Highly washable and friction-resistant ink for cotton fabrics and preparation method thereof

A cotton fabric, friction-resistant technology, applied in the field of water-based ink and its preparation, can solve problems such as lack of mechanical properties of adhesive coatings, and achieve the effect of improving rubbing fastness, mild operating conditions, and improving fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

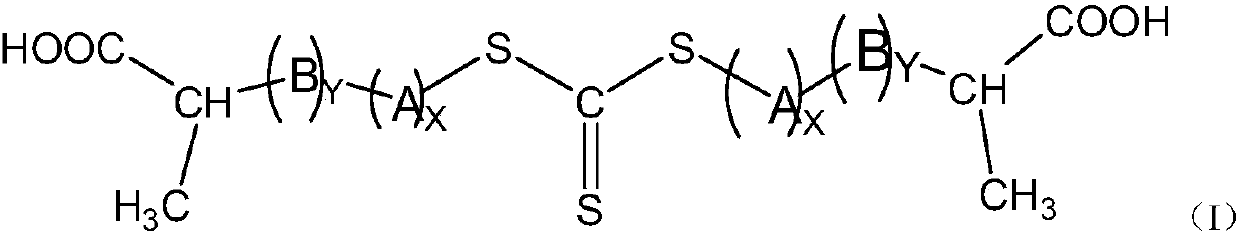

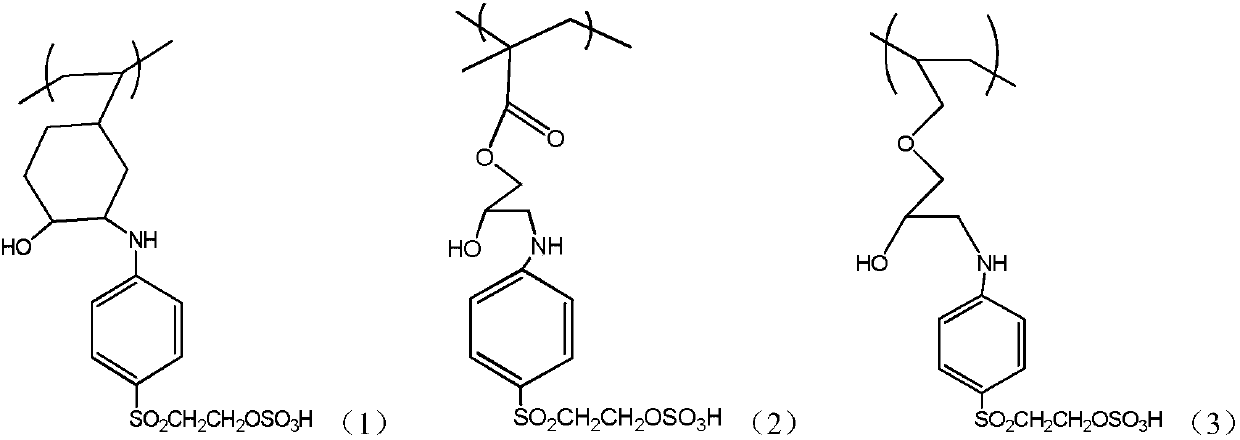

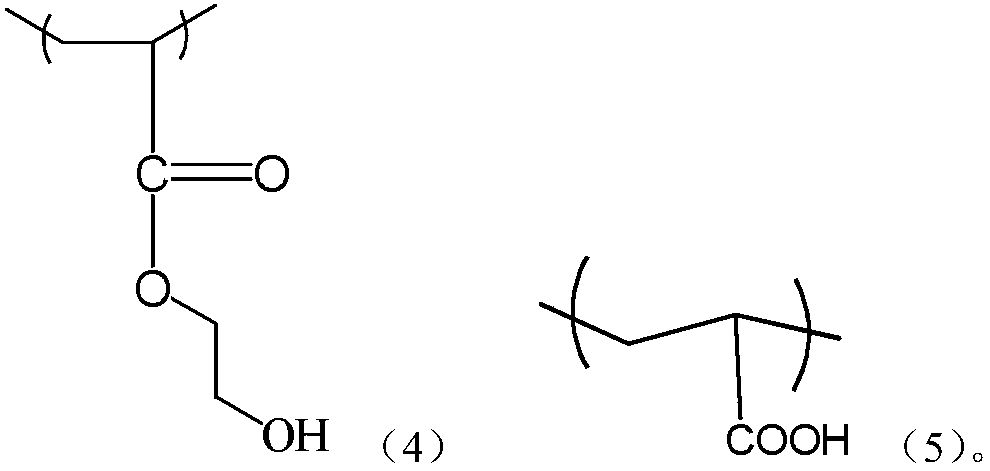

[0045] (1) Synthesis of macromolecular trithiocarbonate compounds

[0046] The chemical structural formula of the target product is shown in Formula I, and the specific parameters are as follows: A is shown in Formula 1a, B is shown in Formula 5b, X=4, Y=20. The specific synthesis steps are as follows: add 1.27g of formula II structure compound, 0.12g of oil-soluble initiator 4,4' azo-(4-cyanovaleric acid), 14.40g of acrylic acid (formula 5b monomer) to 35g of medium solvent In dioxane, stirred and dissolved, then moved into a three-necked flask connected with a serpentine condenser and high-purity nitrogen, passed nitrogen to remove oxygen for about 30 minutes, heated to 80°C in a water bath, and reacted for 2 hours under a nitrogen atmosphere; after the above reaction was completed, then Add the mixed liquid of 0.12g oil-soluble initiator 4,4'azo-(4-cyanovaleric acid), 16.72g formula 1a monomer and 15g medium solvent dioxane to the flask, and continue to React for 12 hours;...

Embodiment 2

[0050] (1) Synthesis of macromolecular trithiocarbonate compounds

