch reaction solution in turn It is 5% sodium sulfate solution, 10mL 2% sodium hydroxide solution and 20mL 0.5% propylene oxide, mixed and stirred at 25°C for 20min, and the gelatinized starch suspension is obtained after stirring and reaction. Mix the gelatinized starch suspension with absolute ethanol at a volume ratio of 3:1 and stir for 10 minutes. After stirring, filter with suction to obtain solids. Continue to grind the solids for 6 minutes to obt...

example 2

[0023] Weigh 40 g of buckwheat starch, add 110 mL of water to the buckwheat starch, mix and stir at 95°C for 1 hour, and obtain a starch paste after stirring. Cool the starch paste to 45°C, and adjust the pH to 5 with a mass fraction of 1% hydrochloric acid. Obtain the starch mixture, and then add 4g isoamylase to the starch mixture for enzymatic hydrolysis at 30°C for 1 hour. After the enzymolysis is completed, filter and remove the filter residue, and the filtrate is the starch reaction solution. Add 30 mL mass fraction to the starch reaction solution in turn 5% sodium sulfate solution, 15mL 2% sodium hydroxide solution and 25mL 0.5% propylene oxide were mixed and stirred at 30°C for 25min. After stirring, the gelatinized starch suspension was obtained. Mix the gelatinized starch suspension and absolute ethanol at a volume ratio of 3:1 and stir for 12 minutes. After stirring, filter with suction to obtain a solid. Continue to grind the solid for 8 minutes to obtain modified st...

example 3

[0025] Weigh 50g of buckwheat starch, add 120mL of water to the buckwheat starch, mix and stir for 2h at 105°C, obtain a starch paste after stirring, cool the starch paste to 50°C, and adjust the pH to 6 with a mass fraction of 1% hydrochloric acid. Obtain the starch mixture, and then add 6g isoamylase to the starch mixture for enzymatic hydrolysis at 35°C for 2 hours. After the enzymolysis is completed, filter and remove the filter residue, and the filtrate is the starch reaction solution. Add 35 mL mass fraction to the starch reaction solution in turn 5% sodium sulfate solution, 18 mL 2% sodium hydroxide solution and 30 mL 0.5% propylene oxide were mixed and stirred at 45°C for 30 minutes. After stirring, the gelatinized starch suspension was obtained. Mix the gelatinized starch suspension with absolute ethanol at a volume ratio of 3:1 and stir for 15 minutes. After stirring, filter with suction to obtain a solid. Continue to grind the solid for 10 minutes to obtain modified s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com