Method for preparing tetrahydrofuran acrylate through continuous esterification reaction and method for preparing catalyst

A technology for tetrahydrofuran acrylate and esterification reaction, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, catalytic reaction, etc., and can solve many side reactions, low production efficiency, complex process, etc. problems, to achieve the effect of reducing product chromaticity, prolonging service life and stabilizing pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

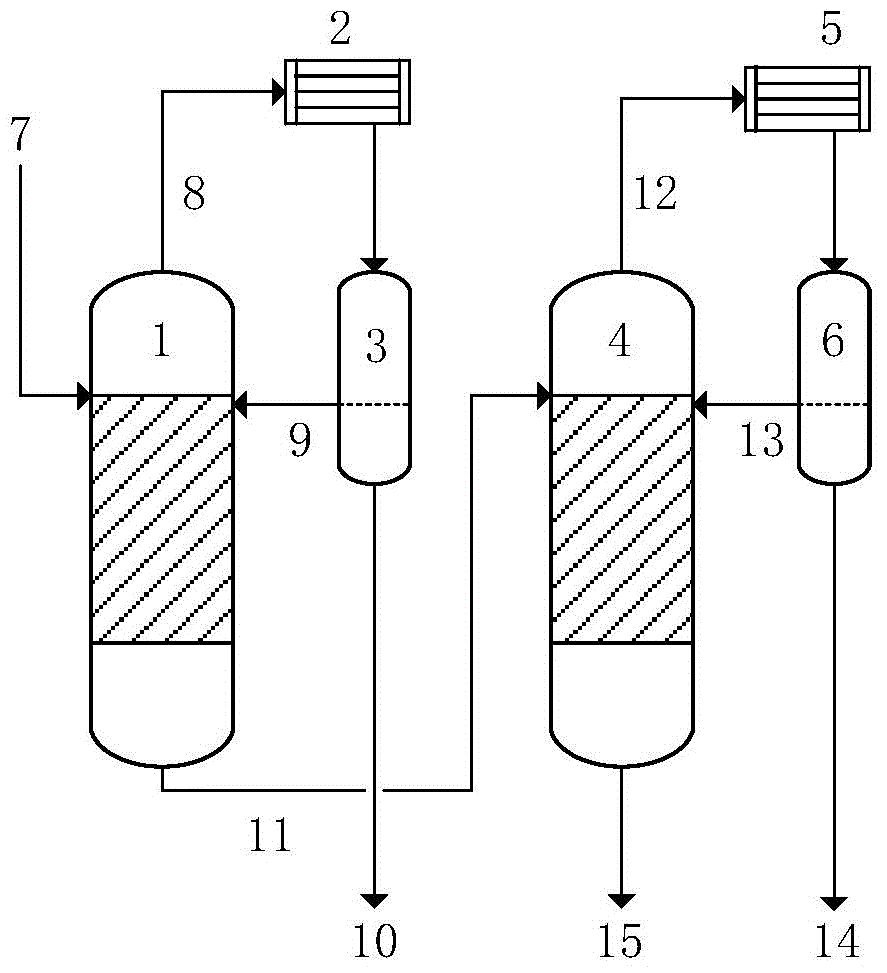

Image

Examples

Embodiment 1

[0062] 1. Add 267g of saturated sodium chloride aqueous solution, 35g of gelatin and 1.8g of polyvinyl alcohol dispersant into a reactor equipped with a high-speed stirrer and a thermometer; Take 150g of o-chlorostyrene and 28g of divinylbenzene, based on the quality of o-chlorostyrene and divinylbenzene 1wt% of submicron silicon carbide whiskers, 0.1wt% of nano-sized tungsten oxide, 1wt% of nano-sized Add zirconia, 1wt% liquid paraffin porogen and 0.5wt% benzoyl peroxide initiator to the reactor, heat up to 60°C and stir for 2h; 3. Cool and filter after the reaction, wash and dry with 50°C hot water 4. Extract the porogen with excess petroleum ether, and sieve out the resin skeleton with a diameter of 0.4-0.6mm; 5. The resulting resin skeleton is swollen with excess dichloroethane; 2% concentrated sulfuric acid, heat up to 75°C and reflux for 1 hour; 7. Evaporate dichloroethane, then add 1% oleum based on the resin mass, heat up the reaction, cool down when the resin exchange...

Embodiment 2

[0065] 1. Add 225g of saturated sodium chloride aqueous solution, 51g of gelatin and 2.6g of polyvinyl alcohol dispersant into a reactor equipped with a high-speed stirrer and a thermometer; 2. Start stirring, and after the dispersant is evenly dispersed in the system, weigh Take 130g o-chlorostyrene and 41g divinylbenzene, based on o-chlorostyrene and divinylbenzene mass 3% submicron silicon carbide whiskers, 0.5% nano-sized tungsten oxide, 0.5% nano-sized zirconia , 2% liquid paraffin porogen and 0.2% benzoyl peroxide initiator were added to the reactor, and the temperature was raised to 45°C and stirred for 6 hours; 3. After the reaction was completed, it was cooled and filtered, washed with hot water at 70°C, and dried; 4. 1. Extract the porogen with excess petroleum ether, and sieve out the resin skeleton with a diameter of 0.4-0.6mm; 5. The obtained resin skeleton is swollen with excess dichloroethane; 6. After the swelling is completed, add 2% concentrated Sulfuric acid...

Embodiment 3

[0068] 1. Add 175g of saturated sodium chloride aqueous solution, 45g of gelatin and 2.2g of polyvinyl alcohol dispersant into a reactor equipped with a high-speed stirrer and a thermometer; Take 140g of o-chlorostyrene and 33g of divinylbenzene, based on the quality of o-chlorostyrene and divinylbenzene 5% submicron silicon carbide whiskers, 0.2% of nano-sized tungsten oxide, 0.1% of nano-sized zirconia , add 3% liquid paraffin porogen and 0.3% benzoyl peroxide initiator into the reactor, heat up to 50°C and stir for 4 hours; 3. Cool and filter after the reaction, wash with hot water at 60°C, and dry; 4. 1. Extract the porogen with excess petroleum ether, and screen the resin skeleton with a diameter of 0.4 to 0.6 mm; 5. The obtained resin skeleton is swollen with excess dichloroethane; 6. After the swelling is completed, add 3% concentrated Sulfuric acid, heat up to 78°C and reflux for 1 hour; 7. Distill out dichloroethane, then add 1% oleum based on the resin mass, and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com