[0051] The chemical structural formula of the target product is shown in Formula I, and the specific parameters are as follows: A is shown in Formula 2a, B is shown in Formula 4b, X=2, Y=60. The specific synthesis steps are as follows: 0.254g formula II structure compound, 0.03g oil-soluble initiator 4,4' azo-(4-cyanovaleric acid), 13.92g hydroxyethyl acrylate (formula 4b monomer) were added to 35g of the medium solvent dioxane, stirred and dissolved, then transferred to a three-necked flask connected with a serpentine condenser and high-purity nitrogen, passed nitrogen to remove oxygen for about 30 minutes, heated to 80°C in a water bath, and reacted for 2 hours under a nitrogen atmosphere; the above reaction was completed Afterwards, the mixed liquid of 0.03g oil-soluble initiator 4,4'azo-(4-cyanovaleric acid), 1.748g formula 2a monomer and 15g medium solvent dioxane was added into the flask, and Continue t...

Embodiment 3

[0055] (1) Synthesis of macromolecular trithiocarbonate compounds

[0056] The chemical structural formula of the target product is shown in Formula I, and the specific parameters are as follows: A is shown in Formula 3a, B is shown in Formula 5b, X=3, Y=30. The specific synthesis steps are as follows: add 1.016g of formula II structure compound, 0.10g of oil-soluble initiator 4,4' azo-(4-cyanovaleric acid), 17.28g of acrylic acid (formula 5b monomer) to 35g of medium solvent In dioxane, stirred and dissolved, then moved into a three-necked flask connected with a serpentine condenser and high-purity nitrogen, passed nitrogen to remove oxygen for about 30 minutes, heated to 80°C in a water bath, and reacted for 2 hours under a nitrogen atmosphere; after the above reaction was completed, then Add the mixed liquid of 0.10g oil-soluble initiator 4,4'azo-(4-cyanovaleric acid), 10.104g formula 3a monomer and 15g medium solvent dioxane into the flask, and continue to React for 12 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com