Microfluidic surface-enhanced Raman scattering detector and its preparation method and use

A surface-enhanced Raman and microfluidic technology, used in Raman scattering, material excitation analysis, etc., can solve the problem that the distribution cannot achieve good uniformity, the time consuming often takes several hours or even longer, and the amount of reagents is large. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Preparation of an active substrate containing several nano-hole structures covered with a metal layer:

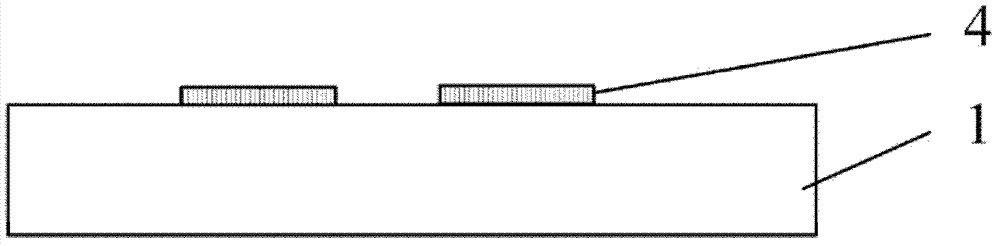

[0067] 1') Spin-coat RZJ-304 positive photoresist with a thickness of 2 μm on the surface of the silicon substrate 1, pre-bake it in a 98°C oven for 15 minutes, use a wavelength of 365nm, and an intensity of 5.4mW / cm 2 The ultraviolet light is exposed through the mask plate 1 for 10s, and after developing for 30s in the developer of RZJ-304 positive photoresist, a nanochannel composed of multiple small photoresist patterns and their gaps is formed. The gap width 100µm, such as figure 1 shown;

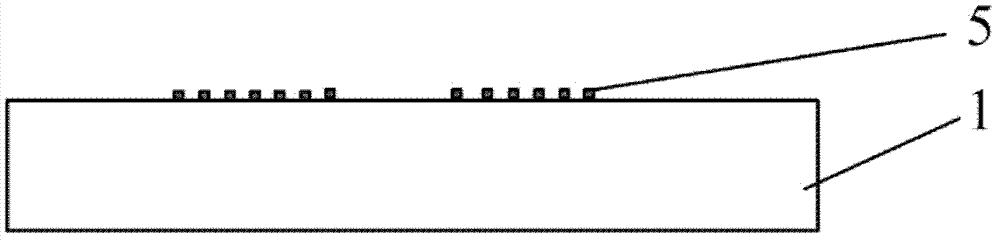

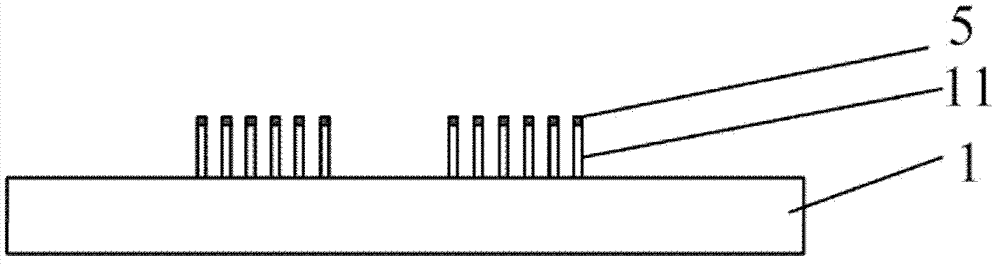

[0068] 2') Put the silicon substrate 1 obtained in step 1') with nanochannels composed of multiple small photoresist patterns and gaps together into an oxygen plasma bombardment chamber with a power of 250W and an oxygen flow rate of 30sccm , bombard the photoresist for 10 minutes, and generate point-like nanomaterial structures uniformly distributed on the silicon substrate...

Embodiment 2

[0078] Preparation of an active substrate containing several nano-hole structures covered with a metal layer:

[0079] 1') Spin-coat RZJ-304 positive photoresist with a thickness of 2 μm on the surface of the silicon substrate 1, pre-bake it in a 98°C oven for 15 minutes, use a wavelength of 365nm, and an intensity of 5.4mW / cm 2 The ultraviolet light is exposed through the mask plate 1 for 10s, and after developing for 30s in the developer of RZJ-304 positive photoresist, a nanochannel composed of multiple small photoresist patterns and their gaps is formed. The gap width 100µm, such as figure 1 shown;

[0080] 2') Put the silicon substrate 1 obtained in step 1') with nanochannels composed of multiple small photoresist patterns and gaps together into an oxygen plasma bombardment chamber with a power of 250W and an oxygen flow rate of 30sccm , bombard the photoresist for 10 minutes, and generate point-like nanomaterial structures uniformly distributed on the silicon substrate...

Embodiment 3

[0091] Preparation of an active substrate containing several nano-hole structures covered with a metal layer:

[0092] 1') Spin-coat RZJ-304 positive photoresist with a thickness of 2 μm on the surface of the silicon substrate 1, pre-bake it in a 98°C oven for 15 minutes, use a wavelength of 365nm, and an intensity of 5.4mW / cm 2 The ultraviolet light is exposed through the mask plate 1 for 10s, and after developing for 30s in the developer of RZJ-304 positive photoresist, a nanochannel composed of multiple small photoresist patterns and their gaps is formed. The gap width 100µm, such as figure 1 shown;

[0093] 2') Put the silicon substrate 1 obtained in step 1') with nanochannels composed of multiple small photoresist patterns and gaps together into an oxygen plasma bombardment chamber with a power of 250W and an oxygen flow rate of 30sccm , bombard the photoresist for 10 minutes, and generate point-like nanomaterial structures uniformly distributed on the silicon substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com