High-strength and easily-degradable composite material for garbage bag

A composite material and garbage bag technology, which is applied in the field of high-strength and easily degradable composite materials for garbage bags, can solve the problems of insufficient tensile strength, great influence on strength and weather resistance, and low elongation at break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

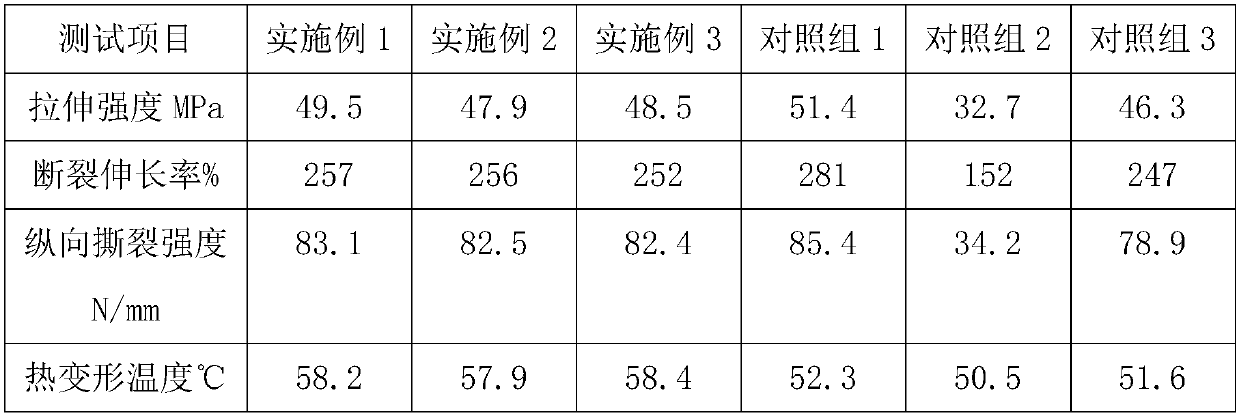

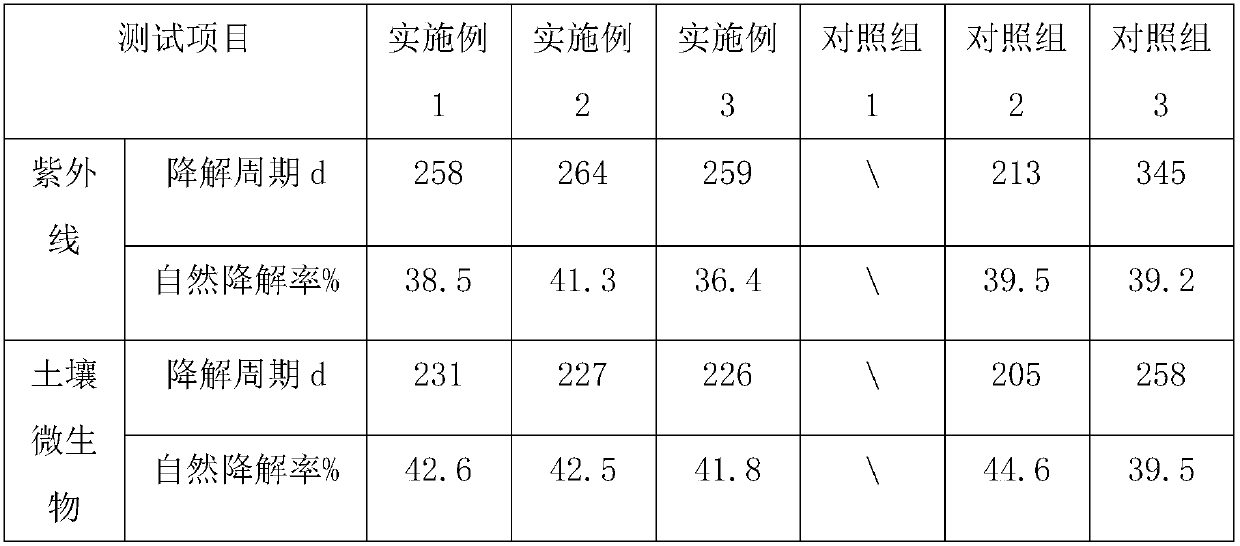

Examples

Embodiment 1

[0030] A high-strength and easily degradable composite material for garbage bags. According to the number of parts by mass, the components of the composite material include: 80 parts of polyvinyl chloride resin, 4 parts of polyamide resin, 2 parts of TPVC elastomer, 50 parts of modified starch, 6 parts of solvent, 8 parts of plasticizer, 6 parts of reinforcing agent, 3 parts of degradation catalyst, 1 part of stabilizer.

[0031] In this embodiment, the method for preparing modified starch includes the following steps:

[0032] (1) Mix the high-viscosity starch and water according to the mass ratio of 1:4, stir in the reactor at a temperature of 45℃ to obtain the starch solution; add 5wt% sodium hydroxide solution dropwise to the starch solution to adjust the starch solution PH value to 8.7, stir evenly at 55r / min for 5min;

[0033] (2) Add 180% of the starch mass of titanium dioxide, 7% of dextran, 12% of fucoidan, 2% of tetradecenyl succinic anhydride and 3.5% of coupling agent in...

Embodiment 2

[0044] A high-strength and easily degradable composite material for garbage bags. According to the number of parts by mass, the components of the composite material include: 95 parts of polyvinyl chloride resin, 7.5 parts of polyamide resin, 5 parts of TPVC elastomer, and 60 parts of modified starch. 10 parts of solvent, 15 parts of plasticizer, 10 parts of reinforcing agent, 6 parts of degradation catalyst, 4 parts of stabilizer.

[0045] In this embodiment, the method for preparing modified starch includes the following steps:

[0046] (1) Mix the high-viscosity starch and water according to the mass ratio of 1:4, stir in the reactor at 65℃ to obtain the starch solution; add 5wt% sodium hydroxide solution dropwise to the starch solution to adjust the starch solution PH value to 9.0, stir evenly for 8min at a speed of 70r / min;

[0047] (2) Add 180% of the starch mass of titanium dioxide, 7% of dextran, 12% of fucoidan, 2% of tetradecenyl succinic anhydride and 3.5% of coupling agen...

Embodiment 3

[0058] A high-strength and easily degradable composite material for garbage bags. According to the number of parts by mass, the components of the composite material include: 90 parts of polyvinyl chloride resin, 6 parts of polyamide resin, 4 parts of TPVC elastomer, 56 parts of modified starch. 8 parts of solvent, 12 parts of plasticizer, 8 parts of reinforcing agent, 4.5 parts of degradation catalyst, 2.5 parts of stabilizer.

[0059] In this embodiment, the method for preparing modified starch includes the following steps:

[0060] (1) Mix the high-viscosity starch and water in a mass ratio of 1:4, stir in the reactor at 55°C to obtain a starch solution; add 5wt% sodium hydroxide solution dropwise to the starch solution to adjust the starch solution PH value to 8.8, stir evenly for 7 minutes at a speed of 60r / min;

[0061] (2) Add 180% of the starch mass of titanium dioxide, 7% of dextran, 12% of fucoidan, 2% of tetradecenyl succinic anhydride and 3.5% of coupling agent into the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com