Manufacturing method of high-interlayer bonding strength high-deflection thin paperboard

A technology combining strength and manufacturing method, applied in the field of papermaking, can solve the problems of easy moisture absorption of starch, reduced stiffness of cardboard, and incompletely suitable manufacturing of thin cardboard, etc. Significant effect of bonding strength and stiffness between

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

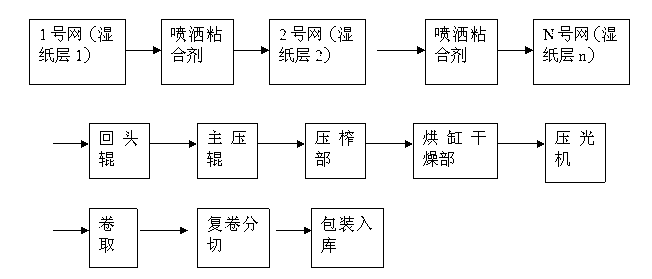

Method used

Image

Examples

Embodiment 2)

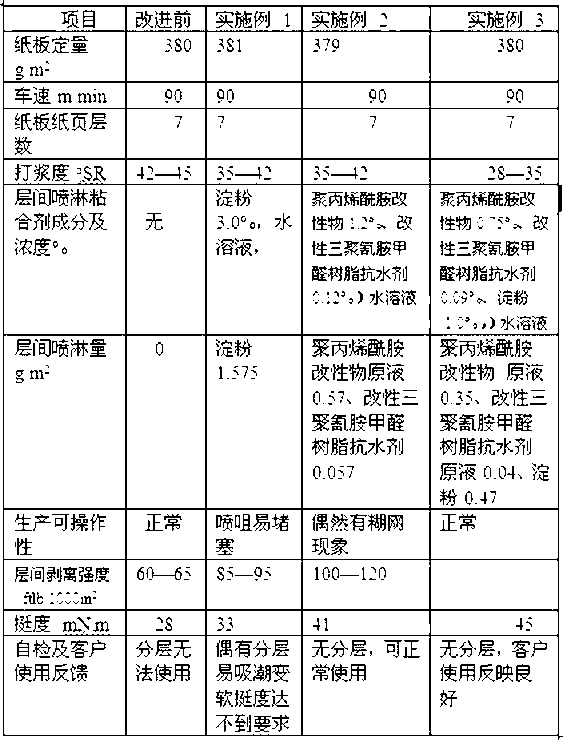

[0018] The composite adhesive aqueous solution is an aqueous solution formed by successively dispersing and dissolving polyacrylamide modified products, modified melamine formaldehyde resin water repellent agent and starch in the same tank of clear water, and its mass concentration is 1.0%-3.5%, wherein polypropylene Amide modified product is 0.3%-1.0%, modified melamine formaldehyde resin water repellent concentration is 0.05%-0.20%, spray starch is 0.65%-2.3%; polyacrylamide modified product between two adjacent wet paper sheets Spray amount of stock solution 0.15g—0.50g / m 2 , The spraying amount of modified melamine formaldehyde resin anti-water agent stock solution is 0.025g—0.10g / m 2 , Spray starch spray amount 0.325g—1.15g / m 2 , The adhesive solution sprayed between the wet paper layers must be in the form of mist, and the sprayed mist adhesive solution covers the paper completely. (See Example 3).

Embodiment 1

[0019] Example 1: The main component of the adhesive is spray starch, the concentration of its aqueous solution is generally 1.0%-4.0%, and the amount of spray starch sprayed between two adjacent wet paper sheets is 0.53g-2.1g. The optimal concentration of spray starch depends on the speed of the paper machine and the amount of starch sprayed, and the preferred concentration is 2.5%-3.5%. Spray amount between starch layers 1.31--1.83g / m 2 .

Embodiment 2

[0020] Example 2: The main components of the composite adhesive are polyacrylamide modified product and modified melamine formaldehyde resin water repellent agent, the concentration of its aqueous solution is generally 0.35%-2.0%, and the polyacrylamide modified between two adjacent wet paper sheets The spraying amount of the raw material liquid of the agent is 0.15g-0.95g per square meter, and the spraying amount of the raw liquid of the modified melamine-formaldehyde resin water-resistant agent is 0.025g-0.10g per square meter. The optimal use concentration depends on the speed of the paper machine and the amount of spraying. The concentration of the stock solution of modified polyacrylamide is 1.2%, and the stock solution of modified melamine formaldehyde resin is 0.12%. Spray amount between layers: stock solution of modified polyacrylamide 0.57 g / m 2 , modified melamine formaldehyde resin water repellent stock solution 0.057 g / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com