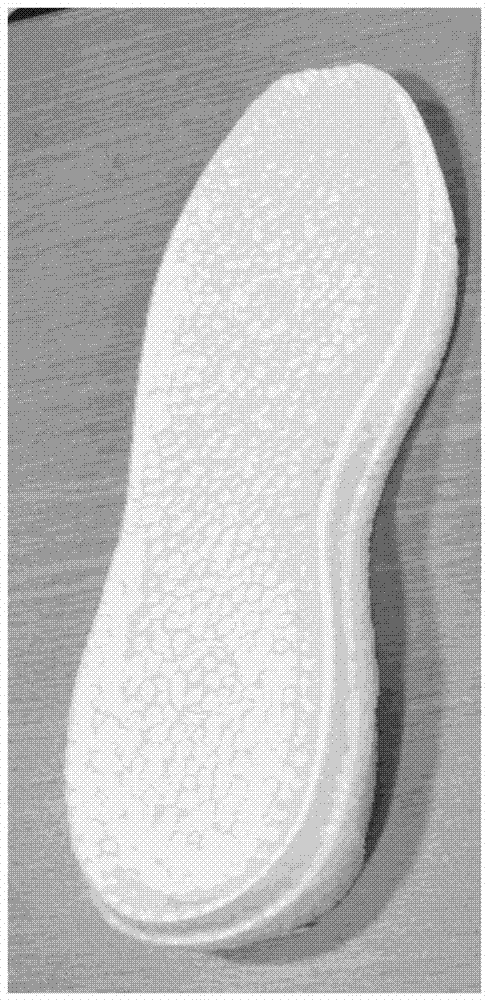

Preparation method for thermoplastic polyurethane elastomer foaming material

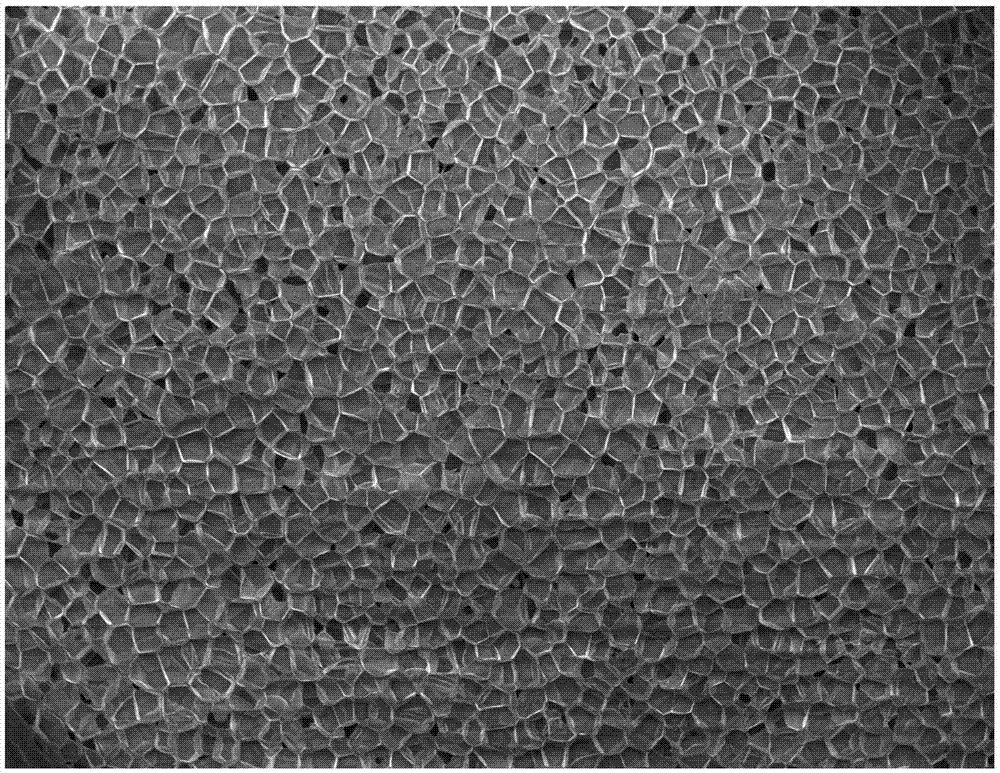

A thermoplastic polyurethane and foaming material technology, applied in the field of thermoplastic polyurethane elastomer and foaming materials, can solve the problems of poor foaming effect, cavitation structure, TPU monomer falling off, etc., and achieve good bead density consistency, The material structure is stable and the effect of increasing the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The method for preparing a thermoplastic polyurethane elastomer foam material disclosed in the present invention includes the steps:

[0021] (1) 100 parts by weight of thermoplastic polyurethane elastic material, 0.5-10 parts of graphene material and 0.05-3 parts of lubricant are stirred and mixed to obtain a mixture; the obtained mixture is melted and mixed, and after cooling, it is cut through The pelletizer cuts pellets to obtain thermoplastic polyurethane pellets uniformly doped with graphene;

[0022] (2) Add the pellets and water obtained in step (1) to a mass ratio of 1:0.3-1:5, and add them to the reactor to start stirring;

[0023] (3) Pour carbon dioxide or nitrogen gas into the reactor to control the pressure and temperature in the reactor so that the carbon dioxide or nitrogen gas in the reactor is in a supercritical state;

[0024] (4) Heat the reaction kettle to dissolve supercritical carbon dioxide or nitrogen in the thermoplastic polyurethane uniformly doped wi...

Embodiment 1

[0029] First put 100 parts of thermoplastic polyurethane elastomer, 3 parts of graphene and 0.5 parts of lubricant into a high-speed mixer for mixing for 10 minutes; then add the evenly mixed mixture into the twin-screw extruder for melting and mixing, the screw speed is 150rpm, Mixing at 135°C for 20 minutes; then extruded by a twin screw, cooled in a water tank, and introduced into a pelletizer for pelletizing operation to obtain thermoplastic polyurethane pellets uniformly doped with graphene;

[0030] Then, the obtained thermoplastic polyurethane pellets and water were added to the reactor at a mass ratio of 1:1 to start stirring; carbon dioxide and nitrogen were introduced into the reactor, and the pressure in the reactor was controlled to 7.5MPa and the temperature at 45°C to make the reactor Carbon dioxide and nitrogen are in a supercritical state; heat the reactor to dissolve supercritical carbon dioxide or nitrogen in the thermoplastic polyurethane uniformly doped with gr...

Embodiment 2

[0033] First put 100 parts of thermoplastic polyurethane elastomer, 1 part of graphene oxide and 0.5 parts of lubricant into a high-speed mixer for mixing for 20 minutes; then add the evenly mixed mixture into the twin-screw extruder for melting and mixing, the screw speed is 150rpm , Mixing at 135°C for 30 minutes; then extruded by a twin screw and cooled in a water tank, then introduced into a pelletizer for pelletizing operation to obtain thermoplastic polyurethane pellets uniformly doped with graphene;

[0034] Then, the obtained thermoplastic polyurethane pellets and water were added to the reactor at a mass ratio of 1:0.8 to start stirring; carbon dioxide and nitrogen were introduced into the reactor, and the pressure in the reactor was controlled to 7.5MPa and the temperature at 50°C to make the reactor Carbon dioxide and nitrogen are in a supercritical state; heat the reactor to dissolve supercritical carbon dioxide or nitrogen in the thermoplastic polyurethane uniformly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com