Preparation method of antibacterial paperboard high in bonding strength

A technology of bonding strength and cardboard, which is applied in the direction of paper, papermaking, textiles and papermaking, etc., can solve the problems of low bonding strength between board layers and poor antibacterial effect, and achieve the effect of improving bonding strength and improving antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

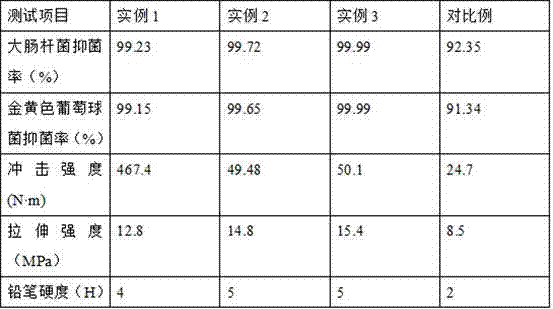

Examples

example 1

[0023]To the four-necked flask equipped with condenser, thermometer and stirrer, add 12g maleic acid, 45mL deionized water and 6g polytetramethylene glycol, mix and dissolve for 10min, then add 50g acrylamide, 4g methyl methacrylate to the flask after dissolving. Acryloyloxyethyltrimethylammonium chloride and 3g N-methylol acrylamide were continuously mixed and dissolved for 16min to obtain a mixed solution. The pH of the mixed solution was adjusted to 4 with a mass fraction of 20% sodium hydroxide solution, and heated. After the temperature was raised to 65°C, 10 mL of ammonium persulfate solution with a mass fraction of 16% and 8 mL of polysorbate were added to the flask for polymerization reaction for 12 min, and 2 g of ammonium persulfate and 1 g of sodium sulfite were added to the flask for a mixed reaction for 5 min to obtain a reaction solution. , and control the temperature of the reaction liquid to be 75 ℃, cool down, the discharge is the self-made amphoteric polyacryl...

example 2

[0025] To the four-necked flask equipped with condenser, thermometer and stirrer, add 14g maleic acid, 50mL deionized water and 7g polytetramethylene glycol, mix and dissolve for 11min, then add 55g acrylamide, 5g methyl methacrylate to the flask after dissolving. Acryloyloxyethyltrimethylammonium chloride and 4g of N-methylol acrylamide, continue to mix and dissolve for 18min to obtain a mixed solution, adjust the pH of the mixed solution to 5 with a mass fraction of 20% sodium hydroxide solution and heat up After reaching 70 °C, 11 mL of ammonium persulfate solution with a mass fraction of 16% and 9 mL of polysorbate were added to the flask for polymerization reaction for 14 min, and 3 g of ammonium persulfate and 2 g of sodium sulfite were added to the flask for a mixed reaction for 6 min to obtain a reaction solution. And control the temperature of the reaction liquid to be 80 ℃, cool down, and discharge the self-made amphoteric polyacrylamide emulsion, weigh 11 g of zeolit...

example 3

[0027] To the four-necked flask equipped with condenser, thermometer and stirrer, add 16g maleic acid, 55mL deionized water and 8g polytetramethylene glycol, mix and dissolve for 12min, then add 60g acrylamide, 6g methyl methacrylate to the flask after dissolving. Acryloyloxyethyltrimethylammonium chloride and 5g of N-methylol acrylamide were continuously mixed and dissolved for 20min to obtain a mixed solution. The pH of the mixed solution was adjusted to 6 with a mass fraction of 20% sodium hydroxide solution, and heated. After the temperature was raised to 75°C, 12 mL of ammonium persulfate solution with a mass fraction of 16% and 10 mL of polysorbate were added to the flask for polymerization for 16 min, and 4 g of ammonium persulfate and 3 g of sodium sulfite were added to the flask for a mixed reaction for 7 min to obtain a reaction solution. , and control the temperature of the reaction solution to be 85 °C, cool down, and the discharge is the self-made amphoteric polyac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com