Method for preparing LFT-D dropping board by means of PP original materials and waste materials

A LFT-D, raw material technology, applied in the field of animal husbandry, can solve the problems such as there is no plan for the recycling and reuse of LFT-D composite material waste, incomplete leakage of manure board defective products, affecting the promotion and use of products, etc. The effect of recycling raw materials, saving modified materials and modification costs, and prolonging aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

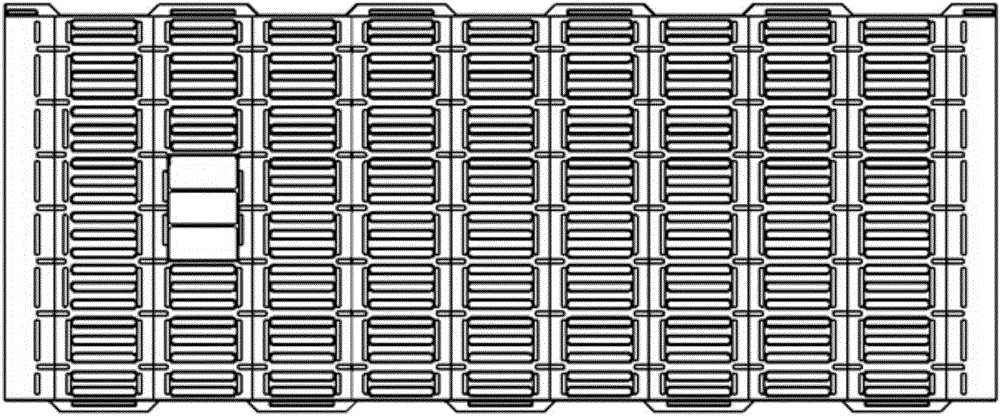

Image

Examples

Embodiment 1

[0040] Embodiment 1: Raw materials are not modified and implemented

[0041] The weight ratio of Y2600PP raw material to glass fiber is 6:1, and the LFT-D leaking manure board with a size of 1500mm×600mm×35mm and a weight of 7.85kg is prepared, and the design service life is 8~10 according to the corresponding national standards. Intensity testing, the pressure in the experiment is 1300T, the holding time is tens of seconds, the obtained index is 53.5Mpa in tensile strength, 21.3Mpa in impact strength, 3.1% in elongation at break, and 40.4% in unnotched impact strength of the support beam. kJ / m 2 . According to laboratory tests, the service life at room temperature is 4 to 6 years, and the aging degree will be accelerated after that, and the service life of the original design cannot be reached.

Embodiment 2

[0042] Example 2: Implementation of Raw Material Modification + Waste

[0043] The weight ratio of Y2600PP raw material, CMG9801 compatibilizer, 1010 anti-aging agent and maleic anhydride MAH grafting agent is 100:1:0.5:1, and the inorganic polymer is grafted and connected by single-screw stirring and melting , the modified melting temperature is 240°C. After modification, take Y2600PP raw material: modified plastic particles: waste particles: glass fiber (weight ratio) is 5:1:0.5:0.6, and the size is 1500mm×600mm× 35mm leaking manure board products.

[0044] In accordance with the corresponding national standards for strength testing, the indicators are the tensile strength is 58.76Mpa, the impact strength is 47.4Mpa, the elongation at break is 4.8%, and the unnotched impact strength of the support beam is 42.0kJ / m 2 , exceed the intensity index of this industry standard product, also exceed the index of embodiment one. Its laboratory test has a service life of 6 to 8 years...

Embodiment 3

[0045] Example 3: Implementation of Raw Material Modification + Waste

[0046] The weight ratio of Y2600PP raw material, CMG9801 compatibilizer, 1010 anti-aging agent and maleic anhydride MAH grafting agent is 100:2:1:1.5, and the inorganic polymer is grafted and connected by single-screw stirring and melting , the modified melting temperature is 190°C. After modification, take Y2600PP raw material: modified plastic particles: waste particles: glass fiber (weight ratio) is 5:1:0.8:0.7, and the size is 1500mm×600mm× 35mm leaking manure board products.

[0047] According to the corresponding national standard for strength testing, the indicators are 64.52Mpa for tensile strength, 56.5Mpa for impact strength, 6.2% elongation at break, and 41.2kJ / m2 for unnotched impact strength of support beams, exceeding the industry standard products The intensity index also exceeds the index of embodiment one and embodiment two. Its laboratory test has a service life of 6 to 8 years at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com