Method for improving toughness of heat-resisting phenolic resin

A technology of phenolic resin and toughness, which is applied in the field of improving the toughness of heat-resistant phenolic resin. It can solve the problems that the impact resistance and heat resistance of phenolic resin do not meet the needs of use, so as to enhance internal bonding force, enhance mechanical strength, and improve thermal fading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

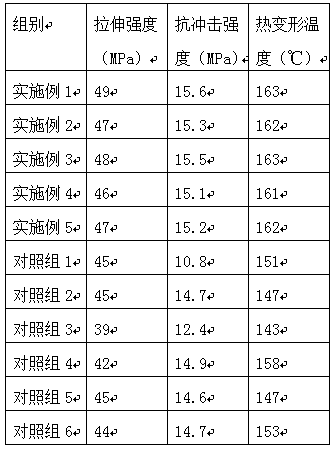

Examples

Embodiment 1

[0041] A method for improving the toughness of heat-resistant phenolic resin, comprising the steps of:

[0042] (1) Including the following raw materials in parts by weight, 42 parts of phenolic resin, 8 parts of hydroxy (meth)acrylate, 14 parts of sepiolite fiber, 4 parts of 2-acrylamide-2-methylpropanesulfonic acid, chitosan 8 parts of magnesium chelate, 4 parts of carbon disulfide, 2 parts of dioctadecyl dimethyl ammonium chloride, 2.5 parts of aromatic oil, 3.9 parts of stabilizer, 3 parts of antioxidant, 0.6 part of release agent, 1.2 parts of accelerator share;

[0043] (2) Mix butyl titanate with ethanol equivalent to 3 times its weight evenly, then add sepiolite fiber to obtain a solid-liquid mass ratio of 1:4, stir for 12 hours, filter, and place the obtained filtrate in a radiation Irradiation treatment is carried out under an irradiation cobalt source device with a dose of 25kGy, and modified sepiolite fibers are obtained after completion;

[0044] (3) Stir carbon...

Embodiment 2

[0051] A method for improving the toughness of heat-resistant phenolic resin, comprising the steps of:

[0052] (1) Including the following raw materials in parts by weight, 40 parts of phenolic resin, 10 parts of hydroxy (meth)acrylate, 12 parts of sepiolite fiber, 5 parts of 2-acrylamide-2-methylpropanesulfonic acid, chitosan 6 parts of magnesium chelate, 2 parts of carbon disulfide, 1 part of dioctadecyl dimethyl ammonium chloride, 2.8 parts of aromatic oil, 3.4 parts of stabilizer, 3.2 parts of antioxidant, 0.4 part of release agent, 0.8 part of accelerator share;

[0053] (2) Mix butyl titanate with ethanol equivalent to 3 times its weight evenly, then add sepiolite fiber to obtain a solid-liquid mass ratio of 1:3, stir for 16 hours, filter, and place the obtained filtrate in a radiation Irradiation treatment is carried out under the irradiation cobalt source device whose irradiation dose is 28kGy, and the modified sepiolite fiber is obtained after completion;

[0054] ...

Embodiment 3

[0061] A method for improving the toughness of heat-resistant phenolic resin, comprising the steps of:

[0062] (1) Including the following raw materials in parts by weight: 45 parts of phenolic resin, 6 parts of hydroxy (meth)acrylate, 16 parts of sepiolite fiber, 3 parts of 2-acrylamide-2-methylpropanesulfonic acid, chitosan 10 parts of magnesium chelate, 6 parts of carbon disulfide, 3 parts of dioctadecyl dimethyl ammonium chloride, 2.2 parts of aromatic oil, 4.4 parts of stabilizer, 2.8 parts of antioxidant, 0.8 part of release agent, 1.6 parts of accelerator share;

[0063] (2) Mix butyl titanate with ethanol equivalent to 3 times its weight evenly, then add sepiolite fiber to obtain a solid-liquid mass ratio of 1:5, stir for 10 hours, filter, and place the obtained filtrate in a radiation Irradiation treatment is carried out under the irradiation cobalt source device whose irradiation dose is 22kGy, and the modified sepiolite fiber is obtained after completion;

[0064...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com