Preparation method of thick paperboard with high bonding strength between paperboards

A technology of interlayer bonding strength and thick cardboard, used in paper, papermaking, textiles and papermaking, etc., can solve the problems of easy pulping, poor dewatering of formed wet paper sheets, easy delamination, etc., to improve retention rate, improve Bond strength, the effect of increasing bond points and bond forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

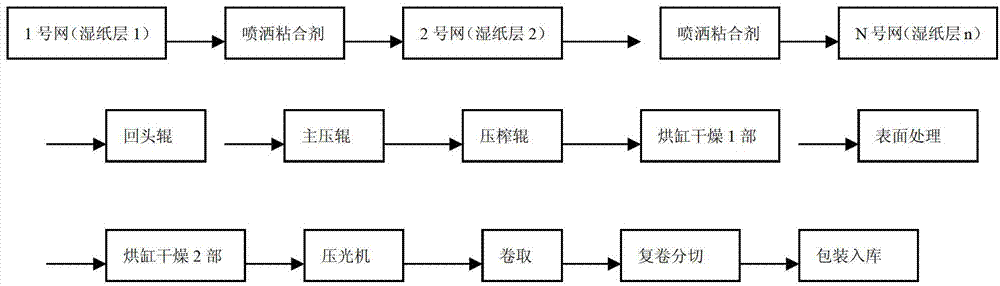

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 The preparation method of the cardboard of a kind of high cardboard interlayer bonding strength shown, this method utilizes beating degree to be 20 o SR~35 oSR After the pulp is formed on the Internet to form wet paper sheets, spray the mist adhesive aqueous solution between the wet paper layers, such as spraying the mist adhesive solution after the wet paper sheets are formed on the No. Aqueous mixture solution, the aqueous binder solution is one of starch, modified polyacrylamide or a mixture thereof, and the concentration of the aqueous binder solution is 0.5% to 6.0%. Then enter the return roller, the main pressure roller, and the press roller to be bonded together, and then dry the first part of the dryer for surface treatment, then enter the second part of the dryer for drying, pass through the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com