Carbon fiber reinforced composite material and preparation method thereof

A technology for reinforcing composite materials and composite materials, which is applied in the field of carbon fiber reinforced polypropylene composite materials and its preparation, can solve the problems of difficulty in controlling fiber length, large differences in particle properties, cumbersome carbon fiber process, etc., and achieves low cost, excellent mechanical properties, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

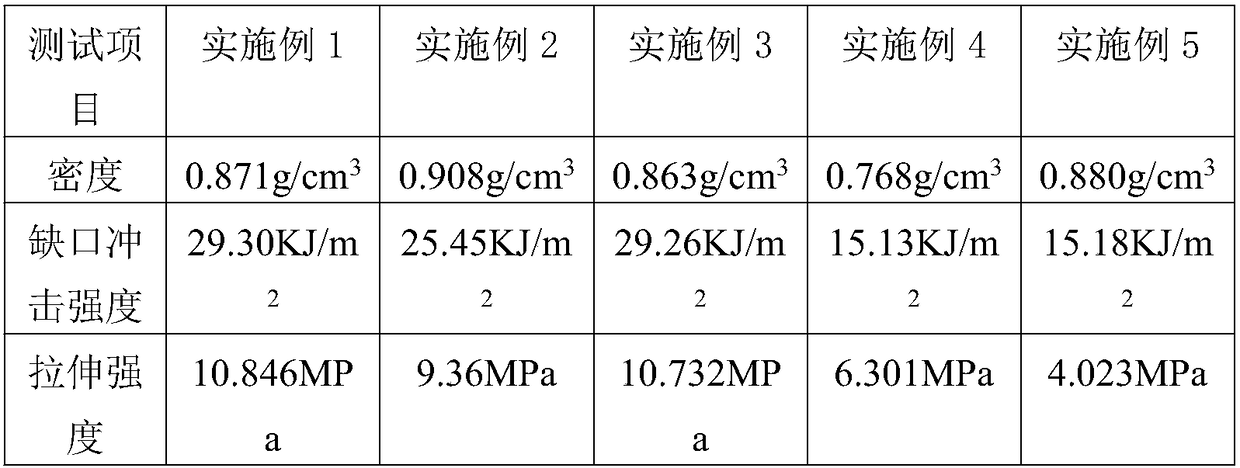

Examples

Embodiment 1

[0026] (1) Weigh 40 parts of chopped carbon fibers treated by liquid phase oxidation method in an internal mixer, and add 1 part of silane coupling agent KH550 to conduct carbon fiber surface treatment.

[0027] (2) Weigh 80 parts of polypropylene, 22 parts of low-density polyethylene, 10 parts of calcium carbonate, 2 parts of paraffin, and 10 parts of magnesium hydroxide and mix them evenly in the internal mixer; the three-stage internal mixing temperature of the internal mixer is set to 210 ℃, screw speed of 10r / min, banburying time of 20min.

[0028] (3) The uniformly mixed material is taken out and put into a hot press template, heated and pressurized, cooled and cooled, and finally solidified and molded to obtain a carbon fiber reinforced composite material. The molding temperature of the hot press was 200 °C, the holding time was 10 min, and the cooling temperature was 60 °C to take out the composite material.

Embodiment 2

[0030] (1) Weigh 35 parts of chopped carbon fiber treated by liquid phase oxidation method in an internal mixer, add 0.5 part of silane coupling agent KH560 to carry out carbon fiber surface treatment.

[0031] (2) take by weighing 70 parts of polypropylene, 10 parts of EVA, 5 parts of PA6, 10 parts of calcium carbonate, 1 part of paraffin wax, 5 parts of magnesium hydroxide and mix them in the internal mixer; the three-stage internal mixing temperature of the internal mixer is set The temperature is 190°C, the screw speed is 10r / min, and the mixing time is 15min.

[0032] (3) The uniformly mixed material is taken out and put into a hot press template, heated and pressurized, cooled and cooled, and finally solidified and molded to obtain a carbon fiber reinforced composite material. The molding temperature of the hot press was 190 °C, the holding time was 10 min, and the cooling temperature reached 50 °C to take out the composite material.

Embodiment 3

[0034] (1) Weigh 30 parts of chopped carbon fibers treated by liquid phase oxidation method in an internal mixer, and add 0.1 part of silane coupling agent TPPP for surface treatment of carbon fibers.

[0035] (2) Weigh 60 parts of polypropylene, 15 parts of low-density polyethylene, 8 parts of calcium carbonate, 4 parts of methyl silicone oil, and 15 parts of magnesium hydroxide and mix them evenly in an internal mixer; The setting is 200°C, the screw speed is 10r / min, and the mixing time is 15min.

[0036] (3) The uniformly mixed material is taken out and put into a hot press template, heated and pressurized, cooled and cooled, and finally solidified and molded to obtain a carbon fiber reinforced composite material. The molding temperature of the hot press was 200 °C, the holding time was 13 min, and the cooling temperature was 40 °C to take out the composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com